Automation Injection Molding

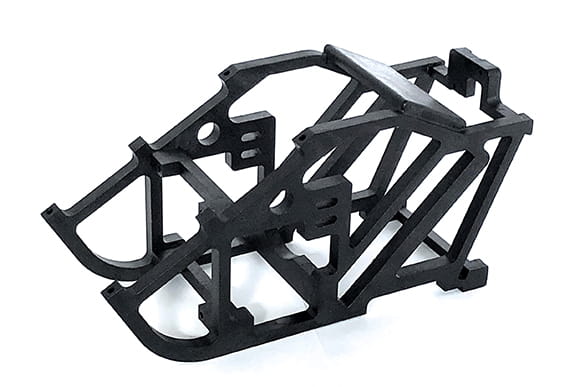

Our team has extensive expertise in plastic injection molding and excels in producing custom parts for your automation equipment needs. Elimold supplies quality plastic automation components at affordable prices. Contact us now for a free quote.

Your Injection Molding Solution for Automation Industry Parts

Elimold is more than just a company that provides injection molding services. We are a plastic parts manufacturing partner that provides a full range of molding services, including contract manufacturing, plastic assembly services, and automation to meet our customers’ needs.

To ensure that all automation industry customers receive a quality experience, we are an ISO 9001:2015 certified company. We use lean manufacturing methods to ensure that our customers receive the best automation industry products with the lowest waste levels and the highest manufacturing efficiency. Therefore, we also provide a full range of manufacturing services for customers in the automation industry. These services include custom molds, fixtures and batch manufacturing, heat staking and ultrasonic welding, and coordinate measuring machines (CMMs) for metrology. In addition, we provide manufacturing design and mold flow analysis to ensure that your products meet your required standards. Our in-house engineering team is always here to support you and our goal is to exceed your custom molding expectations.

Automation Plastic Parts Manufacturer and Supplier

Elimold has been providing custom injection molding services to a wide range of automation equipment manufacturers. Our manufacturing facility is ISO 9001:2015 and ISO 14001 certified. Our state-of-the-art manufacturing facility covers 230,000 square feet and houses over 55 injection molding machines ranging from 85 tons to 2200 tons. We provide our customers with custom and turnkey solutions for their manufacturing needs while focusing on product quality and production efficiency. Our relentless pursuit of production efficiency allows us to provide the most cost-effective injection molding solutions for high-volume production automation equipment parts projects. At Elimold, from our machine operators to our top management, we believe that our success is entirely dependent on the success of our customers, which is our top priority.

Types of processes we offer

Insert Molding

Over-Molding

Gas Assist Injection Molding

Structural Foam Molding

Our turnkey capabilities meet every need of your project

At Elimold we take a holistic approach to production and the wide range of services we offer enables us to tailor our assistance to your specific needs.

Injection Molding

Our production operates 24 hours a day to keep our lead times low and deliver premium parts without wasting time. With 55 injection molding machines and the efficient aid of Elimold, you enjoy high-quality injection molding with quicker turnaround times.

Part Design

Our skilled engineers offer expert design advice to help you build a high-quality part that meets your needs without breaking your budget. Save money without sacrificing quality when you work with our team for professional part design.

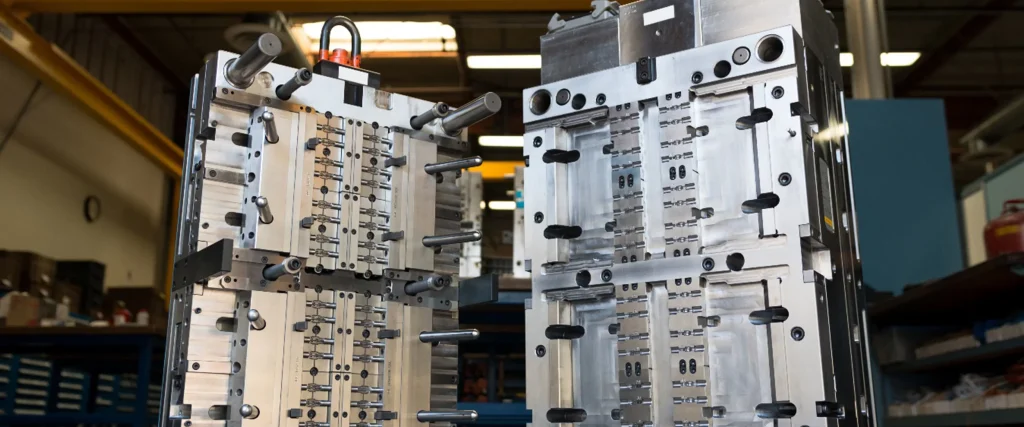

Mold Manufacturing

With in-house mold manufacturing capabilities at our three facilities and overseas locations, Elimold has the tools and technology to easily meet your mold manufacturing needs. We go to great lengths to provide mold repairs and updates, schedule preventive maintenance updates, and perform mold flow analysis to ensure your molds continue to meet your needs for years to come.

Secondary Operations

Our extensive secondary operations offerings empower us to comprehensively serve your production goals and get your product to market faster. We offer sonic welding, manual and robotic assembly, engraving, custom labeling and packaging, and more.

Quality Management System

We’ve developed and maintained a thorough quality management system to ensure every step of our process meets the high standards we’ve set. The high-quality products we deliver to you are backed by a proven methodology that allows us to provide you with data and validation for every step of the production process.

In-House Mold Manufacturing Facility

We know that a plastic injection mold is one of the most important investments you will make when preparing to bring your product to market. At Elimold, we offer a full suite of design and engineering services, as well as a full-service tool room. Because Elimold designs, builds, and maintains our customers’ molds on-site, and then produces the parts, we can immediately address any production issues that may arise. This allows us to deliver molds that meet our customers’ exact specifications and requirements at a reduced cost and turnaround time.

Plus, your molds receive comprehensive mold maintenance between each production run, whether it’s the first cycle or the 200,000th cycle. Maintenance includes disassembly, cleaning, and preventative maintenance, as well as a comprehensive injection mold inspection to find any areas that may be stressed from normal wear and tear. In addition to maintaining your investment, we also offer repair and rebuild services.

Because Elimold manufactures molds from premium tool steels and controls the part production process from design to final product, we offer a lifetime warranty on our molds at no additional cost. We set high standards to ensure that your parts meet or exceed your expectations.

Materials

Elimold provides injection molded plastic parts and assemblies to countless customers in the field of automation equipment manufacturing. We combine traditional customer-first values with cutting-edge equipment, engineering and processing.

- Acrylonitrile Styrene Acrylate (ASA)

- Polymethyl Methacrylate AKA Acrylic (PMMA)

- Polyphenylene Sulfide (PPS)

- Polybutylene Terephthalate (PBT)

- Polyethylene Terephthalate AKA Polyester (PET)

- Polyketone (POK)

- Thermoplastic Elastomer (TPE)

- Thermoplastic Polyurethane (TPU)

- Thermoplastic Vulcanizates (TPV)

- Thermoplastic Polyolefins (TPO)

- Ethylene-vinyl Acetate (EVA)

- Acrylonitrile Butadiene Styrene (ABS)

- Polypropylene (PP)

- Polycarbonate (PC)

- Polyamide AKA Nylon (PA, PA6, PA66, PA612)

- Polyoxymethylene AKA Acetal (POM)

- High-Density Polyethylene (HDPE_

- Polystyrene (PS)

- Low-Density Polyethylene (LDPE)

Complete Quality Inspection

Elimold is responsible for the entire manufacturing process of plastic parts for all automation industries. Our team of experts designs and manufactures plastic OEM parts. Our engineers use virtual models to test the accuracy of CAD/CAM plans. We provide 3-D prototyping and design concept testing to guarantee that your custom parts will fit perfectly. We provide comprehensive quality control checks throughout the design and manufacturing process. Experts analyze plastic products using SPC functions, Meyer Gage Pins, and a 16-inch Quadracheck III optical comparator.

Advantages of Custom Automation Industry Plastic Parts

Custom your automation industry plastic parts is easy with Elimold. Our extensive manufacturing network guarantees that your parts will be precisely manufactured in a short time. Some of the benefits of manufacturing custom plastic parts include:

- Bespoke Solutions

- Cost Effective

- Reduced Lead Times

- Wear Resistance

- High Accuracy & Repeatability

- Versatility

- Efficiency

Elimold is here to help

Our skilled engineers are eager to take on your next project and provide your business with quality industrial automation equipment plastic parts injection molds and industrial automation equipment plastic parts. With rich experience, innovative technology and turnkey capabilities, we can provide excellent products every time. Contact us now for a free quote and DFM analysis.