Semiconductor Sheet Metal Fabrication

Elimold provides superior semiconductor sheet metal production solutions, from material and process selection to prototyping and volume production. With the perfect combination of technical expertise and manufacturing implementation, we effectively bring your semiconductor devices to life. Contact us now for a free instant quote.

Professional Semiconductor Sheet Metal Manufacturer

Elimold Corporation has been providing quality sheet metal production services to customers in the semiconductor industry. We offer a full range of design, prototyping, production and testing services to ensure that your custom semiconductor sheet metal components meet the most stringent specifications and requirements. Our large in-house facility has more than 15,000 standard tooling products to produce custom sheet metal parts for numerous semiconductor applications, and we are able to manufacture custom tooling to accommodate a wide range of shape, size and volume specifications with tight tolerances. And we understand that semiconductor equipment sheet metal components must operate with reliable, repeatable accuracy within extremely tight tolerances. Regardless of the size, shape, volume or precision requirements of your semiconductor sheet metal project, we have the knowledge, experience and equipment to ensure the best possible assembly. When you work with us, our team maintains regular communication with you throughout the process, from design and prototyping to production and testing. Our goal is to provide you with quality sheet metal components in every aspect of your semiconductor equipment manufacturing project.

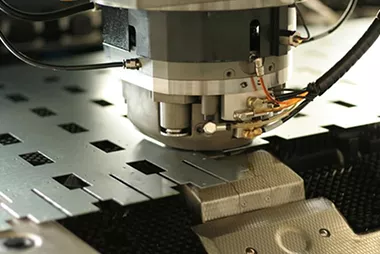

Capabilities of In-House Semiconductor Sheet Metal Fabrication Factory

No matter the size, material, or complexity of the semiconductor sheet metal project, our in-house sheet metal fabrication facility typically manufactures parts to tolerances less than 0.005 inches, and we frequently handle semiconductor equipment sheet metal projects that require highly specialized tooling and custom methods. And in addition to precision sheet metal fabrication, we also excel at performing unique and often complex assembly work. Our assembly department and team are able to handle a wide range of projects from mechanical to hydraulic and pneumatic assembly systems. From assembling large semiconductor equipment sheet metal components to assembling and testing small precision components for our semiconductor customers, we have the experience and expertise to get the job done perfectly. In addition to complex assemblies, we also provide kits of parts for our customers to use in the field or on the shop floor. Elimold’s in-house staff is well versed in applying special labels or packaging for semiconductor applications, and often marks components and packaging to ensure proper end use. As an advanced sheet metal fabrication company specializing in complex and mission-critical work, our sheet metal and assembly departments are vital to our operations.

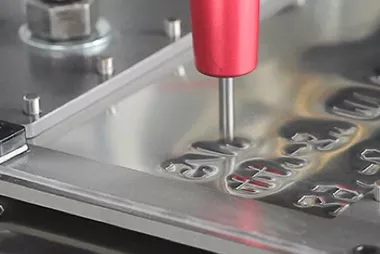

In-House Sheet Metal Die Fabrication Shop

Elimold has the most comprehensive in-house mold fabrication shop to meet your semiconductor sheet metal mold needs, from initial design to maintenance and repair. We offer a wide range of die types with fast turnaround times to meet your application requirements. And, with a team of experienced and proven mold design and fabrication engineers who have close connections with major semiconductor, LED and electronic component manufacturers around the world, we provide complete semiconductor sheet metal part solutions for all customer needs. Elimold provides customers with outstanding results with its semiconductor sheet metal part forming die fabrication and die design services supported by modern technology, thereby reducing labor costs.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities that are ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex and high-quality semiconductor sheet metal parts.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

Embossing

Semiconductor Sheet Metal Parts DFM Services

Design for Manufacturability (DFM) is a key concept in metal manufacturing that involves designing products in a way that optimizes the manufacturing process. A contract manufacturing company’s superior capabilities in DFM are essential to efficiently produce high-quality products, reduce costs, and ensure a smooth transition from design to production. At Elimold, we understand that DFM is essential to being a great manufacturing partner. That’s why we ensure competitive pricing, strong IP protection, and expert DFM guidance. Get prepaid pricing that includes shipping, quality control, and customs clearance. We focus on IP security and guarantee the confidentiality of your designs. Our mechanical engineers provide personalized DFM analysis to optimize your project.

Quality Assurance

At Elimold, quality is our top priority. We adhere to rigorous quality control processes throughout the manufacturing process to ensure that each semiconductor sheet metal component meets industry standards and customer expectations. Our team works closely with you, from concept to completion, to tailor a solution to your specific needs. Our commitment to excellence extends to material selection, manufacturing techniques, and final inspection, ensuring you receive a high-quality product every time. We are a leading name in sheet metal fabrication, known for our commitment to quality, innovation, and customer satisfaction. With decades of experience in the industry, Elimold has honed the expertise to provide best-in-class sheet metal fabrication services and solutions.

High quality precision sheet metal fabricated components

We are proud to showcase our capabilities in the semiconductor processing industry and our high-quality precision sheet metal parts manufacturing capabilities. We are dedicated to serving our customers. We know how important your project is to you and we want to ensure that every aspect of your project is handled with care. Our team of experts will work closely with you throughout the design process so that your final product meets or exceeds expectations. At Elimold, we are continually expanding our knowledge and capabilities in the semiconductor processing industry and will work tirelessly to ensure that your order exceeds all of your expectations. We use the highest quality materials and are committed to accuracy on every project. Contact us today for your precision metal semiconductor sheet metal parts processing needs!

Ready to start your next semiconductor sheet metal production project?

Whether you need custom components, prototypes, or mass production, Elimold is your first choice for sheet metal fabrication solutions. Learn more about how we can support your semiconductor equipment manufacturing needs and help you succeed in this rapidly evolving industry. Contact us today for a free instant quote.

Semiconductor Equipment Sheet Metal Parts Solutions

We work with leading semiconductor companies to provide custom sheet metal parts solutions that meet their specific needs. Whether designing unique semiconductor equipment or optimizing custom sheet metal parts manufacturing processes, our deep expertise means we know how to provide custom solutions to meet the unique challenges facing semiconductor manufacturers. From initial design concepts to fully engineered solutions, our expert engineers work together to optimize the manufacturability of your components. Our capabilities streamline production processes and reduce costs. And we don’t just meet semiconductor industry standards; we exceed them, continuously investing in cutting-edge technologies, including 3D printing services to manufacture rapid prototypes, validate customer semiconductor equipment sheet metal parts designs, and manufacturing processes, guaranteeing unparalleled accuracy and precision that can withstand even the most challenging semiconductor applications. For semiconductor equipment manufacturing, consistency is key, and we are committed to helping companies maintain product reliability and performance. We always adhere to the pursuit of excellence, and our commitment to quality ensures that we consistently deliver reliable products on time while maintaining competitive pricing and continuous process improvements to meet your needs. And drive innovation and reliability components in the semiconductor industry.

Materials for Semiconductor Sheet Metal Parts

At Elimold, we use a wide variety of standard and specialty alloy materials to manufacture semiconductor sheet metal parts for a variety of applications.

- Aluminum

- Stainless Steel

- Cold-rolled Steel

- Copper

- Brass

- Nickel

- Nickel Silver

- Cupronickel

- HY-MU 80

- Titanium

- Monel

- Hastelloy

- Kovar

- Inconel

Surface treatment

Surface treatment can be used for both aesthetic and functional purposes. All processes are completed in-house at Elimiold. We can provide the following surface treatment options.

- Anodizing

- Bead Blasting

- Painting

- Plating

- Polishing

- Powder Coating

- Riveting

- As Machined

- Tumbling

- Electropolish

- Heat Treatment

- Alodine

- Teflon Coating

- Black Oxidize

- Electroless

- Electroplating

- Passivation

- Electrophoresis

Value-added Services and Production Efficiency

We can also provide a range of value-added services. These services enhance the manufacturing process. They ensure that each product meets the high expectations of our customers. Our high-mix, low-volume production approach allows us to produce a wide range of semiconductor sheet metal parts while providing flexibility in design and customization.

- Inspection: To ensure that each product meets industry standards, we conduct extensive quality inspections.

- Assembly: To increase productivity and reduce error rates, we optimize the assembly process.

- Packaging: To help protect goods in transit, we provide secure packaging options.

Semiconductor Sheet Metal Applications

By investing in continuous innovation, we are shaping the future of semiconductor equipment manufacturing companies by providing a wide variety of precision metal parts custom manufactured for semiconductor applications. I can also use a variety of methods to modify or adjust components to meet your specifications and needs.

- Chassis and Enclosures

- Racks and Cabinets

- Front Panels

- Mounting Brackets

- Heat Sinks

- Electromagnetic Shields

- Cable Trays and Ducts

- Connectors and Mounting Plates

- Rack-Mountable Shelves

- Bus Bars

- EMI/RFI Shields

- Louvers and Vents

- Rack Handles and Rails

- Battery Trays and Holders

- Component Brackets

- Wafer Carriers

- Test Sockets

- Lead Frames

- Enclosures for Semiconductor Equipment

- Cleanroom Equipment and Furniture

- Gas and Chemical Delivery Systems

- Ion Implantation Shields

- Chambers and Enclosures for Etching and Deposition

- Vacuum Chamber Components

- Cleanroom Fixtures

- Electrostatic Chucks (ESC)

- Gas Panels

- Heat Exchangers

- Electroplating Racks

- Ion Beam Lithography Components

Additional Manufacturing Capabilities

Injection molding is used in the semiconductor industry to manufacture components such as connectors, switch housings and device covers. Injection molding offers advantages in semiconductor part production such as low cost, high replication accuracy and full design flexibility. In addition, it can produce complex shapes and geometries that are not achievable with other technologies. Elimold can provide services including the use of high-quality materials, provision of appropriate mold designs and rigorous testing and inspection of finished components. Semiconductor injection molding services are an efficient and economical way to produce high-quality semiconductor plastic products with high precision and complexity.

Elimold's innovations as a semiconductor equipment manufacturer

Take advantage of our comprehensive capabilities to simplify the process of finding reliable manufacturing services for your parts. High-volume production can be easily achieved with quality assured manufacturers. One of Elimold’s successful philosophies is its commitment to providing innovative products to meet all customer manufacturing requirements and provide total solutions. We also strive to provide the best customer service in the industry among semiconductor equipment manufacturers. If you have any questions about any of our products, please contact us for a free consultation to discuss your equipment custom sheet metal parts needs.

Request Your Free Semiconductor Sheet Metal Production Quote Today

After receiving your drawings, our engineers will analyze your custom Semiconductor Sheet Metal Production parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.