Marine Die Casting

Elimold is a leader in marine casting manufacturing, meeting marine casting component needs from rapid prototyping to large and small production runs. We provide casting solutions that meet all customer needs and specifications while maintaining international standards and industry compliance. Contact us now for a free instant quote.

Marine Die Casting Manufacturers

Elimold is a leader in marine die casting manufacturing and we cater to all types of orders. We can cater to orders of varying quantities, from low, medium to high requirements. Our commitment to quality sets us apart from the competition as we provide reliable marine die casting solutions. Elimold’s team of highly skilled engineers is able to handle marine casting products that require unique solutions relevant to their industry. We ensure that all solutions meet customer needs while still maintaining efficiency and compliance standards.

At Elimold, we promise to provide a one-stop, fast production marine die casting solution to meet your business needs. From design, assembly to surface treatment and delivery, our modern control facilities are able to do it all. You can benefit from our extensive experience and knowledge when we design mechanical parts with unique features.

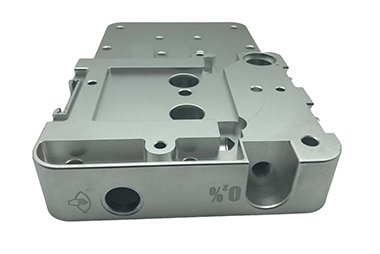

Elimold produces high-quality die-casting parts for leading marine brands

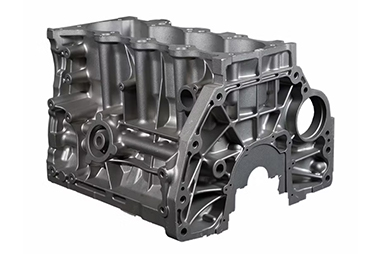

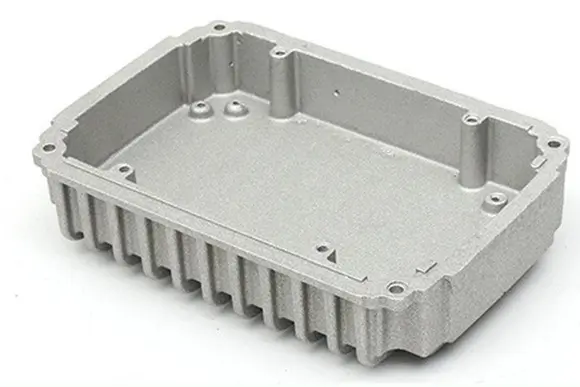

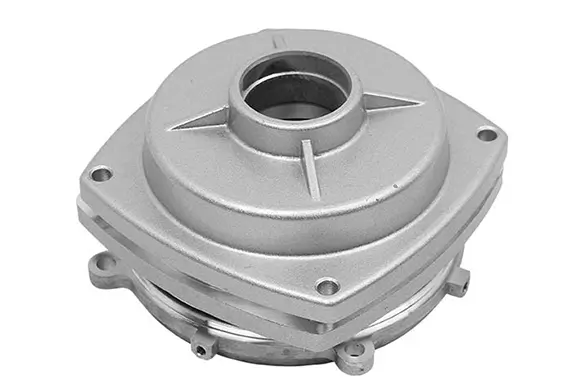

Marine castings we can manufacture include electronic housings for navigation and communication systems, outboard motor components, designer cabin lighting, and sacrificial zinc anodes. Marine die casting parts produced by Elimold can be found on luxury superyachts, leisure boats, and commercial vessels. We are well aware of the harsh working environment of marine castings. Therefore, our aim is to provide strong, corrosion-resistant marine die casting parts with high-quality surface treatment. During the component development process, Elimold provides industry-leading simulation and design tools to optimize your component manufacturing. This shortens development time and minimizes design changes after initial sampling. And we combine die casting and CNC machining to provide the speed and economy of casting with the precision and repeatability of machining.

Marine Metal Die Casting Parts Manufacturing Capabilities

Metal die castings are ideal for marine applications. Our castings offer excellent corrosion resistance when the correct alloy is selected and the proper surface treatment is used. A comprehensive range of surface treatment processes ensures that Elimold can provide a one-stop service to provide complete castings for your assembly line. In addition, our flexible manufacturing processes and proactive attitude ensure that we can quickly respond to changes in demand or shortened timelines for product launches. Our continued investment in our foundry and CNC machining facilities has made Elimold one of the most technologically advanced and flexible marine component die casting plants in the world. We always welcome customer quality teams to visit our world-class manufacturing facilities for audits and manufacturing reviews.

Comprehensive die casting solutions for ship

Corrosion resistance

Our die-cast parts undergo special surface treatment and have excellent corrosion resistance in salt and humid environments, ensuring the long-term reliability of your ship equipment.

High strength and pressure resistance

Our die-cast parts undergo rigorous pressure testing to ensure that they maintain strength and stability in high-pressure underwater environments.

High precision and high reliability

We use advanced mold design and manufacturing processes to ensure high precision and long-term reliability of die-cast parts.

Waterproof performance

The density and compactness of aluminum alloy materials, coupled with surface treatment, make our die-cast parts have excellent waterproof performance, protecting the internal electronic components.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Sand Casting

Investment Casting

Die Casting

Low Pressure Casting

Permanent Mold Casting

Lost Foam Casting

Centrifugal Casting

Vacuum Casting

Strong die-casting mold manufacturing capabilities

Mold design stage

Understand the specific requirements of the product, such as materials, surface treatment, use environment, etc., as well as process requirements and inspection requirements.

Mold processing stage

The production cycle is 25-35 days. If the product structure changes in the middle, the processing cycle may change accordingly.

Mold testing and verification stage

- T0 (test structure and scale)

- T1 (test appearance)

- T2 (trial production feasibility)

- PP (small batch trial to check whether it meets the mass production requirements)

CNC Machining and Other Services

Elimold also offers close tolerance CNC machining, including turning, milling, drilling, boring, and tapping capabilities. With the ability to produce high-quality marine die castings and CNC machining services, Elimold also offers many value-added services to our customers, saving them the time required to obtain multiple quotes and manage multiple suppliers. Our large facilities and knowledgeable staff allow for high-volume production and fast turnaround. Through our testing and quality assurance processes, we ensure the highest quality products with the most cost-effective short-run production services.

Testing and Inspection

We test to international and customer standards and often exceed established standards with ease. Our marine castings are tested to UKAS certification standards. Our machining capabilities enable us to complete your metal castings to exacting standards and perform subsequent machining as required.

- Accreditation – UkA, CAA and Rolls-Royce

- Radiography – X Ray and Gamma Ray

- Ultrasonic

- Dye penetration

- Magnetic particle

- Mechanical analysis

- Chemical testing

- Pressure testing

Start your Marine die casting project now

Have a project in mind? Whether you are at the concept stage or want to move your design from prototype to production, whether it is a small project or a large one, contact us today!

Technologies to Achieve Your Design

Die Casting Capabilities

Elimold is differentiated by its ability to produce large castings to customer specifications using both static and centrifugal casting techniques. Our capabilities include:

- Casting weights up to 35,000 lbs

- Centrifugal cast parts up to 80″ in length

- Centrifugal cast parts up to 158″ in OD

- Static cast parts with no size restrictions

Additional Capabilities

Our facility features an in-house machine shop with advanced CNC equipment, enabling us to provide dimensionally accurate finished castings. Eliminating time-consuming outsourced secondary operations simplifies the customer supply chain. We are able to machine parts such as:

- 150″ OD

- 80″ Length

- Tolerances of +/- .001″

Expertise in manufacturing die-casting parts for ships

No two clients or projects in the marketplace are alike. That’s why Elimold offers a wide range of production processes, including high pressure die casting, sand casting and permanent mold casting, using appropriate alloys including aluminum, brass and bronze, as well as a range of engineering expertise across our multiple locations. While we are generalists, we are also known for being adaptable and responsive in order to maintain high standards while staying within your budget and timeline. Our engineers and team members work with clients from the outset to ensure innovative solutions for every aspect of your project.

We provide one-stop marine casting services

As a marine die casting supplier, we provide fast production solutions from design, manufacturing, assembly to surface treatment of marine components. We use different types of casting technologies to provide customers with the most cost-effective parts even under the most demanding conditions.

High Pressure Die Casting

Low Pressure Die Casting

Hot Chamber Die Casting

Cold Chamber Die Casting

What can we do?

Elimold mainly provides custom die casting services, providing high-quality metal die casting parts for marine applications. From concept to finished product, we can produce custom castings for any marine industry project. And we have rich experience in die casting casting process, alloy material selection and casting marine hardware. All equipment is an automated production line, which has higher production efficiency. We can provide both large and small batches of marine parts. Post-processing such as heat treatment, machining and surface treatment can also be provided. Flexible transportation solutions are also provided.

Why Choose Elimold?

Elimold is a leader in custom die cast marine parts and marine hardware. Whether you need custom manufactured marine deck hardware, custom manufactured marine parts, or marine hardware, Elimold can accurately and quickly quote and provide a good solution for your job. What sets our company apart from other die casting foundries is our attention to detail and our knowledge of your industry. From design, proofing, production import, to delivery, Elimold works with you to ensure that our quality always exceeds your expectations.

Our marine and boat castings feature a high-quality surface finish to ensure that appearance is not compromised. We offer a variety of services that other casting suppliers do not always offer, including investment casting fabrication, shot peening, power polishing, mirror polishing and other available surface treatments, CNC machining, welding and assembly, direct logo printing when necessary, custom packaging, fast delivery, and convenient air or ocean shipping. If you have any questions about marine die castings, please contact us!

Value-Added Services

As a custom manufacturer of precision marine die castings, Elimold offers a full range of metal fabrication capabilities, allowing us to provide turnkey manufacturing services to our clients in the marine sector. We work with a variety of aluminum and zinc materials and specialize in prototypes or low to medium volume production runs up to 100,000 pieces. Our processing capabilities for the marine sector include:

- 3D Modeling

- CAD/CAM

- Computerized Tool Design

- CMM

- CNC Milling

- CNC Turning

- Mechanical Assembly

- Surface Finishing

Material Options

- Aluminum

- Zinc

- Copper

- Magnesium

- Lead

- Tin

- Bronze

- Steel

Surface Finishing Options

- Anodizing

- Chromate

- E-Coat

- Black Oxide

- Powder Coat

- Chrome Plated

- Bright Nickel

- Chem Film

- Cobalt tin

- Electroless nickel

- Gold plating

- Silver

- Nickel-Free Coating

- Polyurethane paint

- Impregnation

- Teflon

Marine die casting project

Whether it’s a yacht, naval vessel or offshore platform, equipment functionality is critical. Failure can put important personnel and the environment at risk. At Elimold, quality is our top priority. Materials are sourced from reputable suppliers and confirmed to be conformant upon arrival. Precision testing and measuring equipment ensures that every part produced exceeds applicable industry standards and customer specifications. All orders are checked for accuracy before shipment. We understand that waiting for parts can keep a ship at dock. Our team can deliver a rough component in as little as two weeks and a finished component in as little as eight weeks, depending on lead times and other factors. Contact us to learn more about our marine industry metal castings.

Marine Parts Application

We can design and manufacture castings for a variety of uses in the marine industry, including:

- Engine components

- Bruce anchors

- Marine steering wheels

- Seal housings

- Pump housings

- Marine cross bollards

- Deck hardware

- Bearing seats

- Marine railing base accessories

- Marine propellers

- Cleats, handles, brackets, covers

- Marine hardware

Ready to start your next project?

Whether you need marine die casting for prototype or production, Elimold’s foundry has a solution for you.