Military And Defense Sheet Metal Fabrication

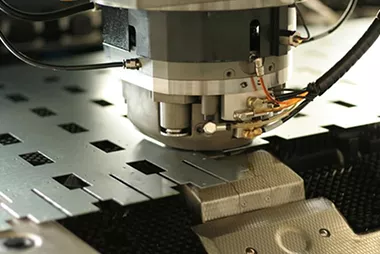

Elimold is proud to serve the military industry. We provide military and defense sheet metal fabrication services with the latest solutions in stamping, bending, cutting or punching, and use machines to create custom forgings, castings and other products in a variety of sizes. Contact us now for a free quote.

Defense and Military Metal Fabrication Services

Elimold is a leading provider of military-grade metal fabrication, specializing in the design and manufacture of military sheet metal parts. Our dedicated engineering and manufacturing teams are dedicated to producing the products needed by the military and defense industries. Our metal fabrication services encompass a range of processes used to shape, form, and fabricate precision metal components. Companies around the world rely on durable, high-quality sheet metal fabrication services to manufacture products for a variety of applications. Elimold has been providing customers with reliable products and excellent customer service since its founding, and we are proud to provide contract metal fabrication services to the defense and military industries.

Our company is ISO 9001:2015 and AS9100D certified, and we offer a comprehensive range of custom sheet metal fabrication services for turnkey fabrication of metal products. Our core competencies in metal fabrication include cutting, bending, grinding, welding, and finishing. Our customers can be confident that they are receiving the highest quality products and services. When you work with Elimold, you can be confident that you are working with a team of experts who are dedicated to providing you with the best quality products and services.

Types of processes we can provide

Innovation brings advantages to military projects. If you have a grand idea but no vetted design, Elimold can help you turn it into reality. Our team works with you to develop concepts, build prototypes, and begin full production. We have the following manufacturing capabilities:

- Saw Cutting

- Shearing

- Punching

- Drilling and Tapping

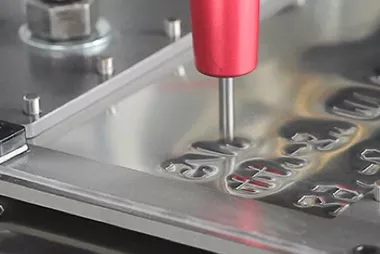

- Machining

- Folding and Bending

- Bending and Rolling

- Metal Inert Gas Welding, or MIG Welding

- Tungsten Inert Gas Welding, or TIG Welding

- Stress Relieving

- Heat Treating

- Straightening

- Sandblasting

- Metal stamping

- Hot Extrusion

- Laser Cutting

- Water Jet Cutting

- Metal Spinning

- Metal Finishing

- Crating and Packaging

- Shipping and Delivery

Importance of Sheet Metal Fabrication in Defense and Military Applications

When providing metal fabrication services for defense and military projects, precision is key. Any product produced for the military through processes such as machining, stamping, welding, etc. must meet applicable military specification requirements, and each part must be virtually identical. These standards are high so that military companies can rely on uniform parts that perform as expected and will not fail in the field.

Custom sheet metal fabricators play a key role in providing defense and military projects with durable parts and products that provide consistent performance in nearly any environment. Many parts and products require alloys or specialty metals that require careful processing. Experienced sheet metal fabrication contractors can reliably produce parts in large quantities while complying with all necessary regulations and certification requirements for these industries.

Our Government and Military Sheet Metal Fabrication Capabilities

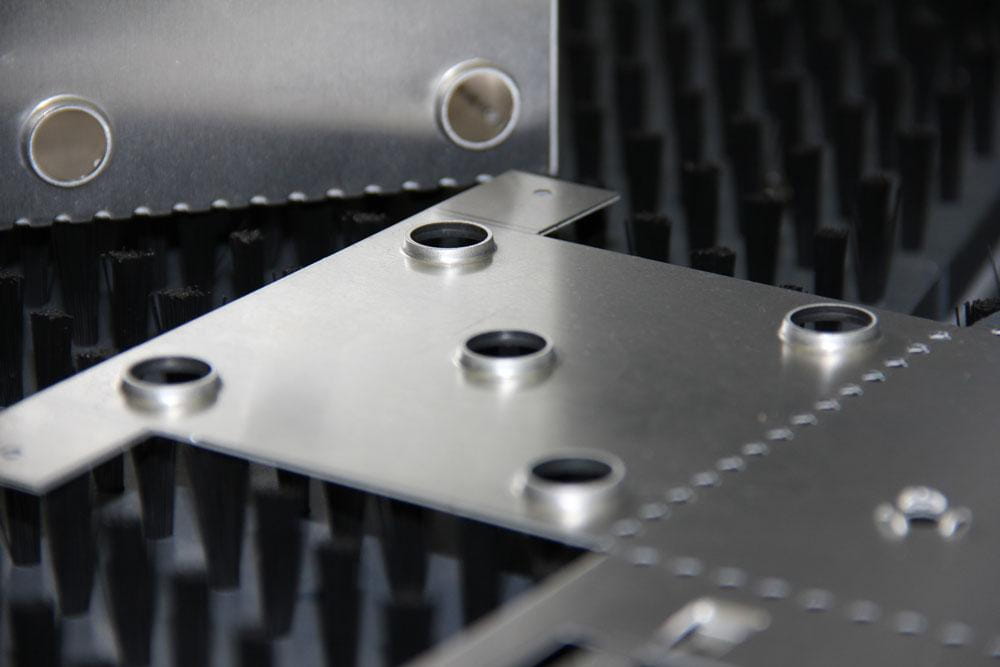

Our metal fabrication shop is well-equipped to provide the metal fabrication services required by military and defense organizations to meet military specification standards and safety quality regulations for contractors. We can fabricate anything from prototypes and low-volume production runs to large-volume orders. We can achieve extremely tight tolerances from ±0.005 inches to ±0.015 inches for metals between 0.015 and 0.187 inches thick.

At Elimold, our sheet metal fabrication services are not only high-quality, but also cost-effective. From prototypes to large assemblies (up to 12 feet long and 50 inches wide), Elimold will expertly fabricate a variety of sheet metal for your military assemblies. Our new 12-foot-long, 240-ton press brake features a programmable touchscreen that allows us to perform multiple tool groups and stations on one machine, and it can bend parts up to ½ inch thick and up to 7 feet long. As a result, Elimold is the best choice for all of your sheet metal fabrication needs for military projects.

And, at every stage of sheet metal fabrication, we adhere to industry-mandated contract process requirements so that our customers can trust the integrity and performance of their parts. We are capable of handling covered defense information (CDI) and comply with DFARS provisions. In addition, we take the security of all our customers very seriously, which is why we have invested heavily in the physical security of our facilities and have contracted with cybersecurity companies for real-time monitoring and alerting.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

Embossing

Turnkey Solutions

Elimold offers a full range of custom metal fabrication capabilities that eliminate costly and inconvenient handoffs. Projects can be completed entirely through Elimold: from 3D digital modeling, laser cutting, bending, welding, CNC water jet cutting, welding and CNC Machining forming, all the way to hardware insertion, finishing, assembly and shipping. We understand the importance of reliable, precise, high-quality metal component manufacturing to the defense industry. At every stage of production, we are committed to providing unparalleled quality, value and service. Elimold will help you achieve precise military and defense equipment that exceeds various certifications. From the customer’s initial design process and development stage, to prototyping and final mass production.

We provide the best quality assurance for critical welded joints. Our experts can also design defense parts to the highest quality standards while minimizing costs. From simple to complex defense parts, Elimold can accurately and efficiently produce them using a variety of advanced metal materials.

Parts Manufacturing for Field-Tested Applications

Since our founding, we have been working with federal agencies and defense contractors to help them streamline their supply and demand needs and expand their manufacturing capabilities. We can help federal agencies, any aerospace or aviation company, and defense contractors enhance their strategic supply plans.

We also comply with the International Traffic in Arms Regulations (ITAR), Defense Federal Acquisition Regulation Supplement (DFARS), and Defense Logistics Agency Joint Certification Program (JCP) security-related standards. All parts uploaded to our applications are encrypted at rest and in transit and controlled in accordance with DFARS.

FAIR

(First Article Inspection Report)

All Levels of PPAP

(Production Part Approval Process)

Capability Studies

(Statistical Process Control)

CMRT

(Conflict Minerals Reporting Template)

From hardware specs to parts drawings, we do it all

Hardworking, meticulous, and dedicated. If you want parts from a supplier that focuses on quality, Elimold is your go-to manufacturing service. Our certified manufacturing services are rigorous, in-depth inspections through the System for Award Management (SAM) and each part has a specific Cage Code number, which means that Elimold Sheet Metal parts are different. By incorporating your specifications and providing you with part drawings, you can be more confident than ever that our parts will be produced exactly as you envisioned.

Your Defense Industry Manufacturing Partner

At Elimold, we pride ourselves on providing precision metal parts that withstand the harshest conditions. Our team of experienced technicians uses advanced techniques and cutting-edge technology to produce high-quality parts that meet or exceed military standards. We are committed to maintaining the highest levels of quality control at every step of the manufacturing process.

If you’re looking for a reliable partner to meet your military defense metal parts manufacturing needs, look no further than Elimold. With our commitment to excellence and expertise in the field, you can trust us to provide the quality parts your service members deserve.

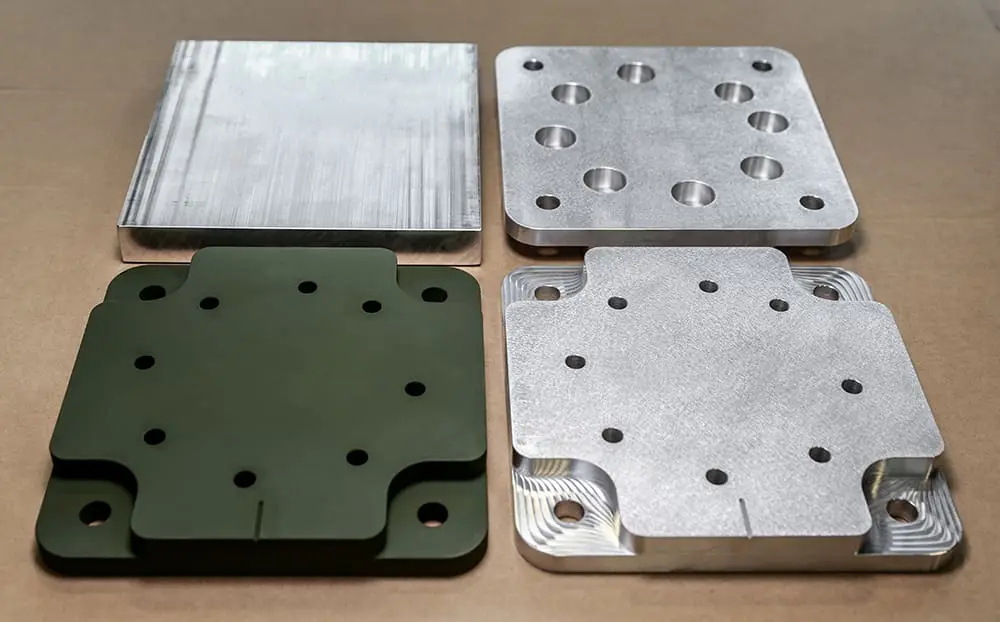

Custom Manufacturing for the Defense Industry

Custom is critical in the defense sector, as standard solutions are often insufficient. Our team works closely with defense customers to tailor our processes to produce sheet metal parts that meet the unique needs of military applications. Our custom solutions ensure optimal performance. Elimold’s sheet metal component mass production skills are essential to meet the large-scale and urgent needs of the defense sector. Our production lines are capable of handling large orders and maintaining the necessary detail and quality control required for defense projects. As the defense industry grows with an increased focus on innovative technologies and advanced systems, Elimold is a trusted ally. Our sheet metal fabrication services go beyond traditional manufacturing to support critical operations in the defense sector. With our advanced manufacturing capabilities and commitment to custom and mass production, we provide the defense industry with the resources it needs to build a secure and resilient future.

Why choose to cooperate with Elimold?

- Our vertical integration capabilities eliminate reliance on external suppliers and the associated bottlenecks and risk of extended lead times.

- We have a wide range of machinery that can process parts of all sizes (large or small) with exceptional precision to ensure the best possible results.

- Our automated and manual processes allow us to support prototype builds and low-volume production runs in the most optimized way.

- Our experienced staff provides valuable insights to enhance part processing and offers cost-reduction initiatives to reduce manufacturing costs.

- Our warehouse space and delivery delivers manufactured goods directly to your integration point or end user, eliminating the risk of expensive excess inventory.

- Our automation technology enables low-involvement manufacturing, which reduces manual labor time, lowers production costs, and improves process efficiency. It also helps improve overall equipment effectiveness (OEE), producing more consistent quality and eliminating human errors and rework.

Materials

- Aluminum

- Stainless Steel

- Cold Rolled Steel

- Hot Rolled Steel

- Brass

- Copper

- Titanium

- Galvanized

- Galvannealed

- Nickel Alloys

- Inconel

- Monel

Comprehensive finishing capabilities

- Anodizing

- Black oxide coating

- Cadmium plating

- Chemical film coating

- Chromate conversion coating

- Chrome plating

- Heat treating

- Nickel plating

- Painting

- Passivating and cleaning

- Powder coating

- Solid dry film lubrication

- Zinc plating

- Assembly

What can you expect from Elimold?

When you work with our team, you are entering into a long-term partnership with a company that believes in meeting your needs. Since our founding, we have been providing sheet metal fabrication solutions to military and defense professionals who rely on us to protect our nation. Partnering with us means you will receive efficient, cost-effective products. We also continue to modernize our processes with resources every day that go hand in hand with changing supply chain demands, price fluctuations, inventory requirements, and many other challenges.

Elimold brings a professional level of expertise to each project and provides comprehensive guidance to our government and contract partners. We are ISO 9001:2015/AS9100 certified, and our products, parts, and assemblies meet global standards and your precise metal specifications. From fast delivery times to constant communication, we build lasting business relationships that our customers continue to leverage year after year.

Ready to start your next project?

If you are looking for a full-service sheet metal fabrication contract manufacturing solution, Elimold is ready to help. With our advanced capabilities, we are able to deliver high-quality, high-value results. Contact us to learn how we can be the best part of your supply chain.