Marine Industry

Durable, high-quality tools and parts are the foundation of every successful shipbuilding and marine project, as are the suppliers you rely on to produce them. With experience serving shipbuilding and marine OEM and Tier 1 manufacturers, we have a deep understanding of the industry and our customers’ needs. This enables us to provide precise, flexible and tailored manufacturing solutions that ensure reliability, efficiency and ongoing satisfaction.

Providing you with all marine grade product parts

Elimold designs solutions for some of the most well-known and prominent marine companies in the industry. Our growing list of custom materials and services we provide along with our extensive industry knowledge enables us to continually expand our technical capabilities, allowing us to stay ahead of our competitors while still ensuring that we meet and exceed our customers’ needs, no matter what they may be. We strive to provide our customers with complete satisfaction with the parts and components ordered, no matter what they may be.

Our success is directly related to the quality and precision with which we undertake each order. The specifications you send us are of paramount importance and we pride ourselves on providing only the best materials to ensure the continued advancement of our manufacturing processes. We strive to provide our customers with innovative solutions to their problems, meeting the ever-changing and increasingly demanding requirements of the marine industry at competitive prices.

Custom Manufacturing of Marine Components

Elimold uses advanced engineering techniques, precision machining with CNC machines, and custom tooling to manufacture replacement parts to extend the life and optimize the performance of high-precision mechanical systems and components for the marine industry. Our team reviews and verifies all technical requirements prior to manufacturing, creates CAD drawings, and checks dimensions throughout the manufacturing process. Manufactured parts undergo necessary testing and approval to ensure compliance with OEM specifications and operational requirements.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. Our own facilities and extensive manufacturing network enable us to efficiently deliver complex, high-quality parts.

CNC Machining

Injection Molding

Sheet Metal Fabrication

3D Printing

Extrusion

Die Casting

Vacuum Casting

Wire EDM

Why Choose Us?

To meet the stringent requirements of the marine industry, you need a supplier you can trust. At Elimold, we meet your needs with:

- We are ISO 9001:2015 certified. With ISO certification, we guarantee the consistency of every component we manufacture.

- First Article Inspection and Records. With first article inspection, we can check our work early in development to ensure that our engineering and manufacturing techniques meet project specifications.

- Dimensional Metrology and Geometric Dimensioning and Tolerancing (GD&T). For projects with tight tolerances, we calibrate our measuring tools at every step of the manufacturing process to ensure their high level of accuracy. We also recognize advanced GD&T engineering language for interpreting customer drawings and applying accurate dimensions, tolerances, and rules for marine components.

- Certified Team. Our trained and qualified welders and fabricators have extensive skills to develop long-lasting shipbuilding parts and port equipment.

- Versatile Facility. Our 130,000 square foot facility features a temperature-controlled quality laboratory for manufacturing strong components and assemblies large enough for offshore operations.

- Smart Inspection Equipment. We have industry-leading inspection equipment to check our work and guarantee you the highest quality components.

- Familiarity with complex parts. We have extensive experience working in the marine industry. Our team can work with the American Bureau of Shipping (ABS) to manufacture certified shipbuilding parts.

Ready to get started on your project?

Talk to the experts in custom parts for the shipbuilding and marine industry today! Our team is standing by and ready to answer questions or get a quote for your project.

Custom Manufacturing of Marine Equipment Parts

The marine industry mainly includes the engineering of ships, boats, oil rigs and other offshore vessels as well as marine engineering. This field mainly involves the application of various engineering technologies related to electrical engineering, mechanical engineering, electronics and telecommunications, and computer science to the conception, design, development, manufacture, operation and maintenance of various vessels. It also includes the study and learning of different aspects of marine technology such as propulsion devices, piping mechanisms, power mechanical systems, automation and control mechanisms of surface and underwater vessels.

The industry also supports the study of the world’s vast bodies of water to better understand the earth. Therefore, the marine industry covers a wide range of applications and technologies. Needless to say, it operates on highly complex and developed precision instruments and equipment. At Elimold, we use our capabilities to produce custom machined precision instrument parts for use in this industrial sector.

The major companies in this field include global shipbuilders, transportation companies (freight and passenger), ship building organizations, oil rigs and other machinery operators.

Materials

Metals

Common materials used in ship parts machining include bronze, titanium alloys, aluminum alloys, and marine grade stainless steel. These alloys are used because they resist oxidation and seawater corrosion.

- 316 stainless steel is an alloy material that is resistant to corrosion by chlorides, bromides, sulfuric acid, and iodides, as well as seawater. Among them, 300 and 400 series, 17-4PH, and 15-5 PH stainless steels are used in marine manufacturing.

- Titanium alloy Ti6Al4V, also known as Ti 6-4, is suitable for marine applications due to its strength and corrosion resistance.

- Aluminum alloys, especially grades 5000, 6000, and 7000, are commonly used in ship machining applications.

- Carbon steel, Ikon nickel alloy, and copper are also used in ship machinery applications.

plastics

- ABS

- Acetal

- Acrylic

- Cpvc

- Delrin

- Ertalyte

- G-10

- Noryl

- Nylon

- PEEK

- Phenolic

- Polycarbonate

- UHMW

Surface Treatment Services

We can provide a comprehensive range of surface treatment services for marine metal or plastic parts. We consider the application requirements and select the options that will provide the best protection. Standard options offered include powder coating, anodizing and light plating.

Applications For Marine Components

There are many applications that require a variety of marine components and fasteners. All these components are designed to make sure you can put together a quality product whether you are a boat manufacturer, build offshore oil rigs, docks, or commercial. Some other applications include:

- Boats

- Commercial Vessels

- Boat Lifts

- Engines

- Piers

- Docks

- Off-Shore

- Coastal

- Submerged items

- Pipelines

- Naval

We provide precision machined parts for the marine industry

We can repair, restore, manufacture or produce different parts for the marine industry, we have the ability to machine precision parts for a wide range of ships and marine vessels. If you do not see a specific part you need machined, please contact us and ask our team for advice.

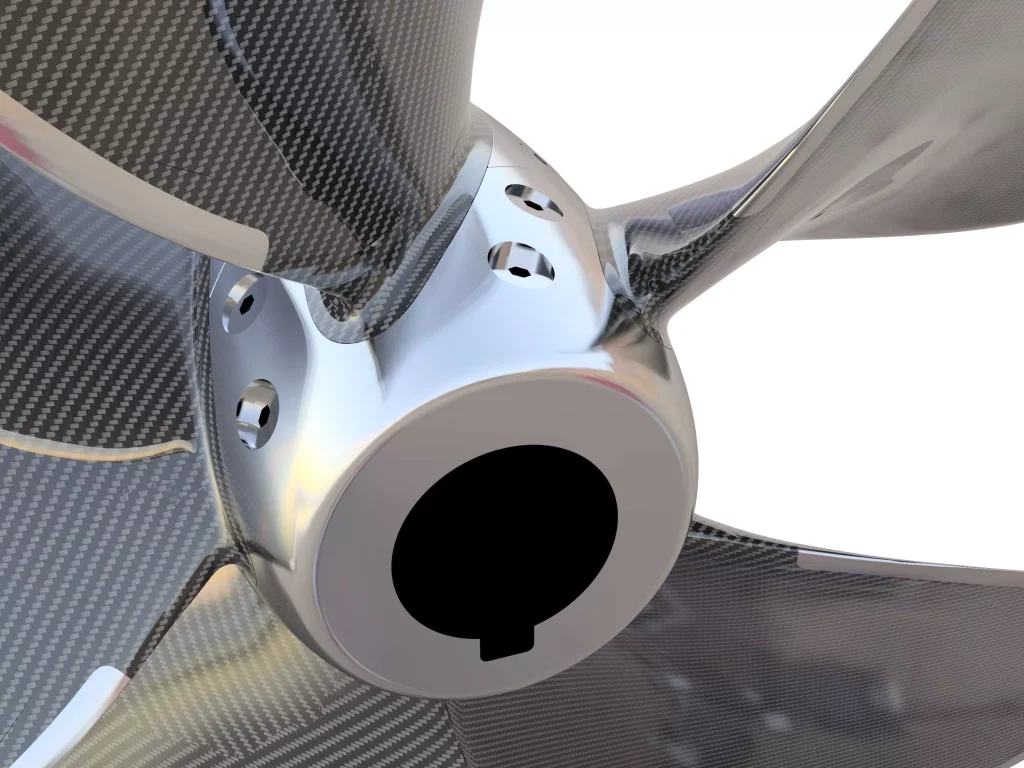

- Propulsion shafts, bushings and hubs

- Pivots and bushings

- Impellers

- Propeller blades

- Rudder shafts

- Capstan drums

- Ship stabilizer parts

- Flanges and valves

Ready to start your next custom marine parts project?

For all your custom machining and OEM project needs, or looking for a custom solution to match your marine and maritime system needs. Contact us today to get in touch with a dedicated engineer!