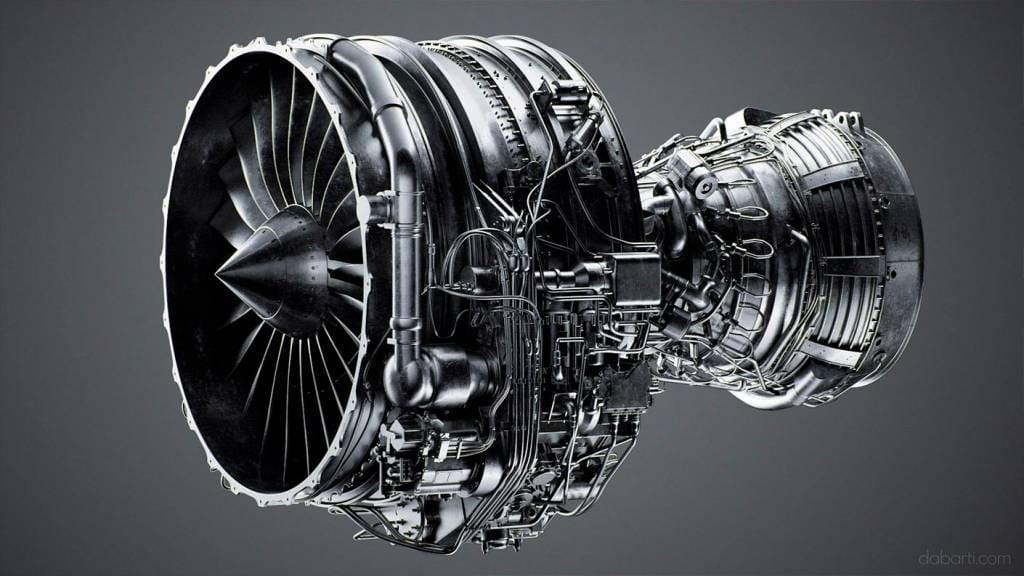

Aerospace Die Casting

Elimold supports the aerospace industry by providing a variety of die casting manufacturing services. Whether it is using our processing technology to provide precision part machining, providing mold design and construction, low-volume part production or precise measurement, we have the technical expertise to meet the challenges of aerospace manufacturing.

Castings for the Aerospace Industry

The aerospace sector requires components cast with the highest precision, regardless of size or purpose. At Elimold, we meet this requirement by manufacturing castings with attention to detail and quality. To meet the high standards of this industry, we use only the best materials and the latest investment casting processes. In addition, our experience working with long-time OEMs, Tier 1 suppliers, and other supply chain members enables us to manufacture high integrity castings for aerospace. We work with AS9100 certified subcontractors and NADCAP accredited laboratories to provide the necessary certifications for this industry.

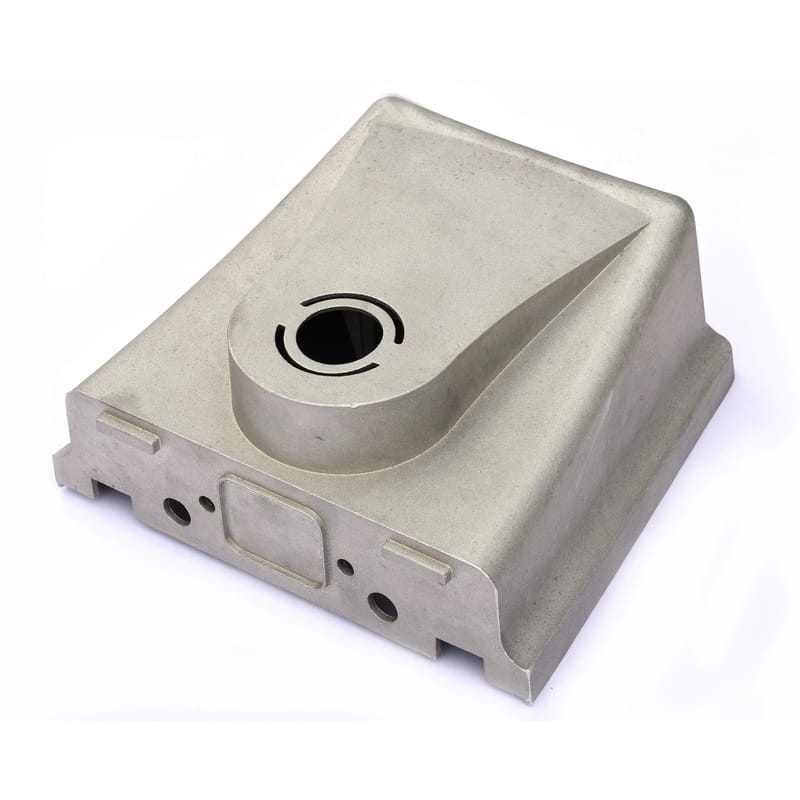

Die Casting Aerospace Parts

Elimold is a leading manufacturer of metal parts and components for the aerospace industry. We use the die casting process, a manufacturing process that we have perfected over the years. Our in-house capabilities allow us to meet the needs and requirements of our customers, and we have been dedicated to this for many years.

We understand the intricate details of aerospace components. We are also experienced in providing quality products and services that meet industry standards. Fortunately, we can produce these products cost-effectively while meeting your expectations and helping our customers succeed.

The die casting process is favored in the aerospace industry mainly because it can produce parts quickly and with almost no errors. Moreover, we work closely with our customers from design to final assembly.

Currently, we supply die casting parts in aluminum, zinc, and more. These are the main metals used in this field. Moreover, we use state-of-the-art machines and equipment to ensure that you achieve the results you expect. Our approach is to produce robust results that exceed your expectations.

This is the only custom solution you need to get the right parts in the aerospace industry. We understand how important it is for you to use only products that can withstand extreme temperatures and harsh environments. With the die casting process, we can develop advanced parts quickly using the best technology.

Precision Aerospace Die Casting Capabilities

If you have a complex part design, Elimold can help you turn it into reality. With the right equipment, strong technical knowledge and a focus on quality. From tool design to finishing to shipping, we ensure that each project is completed to a high standard and your order is delivered on time every time. Below are the various die casting processes we offer.

Sand Casting

Permanent Mold Casting

Lost Foam Casting

Investment Casting

Centrifugal Casting

Die Casting

Low Pressure Casting

Vacuum Casting

Can meet aerospace die casting requirements

From meeting ITAR registration requirements to operating the largest die casting company, Elimold provides leading aerospace and defense manufacturers with the highest quality die casting and engineering solutions to meet their unique needs.

Through long-term partnerships with many major brands in the industry, Elimold focuses on supplier BOM consolidation, cost optimization, and full range of die casting and assembly of aluminum, magnesium and zinc components to create a more efficient supply chain, meeting market needs from concept to delivery, Elimold provides one-stop service for OEMs, aftermarket and Tier 1 suppliers. We have the knowledge and scale to adapt to the seasonal market needs of these industries with five TS certified facilities.

Our Aerospace Casting Services

Assembly Analysis/Casting Integration

We work closely with aerospace clients to identify where costs can be cut. For example, we saved one client 60% in production costs by determining that two castings and one part could be cast as one whole. Thanks to us, the company recouped its tooling costs in less than two years.

Reverse Engineering

We use 3D scanning and provide design analysis, which is key to understanding and replicating a part produced elsewhere. We can also analyze chemical and metallographic properties to determine the materials used and post-production processes. Once we have sorted out the history of a part, we will consult with you to develop an effective plan of action to move into production.

Prototypes

Computer modeling has its place, but nothing beats an actual physical prototype. Prototypes help you evaluate the manufacturing process and preview how a part will look, feel, and operate. At Elimold, we often create fully functional prototypes, as well as non-working prototypes that are useful when presenting to potential investors, stakeholders, and test market groups.

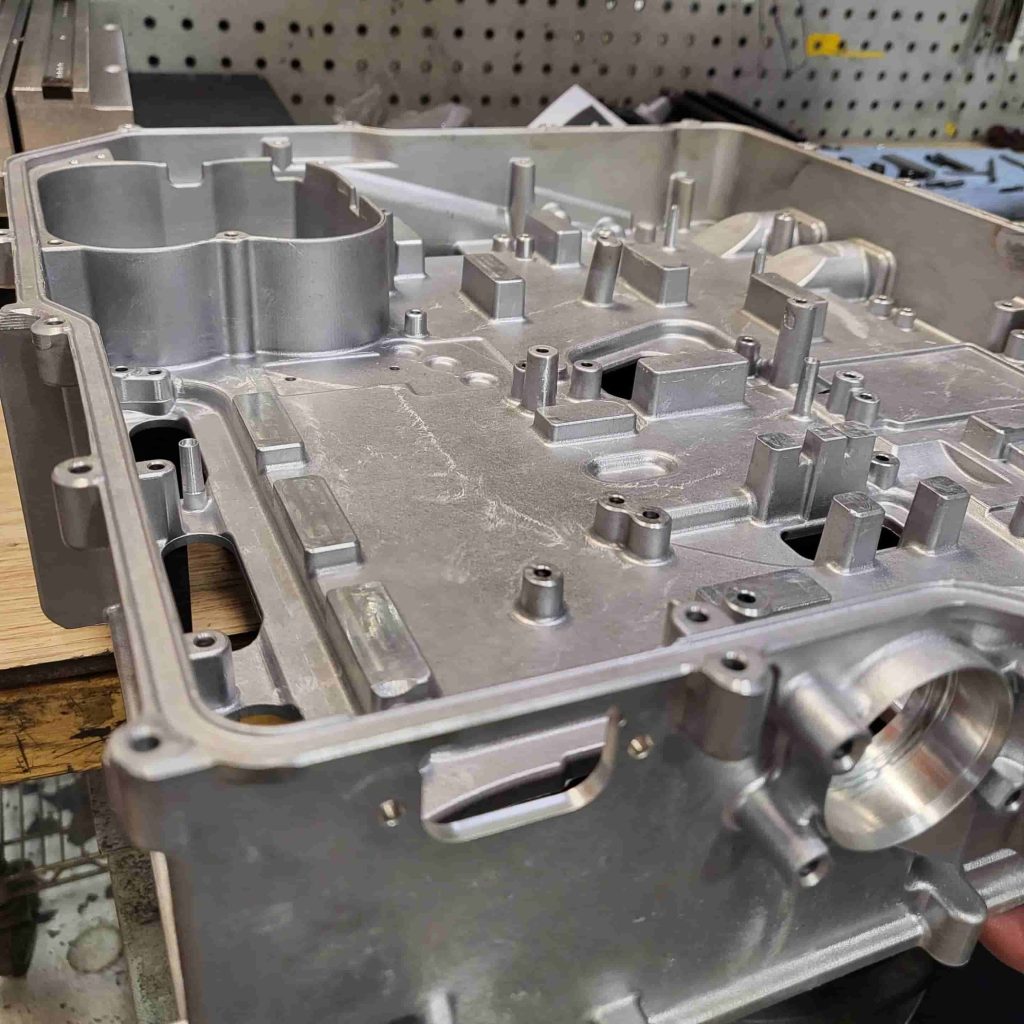

Complete Aerospace Die Casting Solutions

Elimold provides comprehensive die casting solutions for the aerospace industry. We are able to produce strong, durable and consistent metal parts with proven precision manufacturing standards. Die casting is at the heart of the aerospace industry and our processes are able to meet budget and time constraints while exceeding quality standards. Through innovative mold making services and advanced machining solutions, we can provide complex geometric parts for aerospace and other mission-critical applications.

In-House Mold Making and Rapid Prototyping

Our die casting process covers everything you need, from professional in-house mold making and rapid prototyping to a diverse range of die casting services and precision machining. Our mold making department specializes in producing custom parts, our casting solutions meet precise geometric specifications, and our machining services provide precise results for aerospace applications. Our die casting process is built on our experienced team of professionals, advanced machinery, years of experience and vertically integrated processes.

Get a Quote

Tell us about your upcoming project and our team will be in touch shortly.

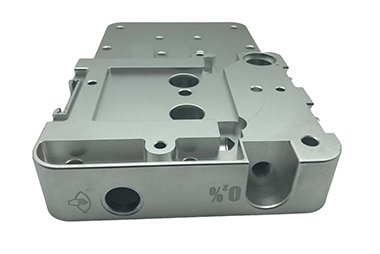

Our Capabilities

Elimold specializes in converting precision machined components into high quality, low cost die cast production parts. Utilizing Design for Manufacturability techniques, we meet individual component specifications by developing die casting processes and machining/finishing procedures to achieve the required quality level of the component in the manufacturing operation. We meet the following NADCA die casting quality and precision standards.

In the aerospace industry, excellence is not just a goal, but a requirement. That’s why Elimold goes above and beyond. Every aerospace casting we produce is of high quality, precision and reliability. Our state-of-the-art facilities feature cutting-edge CMM and VMM capabilities, allowing us to achieve tolerances up to 1 micron with unmatched accuracy.

With capacities up to 400 tons, we can take on projects of any size. We are committed to meeting industry standards, ensuring compliance with the most stringent regulations and codes. Our comprehensive product line has everything you need to take your aerospace applications to new heights.

Value-added Services

We have a wide range of manufacturing capabilities and value-added services to provide turnkey manufacturing solutions, such as:

- 3D Modeling

- CAD/CAM

- Computerized Tool Design

- CMM

- CNC Milling

- CNC Turning

- Mechanical Assembly

- Painting

- Plating

- Powder Coating

- Precision Die Casting

- Silk Screen

Elimold Group and the Aerospace Industry

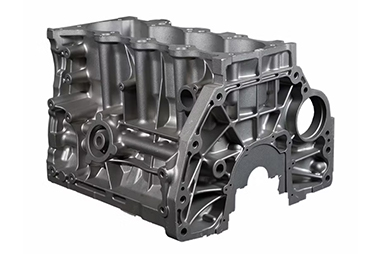

Our die casting process is suitable for manufacturing castings for the aerospace sector. It not only produces precision castings with good mechanical properties, but also castings with thin-walled cross-sections and good surface finish in a wide range of sizes and weights.

With Elimold, you always get high quality at a low cost. Our parts are fully traceable and have an enhanced microstructure that does not require HIP. As a long-time business, we have a deep understanding of the industry and its needs. In addition, we work with AS approved subcontractors and NADCAP accredited laboratories to provide castings that meet customer specifications.

Materials to consider

Aluminium is a key material in the aerospace industry due to its strength, light weight and corrosion resistance. The metal can also be recycled infinitely without losing its properties. The material also needs to be resistant to high temperatures, fatigue and fracture toughness, not to mention high damage resistance (which is essential for airframes, for example).

In addition to aluminium, carbon steel is also common in the sector for its strength and durability. It is a ferromagnetic alloy that can be used in motors and electrical applications.

Whichever material we use, we always focus on quality, so our castings comply with ISO 9001:2005 standards and undergo rigorous inspection and testing.

Why Elimold for Aerospace Castings?

Aerospace precision castings leave no room for error. Therefore, a professional precision casting company with extensive experience is important. Elimold works closely with aerospace customers to design, manufacture, finish and test castings to ensure that the castings will fit well.

- All of our castings are made from high-quality raw materials. We have good working relationships with the best material factories

- From quote inquiries, expedited requests to technical support and final delivery, our team’s responsiveness will exceed your expectations

- Equipped with semi-automatic wax presses, 100% robotic shell making, unique high-speed infrared shell drying tunnels, and 3D modeling capabilities, our high-quality aerospace castings will meet or exceed the stringent requirements of our customers

- Our non-destructive testing capabilities will ensure that the product is qualified before delivery, and even if there are any quality issues after delivery, we will cover all losses and send replacements in the shortest possible time.

Aerospace Die Casting Applications

With a high level of casting expertise, strict process control and certified quality systems, we proudly provide reliable and cost-effective aerospace investment castings for the following applications:

- Valves

- Mounts

- Swirl nozzles

- Engine blades

- Engine rings

- Blades

- Engine impellers

- Aircraft fluid management systems

- Interior components

- Hydraulic oil system components

- Flight critical and safety components

Partner with Us

If you are looking for a reliable partner to meet your aerospace casting needs, Elimold is here to serve you. Simply visit our Contact Us page to discuss how we can help you. We are committed to providing solutions that increase the efficiency and productivity of your operations.