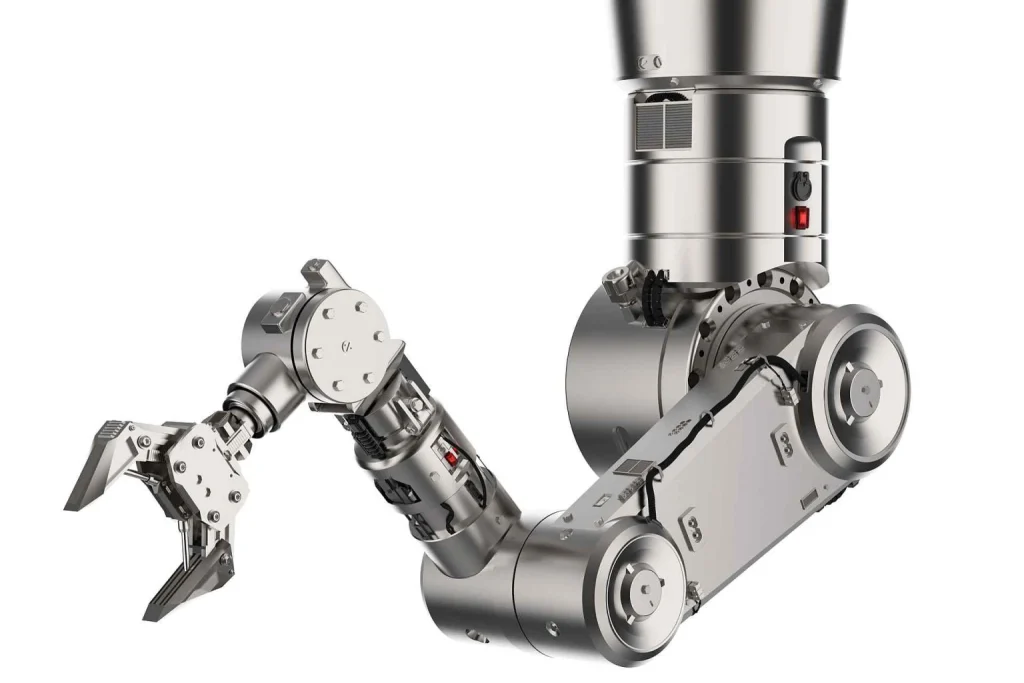

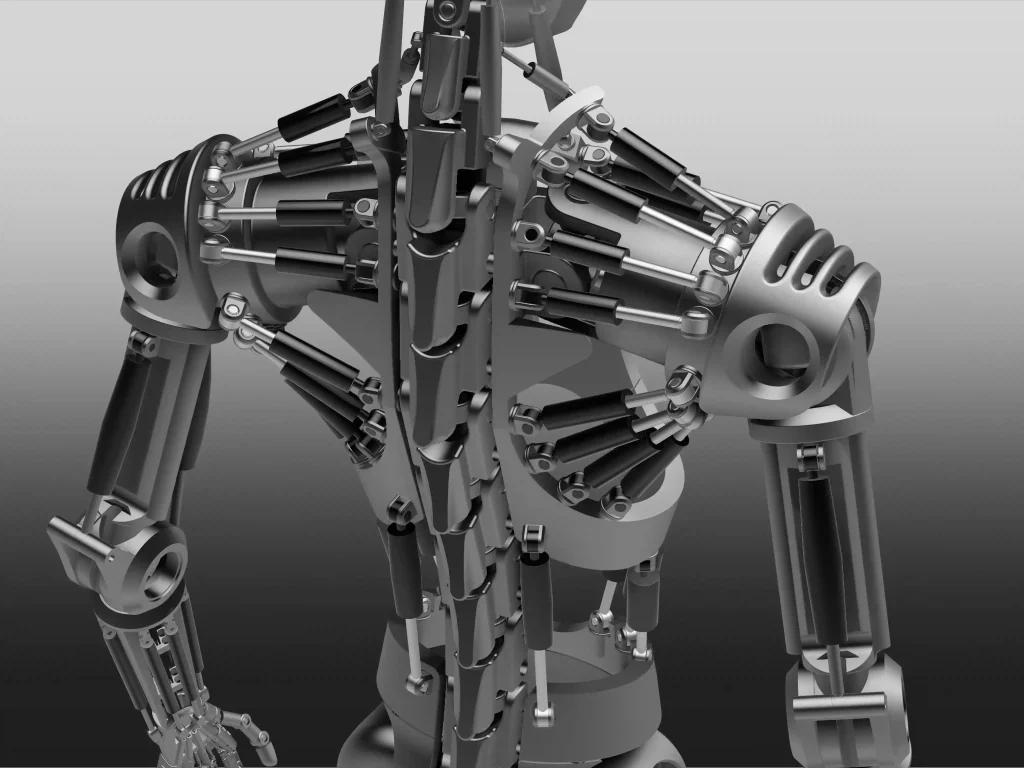

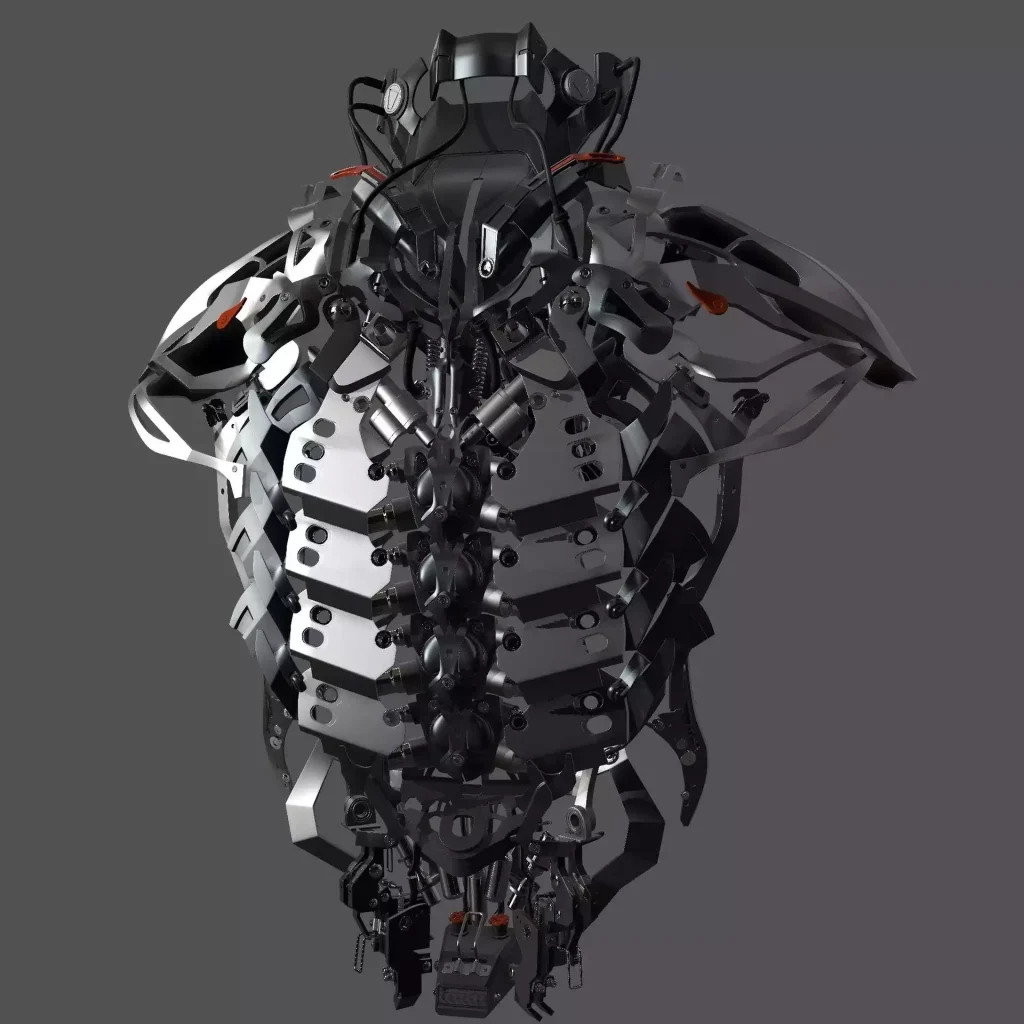

Robotics Sheet Metal Fabrication

When it comes to robotics, precision is critical. Every robotic sheet metal part manufactured by Elimold meets the stringent quality standards required for high-performance robotic systems. We are committed to providing reliable, efficient, and affordable solutions, delivering your parts on time and keeping your project on track. Our comprehensive services coupled with our technical expertise make us the ideal choice for your robotic sheet metal fabrication needs. Contact us now for a free, instant quote.

Robotic Sheet Metal Manufacturer

Elimold offers a range of robotic sheet metal prototyping and production solutions to dynamically scale and meet the needs of the global robotics industry. Reliable, flexible, comprehensive and precise, our services are designed to meet the high levels of detail, accuracy and tight tolerances required for robotic parts manufacturing, while enabling all customers to leverage the flexibility of our on-demand production services to optimize budgets and fill gaps in the supply chain. Our robotic sheet metal parts manufacturing is entirely enabled by our high-quality on-demand sheet metal manufacturing solutions. Whatever type of robotic sheet metal part you need, whether it is a full-blown robotic component prototype or a fully functional robotic sheet metal part, you can rely on Elimold’s sheet metal manufacturing services for the robotics industry to quickly and cost-effectively deliver your product to your target market.

In-House Robotic Sheet Metal Fabrication Factory Capabilities

Elimold’s in-house custom metal fabrication shop can provide complete design-to-ship solutions from prototyping to engineering, manufacturing to assembly. Our in-house full-service sheet metal fabrication facility is 70,000 square feet and has the precise equipment to produce and assemble custom sheet metal parts. It features a sheet metal fabrication department, CNC machine shop, laser cutting department, welding department, hard chrome plating line, powder coating shop and large assembly area. We have the ability to design and produce large as well as small custom robotic sheet metal fabrication projects. Our extensive sheet metal fabrication capabilities allow us to provide effective manufacturing solutions that meet your exact needs rather than providing limited options. And, we can work with your engineering and procurement teams to develop short-term and long-term success plans. We treat each customer as a partner and can meet needs from design and prototype to mass production. In addition, Elimold has a full-time quality control and inspection department, and our engineering team works closely to ensure that your products are in good condition the first time they leave our factory. Elimold is committed to customer service, excellence and quality. Quality is our main focus and we are proud of our customers’ satisfaction.

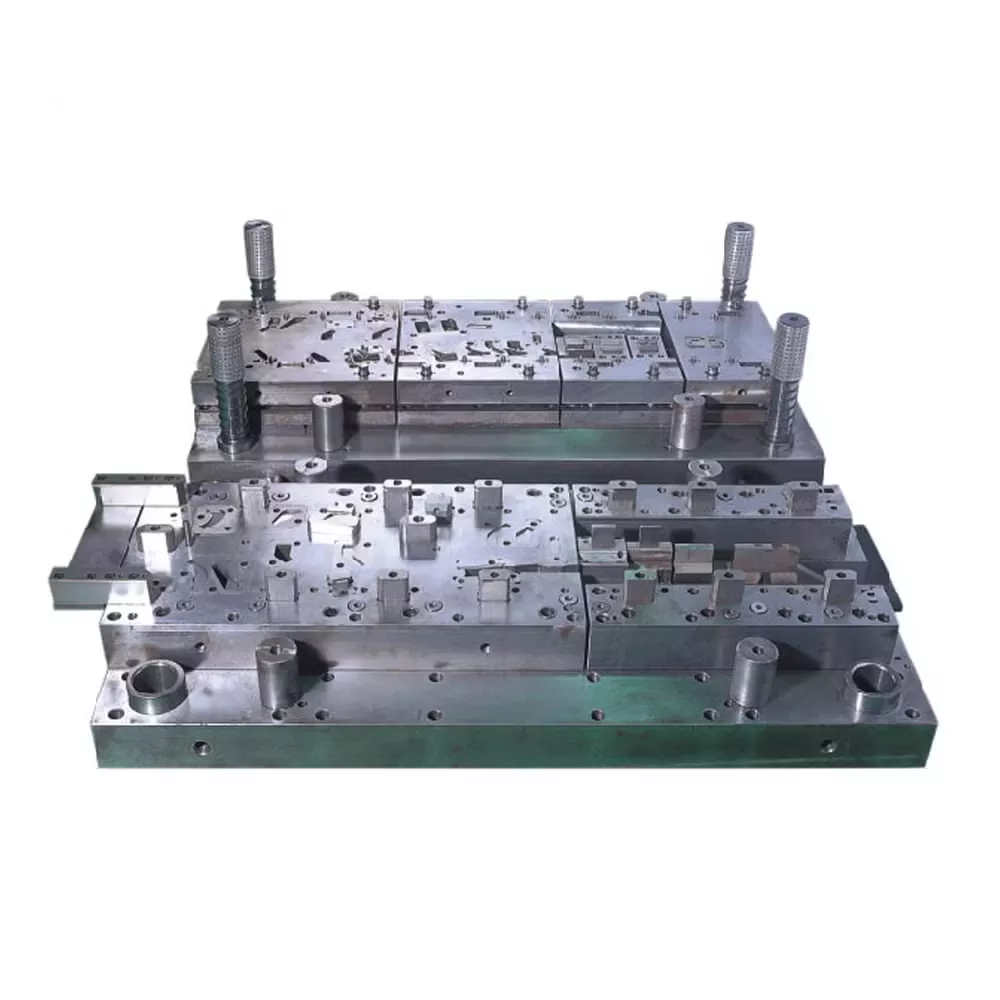

Robotic Sheet Metal Die Design and Production Process

We provide a comprehensive solution from mold design to production, ensuring the highest quality and precision standards. The robotic sheet metal die is developed by Elimold’s professional industrial designers and experienced engineers, and then precisely processed into the required parts and finally assembled.

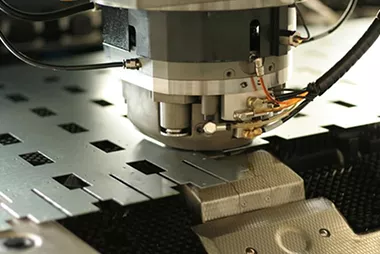

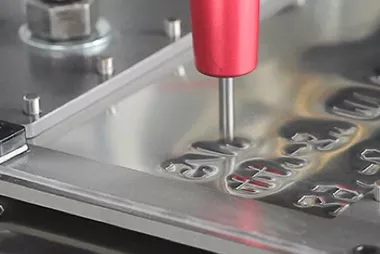

First, our team of engineers will design the required parts of the die in 3D form in a computer environment. After the design is approved by the customer, the mold prototype is made using 3D printing, and necessary modifications and tests are carried out. After the design and prototype are completed, mold manufacturing begins. The die designed for the customer is manufactured on advanced equipment in the internal CNC machining workshop, assembled in the internal die manufacturing workshop, and finally connected to a press with the necessary tonnage for testing. Elimold provides customers with excellent results with its robotic sheet metal die manufacturing and die design services supported by modern technology, thereby reducing project costs.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex and high-quality robotic sheet metal parts.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

Embossing

Rapid Prototyping Services for Robotic Sheet Metal Parts

Rapid prototyping helps robotics manufacturing companies around the world go from rapid prototype parts to production parts in record time. With our specialized rapid prototyping services, we can get your robotic products to market faster and with higher quality. We offer a dedicated prototyping shop for low-volume, fast-turnaround projects, with delivery in as little as one day! Plus, our automated production lines allow us to scale up and produce high-volume robotic sheet metal parts of the highest quality. And we always make sure your parts are fully optimized before the production process, saving you time and money. Our engineers review every part drawing and provide Design for Manufacturability assistance (DFM), so you can be confident that your design is in top shape before we bring it to life.

Ready to start your robotic sheet metal fabrication project?

Get started on your next robotic sheet metal fabrication project today! Contact us today for a free instant quote and experience the Elimold difference. We look forward to being your trusted partner for your robotic sheet metal part fabrication needs.

Technology & Automated Systems

We leverage the power of automation and digital technology whenever possible to improve repeatability, accuracy and speed of comprehensive robotic sheet metal part production while keeping costs competitive. Software modeling and controls reduce or eliminate trial and error and scrap costs for bending operations. Elimold’s in-house facility has adopted an Industry 4.0 approach, using the Industrial Internet of Things to drive our operational systems and improve performance. Order management, nesting, material planning, cutting and reporting are fully integrated. When an order is received through Elimold, our ERP system is automatically populated, allowing visibility at the time of receipt and immediate effect in our production system. Automated, connected systems and data collection allow us to have industry-leading lead times.

Trusted Partner for Robotic Sheet Metal Fabrication

We understand the unique needs of each robotics manufacturer and therefore offer collaborative design services to ensure products of higher quality, performance, and aesthetics. This collaborative spirit has made us the contract manufacturer of choice for countless businesses across numerous industries. We combine advanced manufacturing technology with a people-centric approach to occupy a unique position in the market. From Design for Manufacturing (DFM) collaboration, where our engineering team collaborates to ensure optimized and cost-effective production, to our team of skilled employees and engineers who ensure industry-leading quality, we guarantee results that are not only satisfactory, but also exemplary.

As a result, Elimold is more than just a manufacturer, we are a strategic partner in innovation. We fully grasp the essence of precision and just-in-time production, and this understanding drives our investment in top-notch manufacturing facilities. Leveraging this technological prowess, we can complete projects, no matter their size or complexity, ensuring that every transportation-ready project is executed with the utmost care. When you work with Elimold, you are not just working with a manufacturer, you are aligning with a tradition of excellence.

Our Commitment to Quality Custom Robotic Sheet Metal

From design to finished product, we offer a full range of custom robotic metal parts manufacturing services designed to provide the right solution for your robotic product. We are proud to offer a combined knowledge and innovation approach to bring you custom robotic sheet metal components that are precisely manufactured to exceed your expectations, with parts that will perform with perfect fit, form and function on your production floor. Additionally, Elimold is ISO 9001 certified, demonstrating our commitment to maximizing customer satisfaction and continually reviewing our own processes to improve wherever possible. As part of our ongoing quality control program, we maintain documented procedures for effective application while ensuring we meet our customers’ manufacturing requirements. This helps us provide the ideal solution for both first-time and returning customers. While striving to have the best manufacturing processes, we also support our employees through education, training and a safe work environment.

Quality Management and Certifications

We know that precision robotic sheet metal fabrication is more than just manufacturing, and we pride ourselves on continually improving our customer experience, technology, and support. We work closely with our customers to provide the highest level of service. The Elimold team is known worldwide for our customization capabilities and affordable, high-quality work. We combine our extensive knowledge and expertise with state-of-the-art equipment and software to get the job done quickly, efficiently, and at a competitive price. Our internal factory quality management system exceeds ISO 9001:2015 requirements, and we continually review and improve our procedures to achieve world-class results. We focus on quality, time, and price, and strive to provide our customers with the best possible product at a cost-conscious price.

Advance Your Robotic Sheet Metal Fabrication Project with Elimold

Finding a team that truly understands the complexities of robotic sheet metal part manufacturing can be a challenge. Whether you’re working under a tight deadline or require absolute precision, many suppliers won’t be able to meet your requirements. That’s where we step in.

From concept and design to final assembly, Elimold prides itself on operating entirely in-house and rarely outsourcing any of our operations. We want to have complete quality and schedule control over important elements of our business, including the shipping and delivery process. Because we don’t outsource this critical service, our team is able to ensure that every project is delivered intact and to quality standards. With a team of certified welders, skilled technicians, and experienced engineers, we have built a reputation for reliability and precision in the robotics industry that strives for excellence, focusing on problem solving and exceeding expectations from the initial consultation to the final product.

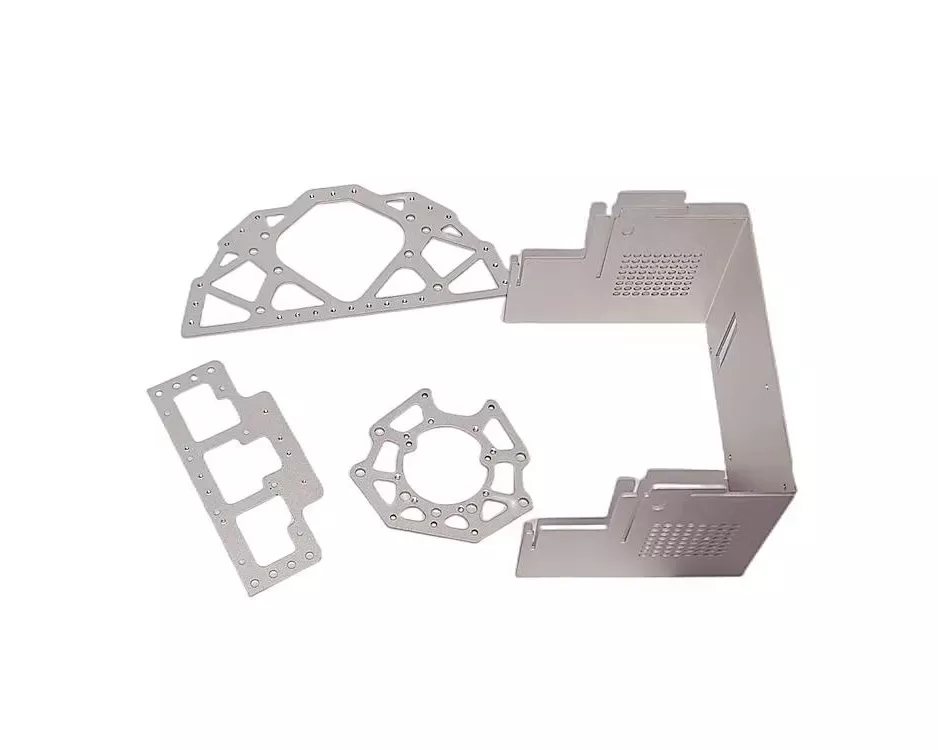

Robotic Sheet Metal Parts Material Options

We offer a wide range of materials, sizes and types required for robotic applications.

- Aluminum

- Titanium

- Brass

- Carbon Steel

- Copper

- Perforated Metal

- Sheet Metal

- Stainless Steel

- Steel

- Steel Plate

Robotic Sheet Metal Part Finishing Options

Surface finishing is a critical part of the manufacturing process for robotic sheet metal parts. Robotic sheet metal parts often require a certain degree of smoothness, roughness, and texture. The right surface finishing will allow them to perform their tasks effectively. Therefore, we offer a variety of surface finishing and post-processing services.

- Texturing

- Anodizing

- Polishing

- Insert installation

- Media blasting

- Painting

- Electroplating

- Passivation

- Heat treatment

- Powder coating

The Clients We Serve

At Elimold, we offer a range of sheet metal fabrication services for the robotics industry, serving every player in the industry worldwide.

- Direct Robot Manufacturers

- Robotics-as-a-service (RaaS)

- Aftermarket robotic end-effector manufacturers

- Robotic engineers and design experts

- University robotic and engineering departments

- Industrial and general manufacturing

- Automobile engineers

- Robotics software experts

- Medical Robotics

- Autonomous mobile robots

- Service and diagnostic centers

- Aerospace robotics

- Exoskeleton component manufacturers

- Standalone, collaborative, and production line robots

- Articulated, SCARA, Delta, and Cartesian robot engineers

Robot Sheet Metal Parts Application

By using modern engineering software and cutting-edge metal fabrication equipment and techniques, Elimold is able to provide custom metal fabrication products to top companies in the global robotics industry.

- Robot frames

- Support Structures

- Harnesses

- Wire guides

- Brackets

- Frames

- Chassis

- Enclosures

- Covers

- Shields

- Tooling and fixtures

- Custom housings and parts

- Chassis, housings and brackets

- Robot cosmetic modifications

- Tooling and fixtures

- Cable routing dividers

- Custom housings and parts

- Robot accessories and components

- AI smart robot prostheses

- Fingers

- Control boxes

- Adapter housings

- Sensors

- Actuators

Request Your Free Robotic Sheet Metal Production Quote Today

After receiving your drawings, our engineers will analyze your custom Robotic Sheet Metal Production parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.