Carbon Fiber CNC Machining

Elimold provides you with the best carbon fiber CNC machining services, ensuring high quality and fast turnaround time. Our professional team and cutting-edge technology ensure precision, reliability and excellence in every project, and manufacture prototypes of carbon fiber CNC parts as well as mass production of carbon fiber CNC parts at the lowest cost. Contact us now for a free instant quote.

Carbon Fiber CNC Machining Manufacturer

Elimold can provide custom carbon fiber CNC machining services to a wide range of industries. We provide milling, drilling and cutting services for carbon fiber sheets, plates and tubes. The advanced CNC machines in our in-house CNC machining shop can produce products with complex shapes and tight tolerances. We can handle prototypes to mass production of carbon fiber parts. And our team has many years of experience working with carbon fiber materials. In addition, we offer fast turnaround times and competitive pricing. Our comprehensive quality control ensures that each part meets precise specifications at every step. From concept to final product, we are committed to providing excellent quality and fast delivery times for every project. Whether you need a small number of custom parts, prototypes or high-precision components for critical applications, our experienced team is here to help. Contact us today to get a free quote or discuss your project. Let’s work together to make your custom carbon fiber parts precise, durable and cost-effective.

Carbon Fiber CNC Machining Factory

As a leading CNC machined carbon fiber parts supplier for many years, Elimold is specially equipped with 35 CNC machines, including 15 5-axis, 8 3-axis, 12 turning and milling composite machines to manufacture carbon fiber parts for customers. These machines allow us to manufacture prototypes, small batches and mass production parts of carbon fiber. The fastest delivery time is 3 working days. In addition, our expertise in handling carbon fiber materials allows us to effectively implement adaptive processing strategies. This proficiency allows our team to expertly manage a variety of shapes when making carbon fiber parts to provide the best service to our customers.

As one of the professional carbon fiber CNC machining manufacturers, we have our own professional technicians and management team for carbon fiber parts manufacturing. Our team has extensive experience in the manufacturing and mass production of carbon fiber parts. In addition to our state-of-the-art carbon fiber parts custom manufacturing capabilities, we believe that communication is essential to a successful customer relationship. Every customer of Elimold has a contact person who will work with them every step of the way. As our customer, you will never have to ask about the status of the project, and we will send continuous updates as the project progresses.

You Design, We Make

Elimold has been providing CNC machining carbon fiber parts to our customers. If you are looking for custom carbon fiber parts, we can make them a reality for you, just provide us with Auto CAD/Solid Works/DFX/STP or IGS files, if you don’t have any files, you can also send us your samples and we can customize them for you.

If you are considering a project that requires CNC machining, be sure to find a machinist who has experience cutting carbon fiber or leave the machining to us. We provide 24-hour engineering assistance and we have a professional support team. They can help you solve any carbon fiber manufacturing problems and are always available to help you with your orders.

Carbon Fiber CNC Machining Suppliers

We offer more than just a machine shop. We work with our customers to understand project requirements, such as assembly tolerances and integration, structural stiffness, environmental concerns, and surface finish. Our engineering team helps designers and project managers analyze metal, plastic, and carbon fiber composite parts and assemblies, and then once final design approval is obtained, we provide turnkey manufacturing services.

We deliver complex CNC machined components quickly, whether for prototyping or production. Elimold specializes in the production of small to medium batches of machined components. As a professional CNC machining company, your organization will receive fast, professional customer service, engineering support, and high quality.

We have been engaged in CNC machining services for a long time and use only the best CNC machining materials to manufacture precision carbon fiber CNC machined parts, carbon fiber turned parts, carbon fiber milled parts, and more. We also do CNC fast custom machining, part design, carbon fiber prototyping, and production. We have a good reputation and our customers trust us because we have a wide range of carbon fiber components, we guarantee their quality, our prices are low, and we ship quickly. In CNC production machining, our goal is to keep prices low and delivery times short without compromising any part quality. This way, we can ensure every customer is satisfied, every time.

What is Carbon Fiber Machining

Carbon fiber is a high molecular weight, high strength, high modulus fiber that is made up of carbon atoms bonded together to form long chains. The carbon content is over 90%. Therefore, it is very strong and lightweight. This allows carbon fiber to be used to manufacture a variety of complex parts using CNC machining processes.

Carbon fiber machining, also known as carbon fiber reinforced polymer (CFRP), is a collection of carbon fibers. It is used to manufacture high-performance, low-weight but durable components. Its versatility and efficiency have enabled tremendous manufacturing innovations in multiple industries.

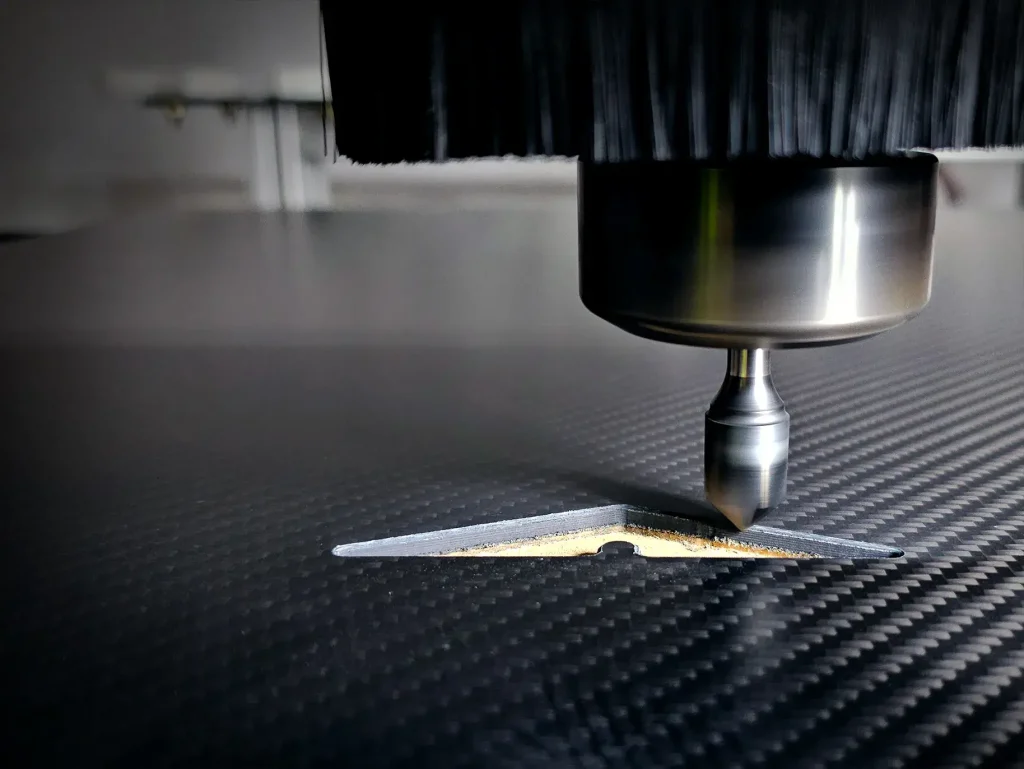

CNC machining carbon fiber is a process that applies computer-controlled digital technology to remove excess material and complete any necessary cutting, turning or milling. This can be done using machine tools according to your specific programming needs before the final product can be obtained from the carbon fiber in its final form.

CNC Carbon Fiber Material Options

Carbon fiber materials for CNC machining vary in strength, modulus, and elongation for different applications. Elimold offers a variety of carbon fiber material types that provide a variety of mechanical properties, allowing us to select the most appropriate material based on the strength, stiffness, and durability required for your CNC machined carbon fiber part project.

- Tensile strength – 3530 MPa

- Tensile modulus – 230 GPa

- Elongation – 1.5%

- Density – 1.76 g/cm³

- Tensile strength – 4900 MPa

- Tensile modulus – 230 GPa

- Elongation – 2.1%

- Density – 1.80 g/cm³

- Tensile strength – 5880 MPa

- Tensile modulus – 294 GPa

- Elongation – 2.0%

- Density – 1.79 g/cm³

- Tensile strength – 6370 MPa

- Tensile modulus – 295 GPa

- Elongation – 2.2%

- Density – 1.79 g/cm³

- Tensile strength – 4410 MPa

- Tensile modulus – 377 GPa

- Elongation – 1.2%

- Density – 1.82 g/cm³

- Tensile strength – 4210 MPa

- Tensile modulus – 395 GPa

- Elongation – 1.1%

- Density – 1.83 g/cm³

- Tensile strength – 3920 MPa

- Tensile modulus – 540 GPa

- Elongation – 0.7%

- Density – 1.83 g/cm³

- Tensile strength – 5690 MPa

- Tensile modulus – 276 GPa

- Elongation – 1.9%

- Density – 1.79 g/cm³

- Tensile strength – 4480 MPa

- Tensile modulus – 231 GPa

- Elongation – 1.7%

- Density – 1.78 g/cm³

- Tensile strength – 6000 MPa

- Tensile modulus – 377 GPa

- Elongation – 1.5%

- Density – 1.80 g/cm³

- Tensile strength – 4900 MPa

- Tensile modulus – 500 GPa

- Elongation – 1.2%

- Density – 1.82 g/cm³

- Tensile strength – 7000 MPa

- Tensile modulus – 290 GPa

- Elongation – 2.3%

- Density – 1.79 g/cm³

- Tensile strength – 5400 MPa

- Tensile modulus – 280 GPa

- Elongation – 2.0%

- Density – 1.79 g/cm³

- Tensile strength – 2500 MPa

- Tensile modulus – 880 GPa

- Elongation – 0.3%

- Density – 2.10 g/cm³a

- Tensile strength – 2400 MPa

- Tensile modulus – 930 GPa

- Elongation – 0.3%

- Density – 2.15 g/cm³

Carbon Fiber Machining Capabilities

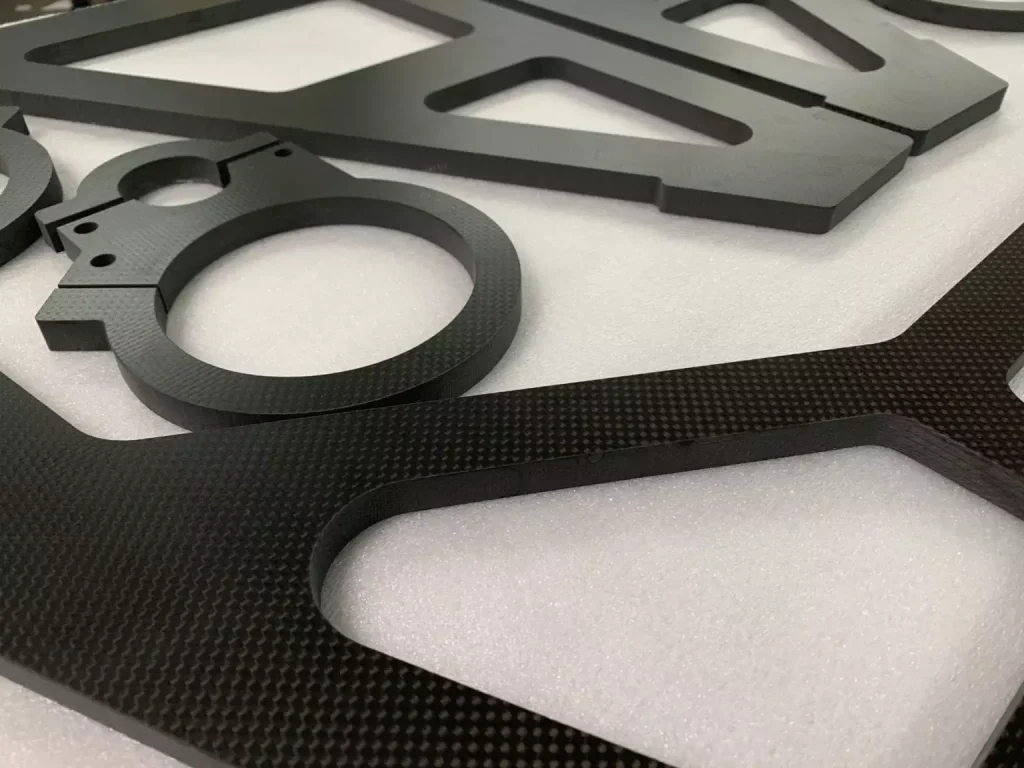

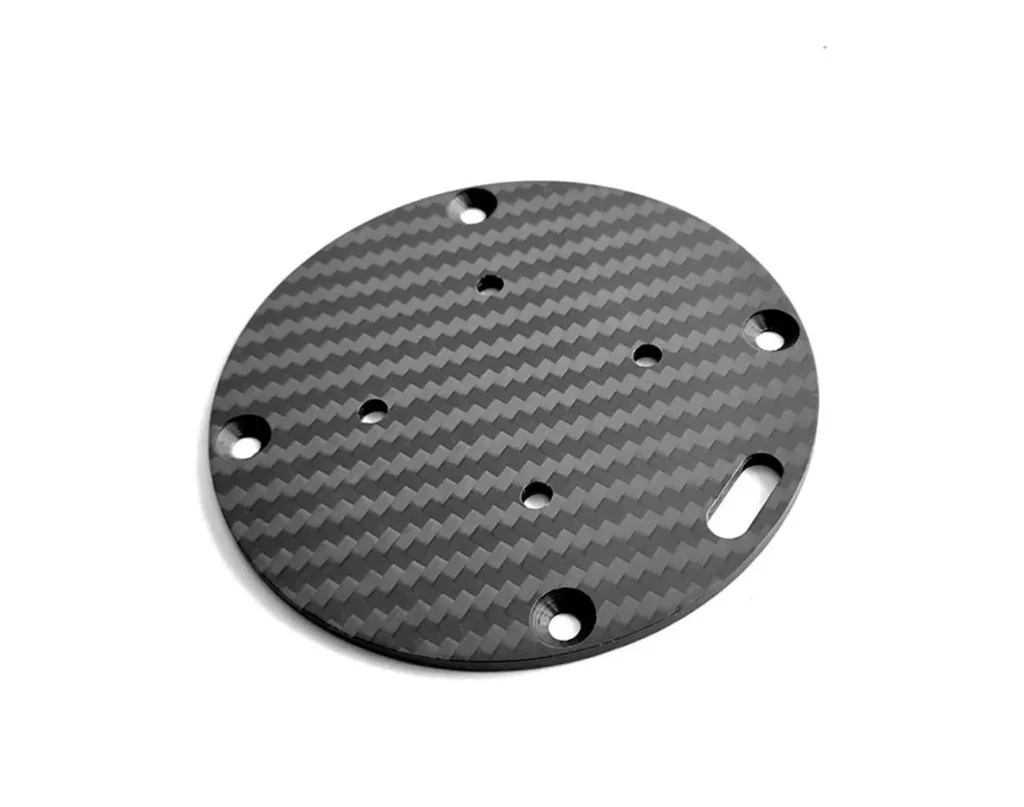

At Elimold, we use state-of-the-art equipment to provide you with a variety of carbon fiber CNC machining services, including milling, turning, EDM and wire cutting, surface grinding, and more. Using our imported 3, 4, and 5-axis CNC machining centers, our skilled machinists can create CNC turned and milled parts from carbon fiber materials. Whether you need a one-off model to meet a functional requirement, a small batch production for marketing and testing, or a small batch production, Elimold has a solution for you, we have a full range of carbon fiber material CNC machining services. Capable of manufacturing parts up to 4 inches thick with a tolerance of +/- 0.003 inches. Other capabilities include boring, drilling, knurling, milling, turning, tapping, and threading. Design, prototyping, and drafting services are also available.

Our Superior Manufacturing Capabilities

Elimold’s in-house facility features a range of advanced CNC machines with 3-axis, 4-axis and 5-axis capabilities. Our expertise in handling carbon fiber materials allows us to effectively implement adaptive machining strategies. This proficiency enables our team to expertly manage a wide range of shapes when crafting carbon fiber parts, providing the best possible service to our customers.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

CNC Routing Service

CNC Grinding Service

Swiss Machining Service

Carbon Fiber Machining Shop

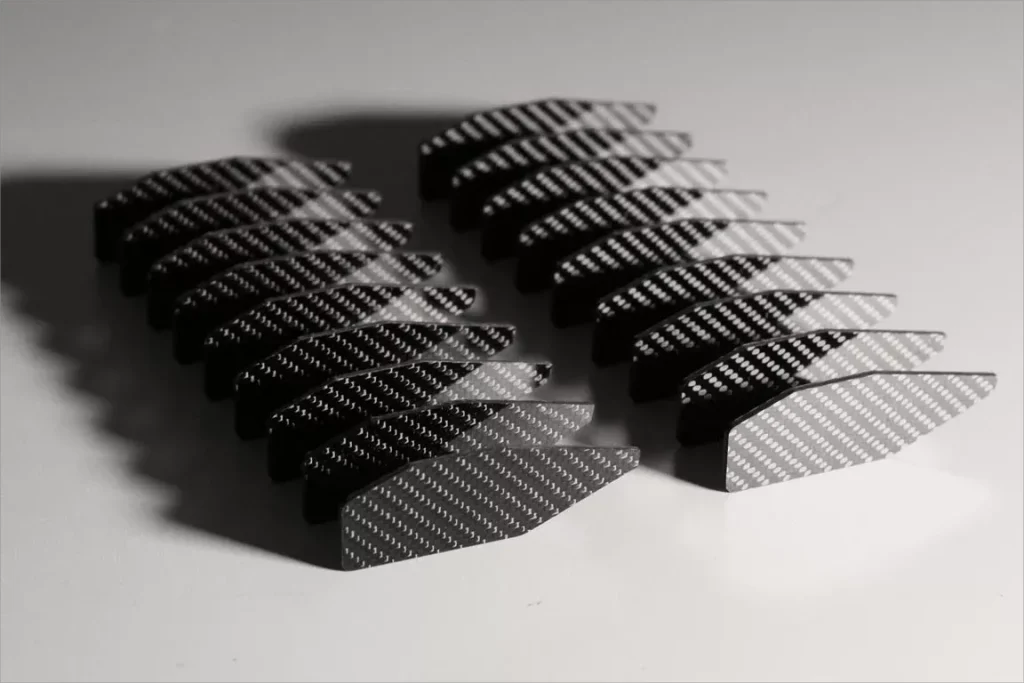

Elimold offers carbon fiber CNC machining to produce high-quality parts with tight tolerances and complex geometries. With years of experience in providing custom carbon fiber CNC machining services, we will provide precise quality to meet your project requirements at a competitive price. When you work with Elimold, we deliver details and components without any defects (such as bulges), with smooth edges, dimensions exactly to specification, and beautiful appearance. We can provide a comprehensive carbon fiber CNC machining service with 3-axis, 4-axis and 5-axis milling CNC machines with accuracies up to 0.05 mm (0.002 inches), working ranges of 200 x 600 cm (78 x 118 inches), and thicknesses from 0.5 mm to 50 mm (0.02 to 2 inches). Whether it is custom carbon fiber sheet, plate or tube parts can be made to meet your specifications. Our in-house CNC machining capabilities enable us to cut your carbon fiber (CFRP) parts efficiently and economically.

Our Tolerances For Carbon Fiber CNC Machining

Our commitment to quality and precision stands out. With advanced measuring equipment, highly skilled QC inspectors, and a relentless pursuit of extreme tolerance, we offer custom CNC machining parts of the highest standard. Our expertise makes us an industry-trusted supplier you can rely on.

- Grinding: general tolerances of ±0.02mm, can achieve ±0.01mm with a surface finish of N2/N3

- CNC Turning: general tolerance of ±0.03mm, can achieve ±0.01mm with a surface finish of N4/N5

- CNC Milling: general tolerance of ±0.03mm, can achieve ±0.01mm with a surface finish of N4/N5

- Our CNC machine equipped with synchronized rigid tapping for perfect internal threads

Quality Management Capabilities

Our extensive experience has helped us understand the subtleties of machining an unusual, high-performance material like carbon fiber. Our in-house CNC machining capabilities allow us to produce your parts quickly, efficiently, and cost-effectively. Our in-house coordinate measuring machine (CMM) capabilities allow us to conduct strict process control and provide dimensional certification when necessary. In addition, our ISO 9001:2015 certified quality management system ensures that all teams, materials, and machines are in a state of normal quality assurance, and we make the right judgment the first time not only for ourselves but also for our customers. We inspect and maintain our machines every day except holidays. During the production stage (including samples), the production workers frequently check the dimensions, then the production manager checks the dimensions again, and finally our quality inspection department will use CMM for final inspection. We inspect 100% of the parts, especially the threads and surfaces.

Ready to get your carbon fiber CNC machined parts?

Get custom carbon fiber CNC machined parts with our online CNC machining services. Rapid prototyping produces parts in days, with ISO 9001:2015 quality assurance and fast delivery. Get a quote now.

Custom Carbon Fiber CNC Parts Manufacturing

We have extensive carbon fiber CNC parts custom manufacturing capabilities, and our in-house CNC machining facility’s carbon fiber parts manufacturing shop has huge production capacity and a wide range of machinery, allowing us to fulfill a variety of orders and produce very complex carbon fiber parts. Therefore, our complete carbon fiber CNC machining service can produce simple blanks to complex components with tight tolerances using carbon fiber materials. By utilizing advanced CNC technology and an experienced team of machinists, our carbon fiber parts CNC machining process can ensure high precision and maintain the integrity and strength of the carbon fiber to meet the specific requirements of various industries. The expertise of our team also ensures that each carbon fiber component meets the highest quality and performance standards. Therefore, we can perform CNC fast custom machining, part design, carbon fiber prototyping and production. In addition, we have a good reputation in the field of carbon fiber parts custom manufacturing, and customers trust us because we guarantee the quality of the parts, our prices are low, and we ship quickly. In carbon fiber parts CNC production processing, our goal is to keep prices low and lead times short without compromising any part quality. In this way, we can ensure that every customer is satisfied every time.

Advantages of Carbon Fiber CNC Parts

Carbon fiber (CF) is a term for high-strength, high-modulus fibers that have more than 90% carbon in them. Organic fibers (like viscose, pitch, polyacrylonitrile, etc.) are used to make it.

High-performance carbon fiber has great properties that can’t be found in many other materials. For example, it is light, strong, has a high modulus, can withstand high temperatures, is resistant to corrosion, erosion, and sputtering, and is easy to design and mix with other materials. Strategic new materials that are needed to make things like satellites, missiles, fighter jets, and ships that are at the cutting edge of technology.

Carbon fiber is an important new material that works very well. Its density is less than 1/4 that of steel, and its strength is 5–7 times that of steel. When compared to structural parts made of aluminum alloy, carbon fiber composite materials can cut weight by 20%–40%. When compared to steel metal parts, carbon fiber composite materials can cut weight by 60%–80%.

Precautions for Carbon Fiber CNC Machining

When using CNC to process carbon fiber products, problems such as delamination and tearing of carbon fiber materials are often encountered. In addition, the carbon fiber composite material formed by the fusion of carbon fiber and resin matrix is not difficult to process after curing. However, due to the low melting point of the resin, there may be burning during the processing due to overheating, which can cause performance damage to the carbon fiber product. CNC technicians need to fully consider the relationship between cutting force and deformation to ensure that processing does not affect quality.

When CNC precision machining carbon fiber products, the impact of oil pollution on the products should also be considered. It is possible to perform dry cutting without adding coolant, which not only softens and burns carbon fiber products, but also causes excessive tool wear. Therefore, it is necessary to choose a suitable tool.

Surface finishing and post-processing options

Although CNC machining carbon fiber provides a superior surface finish compared to traditional methods, ensuring smooth edges and surfaces. However, customers often have higher requirements for the aesthetics and performance of carbon fiber parts, so we provide you with a variety of surface finishing and post-processing options.

- Sanding

- Polishing

- Clear Coating (Epoxy or Polyurethane)

- Painting

- Vapor Deposition Coating

- Plasma Treatment

- Chemical Etching

- Adhesive Priming

- UV-Curing Coating

- Electroless Plating (for conductive layers)

- Anodizing (for hybrid metal-carbon fiber parts)

- Silk Screening

- Laser Engraving or Etching

Main Applications of CNC Carbon Fiber Parts

Elimold has been providing CNC machining carbon fiber parts to our customers for many years. So far, we have completed more than 100 machining projects with carbon fiber materials in different shapes, and our customers are very satisfied with them. The following are the main applications of CNC carbon fiber.

- Suspension arms

- Camera rig components

- Robot arms

- Protective covers

- Antenna mounts

- Sporting equipment parts

- Instrument panels

- Custom dashboard trims

- Brackets

- Mounting plates

- Gaskets

- Aircraft parts

- Satellite parts

- Automotive body panels

- Interior parts

- Chassis parts

- Bicycle frames

- Sports equipment

- Fairings

- Robots

- Toy race cars

- Marine

- Structural supports

- Chassis components

- Drone frames

- Motorcycle fairings

- Bicycle components

- Aerospace fittings

- Automotive interior trims

- Electronic device casings

- Prosthetic components

- Racing seat backs

- UAV propeller blades

Request Your Free Carbon Fiber CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Carbon Fiber CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.