New Energy Sheet Metal Production

Elimold has all the capabilities needed to manufacture durable, precise sheet metal parts for new energy equipment in a short time. From precision sheet metal services such as laser cutting, welding and forming to assembly and finishing services, we have everything you need to handle your project and manufacture high-quality metal parts for today’s new energy industry. Contact our team today or request a quote to learn how we can support you.

Sheet Metal Fabrication for the New Energy Industry

As environmental concerns continue to grow, more people and companies are choosing to use new energy products. Technological advances have made the use of new energy more efficient and cost-effective, driving the demand for solar and wind energy.

At Elimold, we understand that high-quality, durable materials are needed to create long-lasting new energy applications. New energy parts and components are exposed to the elements and are subject to harsh conditions. These parts need to be durable enough to withstand sunlight, precipitation, wind, temperature fluctuations, and any other weather conditions. Therefore, sheet metal parts used in the new energy industry must be able to withstand these harsh conditions without damage or corrosion.

If you need our comprehensive sheet metal production services dedicated to the new energy industry to support your new energy sheet metal parts needs, please contact our team for a free quote.

Custom Sheet Metal Components for New Energy Equipment

In the demanding industry of new energy, Elimold is a brand that both private and public companies trust to produce parts that are manufactured exactly as designed and perform as or better than the original equipment manufacturer. Elimold’s team of engineers has decades of expertise in custom metal manufacturing, from medium to large assembly and welding components, to complete assembly of medium to heavy plates and plates, and a variety of industrial-grade metal components in between. Starting with your design, Elimold carefully analyzes and reviews the project requirements, then provides a detailed cost and time quote, and then works quickly to meet or exceed the quality and precision guidelines associated with manufacturing your parts. We won’t rest until we know you’ll be satisfied.

If your new energy business depends on reliability, precise quality, on-time delivery, competitive pricing, and proven engineering expertise – then Elimold is the new energy industry sheet metal parts manufacturing expert you can trust to handle any capacity and provide excellent parts.

Our sheet metal fabrication services for the new energy industry

Our sheet metal fabrication services for the new energy industry use thin metal sheets to manufacture parts. We combine manual and automated processes to directly shape the sheet metal in the CAD file into the parts or components you need through laser cutting, bending, welding, painting and other process steps. Materials include aluminum, stainless steel, cold-rolled steel and copper. According to the part or component specifications, materials are selected based on metal properties, aesthetics and performance characteristics.

Elimold can match the correct sheet metal fabrication process with the most suitable material to shorten the production cycle of your new energy equipment sheet metal parts and reduce comprehensive costs. We have a complete process chain and equipment to provide customers with overall sheet metal production and assembly solutions and one-stop services.

Sheet metal production capabilities for custom new energy parts

With over 100 advanced machines such as laser cutters, benders and welders, our in-house factory can supply any number of sheet metal parts, from small batch prototypes to large-volume production. Our team of engineers provides precise and fast delivery.

Laser Cutting

Bending

Welding

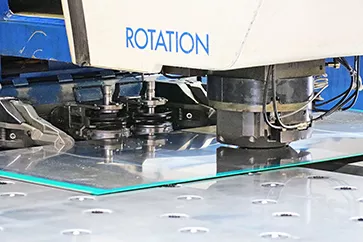

Punching

Riveting

Stamping

DFM Analysis & Quality Management

At Elimold, we focus on quality at every step from design to production to deliver precision new energy sheet metal parts. We follow Design for Manufacturability (DFM) principles, taking the time to understand your requirements and provide the best solution for your project. Our capabilities include computer-controlled manufacturing processes such as laser cutting, bending, punching, welding, stamping, and riveting. Advanced inspection tools such as CMMs, 2D measuring machines, XRF analyzers, gauges, micrometers, and calipers ensure that all parts meet stringent requirements. With years of experience and ISO-certified manufacturing facilities, we complete each project to the highest quality standards. Choose Elimold to manufacture precise, custom new energy sheet metal parts to your specifications.

Comprehensive services

At Elimold we strive to provide all of our sheet metal fabrication services to clients in the new energy industry so that our customers receive a high quality finished product.

Rapid Manufacturing Services

Our engineers at Elimold. ensure that your part is fully optimized before the production process begins, meaning you save both time and money on the manufacturing process. We work closely with you to make sure you are getting a product that is the best it can be. Rapid manufacturing services at Elimold. provide quick turn-around for projects with our automated lines.

Sheet Metal Services

With a broad range of services, at Elimold. we are prepared to tackle all of your precision sheet metal services. We offer laser cutting, metal forming, cnc machining, and painting services for the New Energy industry, so you get the highest quality, durable, corrosion-resistant metal components for your power generation needs.

Metal Finishing Services

At Elimold. we don’t stop at the production of the metal. We want to take your product all the way. Our premium metal finishing services complete your project. With our innovative powder painting and silkscreening capabilities, we can finish your metal project to meet your specifications.

Metal Assembly Services

Elimold offers expert sheet metal assembly services to complete your project in-house. We always strive to deliver a high-quality product, and we are happy to assemble metal components so you can save time and money. Our assembly services ensure that your product is assembled with maximum accuracy to fit your specific requirements.

Sheet Metal Materials for New Energy Applications

Choose from a wide variety of sheet metal materials we offer. Each material is selected for its unique properties, which enables us to recommend the best match for the specific needs and application of your project.

- Aluminium

- Brass

- Copper

- Steel

- Stainless Steel

Post Processing Used in New Energy Industry

- Anodizing

- Hard Anodizing

- Passivation

- Electroplating

- Powder Coating

- Painting

- Pad Printing

- Vapor Polishing

- Insert Installation

- Heat Treatment

Why use sheet metal for new energy equipment housing parts?

Sheet metal processing provides solutions that last longer than other products with similar uses. For example, similar shapes and functions can be achieved using casting. However, casting does not have the durability and lifespan of metal.

When you need precision, sheet metal processing allows you to cut, bend, and shape metal as needed. Not only does metal conform to new shapes, it also maintains the shape indefinitely. In industries that require materials to withstand impact or harsh conditions, the strength of metal far exceeds that of any type of plastic. Sheet metal processing is also a faster and more cost-effective alternative to other methods of manufacturing similar products.

Get an instant quote for new energy sheet metal production now

Are you looking for a reliable and professional new energy industry sheet metal parts manufacturing factory, Elimold provides sheet metal fabrication, parts assembly services and custom metal and plastic parts manufacturing services? Contact our team of experts now!