Medical Sheet Metal Fabrication

Elimold is a manufacturer that can produce high-precision medium to large medical sheet metal components. With advanced technology and a skilled team, we specialize in providing reliable sheet metal parts for the medical sector. From concept to production, our focus on quality, innovation and compliance drives each project. Contact us now for a free instant quote.

Sheet Metal Fabrication, Assembly and Component Assembly for the Medical Device Industry

Elimold is the epitome of excellence in sheet metal fabrication for medical devices. With an unwavering commitment to quality and precision, Elimold has become a trusted partner for medical device manufacturing companies that require complex sheet metal components and assemblies. Our team of skilled craftsmen have extensive experience in precision sheet metal fabrication, ensuring that each product is carefully engineered to meet the rigorous requirements of the medical device industry. Whether producing a specialized component, a complex assembly, or a complete component assembly solution, Elimold delivers with precision and focus, setting the industry standard for quality, reliability, and innovation. And, Elimold understands the critical requirements of precision and quality in the dynamic and highly regulated environment of the medical device industry. As a result, we remain committed to producing best-in-class sheet metal fabrication and assemblies for medical devices. We work closely with our customers to develop custom solutions that not only meet, but often exceed, their exacting specifications. Elimold’s reputation as a leading provider of precision sheet metal production services for the medical device industry is built on precision engineering, stringent quality control, and a deep understanding of the industry’s unique requirements. When it comes to sheet metal fabrication, assembly and component assembly of medical devices, Elimold is trusted for precision, reliability and a relentless commitment to excellence.

Medical Device Sheet Metal Manufacturer

As a trusted partner to the medical industry, Elimold provides custom precision sheet metal fabrication products to many medical device manufacturers around the world. Our engineering and production staff often meet with customers early in the product development and design phase to communicate project details to ensure the required parts are cost-effective. From that point on, our team guides customers through the manufacturing process and works tirelessly to provide the highest quality precision machined parts to meet or exceed customer expectations. With the demands of the medical industry in mind, we only accept the highest quality work.

Whether you need a simple design or a complex medical sheet metal component, our experienced team will produce it accurately and efficiently to exceed your expectations. We have a state-of-the-art facility with advanced manufacturing machines to meet the tightest tolerances. Guaranteed quality control processes, meticulous production, and fast turnaround. You can count on our strong quality management, reliable production, and assembly.

Our Medical Component Sheet Metal Fabrication Capabilities

Our team has the knowledge, skills, and tools to meet a wide range of manufacturing requirements, whether the design is simple or complex. We are able to achieve the level of precision and accuracy required for a wide range of medical finished components. Elimold offers a complete solution with a 50,000 square foot manufacturing facility equipped with dedicated cutting-edge equipment and metal processing departments. We can process a variety of metals ranging from 0.02″ to 0.50″ in thickness with a tolerance of ±0.001″, as a full-service manufacturing solutions provider, we also provide complete engineering services and a number of value-added services. These additional capabilities enable us to provide a one-stop solution for many medical device manufacturing needs. We provide prototypes, short to medium runs, and low to high volume production capabilities. Plus, we offer flexible production, storage, and delivery options, so you don’t have to worry about when you will receive your parts. If you are looking for a long-term partner as your medical device sheet metal parts manufacturer, please contact us.

Medical Sheet Metal Parts Custom Manufacturing And Machining

Custom sheet metal fabrication solutions cover all phases of a standard manufacturing project. However, in addition to bringing a design to life, manufacturers often help create custom functional and feasible designs. Our team advances medical industry projects from the concept stage to completion by providing design assistance and consultation, material and finish selection, fabrication, finishing, and assembly services.

Whether you are seeking a small-scale solution or require large-scale manufacturing, our custom manufacturing capabilities allow us to scale our services to perfectly meet your specific project needs. Our flexible approach means we are both adept at creating reliable prototypes and managing mass production. Providing everything from metal sales to prototype manufacturing, we are a full-service provider that anticipates and meets your complex needs. From conceptualization to production, we support you from start to finish. We tailor our services to the unique challenges of the medical industry. Sheet metal fabrication for medical devices requires collaboration, which is essential to our process. Experience a customer-centric approach that values clear communication and comprehensive support. Our conversations with our customers take into account their goals, ensuring that the results not only meet expectations, but exceed them. In addition, we prioritize efficient and reliable timelines so that you get the parts you deserve when you need them.

Custom Manufacturing Solutions for Medical Device Parts

Customization is key to our business operations. The medical device industry often requires custom solutions, as each device often has unique specifications. Our team works closely with our customers to adapt our processes to manufacture sheet metal parts that meet the specific needs of medical professionals and patients. We have developed over 1,000 custom solutions for medical applications, from high-tech imaging machine housings to specially designed surgical instrument trays. In addition, Elimold excels in batch production, a critical capability for manufacturers who need consistency in high-volume production. Our facilities are fully equipped to manage the delicate processes required for medical applications, as well as the high-volume demands of this industry.

Our Manufacturing Services

Elimold offers best-in-class medical sheet metal parts manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently provide complex and high-quality medical device sheet metal parts.

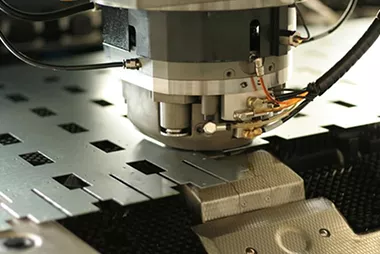

Laser Cutting

Plasma Cutting

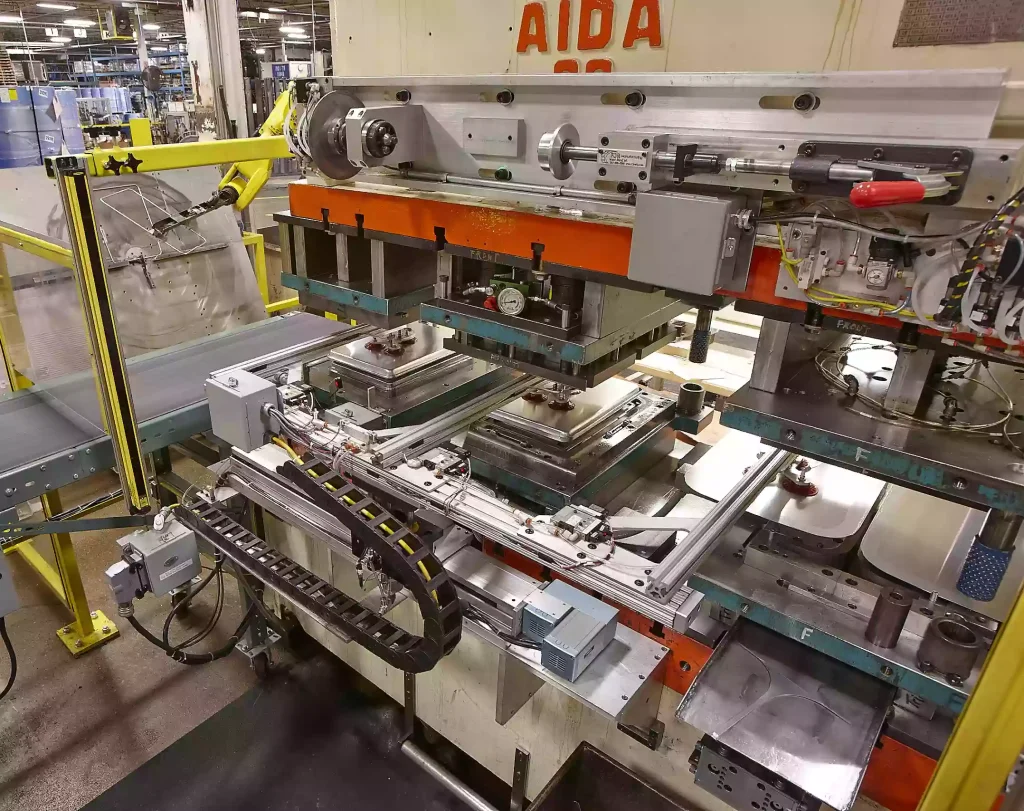

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

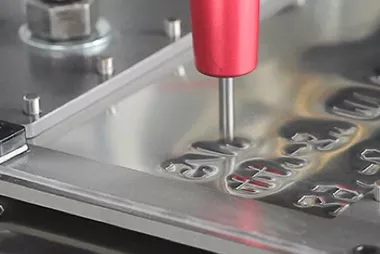

Embossing

Ready to start your next medical sheet metal fabrication project?

At Elimold, we specialize in medical sheet metal fabrication services that meet the highest standards of quality, precision, and regulatory compliance. With years of experience manufacturing complex medical components, we are your trusted partner for precision parts used in medical devices. Our ISO-certified processes ensure that every part we produce is of the highest quality and meets all medical industry standards and regulatory requirements. Whether you need medical sheet metal prototyping or full production, Elimold can provide a cost-effective, on-time, and reliable solution tailored to your specific need.

Sheet Metal Fabrication for the Medical Industry

Elimold is an integrated medical sheet metal parts fabrication facility that works closely with medical device manufacturers around the world to provide reliable metal fabrication services, precision parts, and design consistency. We understand the need for accurate, reliable, and high-quality metal fabrication and machining services in the highly regulated and demanding medical industry. Because part performance is critical to the operation of medical equipment and devices. Elimold excels in providing top-notch medical precision sheet metal fabrication services that meet the stringent requirements of medical device manufacturing. Our advanced manufacturing processes ensure that every component we produce meets the highest quality and safety standards, making us a trusted partner in medical applications.

Whether the medical device designs your company produces are simple or complex, our experienced and knowledgeable medical sheet metal fabrication team will produce parts that consistently exceed your expectations. Our state-of-the-art facilities can produce components to the tightest tolerances. Elimold’s quality control processes are unmatched in the industry.

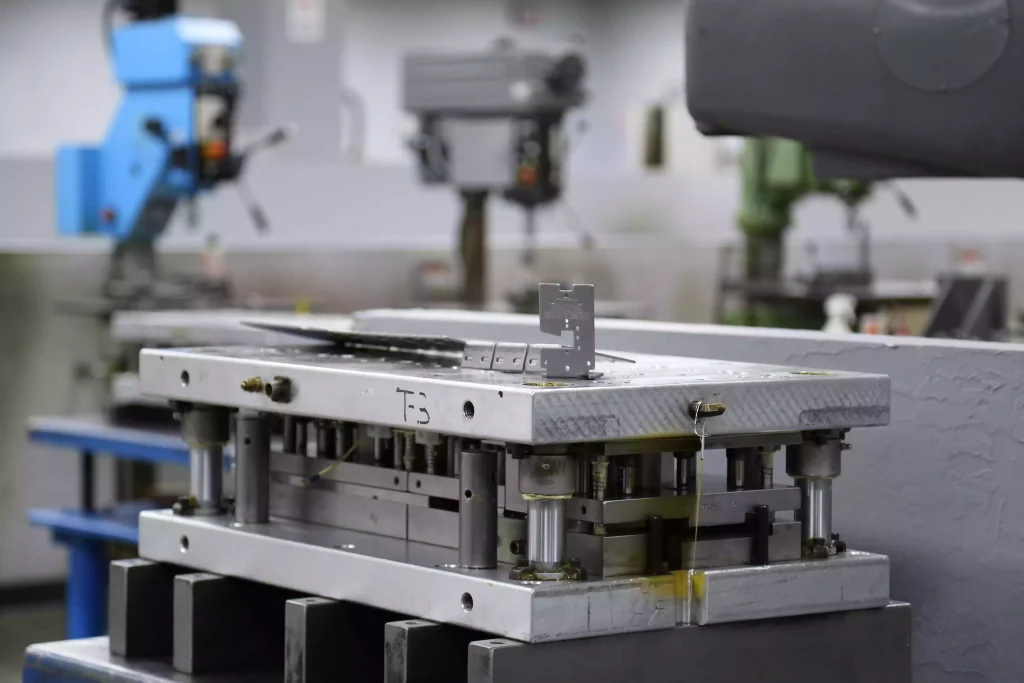

In-House Tool & Die Shop

To ensure that all parts conform to our customers’ designs and meet our own high quality standards, our Shenzhen, China facility features a complete in-house tool and die shop. Elimold’s in-house tool & die shop can produce all types of sheet metal dies, including large sheet metal dies, and is able to achieve tolerances of +/- 0.005 inches during production. Additionally, our in-house tool & die shop is under the same roof as our production shop, which allows us to produce medical sheet metal parts faster and on time because we don’t have to wait for finished dies to be shipped to our location.

Partner with the Elimold Team for Your Medical Metal Fabrication Need

We understand the importance of efficient, quality, and precise production of medical products. Our extensive metal fabrication services will ensure that your products meet all regulatory requirements and tight tolerances for the medical industry. Throughout the process, our team will work with you to ensure that the product is fully compliant.

Quality Assurance Team

In our Quality Assurance Team, we meticulously ensure a 99.8% accuracy rate on each project, reflecting our dedication to superior quality and a zero-error approach to sheet metal fabrication.

R&D Team

Our R&D team leads over 30 innovative technologies that increase manufacturing efficiency and accuracy by 25%, continually redefining the creativity and scientific accuracy of sheet metal fabrication.

Engineering & Design Team

With over 500 custom projects under our belt, our Engineering & Design team skillfully blends creative design with engineering precision to ensure that each fabrication project excels in functionality and aesthetics.

Medical Device Manufacturing Certifications

We pride ourselves on manufacturing medical sheet metal components that exceed industry standards. Our quality management system is certified to the AS9100D 2016 standard, ISO 9001:2015, and ISO 13485:2016, ensuring that the medical device sheet metal parts we manufacture meet the most stringent standards. These certifications underscore our commitment to consistently delivering products that meet regulatory requirements and customer expectations. By adhering to these standards, we ensure that our manufacturing and processing processes are optimized to produce safe and effective medical products.

On-Time Delivery and Lead Time Management

We understand the pressures of the medical industry to adhere to strict timelines. Elimold has four large sheet metal manufacturing facilities in major cities across China, which gives us the flexibility to efficiently manage both small-scale medical sheet metal part prototyping and high-volume production. Our experienced project management team ensures that all aspects of the manufacturing process are coordinated, helping us to deliver on time without compromising quality. We provide clear lead time estimates and update them regularly, so you can plan and manage your custom medical device projects with confidence. Whether it’s a prototype for a clinical trial or full-scale production for mass market distribution, we are committed to delivering on time, every time.

Communication & Transparency

Effective communication is at the heart of everything we do at Elimold. We provide a dedicated project manager to each medical sheet metal parts manufacturing project, ensuring consistent communication throughout the process. Our project managers provide regular updates, tracking the progress of the project from design to delivery. We maintain full transparency every step of the way, and if any issues arise, we have clear processes to resolve them quickly. In addition, our online project management tools make it easy to access real-time updates, review drawings, and approve design revisions. Our goal is to ensure that you are confident and informed at every stage of the process.

From Prototyping To Full Production

Elimold provides end-to-end sheet metal manufacturing services for the medical device industry, from prototyping to full production. Whether you need a single prototype for clinical trial testing or high-volume production for a mass-market medical device, we have the capabilities and expertise to provide everything you need.

Optimized Design

We believe the best results come from collaboration. Elimold’s engineers can review your designs and provide feedback, as well as thoughtful solutions to improve manufacturability, cost-effectiveness, and efficiency.

Engineering

Our team of highly skilled engineers provides contract engineering services as well as project management for medical sheet metal parts manufacturing using a variety of technologies, as well as full turnkey systems.

Rapid Prototyping

When you start working with us. We make fit and functionality prototypes, so you can test if the part meets your requirements, and even perform sterilization validation testing. This allows any issues to be quickly resolved before the part goes into production.

Rapid Manufacturing

With Elimold, you get a one-stop medical sheet metal parts manufacturer that will be with you from the beginning of your project. We have a shop dedicated to medical sheet metal fabrication and cost-effective solutions.

Parts Assembly

Our medical and emergency services industry experts are able to assemble sheet metal fabrication projects based on your specific requirements. They can also provide technical documentation, standard operating procedures, and training manuals.

Our Quality Management Team

With Elimold’s ISO 9001 system and a highly skilled quality management team, the medical industry can be assured that there will be no issues with the quality of their products. We work with different medical device manufacturers around the globe and always provide them with high-quality medical sheet metal manufacturing. Our customers should not expect too little from us. We also undergo multiple inspections to ensure that we comply with medical industry device manufacturing regulations and have never had these issues in the past. You can rest assured that your production is in reliable hands that will not let you down. Elimold’s full range of custom medical device sheet metal parts services make us your first choice for all your medical device needs because you can get everything under one roof.

Modern Quality Assurance Technology

Our Quality Assurance department has a wide range of equipment and instruments. This includes Zeiss Contura coordinate measuring machines with VAST scanning technology for precise form analysis, FabriVISION, several Brown & Sharpe 9159 CMM machines using PC-DMIS software, numerous optical comparators and a variety of specialized instruments. And our quality management team can complete FMEA and PPAP documentation, capability studies, gage repeatability and reproducibility (Gage R&R), process diagrams, statistical analysis and other documentation.

Compliance and Regulations for Metal Fabricating Companies Making Medical Devices

Products for the medical industry must comply with strict quality and safety regulations given their critical applications. Standards for medical device fabrication are often based on your manufacturing partner’s location, but common examples include:

Regulations for medical devices

The Food and Drug Administration (FDA) and the European Union Medical Device Regulation (MDR) organizations in the U.S. and Europe, respectively, set forth regulations governing devices for the medical sector. These regulations set the standards for device design, production, labeling, quality, safety, and performance.

Biocompatible materials

As medical devices must be safe to use in and around patients, the healthcare industry has standards in place to regulate materials and their biocompatibility for such devices. For example, the standard ISO 10993 offers manufacturers guidance on biocompatible metals for this sector.

Quality management system (QMS)

With an emphasis on continual improvement, quality management systems set the standards for good manufacturing practices in device design, manufacturing, and sale. H&S Manufacturing is ISO 9001:2015-certified.

Medical Sheet Metal Part Material Options

The most commonly used metals and alloys in custom medical sheet metal parts include:

- Aluminum

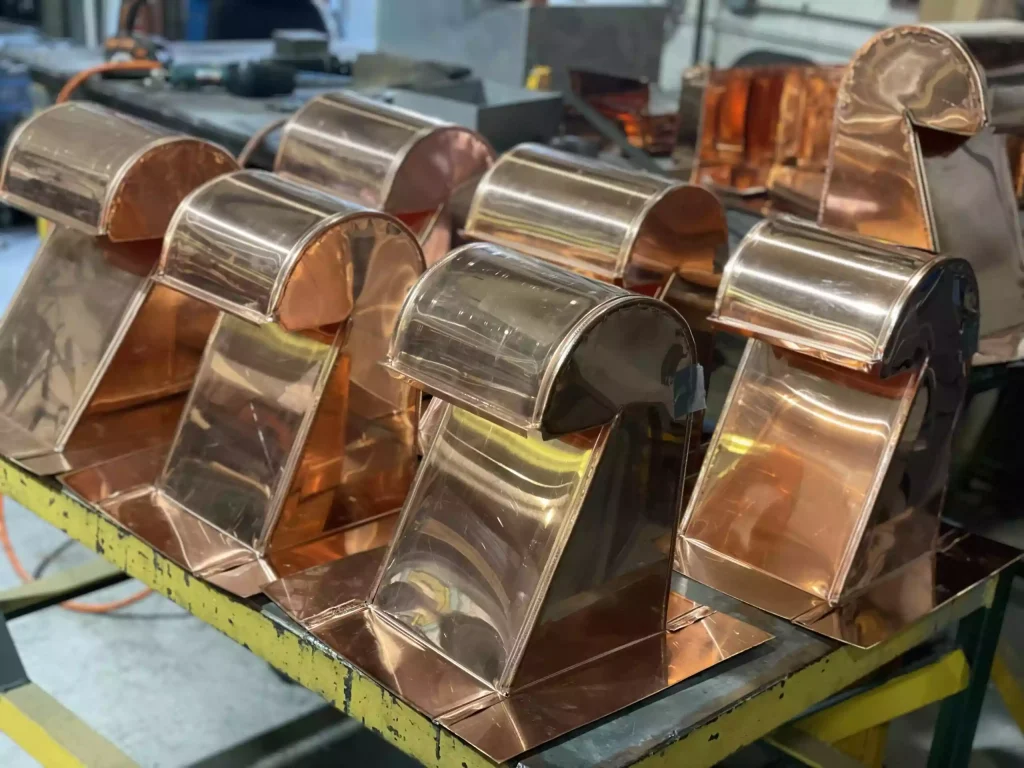

- Brass

- Cobalt-chrome alloy

- Copper

- Gold

- Iridium

- Nitinol

- Platinum

- Silver

- Stainless steel

- Tantalum

- Titanium

- Tungsten

Advanced Surface Finishing for Medical Applications

Surface finishing is critical to medical sheet metal fabrication, improving durability, corrosion resistance, and sanitation. We offer a variety of finishing options, including:

- anodizing

- assembly

- Deburring and cleaning

- Drilling and tapping

- Finishing, painting and powder coating

- heat treatment

- processing

- Milling

- welding

- and more

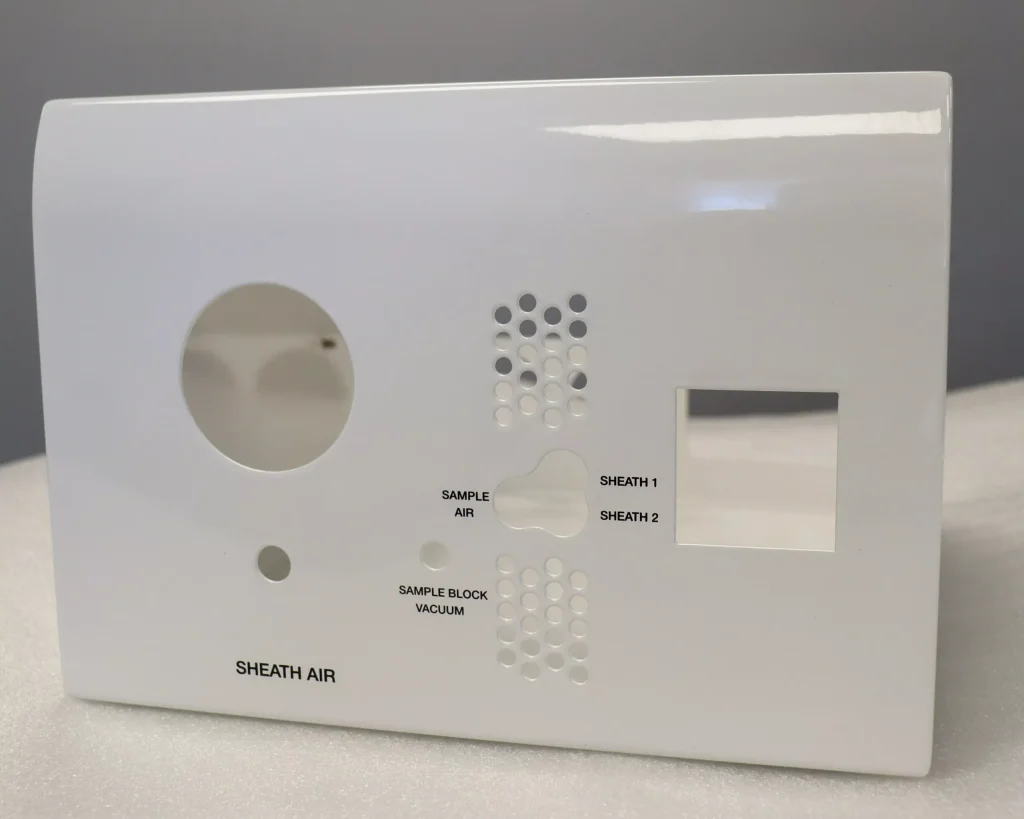

Medical Devices and Components Fabricated with Precision Sheet Metal Fabrication

Elimold specializes in manufacturing a wide range of medical devices and components utilizing our advanced sheet metal fabrication services. With our extensive experience in the medical industry, we understand the stringent requirements for functionality and safety. Our team of experts works closely with you to ensure that every component we manufacture meets the precise standards of a medical device while also providing the durability and performance required in a healthcare environment.

- Medical Equipment Enclosures

- Cabinets and Carts

- Instrument Trays and Racks

- Housings for Diagnostic Equipment

- Surgical Tables

- Medical Furniture

- Dental Equipment

- Sterile Processing Equipment

- Medical Carts

- Ventilation and Air Filtration Systems

- Lighting Fixtures.

- Diagnostic Test Kits

- Prepare the tray

- electrical enclosure

- IV pole

- infection control station

- medical cart

- linen gift basket

- Glove rack

- Mobile phone printer holder

- Handheld devices

- Surgical Instruments

- Ventilator

- prosthetic components

More Services

Your medical device components require the highest quality and precision. Elimold continuously invests in cutting-edge technology, equipment, and skills development, such as additive manufacturing and 5-axis machining. Thanks to our in-house, fully-fledged manufacturing operations, we have the experience and technology to produce your extremely precise medical devices and components, while having cutting-edge equipment such as 3D printing, wire EDM, Swiss turning, laser cutting, etc. to meet all your precision medical device sheet metal parts manufacturing needs. And our processing processes are all under one roof. This means you can get better prices and shorter delivery times because we can achieve efficiencies and economies of scale that other companies can’t match. Elimold can simplify your supply chain, eliminate coordination with multiple suppliers, and reduce the risk of errors.

Request Your Free Medical Sheet Metal Production Quote Today

After receiving your drawings, our engineers will analyze your custom Medical sheet metal production parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.