Electronics Die Casting

Elimold offers electronic die castings. We have the experience and facilities to meet the detailed requirements of the electronics industry. With state-of-the-art metal casting machines, a wide range of inexpensive materials, and an unrivalled comprehensive order and stock service, we can meet the most demanding needs. Elimold will provide you with any quality electronic die casting you require. Contact us for a free quote.

Electronics Industry Die Casting Factory

Ever wondered how electronic components achieve such high precision and reliability? At Elimold, we specialize in electronics die casting, a critical process for manufacturing precision electronic parts with extreme accuracy. Our team’s decades of experience and state-of-the-art technology ensure that every component we produce meets the highest standards. No matter what type of electronic product part you need, our die casting solutions can meet your specific needs.

Our commitment to precision has made us a trusted name in the industry. From the design stage to production, we ensure that every step of the process is carefully managed. This attention to detail guarantees the quality of our products and gives our customers confidence in their components.

As a branded company, we inject a personal touch into every project. This hands-on approach and extensive experience allow us to provide custom solutions that perfectly meet our customers’ requirements. Learn more about how our electronics die casting services can benefit your business.

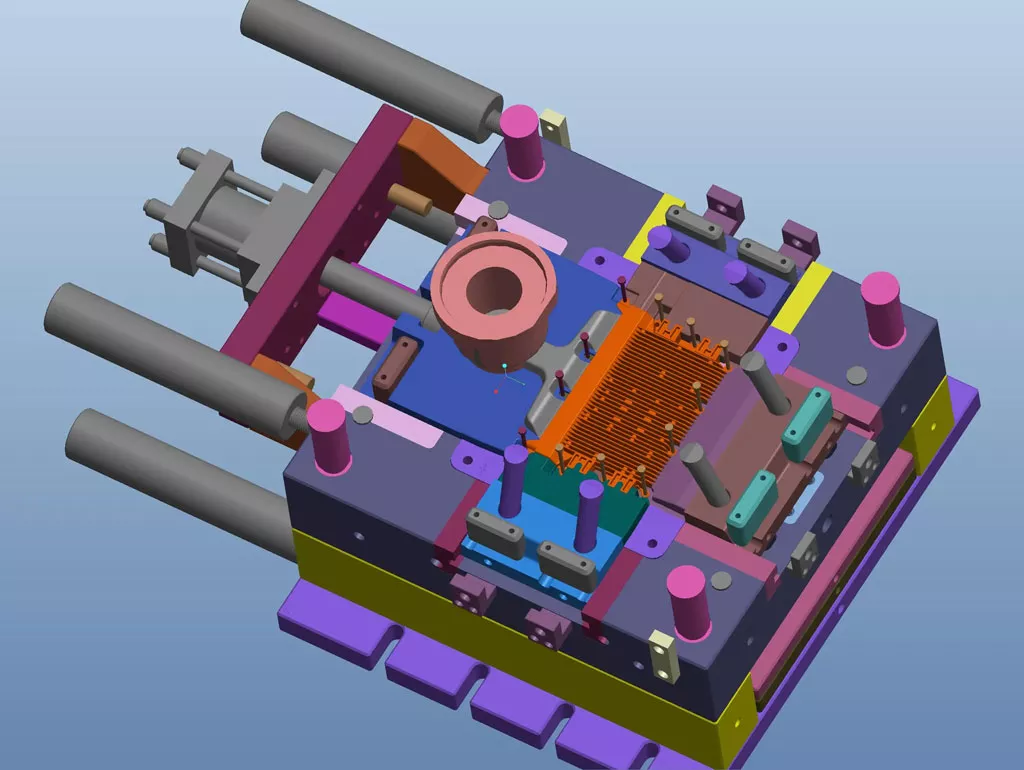

Capabilities of our Die Casting Factory

Elimold is one of Asia’s leading full-service die casting companies for parts in the electronics industry. With strategically located offices around the world, we are more than just a die casting company. We are a solutions provider that offers a wide range of capabilities and services.

Our casting capabilities are extensive. We offer die casting machines from 400 tons to 3,800 tons for our aluminum die casting customers. Our zinc die casting customers benefit from both smaller machines as well as conventional machines up to 500 tons. We also offer impressive magnesium die casting capabilities, with machines ranging from 150 tons to 350 tons.

In addition, we offer a complete range of value-added services, including engineering support, design, shot peening, complex machining, dipping, tumbling, chromating, wet painting, powder coating, polishing, assembly and other finishing services.

This is just a portion of what Elimold offers. We are also a Tier 1 supplier to multiple customers, managing all aspects of their supply chain. We are truly a one-stop shop for your die casting needs and more.

Full range of die casting services

From tooling to molding production, board-level shielding and assembly, we provide full range of services. Contact us easily to complete your project for you!

No or minimal tooling costs

Your ideas deserve to be realized quickly, and we will send you a prototype without tooling costs within 1-2 days, helping you save time and money!

Full range of services

Elimold can provide various types of services for electronics companies, including parts manufacturing, mold manufacturing, parts processing, material testing and analysis, technical support and consulting, etc. These services can help consumer electronics companies improve production efficiency, reduce costs, improve component quality and reliability, thereby better adapting to the needs of the renewable energy industry.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Sand Casting

Investment Casting

Die Casting

Low Pressure Casting

Permanent Mold Casting

Lost Foam Casting

Centrifugal Casting

Vacuum Casting

Casting Solutions for Demanding Electronics

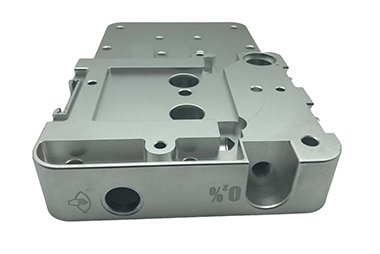

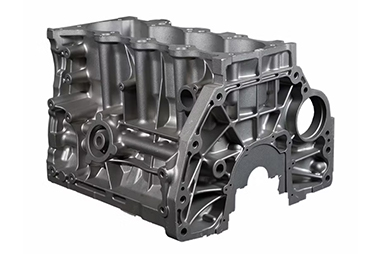

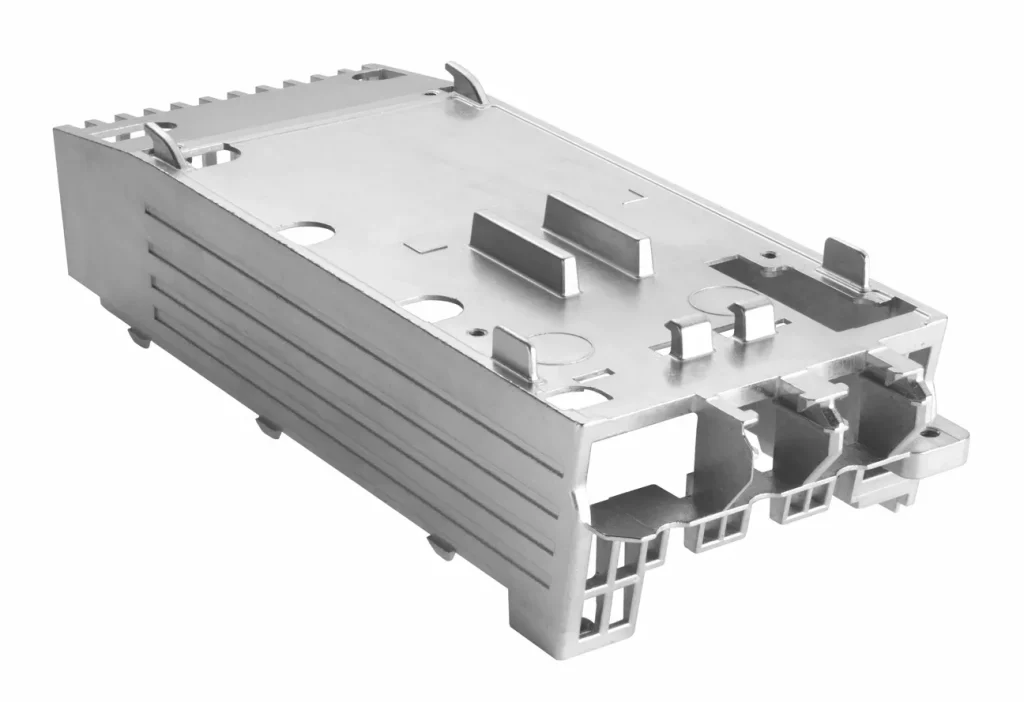

Elimold’s team of dedicated technicians is dedicated to providing high-quality electronics castings with precise dimensional tolerances. Every part we produce is carefully designed to meet the most stringent specifications of our customers’ products. Elimold’s die castings power the electronics that shape our world. Our expert engineers work closely with our customers to optimize part designs and produce the high-quality housings, cases, brackets and heat sinks required for today’s complex devices.

Our tools undergo rigorous validation testing to ensure specifications are met for key factors that affect electronic performance, such as dimensional tolerances, surface finish and material flow. This produces precision components that improve thermal and electromagnetic performance while enabling lighter, more compact designs. Our expertise provides reliable castings for a wide range of products, from smartphones and network analyzers to medical imaging systems.

Our Electronics Casting Services

Assembly Analysis/Casting Integration

We work closely with our electronics clients to identify where costs can be cut. For example, we determined that two castings and a weld could be combined into one casting, saving one client 60% in production costs. Thanks to us, the company recovered its tooling costs in less than two years.

Reverse Engineering

We use 3D scanning and design analysis to understand and replicate parts that are produced elsewhere. We can also analyze the chemical and metallographic properties of the part to determine the materials and post-production processes used. After that, we work with you to develop an effective production action plan.

Rapid Prototyping

Computer modeling has its advantages, but nothing beats an actual physical prototype. Rapid Prototypes help you evaluate the manufacturing process and preview how a part will look, feel, and operate. At Elimold, we often create fully functional prototypes, as well as non-working prototypes that our clients use for demonstrations to potential investors, stakeholders, and test market groups.

We offer a wide range of solutions and support

Casting electronic equipment parts with metal increases precision and saves money by reducing the need for secondary machining. Working with us to design your next component, you’ll benefit from our team’s years of experience supplying precision casting products. Plus, our unparalleled attention to detail dictates that each product is meticulously polished and hand-assembled. As a result, we’re able to provide components that continually improve the way end users interact with our customers’ products. Our zinc castings for the electronics industry include:

- Durable cast housings for electrical devices and components.

- Cost-effective and high-volume production.

- Intricately designed components with thin walls.

- Consistent quality and expert finishing.

- Tight tolerances and extremely long service life.

- Cost savings through value engineering.

- Reduced additional machining.

Types of Die Castings Elimold Offers

Elimold works with die casters who use the latest die casting machines and technology to provide high-quality, on-demand parts for a wide range of industries. Our offerings focus on two main types of die casting: hot chamber casting and cold chamber casting. Both types can produce parts with complex geometries, close tolerances, and strong mechanical properties.

Hot Chamber Die Casting

The hot chamber die casting process, also known as gooseneck casting, is the most popular die casting process. It is best suited for alloys with lower melting points, such as zinc, magnesium, and lead. Metal is poured into a holding pot and heated by a furnace attached or built into the hot chamber die casting until the metal is molten. A feature of the hot chamber system is a tube called a gooseneck, which creates a holding chamber inside the pot and a nozzle-like channel that connects to the injection cavity in the stationary half of the mold. A plunger located above the cavity allows it to be filled with molten metal from the holding pot. When the cavity is filled with metal, the plunger descends and pushes the molten material along the gooseneck into the mold cavity. The mold is held together under pressure while the metal cools and solidifies in the mold. Once the metal has cooled enough, the mold opens and the casting is ejected by an ejector pin.

Cold Chamber Die Casting

In the cold chamber die casting process, the die casting chamber is kept at room temperature and there is no holding tank for the molten metal. The metal is melted in a separate furnace and then poured manually into the shot chamber using a spoon through a pouring hole. In cold chamber die casting, the mold is directly connected to the shot chamber and no plunger system is used. Instead, the plunger forces the molten metal into the mold and maintains high pressure as the metal solidifies. This type of die casting is suitable for materials with relatively high melting points, such as aluminum.

Die Casting Materials for the Electronics Industry

Cast aluminum and cast zinc are used to manufacture electronic products, with cast aluminum often used for applications that require high dimensional accuracy and stability, such as housings and heat sinks. Aluminum has good electrical and thermal conductivity, as well as corrosion resistance and durability, making it well suited for electronic applications. In addition, aluminum can be easily formed into complex shapes and thin walls, which are often required in the electronics industry. Cast zinc is used for applications that require high mechanical strength, such as connectors and terminal blocks. Zinc has good castability and can be easily formed into complex shapes, making it well suited for die casting. In addition, zinc has good electrical conductivity and corrosion resistance, both of which are important factors in the electronics industry. However, zinc has a lower thermal conductivity than aluminum, which limits its use in applications that require high heat dissipation.

Available Die Cast Surface Finishes

- Annealing

- Shot Bead Blasting

- Chromate Conversion

- Clear Anodizing

- E-Coating

- Black Zinc chromate

- Yellow Zinc chromate

- Liquid Paint

- Pad Printing

- Powder Coat Paint

- X-Ray

- Assembly

Benefits of Die Casting for Electronics

- High precision and dimensional stability, producing consistent, reliable parts

- Ability to produce complex shapes and intricate details with thin walls and tight tolerances

- Parts are strong and durable with good mechanical properties

- Smooth surfaces, no need for additional finishing operations

- Ability to incorporate internal voids and channels for electrical and mechanical connections

- Large-scale production with low unit costs

Electronic parts we can die-cast

- Housings for electronic devices and components

- Heatsinks

- Connectors and terminal blocks

- Chassis and frames

- Bases and mounting plates

- Lids and doors

- Brackets and supports

- Cable connectors

- Handles and knobs

- Bezels and trim

Start your electronics die casting project today

Our die casting engineers are ready to work with you to ensure you get quality parts quickly. When you submit your 3D design files, we will consult with you to ensure design manufacturability, resulting in a part that meets or exceeds your expectations.