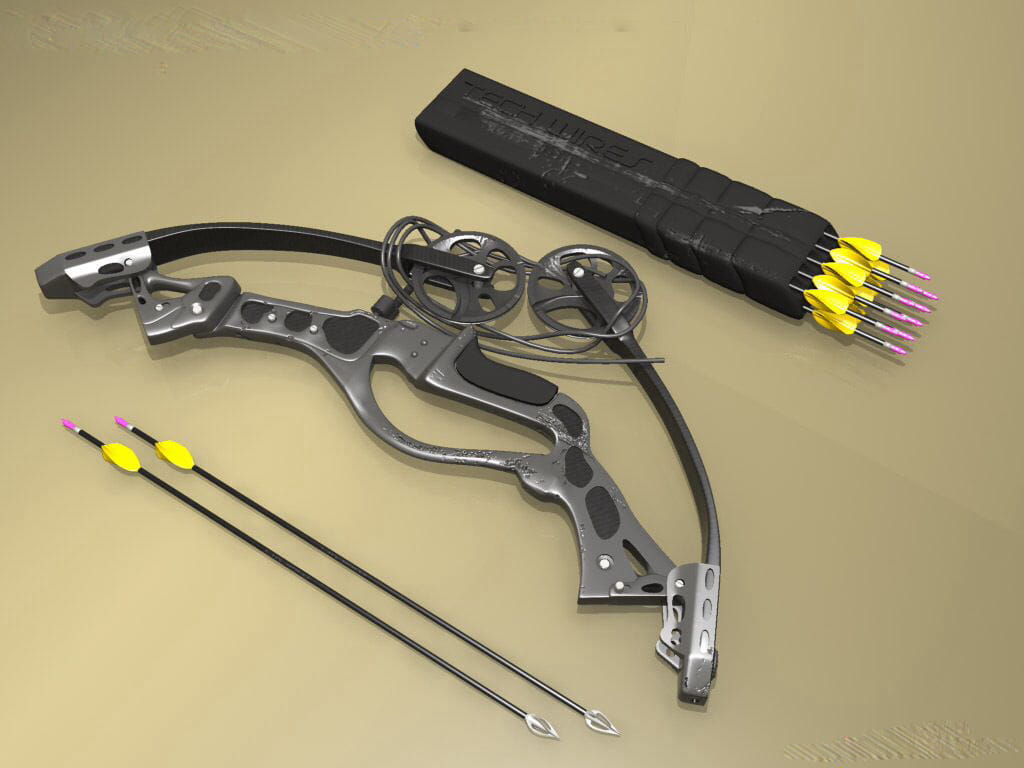

Compound Bow Die Casting

Elimold provides both high and low volume die casting services for a wide range of compound bow products. Our project engineers can utilize the latest technology and our extensive die casting experience to optimize your design for cost savings. By utilizing the latest equipment and the most efficient manufacturing processes, Elimold is able to meet the on-time delivery performance required to bring your compound bow product to market quickly.

The pinnacle of compound bow die-casting manufacturers

Welcome to Elimold, your trusted partner for premium compound bow die-casting solutions. As a leading compound bow die-casting manufacturer, we specialize in providing precision-engineered components that meet the highest industry standards. Our state-of-the-art facilities and cutting-edge technology ensure the production of lightweight, durable, and ingeniously designed compound bow parts.

We take pride in our commitment to excellence and employ a team of highly skilled professionals dedicated to providing premium compound bow products. With years of expertise serving a diverse range of industries, we provide solutions tailored to your specific needs. Our compound bow die-casting process ensures tight tolerances, optimal material properties, and cost-effective production.

Partner with us for reliable, high-performance compound bow die-casting services. Experience the difference of working with us—every casting is precise and flawless. Our unmatched expertise and quality assurance will elevate your project.

Professional Compound Bow Die Casting Services

Elimold Die Casting specializes in manufacturing services that produce high-quality compound bow metal components using a variety of alloys. With our expertise in die casting, Elimold offers a wide range of services including design assistance, prototyping, tooling, and production. By utilizing alloy materials, we can create complex shapes with excellent dimensional accuracy and tight tolerances. Our compound bow die casting services are known for their excellent strength-to-weight ratio, corrosion resistance, and excellent electrical conductivity. And, our company uses state-of-the-art equipment and advanced technology to ensure precise and efficient production. Elimold plays a vital role in providing cost-effective and reliable compound bow metal components.

Advanced Technology, Custom Services

As an industry leader, we pride ourselves on providing best-in-class compound bow casting solutions that meet the highest standards of quality and precision. Our state-of-the-art facilities and cutting-edge technology ensure that each casting project is executed with unparalleled precision and efficiency. Elimold is the leading name in compound bow die casting companies. We are committed to precision and excellence, providing top solutions to the sports industry. Our state-of-the-art facilities have cutting-edge technology to ensure the production of high-quality aluminum parts with tight tolerances.

Our team of professionals utilizes advanced die casting technology to meet the most demanding specifications. Whether you require an intricate design or large-scale production, we tailor our services to your unique needs. Our focus on quality control guarantees perfect results, making us the first choice for customers who seek reliability and efficiency. Explore the possibilities of a premium aluminum casting company with us – a combination of innovation and precision that sets a new benchmark in the industry. Trust us to turn your vision into reality with unparalleled craftsmanship and dedication to quality.

Request a quote today for precision die casting of your compound bow product.

Elimold leverages our comprehensive manufacturing capabilities to handle your compound bow project, allowing us to quickly produce any part and move your project from prototype to production quickly and efficiently.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Sand Casting

Investment Casting

Die Casting

Low Pressure Casting

Permanent Mold Casting

Lost Foam Casting

Centrifugal Casting

Vacuum Casting

Our Capabilities

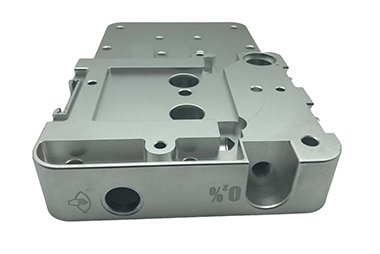

Elimold produces complex, high-quality compound bow die castings for a wide range of industries. With over 100,000 square feet of manufacturing space, we have the capability to produce large castings and CNC machining. Today, we have over 25 modern casting machines ranging from 500 to 2,200 tons, capable of machining, finishing, and assembling castings to meet the most challenging design requirements. We pride ourselves on using our experience and technology to produce castings with complex geometries and tight porosity requirements using a wide range of casting alloys. Our rapidly growing CNC machining department and die casting division use the latest technology to machine features with very tight tolerances. All of this adds up to our ultimate goal: to provide our customers with the best products, value, and service.

The Elimold Advantage

- Precision aluminum castings, from <1 pound up to 26 pounds

- 360, 380, and 390 aluminum alloys

- ZA 27 aluminum zinc alloy

- Design for manufacturability and early design support

- CAD compatibility for web-based communication and fully interactive manufacturing

- Complete part solution—casting, machining, and finishing—all under one roof

- Advanced, proprietary closed-loop shot control system

- Dendrite control and measurement capabilities

- Commitment to quality and exceeding customer expectations

- In-house tool building

- Rapid lead times

- Serving international customers all around the world

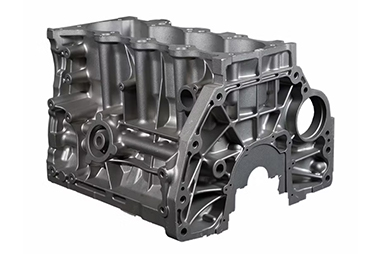

Compound Bow Die Casting Manufacturing Process

We provide custom services to meet the specific needs of our customers. We can work with you to design and produce precision die castings that meet your unique requirements. The manufacturing process generally includes the following steps:

- Design the mold: Design a precision mold according to the requirements of the part.

- Melting metal: The selected metal (such as aluminum or zinc alloy) is placed in a furnace to melt.

- Injecting molten metal: The molten metal is injected into the mold under high pressure.

- Cooling and solidification: The molten metal cools and solidifies in the mold to form the shape of the part.

- Ejecting the part: The finished part is ejected from the mold.

- Post-processing: The part may undergo post-processing operations such as trimming, deburring, surface treatment, etc. to ensure its quality and appearance.

Your Preferred Compound Bow Die Casting Company

If you are looking for a reliable compound bow die casting company, look no further than Elimold. We pride ourselves on being able to provide you with a comprehensive solution for all your compound bow die casting needs. With years of experience in the industry, we deliver high-quality metal components through advanced die casting services. Our skilled team is committed to providing excellent customer service and unparalleled precision in every project. From design and prototyping to tooling and production, we cover it all to meet your specific requirements. With state-of-the-art equipment and innovative technology, we ensure that each product has excellent dimensional accuracy. In addition to compound bows, we also serve various industries such as automotive, electronics, and aerospace, and are your trusted partner for reliable and efficient die casting solutions.

Ready to get a quote for your compound bow die cast parts?

With Elimold for compound bow die casting services you get the support of a dedicated team of engineers. No matter where you need your parts, our dedicated team of engineers and global network of facilities can serve you quickly and efficiently.