Communications Sheet Metal Fabrication

Elimold is extremely proud of our consistent pursuit of precision, quality and efficiency, which are essential to meet the unique requirements of the field of sheet metal production for communications equipment. Whether it is mass production of sheet metal parts for the communications industry or manufacturing replacement parts, we are fully capable of being your preferred supplier.

Your Valued Communications Sheet Metal Production Partner

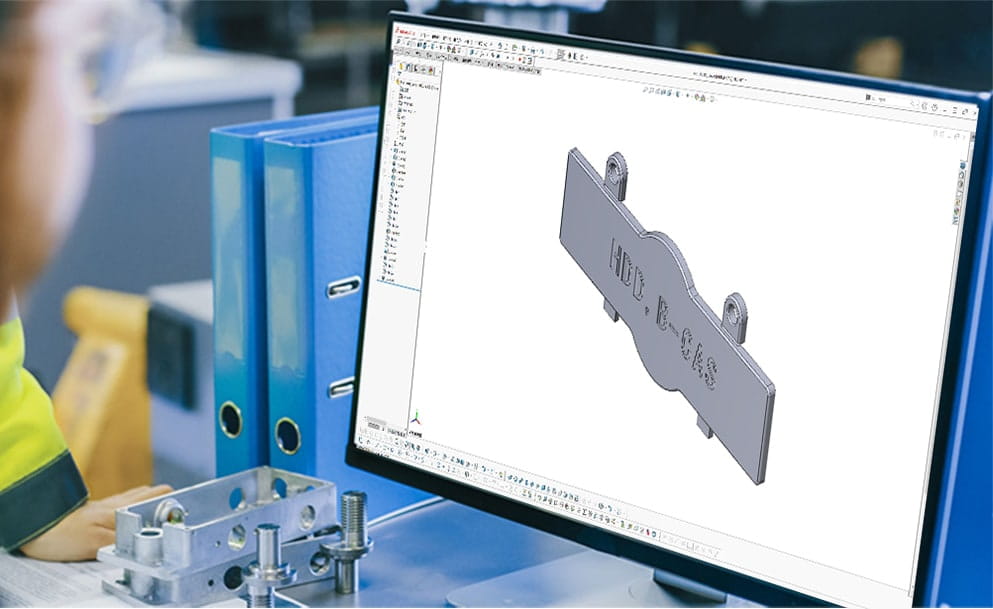

Experience the Elimold difference with our premium communications equipment sheet metal fabrication services as well as metal assembly and metal finishing. We provide high-quality custom sheet metal to your precise requirements in Shenzhen, China. In addition to our quality services, we also provide comprehensive support. We bring together a vast experience in manufacturing projects to meet the individual needs of our customers. We are experts in providing innovative value-added manufacturing services such as new product design/prototyping, design for manufacturing, and supply chain management solutions such as Just-in-Time Manufacturing (JIT) and Vendor Managed Inventory (VMI) to the communications market.

As your one-stop sheet metal fabrication shop, we guarantee to be with you at every step of production, ensuring that your parts are manufactured to your specifications. We also provide extensive DFM and design support, as well as automated machinery and just-in-time delivery services so that your products can get to market faster. Explore our services to see how Elimold can help you elevate your products. Contact our team today.

Elimold's Communications Industry Experience

Elimold excels in providing communications companies with top-tier sheet metal fabrication and precision machining solutions to meet the unique needs of their end products. The efficiency and quality of our services play a key role in ensuring quality communications products and a strong infrastructure.

With extensive experience in the communications industry, we have a proven track record of providing exceptional manufacturing and machining services. Our expertise is reflected in our ability to meet the rigorous demands of the telecommunications industry. Our commitment to quality is backed by our AS9100 certification and NADCAP accreditation, ensuring that every component manufactured meets the highest standards of quality and precision.

Providing Quality Service Regardless of the Communications Product

In the rapidly evolving communications industry, the need for precise, reliable and high-quality sheet metal fabrication processes and machining services is paramount. Sheet metal parts manufacturing plays a key role in providing innovative solutions for a variety of communications projects, and precision machining enables the manufacturing process to provide the high-precision and finely detailed complex parts necessary for communications equipment and infrastructure.

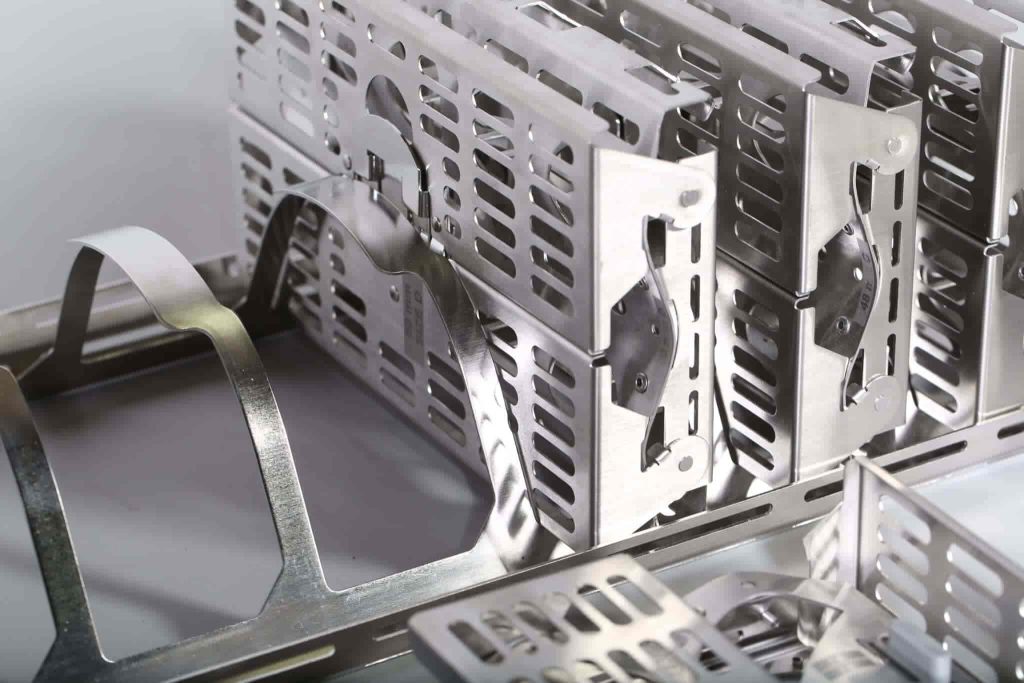

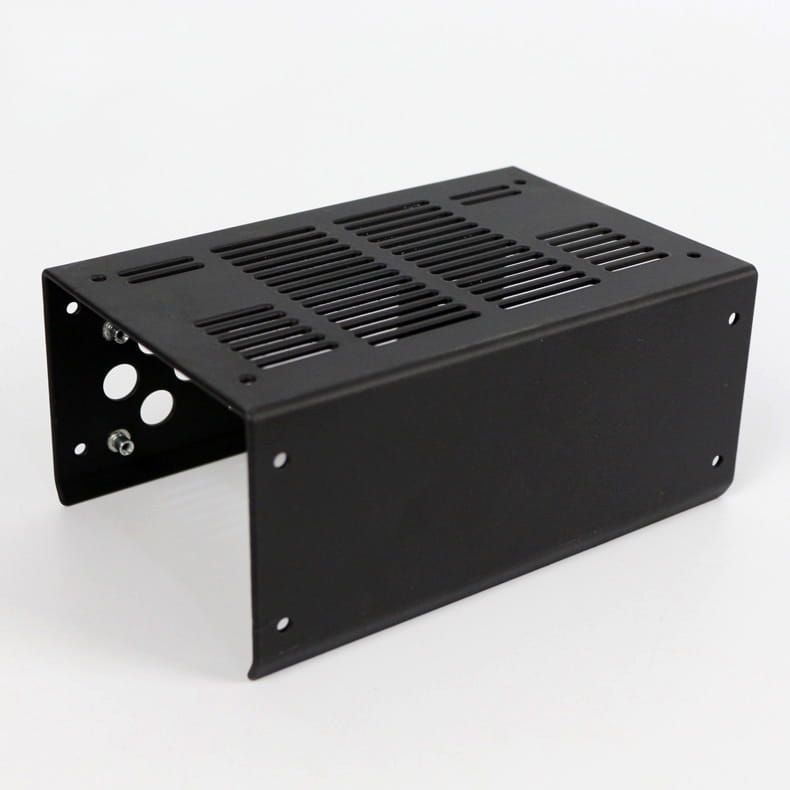

The communications industry relies heavily on sheet metal fabrication services to design parts and equipment, including access panel frames, heat sinks and other components. Precision metal fabrication produces high-spec, durable metal communications parts. The use of precision machining ensures consistent quality, tight tolerances and no lag requirements to meet the needs of this technology-driven industry.

High Quality Custom Metal Telecom Parts

The communications industry relies on precision sheet metal production processes to create high-spec, durable metal communications parts and other premium metal components that play a role in communications. At Elimold, we have been a skilled manufacturing partner to demanding communications companies for decades, using advanced machinery and efficient processes to create quality sheet metal parts to precise requirements. With rapid capabilities and start-to-finish support, including design guidance, manufacturing, assembly, and finishing, we are a full-service manufacturing facility dedicated to meeting your communications equipment sheet metal parts needs. Whether you need small or large-volume production, we have the capabilities and commitment to serve you.

Our Communications Sheet Metal Production Process Types

At our company, we are committed to providing the highest quality communications equipment sheet metal fabrication services to meet your unique needs. Our state-of-the-art facilities are equipped with cutting-edge machinery and technology to ensure that our products are of the highest precision and quality. No matter how complex or large your project, our experienced team is ready to help you turn your ideas into reality. The types of processes we can provide include:

Laser cutting

Plasma cutting

Punching

Stamping

Die cutting

Bending and Forming

Welding

Tube laser cutting with automatic feeder

Our Capabilities

Elimold’s manufacturing division has a reputation for manufacturing high-quality, tight tolerance sheet metal products for the communications industry. We excel in lightweight steel, stainless steel, and aluminum products from prototype to volume production. With years of experience, we know how to maintain tight tolerances; our bend tolerances are ±.005″, hole to hole tolerances are ±.005″, hole to edge tolerances are ±.010″, and hole to bend tolerances are ±.015″ in material thicknesses from .015″ to .187″.

Material

- Aluminium (5052, 6061, 6063, 1060)

- Carbon Steel (SPCC, HRS, SAPH440

- Stainless Steel (201, 304, 316)

- Cold Galvanized Steel

- Cold Rolled Steel

- Copper

- and much more

Secondary Processes

- TIG and MIG Welding

- Robotic Welding

- Spot Welding

- Laser Welding

- CNC Sheet Bending

- Riveting

- PEM & Rivet Nut Insertion

- Laser Etching

Surface Finishing

- Powder Coating

- Anodizing

- Electro Coating

- Trivalent Zinc Plating

- Hot Dip Galvanized

- Passivation

- Geomet

- Dacromet

- Sandblasting

Why Choose Us

Our state-of-the-art facilities feature advanced technology that ensures precision and efficiency in producing sheet metal components for communications applications. With over 15 years of experience in sheet metal projects for the communications industry, we pride ourselves on understanding your specific needs and providing custom solutions that meet or exceed your expectations.

- Expert Project Management and Consulting: Our skilled engineers and technicians provide timely communication and updates, ensuring seamless project management from initial Design for Manufacturability (DFM) to shipment.

- Smart Manufacturing: As part of our commitment to innovation, we continually invest in upgrading our manufacturing facilities to smart factories, leveraging real-time data and monitoring from quote to shipment.

- In-House Tooling and Secondary Operations: We manufacture complex, high-precision parts and assemblies, and build stamping tools in-house, allowing for faster turnaround and superior control over design and quality.

- Fast Turnaround Times: Our strong in-house sheet metal fabrication capabilities, along with an extensive inventory of raw materials, standard fasteners, and a supporting supplier base, allow us to quickly get sheet metal products into production.

- High Quality Standards: We adhere to stringent quality control measures to guarantee that your sheet metal parts and assemblies meet the highest quality standards.

Ready to start your next communications sheet metal production project?

Ready to create custom metal communications parts to drive your innovation in the communications industry? Contact the team at Elimold to provide you with quality services that exceed your budget and time requirements. With our advanced equipment and extensive facilities, we are able to produce quality communications sheet metal parts to your precise specifications. Contact us today to get started.