Energy Die Casting

Elimold provides end-to-end die casting manufacturing solutions for the energy industry. We are committed to providing design, procurement, manufacturing, finishing and inspection services, and are committed to providing the highest quality standards. Contact us now for a free quote.

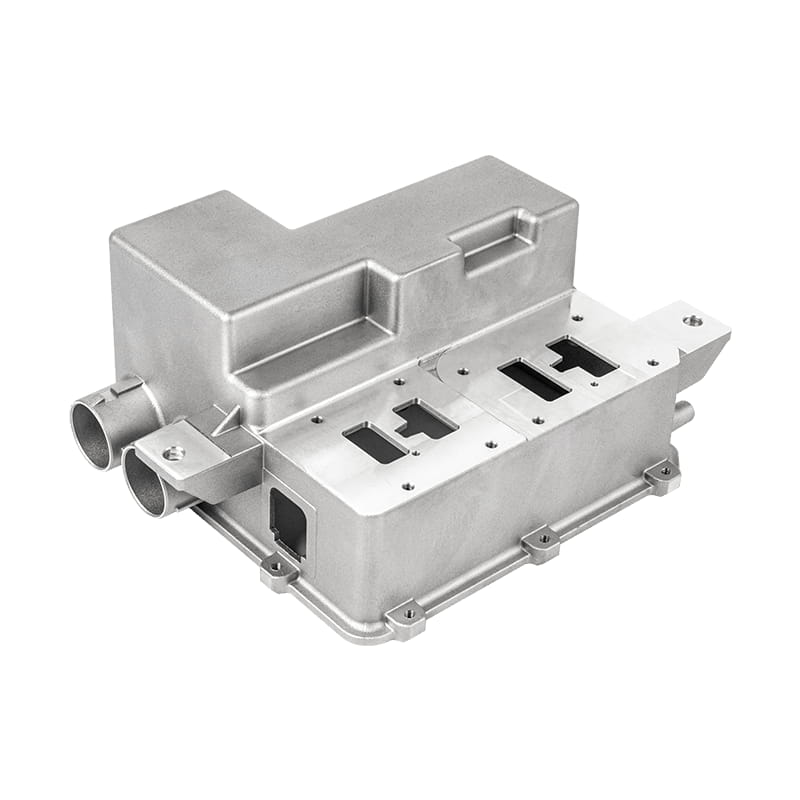

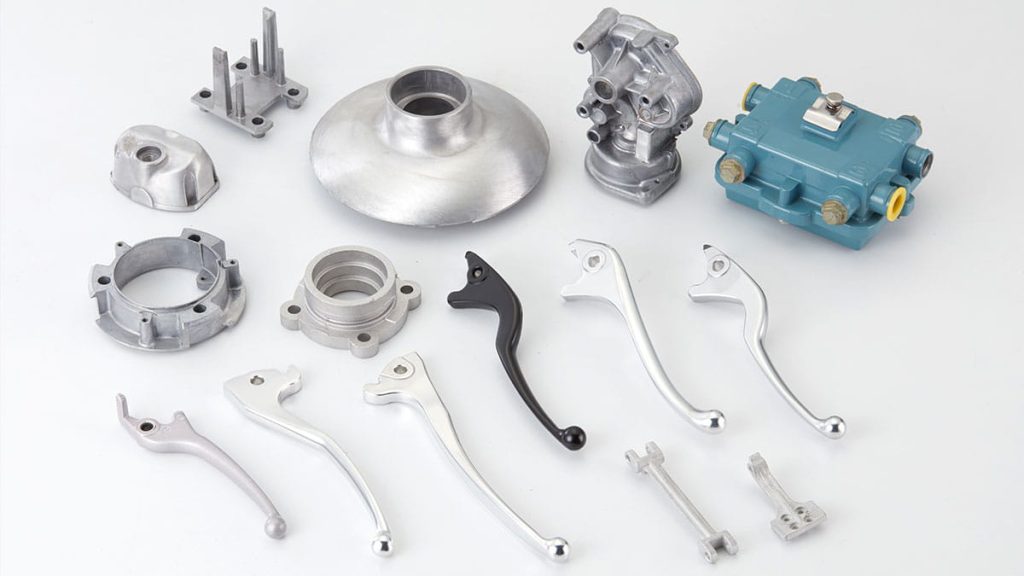

Energy Parts Die Casting

If you are in the energy industry, then you need reliable metal die cast parts. Elimold is your trusted supplier of die cast parts. With years of experience in the die casting industry, you can be sure that we are the company you can count on when you need die casting for solar panel brackets, wind turbine parts, and other alternative energy parts.

Quality-conscious companies know to choose Elimold for their die casting needs because we can save them money while producing strong and reliable parts. That’s why leaders in the energy industry rely on Elimold time and time again.

We are a business that values customer service. You can’t be in business for many years if you don’t know how to treat your customers. We are looking for long-term partners to help them succeed, not just sell out and walk away. Once you start working with Elimold, you will be so pleased with our level of service, and in addition to the savings and quality parts you enjoy, you’ll know you’ll never need to go anywhere else for your die casting again.

Our Full Range of Services

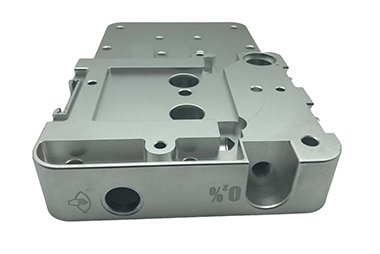

Elimold is a full-service energy industry die casting company dedicated to reducing your costs and improving the quality of your components. We assist in the production and testing of prototypes and in the mass production of specific components. We also provide consultation, reverse engineering and part redesign. Consulting is also available for businesses seeking to manage inventory to ensure the availability of critical spare and replacement parts. With production facilities in China and internationally, our strong design and manufacturing capabilities can help energy industry companies of all sizes.

When you work with Elimold, we will help your business select the best alloys to create durable components suitable for specific environments. We provide assistance in the design and production of tooling components. Rely on our quality control and testing services to help you ensure that the components produced meet your specifications and tolerances are within acceptable limits.

As a contract manufacturer, we provide custom casting, forging and machining production services. Entrust part (or all) of your manufacturing process to us. Our capabilities include professional material selection, casting, forging, machining, surface and heat treatment operations, tooling and manufacturing. Today, contract manufacturing plays an increasingly important role in many energy-related fields. Companies rely on Elimold’s strong capabilities to help them meet the demands of this competitive market.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

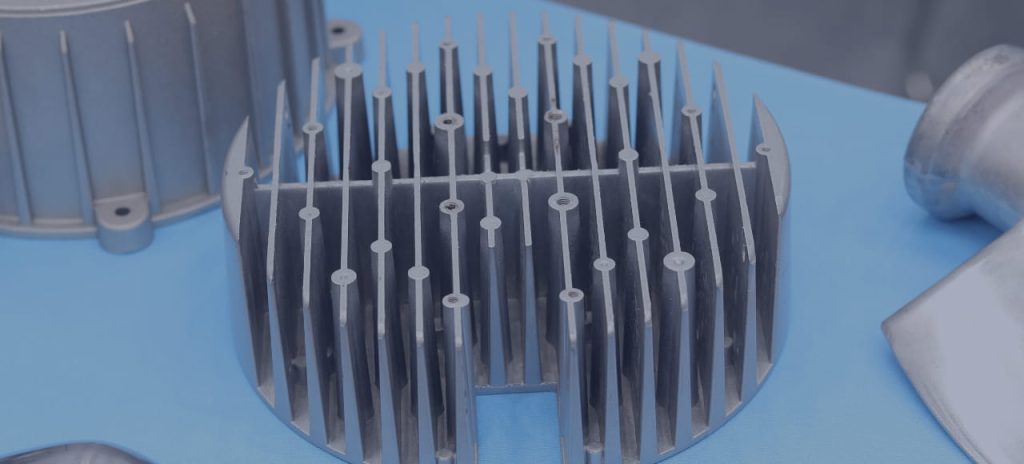

Sand Casting

Investment Casting

Die Casting

Low Pressure Casting

Permanent Mold Casting

Lost Foam Casting

Centrifugal Casting

Vacuum Casting

Services We Provide Support

Elimold has a comprehensive range of services to meet the diverse needs of the energy industry, from design and development to large-scale manufacturing. Services we provide include:

- Industrial casting sizes range from 10 pounds to 4,000+ pounds.

- Casting heat treatment (annealing, quench and temper, normalizing and tempering, through hardening, age hardening, case hardening, etc.)

- Proprietary and industry standards (ASTM, ASME, NAVSEA TECH PUB 278, NACE, MIL-STD, etc.)

- NDT (Non-destructive Testing) at all levels

- Low-volume loose pattern capabilities

- Smooth surface finish for superior performance

- Magmasoft® Solidification Software supports complex castings

- Casting prototypes

- Assembly and testing to ensure quality

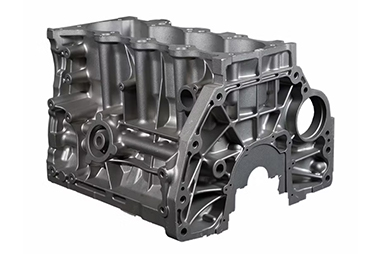

Processes Used in the Manufacturing of Custom Parts for the Energy Industry

Certain parts required by energy production companies must withstand harsh environmental conditions, corrosion, and/or severe wear. Strong, high-quality parts produced within tight tolerances are often in high demand. Elimold’s dedicated design team works closely with customers to produce custom prototypes and parts that meet unique specifications. We excel as a contract manufacturer serving companies in the energy industry. Here are some of the industrial processes we often use on behalf of our customers:

CNC Machining

CNC machining processes allow manufacturers to complete parts to the manufacturer’s specifications. Whether you need surface treatments to enhance corrosion resistance or require drilling, cutting, milling, or welding services, Elimold is the place for you!

Stamping

Manufacturers use stamping machines and dies to cut, bend, or form materials. We provide personalized assistance to create stamped mechanical parts within tight tolerances.

Die cutting

Die cutting machines can shear a variety of materials, including foams, rubbers, and foils. The die cutting process allows manufacturers to produce useful industrial tools, such as dies. Using our automated die cutting process can help you produce mechanical seals and other important parts.

UKAS approved standards

With X-ray, crack detection, ultrasonic testing and chemical and mechanical analysis capabilities, our customers can be assured that our energy castings are tested to UKAS approved standards. Our processing capabilities allow us to finish your castings to exacting standards and perform subsequent processing as required.

Testing and Inspection Technologies

- Certifications – UkA, CAA and Rolls-Royce

- Radiography – X-ray and Gamma Ray

- Ultrasonic

- Dye Penetrant

- Magnetic Particle

- Mechanical Analysis

- Chemical Testing

- Pressure Testing

Advantages of Die Casting for the Energy Industry

Die casting is particularly useful for:

- Complex Designs: Suitable for parts with complex geometries, such as turbine blades.

- Excellent Surface Finish: Parts have an excellent surface finish without extensive post-processing.

- Economical Benefits for Small Batch Production: Suitable for small to medium batch production, allowing for cost-effective manufacturing.

Metal Casting for the Energy Sector

The wide range of metal casting processes we offer is flexible enough to tailor components and optimize designs for efficiency in specific energy systems. This is further improved when our customers invest in our Rapid Casting Prototyping service, which quickly delivers physical wax samples for design review.

Metal cast components have inherently high strength, ensuring longevity of critical components in demanding applications in the energy sector. The high precision of our metal casting processes minimizes material waste, in line with the sustainability goals of the energy sector. This can also be further supported by the previously mentioned prototyping services or when our cast components are used as renewable energy castings.

Metals Commonly Used in the Energy Industry

The diversity of the energy industry requires suppliers to have a comprehensive understanding of the metals and metal alloys that can be used to manufacture parts. For example, some customers extract oil and gas in hot tropical environments; others perform field operations in Arctic regions; and others may require tools that can withstand a variety of climates and weather conditions. We use the most widely used commercial metals and metal alloys, including steel, stainless steel, iron, aluminum, titanium, copper, and brass.

Components for the Energy Industry

By its very nature, the Energy industry has very demanding quality requirements. Because your industry operates in very harsh conditions, your components must be able to withstand extreme temperatures, pressures, and hydrogen environments. They must resist wear, corrosion, heat, and abrasion. At Elimold, our casting manufacturers specialize in meeting your stringent component requirements, including:

- Feed chute castings

- Impact plate castings

- Coal spreader castings

- Diffuser castings

- Grate castings

- Grate block castings

- Burner head castings

- Burner tip castings

- Elbow castings

- Tube hanger castings

- Tube shield castings

- Rapper bar castings

Interested in starting your journey into die casting for energy components?

Our engineers are here to answer your questions and show you how innovative die casting technology can revolutionize your next project.