Compound Bow CNC Machining

At Elimold, you can experience a comprehensive range of compound bow CNC machining services. Our capabilities are designed to meet the needs of businesses seeking high-quality OEM compound bow parts.

Compound Bow CNC Machining Manufacturer

Elimold has established a special Compound Bow CNC Machining department to manufacture and produce a variety of precision parts used in compound bows. This department specializes in serving the archery leisure sports industry, producing parts for not only recreational and competitive compound bows, but also related parts for hunting bows. Our company is equipped with state-of-the-art machinery, skilled engineers and advanced software to meet the specific needs of compound bow production. Our experienced team of engineers also provides prototyping, design consulting and custom manufacturing services, and can provide tailor-made products according to customer requirements. We often work with bow designers, archery brands and industry experts to ensure that the products we manufacture meet the highest quality standards.

Our Capabilities

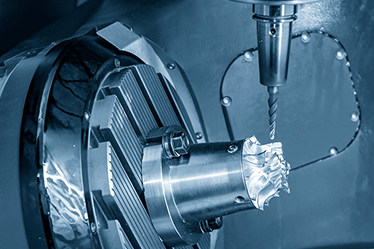

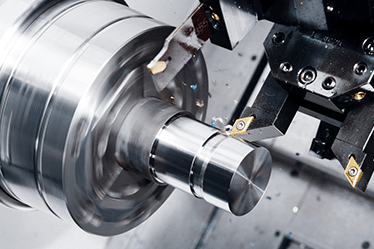

Rapid prototyping and custom manufacturing experience are essential for developing new designs or improving existing ones, and our company has advanced equipment, precision capabilities and expertise for CNC machining of compound bow parts. Machine tool equipment includes multi-axis CNC machines such as 4-axis or 5-axis, which enable us to produce parts with complex geometries, such as cams, bow handles and bow arm pockets in compound bows. In addition, the accuracy and tolerance of machining can be controlled within 0.001 inches to ensure that the relevant components of compound bows fit and operate perfectly.

We also have skilled engineers who are proficient in various manufacturing and material science expertise. They can perform DFM analysis on components before production to ensure that parts can be produced efficiently and with fewer production errors. Material expertise can help select the right materials to ensure that the materials used in the relevant parts meet the design requirements and have price advantages.

In addition, we can maintain strict quality control throughout the production process to ensure that we can produce consistent, high-quality compound bow parts that meet industry standards and customer expectations.

Our Manufacturing Services

If you are looking for a reliable compound bow custom parts manufacturer, Elimold will be your ideal choice. Our company has several types of milling and turning centers. Whether it is simple or complex geometric parts, we are confident in our ability to produce with tight tolerances and high precision.

Our skilled team is ready to assist you with your compound bow custom parts

Types of Materials Used in Compound Bows

The materials used in modern compound bows are primarily chosen based on their strength, durability, and weight characteristics. Common materials include:

- Aluminum alloys (6061-T6 or 7075): These alloys are widely used for bow handles and cams due to their strength, light weight, and corrosion resistance.

- Carbon fiber composites: Carbon fiber is commonly used in bow arms, offering a high strength-to-weight ratio, durability, and vibration reduction.

- Steel and stainless steel: These materials are commonly used for shafts and screws, providing the necessary strength and wear resistance for moving parts.

Surface Finishing Options

The surface finish chosen for compound bow parts is primarily based on the material involved, but can also improve the aesthetics and durability of a compound bow component. Common finishes include:

- Anodizing: Aluminum parts are often anodized to enhance corrosion resistance and allow for color customization (e.g., matte black, camouflage patterns).

- Powder coating: Used to make risers and limbs more durable and aesthetically pleasing.

- Polishing: Cams and other parts are sometimes polished to reduce friction and improve functionality.

Compound Bow Related Parts We Can Machine

The main parts of compound bows we manufacture using CNC machining include:

- Riser: The centerpiece of the bow, typically made of lightweight yet strong aluminum, CNC machined for precision and structural integrity.

- Cam: The heart of a compound bow’s pulley system, CNC machined cams control the bow’s draw cycle and power output, requiring intricate design and high precision.

- Arms: These are typically machined for mounting points and custom mounting to the riser and cam system.

- Shafts and Bearings: Precision machined to ensure smooth rotation of the cams.

- Mounting Points: Threaded or non-threaded points for attaching accessories such as sights, stabilizers, and quivers that are precisely machined to ensure proper fit and alignment.

Advantages of CNC Machining Compound Bows

Using CNC machining to produce compound bows offers several advantages:

- Precision: You can ensure that all parts are manufactured to exact specifications, which is critical to the performance and reliability of a compound bow.

- Consistency: Highly repeatable machining ensures that all bows produced meet the same standards with minimal variation between products.

- Customization: Components can be easily customized, allowing bow manufacturers to provide tailored designs and finishes for different users and applications.

- Efficiency: Large numbers of parts can be produced quickly, reducing production time and costs.

- Material Flexibility: A wide range of materials can be machined, from metals such as aluminum and steel to composites such as carbon fiber.

- Enhanced Durability: CNC machined components tend to have better structural integrity, resulting in longer bow life with fewer mechanical issues.

Get a free quote on Compound Bow CNC machined parts today

We have a team of highly skilled engineers ready to support you throughout the entire product development process, from prototyping to production. When you are ready to start your next project, simply upload your design files and our engineers will provide you with a quote instantly.