Medical 3D Printing

Elimold offers a comprehensive portfolio of medical 3D printing services and materials to meet the needs of medical device manufacturers, from prototyping to tooling to production. Elimold end-to-end solutions enable you to quickly iterate, verify, validate, and manufacture. Contact us today for a free instant quote.

Medical 3D Printing Manufacturer

Elimold’s medical 3D printing and scanning services provide physicians, researchers, and medical device manufacturers with faster custom manufacturing solutions for medical parts, helping to better test concept product designs and custom medical products in unprecedented ways. Our services meet the needs of customers ranging from medical device OEM and teaching hospitals to individual healthcare professionals. We are committed to enabling high-tech medical product manufacturers to test medical product fit, form, and function, and in some cases test their products in real-world conditions, rapid prototyping, and ultimately mass production of related medical products.

Medical 3D Printing Capabilities

Elimold has produced more than 2 million implants and instruments for more than 100 CE-marked and FDA-approved medical devices. With a world-class, FDA-registered, ISO 13485-certified facility in Shenzhen, China, we have unparalleled expertise in medical product 3D printing, engineering, quality control, and healthcare regulatory requirements. Our experience in designing and developing new products, ensuring precision production, and guiding the commercialization process enables our partners to bring revolutionary medical devices to market faster than ever before.

Additive Manufacturing for Medical

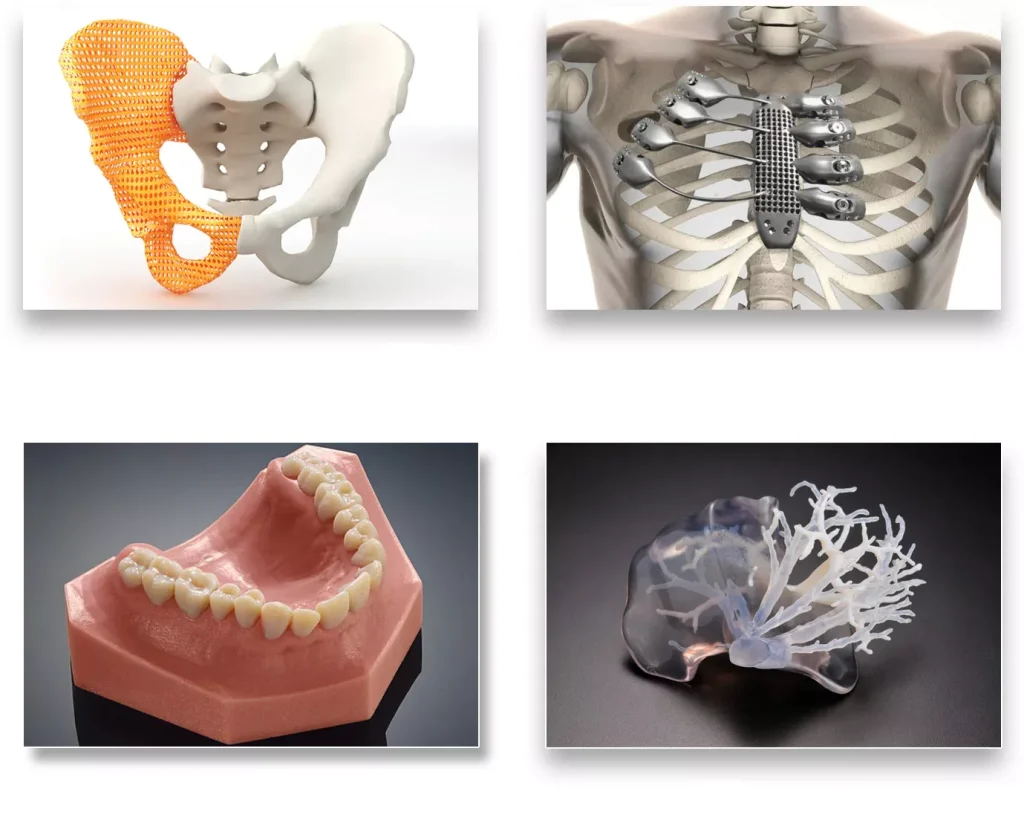

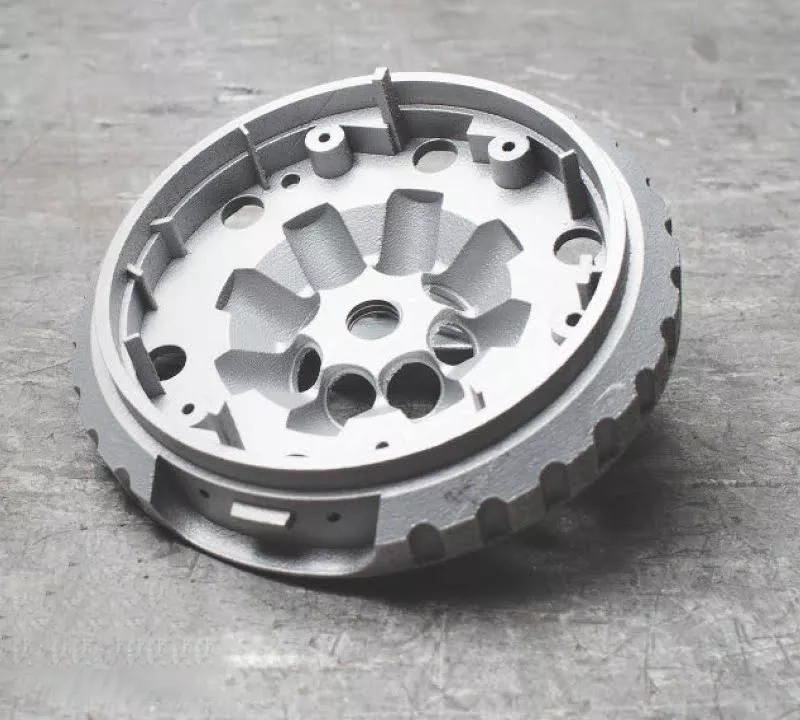

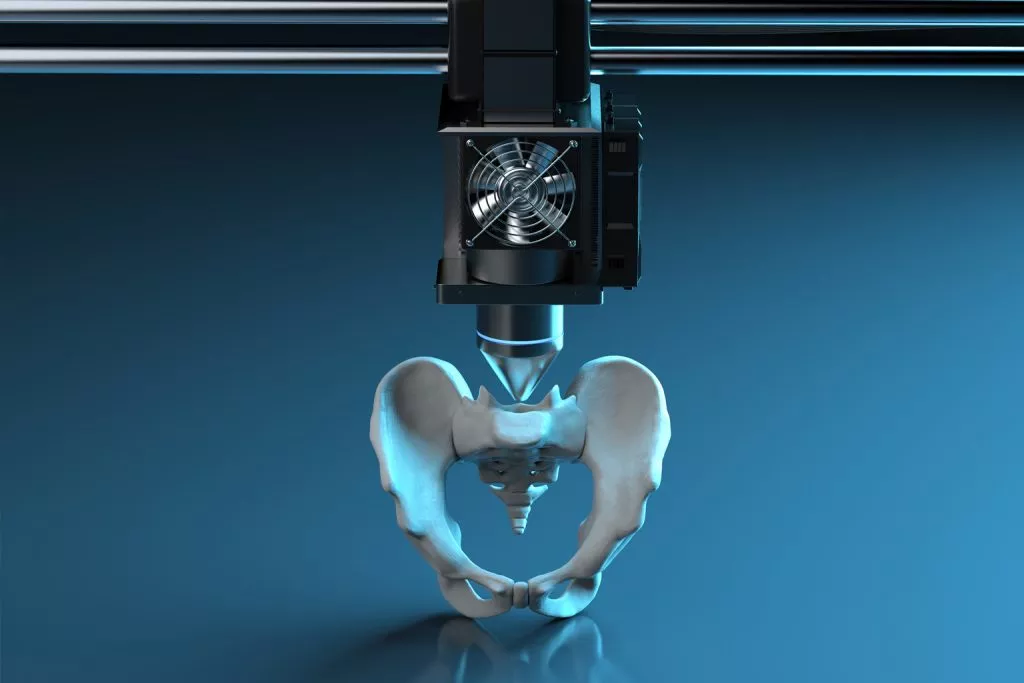

Elimold provides the medical industry, including medical device manufacturers, equipment manufacturers, and medical manufacturing companies, with the revolution in industry product development driven by 3D printing technology. Unlike traditional subtractive manufacturing methods, medical 3D printing can create complex geometries, patient customization, and lightweight designs that are difficult to achieve with other methods. This revolution covers medical devices, equipment, models, and surgical tools, increasing innovation and efficiency.

Over the years, we have accumulated extensive experience in manufacturing medical devices and anatomical components. Through our ISO 13485 certified facilities. We can provide custom parts manufacturing services to a wide range of healthcare product manufacturers. Our commitment to quality and excellence is reflected in our dedication to meeting the highest standards in medical 3D printing. Utilizing industrial additive technology and a variety of medical-specific materials, including USP Class 6 materials known for their biocompatibility, we ensure that our innovative solutions provide precision, reliability, and superior performance.

One-stop medical 3D printing production solutions

We offer customer-specific medical 3D manufacturing solutions for the entire value chain, from conception, design and engineering to production and post-processing, right up to the finished part. Benefit from our many years of experience in additive manufacturing and use our full portfolio of systems, consulting and services for industrial 3D printing of orthopedic technology and devices, all from us. Working with you and our efficient factories and supply chain partners, we can develop the solutions you need for production, resulting in a comprehensive solution portfolio.

Prototype-to-Production Capabilities

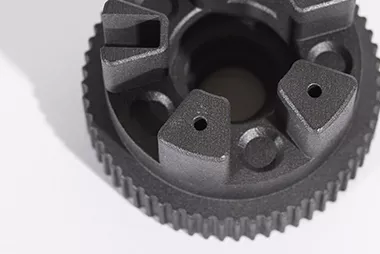

We utilize a variety of 3D printing and medical additive manufacturing processes and materials to meet your needs when designing and producing medical devices and device components. Plastic and metal 3D printing allows the creation of highly complex and sophisticated parts in a short time. Our in-house capabilities are not limited to medical 3D printed prototypes and production parts. We also have the capabilities, equipment, and expertise to move your production projects forward. We operate Wire EDM, CNC turning, 3-axis and 5-axis CNC machining, as well as medical injection molding and polyurethane molding. We provide parts to original equipment manufacturers (OEM) of medical devices and diagnostic equipment, such as MRI and X-ray equipment, as well as parts for surgical devices. Our team will work with you to help design, develop, and control the most efficient manufacturing process to meet your timelines, quality requirements, and production cost goals.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused DepositionModeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

Rapid Prototyping of Medical 3D Printing Parts

Rapid prototyping is a technique that uses 3D CAD (computer-aided design) data to create models of plastic parts. Medical 3D printing technology offers unprecedented freedom to medical product designers and flexibility to medical product manufacturers to develop prototypes for even the most complex and intricately designed medical devices. With medical 3D printing, new iterations can be implemented and completed in a very short time. The speed of the process helps determine if further changes are needed. Moreover, medical 3D printing eliminates the need for initial molds and produces parts with similar mechanical properties. It also enables the development of medical device prototypes using various types of materials. 3D printed medical device prototypes can also be used for trade show demonstrations and for pitching to investors or interacting with future customers.

From standardized solutions to improved functionality

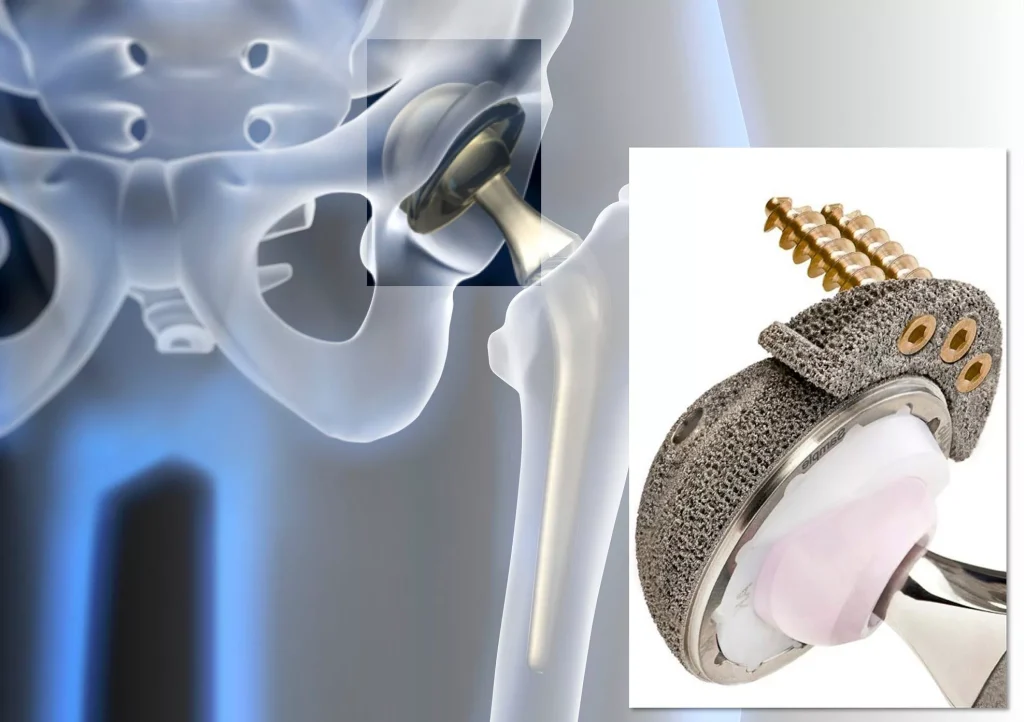

In orthopedics and the manufacture of complex medical devices, the ability to create complex geometries and integrate functions with additive manufacturing processes creates huge advantages. For high-tech medical devices and special machines, the freedom of design means that assembly can be simplified and functions can be integrated into the component. In this case, additive manufacturing pays off even for small batches. Tool costs as well as any assembly and logistics costs can be saved. With 3D printing, the driving force behind design is no longer manufacturability, but functionality. Whether you are manufacturing implants, surgical instruments or complex medical technology products: Additive manufacturing allows you to reimagine geometries. As a result, you can design and manufacture products more efficiently for their specific application.

Partner with Elimold’s Additive Manufacturing Technology Team

Bringing medical devices to market can take years and requires deep expertise to determine product requirements and optimal product design to meet clinical needs. Elimold’s additive manufacturing capabilities enable medical device designers to choose from a wide range of medical-grade plastics with specially engineered material properties and designed components, including multi-material and multi-dimensional constructions. Contact us now for an instant quote.

Our Certifications

We have extensive experience in medical device manufacturing applications, from helping large diagnostic system manufacturers find new, more cost-effective parts to providing high-precision 3D printed prototypes for custom surgical implants in hours. We understand that medical devices require expertise and rigorous industry standards, so we are certified to ISO 13485:2016, a comprehensive quality system standard for the design and manufacture of medical devices. This international certification demonstrates our commitment to our customers and the regulatory requirements necessary to produce medical devices, including those used in diagnostic imaging and surgical instruments. We also hold the quality standards of WBENC (Women’s National Business Enterprise Certification) and WOSB (Women Owned Small Business) to successfully meet the WBENC standards for women-owned, operated and controlled women-owned business enterprises.

Medical Cleanroom 3D Printing

Elimold built a state-of-the-art cleanroom for its medical additive manufacturing business, allowing for the handling of sensitive and mission-critical materials and components in a cleanroom environment. The cleanroom houses additive manufacturing equipment and materials, including 120 production-specific machines that can run 24/7 and be remotely monitored from anywhere in the world. Applications range from R&D prototypes to production-ready parts for medical use, including human devices. The cleanroom is Class 7 certified. We also have HEPA air filtration systems, pressure and temperature controls, static control systems, and procedures to ensure purity. And, we meet all FDA requirements for cleanliness and care of materials, equipment, and tools.

Design for Manufacturing and Assembly

Elimold recognizes the importance of creating a device from both a functional and manufacturing perspective. Therefore, in addition to creating products that meet preclinical and clinical needs, we also support concept development builds. Our goal is to have a functional prototype as quickly as possible. Our in-house rapid prototyping capabilities help us achieve this goal. Throughout the project phases, we apply Design for Manufacturing (DFM) techniques and provide advice and support for design changes. By implementing these changes during the design phase, we can meet your target manufacturing costs.

Device Design and Manufacturing

Medical device manufacturers need innovative ways to bring high-quality, reliable products to market faster. Our customers trust our unmatched capabilities and experience in additive manufacturing to help them develop innovative medical devices and instruments. We also work with them to determine the best approach to commercialization, whether through contract manufacturing support at our two device manufacturing facilities or rapid device prototyping for our customers using 3D printing technology.

Achieve better outcomes with solutions tailored to the patient

Leveraging 3D patient-specific models for surgical planning can improve clinical outcomes and positively impact surgical economics, resulting in significant cost savings and financial advantages for medical product manufacturers. Elimold’s team of medical parts custom manufacturing experts has developed a custom medical product custom production service process framework that can be adapted to any medical environment. Through the economic analysis of medical product custom manufacturing, the framework shows how implementing a 3D printing program can help reduce medical device custom manufacturing expenses, improve medical device manufacturer enterprise operational efficiency and create new products and open up new markets. The real value that medical 3D printing can bring to your business.

3D Printing Materials Used in Healthcare

There are many different materials used for 3D printing in healthcare, all of which need to meet strict safety, quality, and efficiency standards. They must be strong, durable, sterilizable, corrosion-resistant, and lightweight. Not all materials compatible with 3D printers are suitable for medical use, but here are some of the most commonly used 3D printing materials from Elimold in the medical and healthcare fields.

- Nylon PA-12

- PC-ISO

- ABS M30i

- Silicone

- Titanium

- Cobalt chrome

- Stainless steel

- Thermoplastic polyurethane (TPU)

- Polylactic acid (PLA)

- Polyetheretherketone (PEEK)

- Polyetherketoneketone (PEKK)

- Polymethyl methacrylate (PMMA)

- Bioceramics

- Polyethylene glycol (PEG)

Custom Medical 3D Printed Parts Finishing

We offer custom finishing options to meet your exact specifications.

Plastics

- Clear Coat

- Thermal Cure

- Plating

- Painting

- Dyeing

- Texture

- Cerakote

- Custom

Metals

- Standard

- Heat Treatment

- Hot Isostatic Pressing (HIP)

- Annealing

- Aging

- Polishing

- Cerakote

- Custom

Medical applications of 3D printing

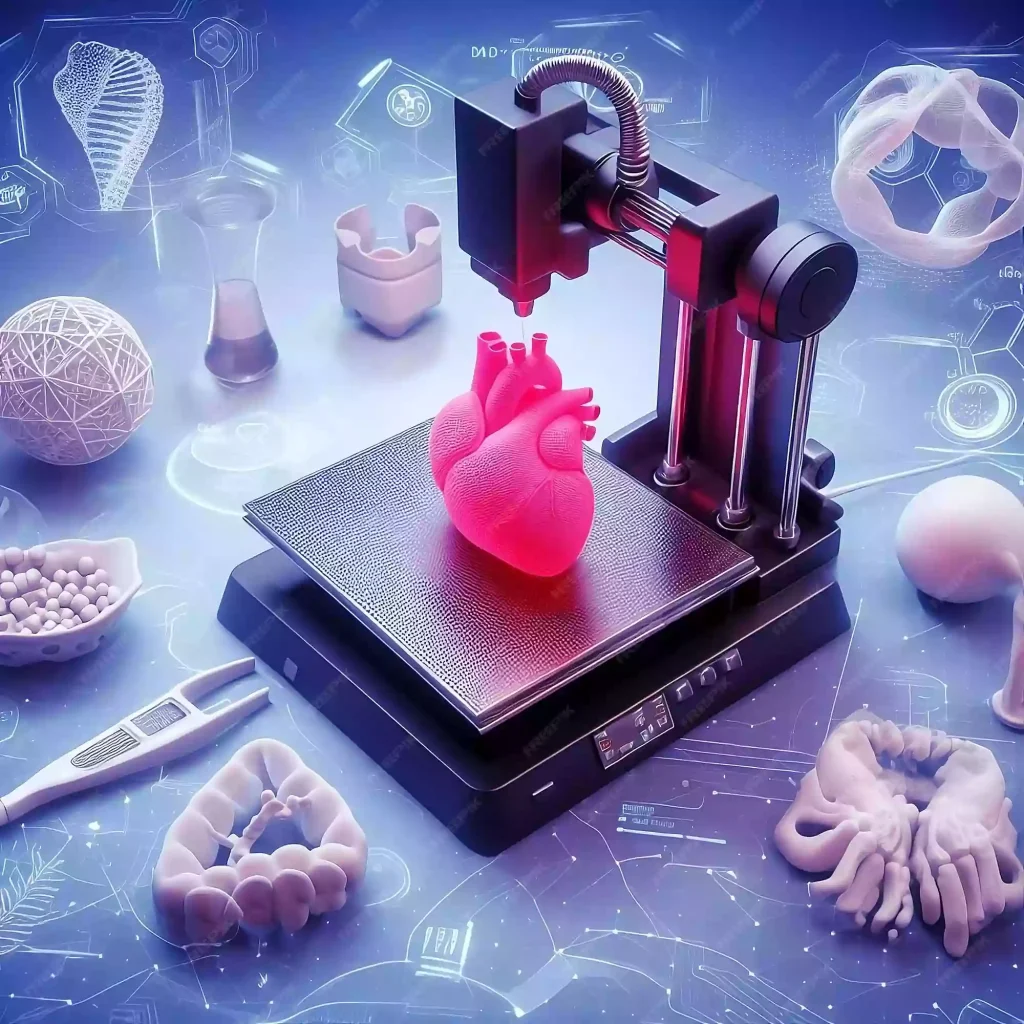

3D printing has revolutionized the way surgeons and other interventionalists perform complex procedures. Instead of imagining a surgical procedure, doctors and patients can hold an accurate 3D model of the disease in their hands. This could be a diseased heart valve, a tumor in the abdomen or prostate, or an injury to the face. 3D printing allows for practice before surgery, shortening the procedure and recovery time.

- Custom fixtures

- Surgical instruments

- Surgical guides

- Prosthetic components

- Wearables

- Electronic enclosures

- Breakers

- Implantable Components

- Cartridges

- Functionally clear parts

- Robotic arms

- Handheld devices

- Microfluidics

- Imaging Equipment

- Orthopedics

- Test Tubes

What are the potential applications of 3D printing in healthcare?

The potential applications of 3D printing in healthcare are nearly limitless. This technology has the potential to revolutionize the way we deliver healthcare and has the potential to change the face of medicine as we know it. 3D printing technology has the potential to revolutionize healthcare. Here are some of the potential applications of 3D printing in healthcare:

- Custom medical implants: 3D printing can be used to create custom medical implants that are specifically designed to fit each patient’s individual anatomy. This could potentially eliminate the need for invasive surgeries to implant traditional one-size-fits-all devices.

- Personalized medicine: 3D printing can be used to create personalized medicine, such as drugs that are specifically tailored to each patient’s genetic makeup. This could revolutionize the way we treat disease and could lead to more effective, targeted treatments.

- Tissue engineering: 3D printing can be used to create artificial tissues and organs. This could be used to replace damaged tissues and organs, or to create new tissues and organs for transplantation.

- Prosthetics: 3D printing can be used to create custom prosthetics that are specifically designed to fit the individual needs of each patient. This could improve the function and appearance of prosthetics and make them more affordable.

- Surgical Planning: 3D printing can be used to create models of patient anatomy for surgical planning purposes. This may help surgeons plan complex surgeries and can also be used to create practice models for training purposes.

- Medical Research: 3D printing can be used to create models of diseases and conditions for use in medical research. This may help researchers develop new treatments and therapies for diseases.

- Education: 3D printing can be used to create anatomical and physiological models for educational purposes. This may help students learn more about the human body and can also be used to create training models for medical professionals.

The Future of 3D Printing in Medicine

Given the unique needs of each patient and body, medical devices often require the highest degree of customization of any type of product in any industry. However, these devices have historically been costly and slow to produce due to the high costs of traditional manufacturing and long tooling lead times. Medical 3D printing is redefining what is possible in medicine with its unparalleled ability to produce highly custom parts in small batches. Tailoring medical solutions to patients and physicians improves outcomes; reducing costs and production times increases accessibility. Custom medical devices, implants, and tools are now more accessible than ever before. As 3D printing technology continues to advance, healthcare providers and researchers will continue to explore new applications, from implants and surgical tools to tissues and functional organs.

Do you have any burning questions?

3D printing may not have been in production as long as CNC turning, CNC milling or injection molding. As a medical product design engineer, maybe you haven’t really experienced printed parts yet. And you’re not sure how 3D printed products will perform in your machine. We totally understand that! We’ll help you put your mind at ease. So have you considered 3D printing for medical applications? 3D print medical parts and give it a try? See if it holds up? Then contact Elimold to start making samples.

Ready to start your next medical 3D printing project?

The Elimold team is made up of dedicated experts who know how to support you and your company’s needs. Contact a medical 3D printing expert today to find a solution that meets your business goals.