Marine Sheet Metal Fabrication

Elimold specializes in precision sheet metal fabrication for the marine industry. With years of experience meeting the unique challenges of this sector, we understand the complexities of a wide range of marine applications. Our team is able to handle a variety of projects, from onboard safety system fabrication to electronic housings for communications and navigation equipment.

Providing Quality Metal Fabrication Solutions for the Marine Industry

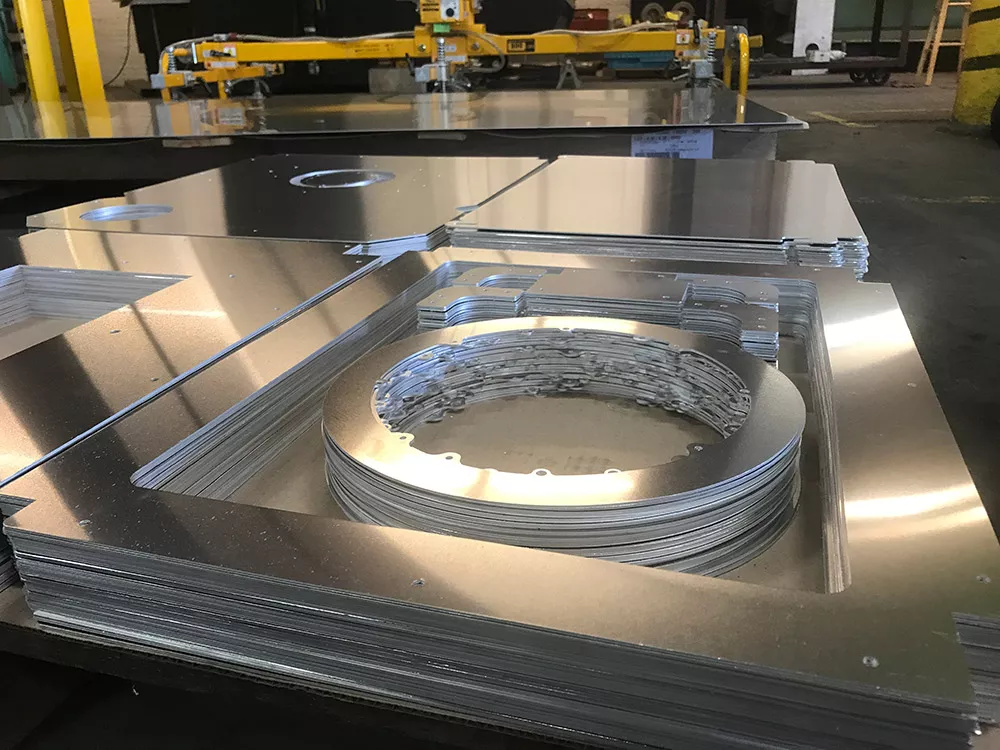

Elimold is a marine sheet metal parts manufacturer. We provide a competitive advantage to the marine industry with state-of-the-art metal cutting and forming technology, extensive experience welding a wide range of metals, precision CNC machining, complete assembly services, on-time delivery, and unmatched customer service.

We are experienced in marine parts manufacturing. We know what the marine industry needs: rugged, durable, built to last in harsh conditions, and built to withstand all weather conditions, including constant immersion.As a result, we continually strive to improve our services and production techniques. Whether it is sheet metal, bar metal, or any other form of metal component, our production work is completed with the highest quality. In addition, our ability to control quality and time is enhanced through our in-house vertically integrated production optimization. All key manufacturing processes are completed in-house to ensure that our customers receive the best service.

Finally, we focus on the overall customer experience: clear communication, meeting tight schedules, and producing high-quality parts. Whether your order is large or small, one-off or recurring, you can expect a positive experience every time.

High Quality Marine Sheet Metal Fabrication Solutions

Elimold provides a wide range of marine custom sheet metal fabrication solutions to marine manufacturers worldwide. We have a facility that covers over 40,000 square feet. Our extensive equipment inventory, large supplier network, and large facility allow us to expedite the delivery of orders within the most demanding timeframes. At Elimold, we pride ourselves on our ability to complete your project within a timeframe that most suppliers would consider unreasonable. In addition to our facilities and equipment, we also maintain a qualified set of welding procedure specifications (WPS). We can use processes that are pre-qualified by the American Welding Society (AWS) or the American Society of Mechanical Engineers (ASME), or we can help you develop a process qualification record (PQR) to meet your unique certification needs.

Our Fabrication Capabilities

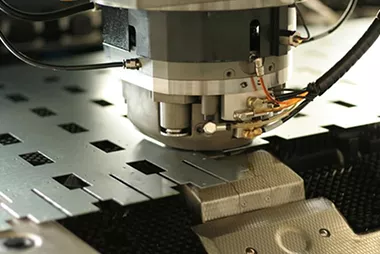

Our state-of-the-art facility features 100 tons of bending tonnage, and our machines can cut sheet metal up to 4′ x 8′ in thicknesses ranging from .020″ to .316″ with tolerances of ± .005″. We produce high-quality fabricated, assembled, and welded products with short lead times, typically just 4 to 5 weeks. We offer expedited and emergency services as needed, as we accept orders ranging in volume from a single prototype to large-scale full-scale production.

The versatility of our sheet metal fabrication capabilities speeds up the production of sample parts so that design, form, fit, function, and manufacturability can be tested, analyzed, and validated. We focus on understanding your product application, cost constraints, quality goals, and any other areas of concern so that we can provide you with everything you need within your budgetary guidelines.

One-Stop Custom Marine Metal Fabrication

Our expertise in design and manufacturing enables us to bring products to market on time, within budget, and with the quality and service levels you expect from an industry leader.

Design, Engineering and Product Development

We are always at the forefront of new product innovation and development, striving to create the most cost-effective, high-performance products to meet the needs of every customer.

Custom Manufacturing and Production

Our in-house manufacturing capabilities and strategic “best-in-class” supply chain partners provide our customers with a full-service solution for all their finished parts needs.

Inventory Management

With over 150,000 square feet of warehouse space, we can manage and maintain a large inventory, eliminating lead time worries and concerns and ensuring on-time delivery.

Shipping and Distribution

All product packaging, handling and delivery are handled by our team of service experts, ensuring your order arrives intact and on time. In many cases, we deliver directly to the warehouse via our in-house trucks.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

Embossing

Design Assistance Services

Our goal is to help our clients reduce design errors, clearly demonstrate design intent, and get to manufacturing as quickly as possible. We achieve this through expertise and experience by providing design support through a variety of CAD/CAM tools.

All of our designers have extensive experience in metal fabrication. When you hire us for design and drafting, our staff doesn’t just draw a product without understanding how it will be manufactured. Before we begin, our designers walk through the entire manufacturing process to try to identify any design or functional issues that may arise. If any issues arise at this point, our team will sit down with you to discuss what we think is the best solution before the project goes into production.

Complete Assembly Manufacturing Services

Our comprehensive assembly services streamline your production process from start to finish. We manage everything from individual components to complete systems, ensuring seamless integration. Through our supplier inventory management and inventory programs, we guarantee timely availability of parts, optimizing your supply chain efficiency. With our complete assembly, packaging and delivery services, you can count on our team to meet your production schedule quickly and reliably.

Ready to get started on your next marine sheet metal parts fabrication project?

Elimold’s in-house metal fabrication services deliver custom solutions on time and with the quality you expect from industry leaders. Whether you need a single piece or a large quantity, the possibilities are endless. Contact us now for a free instant quote.

Quality Assurance

Our quality certifications include ISO9001 and ISO14001, as well as AS9100, IATF 16949 and ITAR. Our certifications guarantee that we maintain strict quality control measures and minimize our impact on the environment. For offshore sports, our ISO14001 certification is key to supporting marine ecosystems and complying with environmental regulations.

Quality service commitment

Quality and customer satisfaction are Elimold’s top priorities. No job is complete unless the customer is 100% satisfied that all needs have been met. Each project is measured and custom made to fit your boat, ensuring the best possible fit every time. No “quick rails” or “bolt-on” tops here. Each job is carefully designed with your specifications and needs in mind, paying attention to every detail. We will guide you step by step through the project and answer any questions along the way.

Benefits of Sheet Metal Design Optimization

Why is it important to use the correct materials and test designs before manufacturing? Benefits of optimizing sheet metal designs include:

- Improved Cost to Useful Life Ratio. A well-optimized design will give you the best bang for your buck possible by making sure that the sheet metal form you order lasts for a long time without costing you too much. Using the wrong material can cause a custom metal form to wear out quickly. When your parts last for years or decades rather than months, you save money on constant re-orders.

- Better Performance. Sometimes, an existing design could be greatly improved with just a few minor tweaks. For example, adding a removable side panel to materials handling basket can make unloading materials faster, saving on labor. Adding more supports to a shelf design can increase its ability to handle heavy loads.

- Faster Delivery. By testing metal fabrication designs virtually, you can be spared the lengthy and expensive process of building, shipping, and testing multiple physical prototypes. If a design doesn’t pass the Autodesk simulation, it goes back to the drawing board to be reworked in a way that addresses the cause of the failure. This way, you know you’ll be getting a custom metal form that will meet or exceed your needs the first time, not after months and months of painstakingly slow tests.

Materials Options

We understand that different customers have different needs, and we pride ourselves on being able to meet each customer’s specific requirements. Our team is well-versed in working with different metals and plastic materials, and not every metal fabricator offers such a wide range of capabilities or such large production volumes. As a result, we can process any number of materials, including stainless steel, brass, copper, mild steel, galvanized, and aluminum. But we are not limited in our capabilities, and we welcome any challenging project and material you bring to us. Elimold prides itself on being able to meet the unique needs of each of our customers.

Surface Finishing Options

Elimold’s finishing department facilities include; metal polishing, graining, chromic and sulphuric anodising including black and hard anodising. Alocrom 1000 & 1200 chromate conversion coating and non-chromate conversion coating such as Iridite NCP, SurTec 650V. We can apply 3M Scotch-Weld™ E396O adhesive primer, PPG PR30B adhesive primer & PPG PR143 epoxy primer (aviation undercoat for powder coat and paint). Zinc plate and clear passivate to 5 — 25μm. Spray paint and powder coating. Printing; screen for branding, model and serial numbers, part marking with die stamped, laser etched or engraving.

Products We Manufacture for the Marine Industry

We pride ourselves on providing the highest quality marine products to our customers as well as the renowned international marine companies we supply to. From custom fabrication to off the shelf parts, we are your one stop shop for all your marine needs. Below is a list of some of the parts we can manufacture.

- Rub Rails

- Sea Chests

- Cradles

- Rudders

- Alignment Sleeve

- Mechanical Door

- Exhaust Systems

- Rod Rack Holders

- Stern Tubes

- Extensions

- Bulbous Bow

- Plumbing systems

- Interior Finishes

- Hull Plating & Inserts

- Rocket Launchers

- Hop up showers

- Hatch Frames/Lids

- Stainless Steel Hand Rails

- Cleats and Anchor Pockets

- Fairleads and Striker Plates

- Masts and Flag Poles

- Galley modifications

- Stainless Steel & Aluminum Ladders

- Custom Metal Artwork and Sculptures

- Comprehensive Yacht Component Fabrication

- Davit Repairs and Installations

Other Services

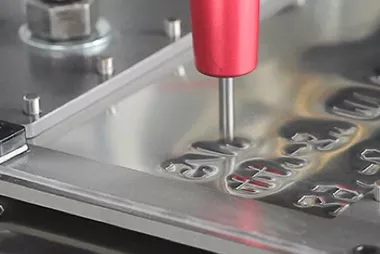

CNC Machining Solutions & Equipment

Elimold has a complete in-house CNC machining shop dedicated to developing the tools, fixtures and components required for prototypes or full production. This adds to a host of support services and capabilities that enable Elimold to provide specific components or complete system solutions for any application.

- CNC Lathes with Bar Feeders

- CNC Vertical Milling Machines

- CNC Horizontal Milling Machines

- Manual Milling and Lathes

- Tornos Swiss GT

- Star CNC Swiss-Type Automatic Lathes

- Mitsubishi Wire EDM

- Fanuc Robocut Wire EDM

- Mastercam CAD/CAM Software

- Tool and Die Design and Manufacturing

End Forming

With Elimold, precision tube end forming can be accomplished with single or multiple impact end forming or rotational forming units from small to large diameters.

Multiple impact end forming

- Offset expansion

- Coping

- Punching

- Tube reduction

- Forging

- Punching and notching

- Beading

- Flagging

- Expanding and stamping

- Square, rectangular, oval, round tube or any special shape

Rotational forming

- Beading

- Flagging

- Knurling

- Beading

- Finished cutting after bending

- OD notching and hose barbs

Tube dilation

- Small to large diameter

Request Custom Design, Fabrication and Sheet Metal Fabrication

We are a full turnkey manufacturing facility that, in addition to providing high quality marine products, has state-of-the-art equipment to manufacture everything from simple parts to complex multi-component assemblies.