Stainless Steel CNC Machining

Elimold routinely machines many different grades of stainless steel. We have extensive machining experience and can manufacture custom stainless steel CNC machined parts to meet any requirement or specification. Our machining services take a streamlined approach to solving your most challenging projects. With our in-house expertise and state-of-the-art equipment, our solutions are flexible and customizable to meet your needs.

Custom Stainless Steel Parts Manufacturer

Stainless steel parts manufacturing is an area of expertise for Elimold. We have many years of experience in machining and finishing precision stainless steel CNC parts. Elimold can help you take your stainless steel parts or components from drawing to production, which is the core of our business. We have extensive skills and experience in this field and a deep understanding of the unique challenges and requirements that stainless steel machining brings. And we have the necessary advanced equipment and machining technology to provide high-quality parts to your precise specifications. The capabilities of our CNC machining factory can meet your short-term and long-term production needs of parts. Stainless steel parts and components of any shape and tolerance can be manufactured using a variety of CNC machining technologies. In addition, the Elimold team of engineers has experience in processing stainless steel under high thermal loads and knows how to maintain the integrity of the material under these conditions. Our innovative equipment, well-trained staff and obsession with quality enable us to provide a range of customer-specific services to simplify the supply chain. Please let us know your existing part design or idea, and our manufacturing engineers will assist you in creating prototypes and mass production parts.

Professional Stainless Steel CNC Machining Factory

Elimold helps you easily complete the manufacturing of stainless steel parts or components from drawing to production. We are an ISO 9001:2015 certified machining shop, and our factory in Shenzhen, China covers an area of 80,000 square feet. , focusing on manufacturing high-value parts and precision components to meet the needs of harsh environments.

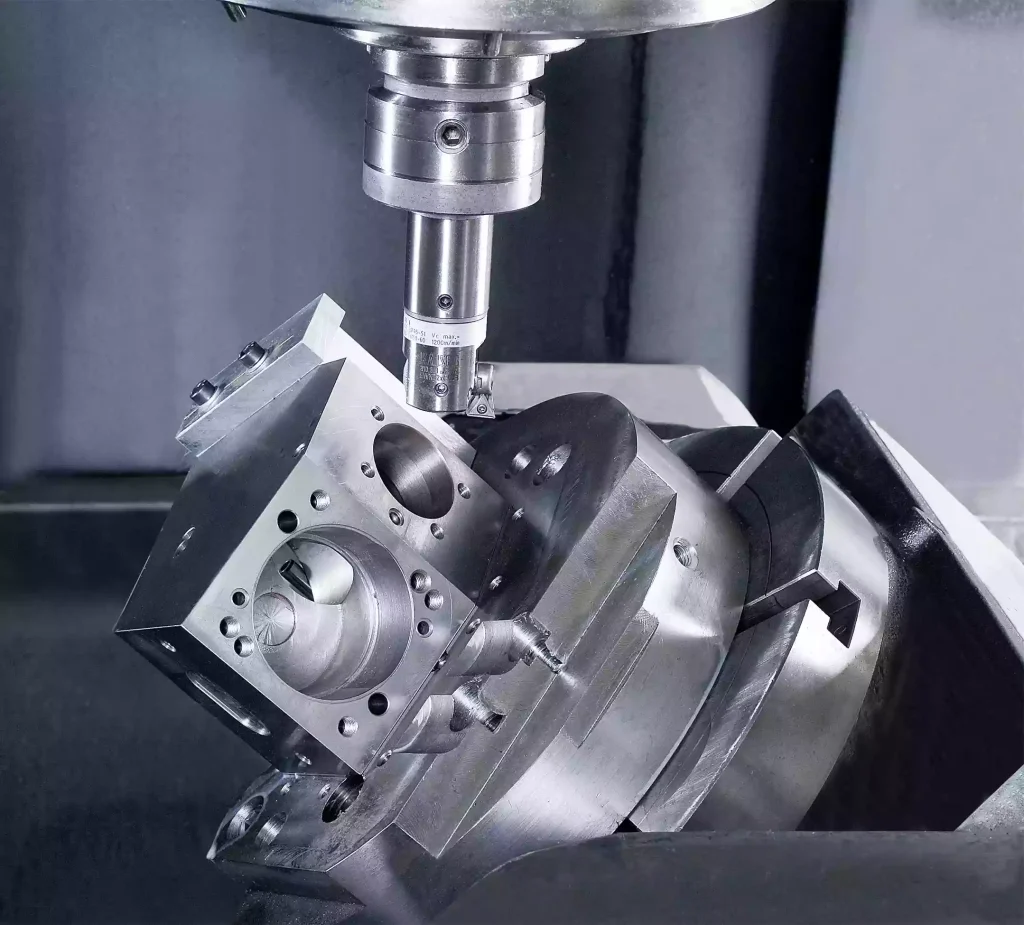

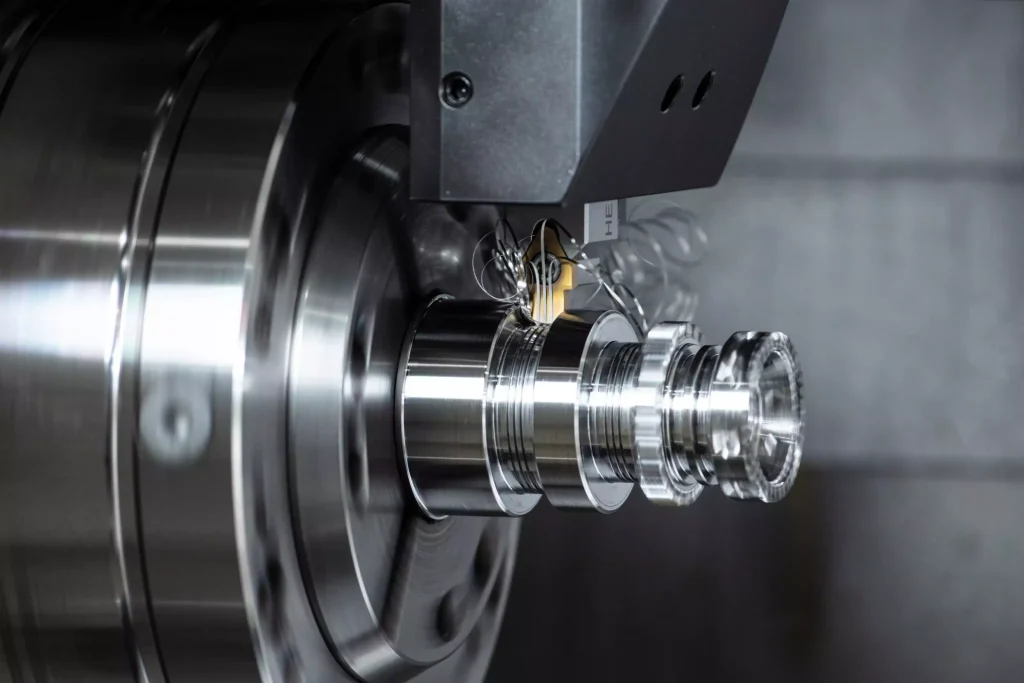

With more than 20 years of experience in CNC machining, we continue to improve our skills and equipment performance. Our factory has more than 150 CNC machining centers and is equipped with 45 CNC lathes to meet various manufacturing needs. For increased precision and versatility, we have invested in 30 four-axis machining centers and 40 five-axis machining centers and 35 bridge cranes that can carry up to 20 tons. In addition, we have 10 Citizen Swiss-type lathes, which can undertake almost any custom metal CNC machining project, further consolidating our commitment to high-precision production. This extensive infrastructure ensures that we provide excellent quality and efficiency in various machining projects.

Elimold's Stainless Steel CNC Machining Capabilities

Whether you need CNC machined stainless steel parts for prototypes, low-volume production runs, or large-volume orders, our experienced team of technicians can handle projects of any size using advanced CNC machinery. We are able to produce stainless steel parts with accuracies as fine as 0.0002 inches. We are able to manufacture stainless steel parts as small as 3″ x 3″ x 3″ (or weighing less than 1 pound) to as large as 150″ x 92″ x 48″ (or weighing up to 44,000 pounds). We operate entirely in-house to reduce overall costs and delivery times while ensuring professional service from start to finish.

Engineering & Design Services

You leverage our expertise and technology to achieve your manufacturing goals. Elimold has extensive expertise in stainless steel CNC machining and is equipped to handle your project. Design and manufacturing collaboration is a key part of our business operations. Therefore, we provide DFM analysis for every quote. Our experienced engineers, designers, and production teams will help you find the right manufacturing processes, materials, and finishing steps to meet your needs. We will also help you streamline every stage of the product development process, from design and prototyping to mass production validation.

Complete Stainless Steel CNC Machining Services Process

At Elimold, our stainless steel parts CNC machining project service process ensures that every part we produce has precision, efficiency and unparalleled quality. Here is how we take your project from concept to final completion:

1. Strategic Material Selection

We carefully select the right stainless steel grade for your project, such as 304 stainless steel (versatility), 316 stainless steel (corrosion resistance), or 17-4 PH stainless steel (higher strength). This ensures optimal performance even in the most demanding applications.

2. Comprehensive Design Analysis

Our experts carefully review your 3D and 2D CAD files to ensure that all designs are optimized for manufacturability, functionality, and industry standards.

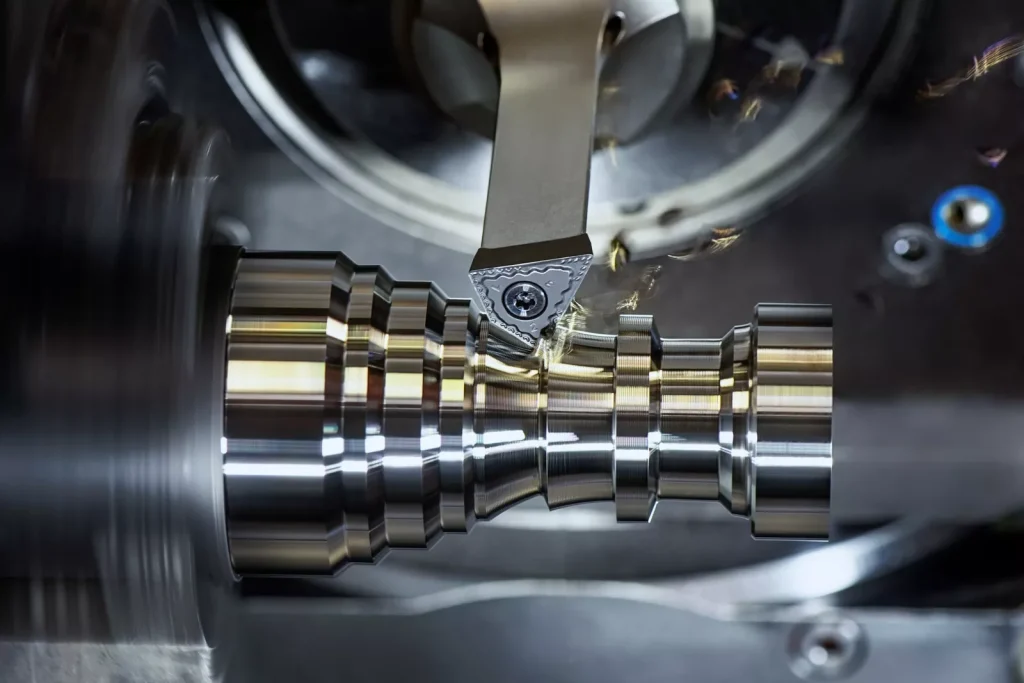

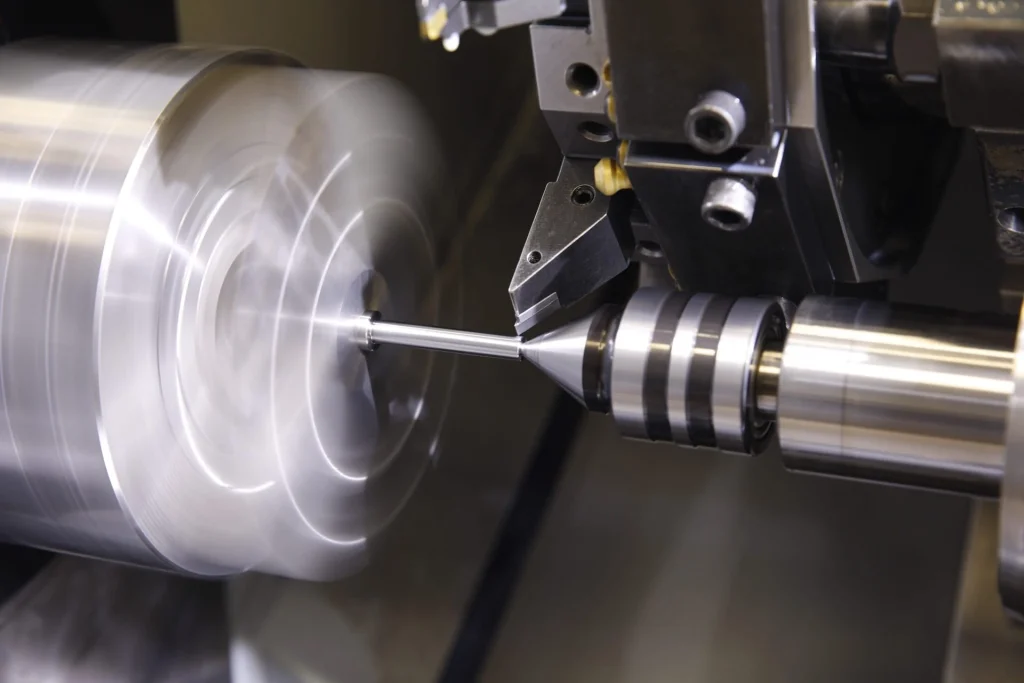

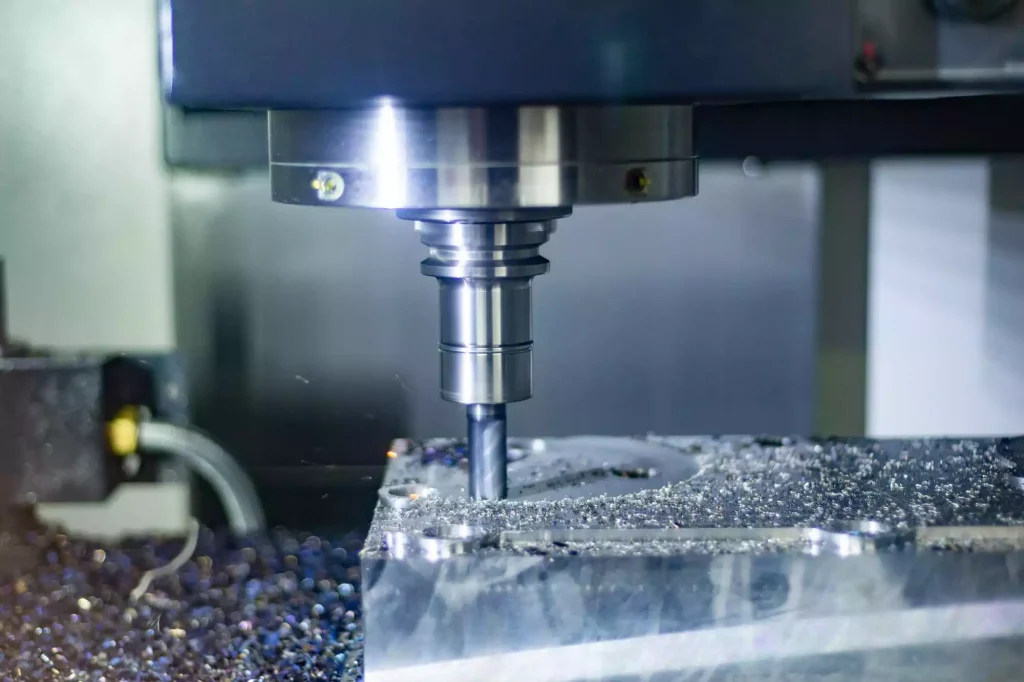

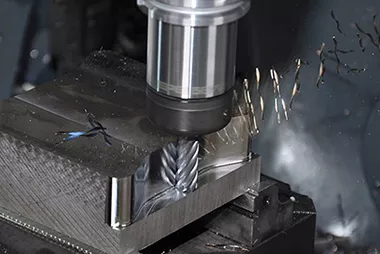

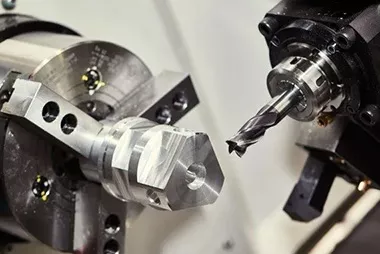

3. Advanced Machining Execution

We utilize a wide range of advanced CNC machining techniques to manufacture your parts to tight tolerances of ±0.02 mm. Whether producing complex geometries or high-performance components, we ensure exceptional precision at every stage.

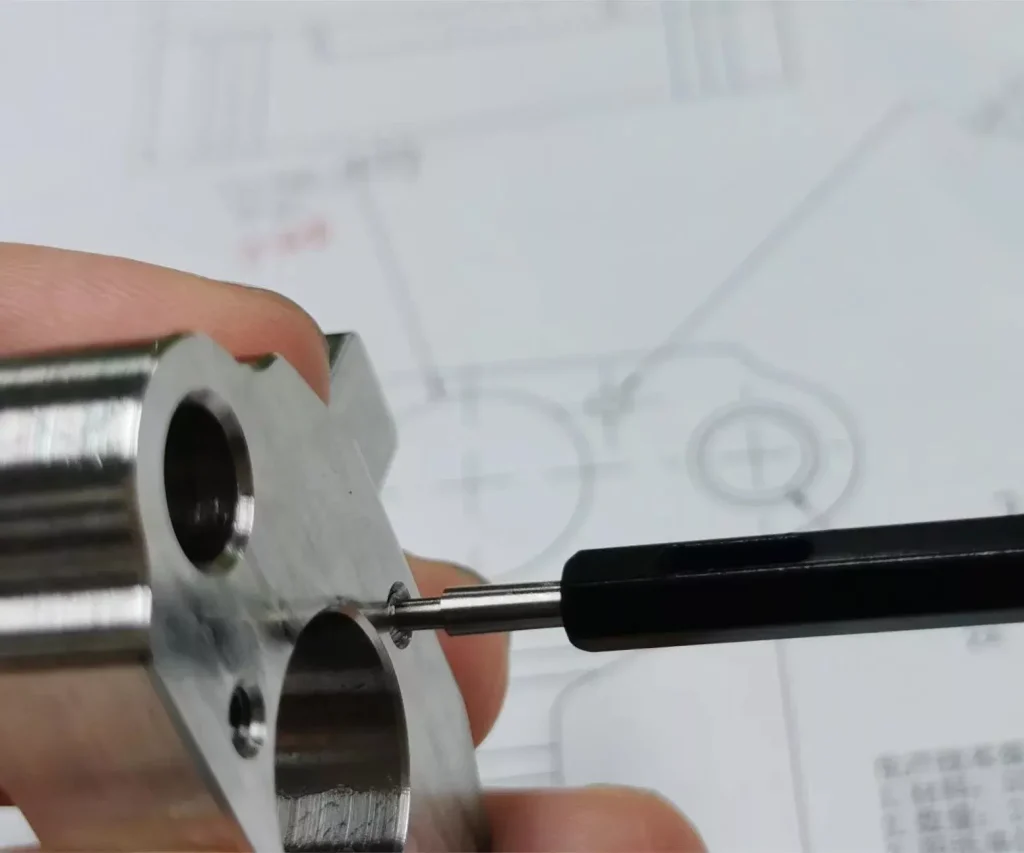

4. Rigorous Quality Assurance

Every component we produce undergoes rigorous dimensional inspection, surface inspection, and functional testing. This ensures that it meets your specifications and our ISO-certified standards.

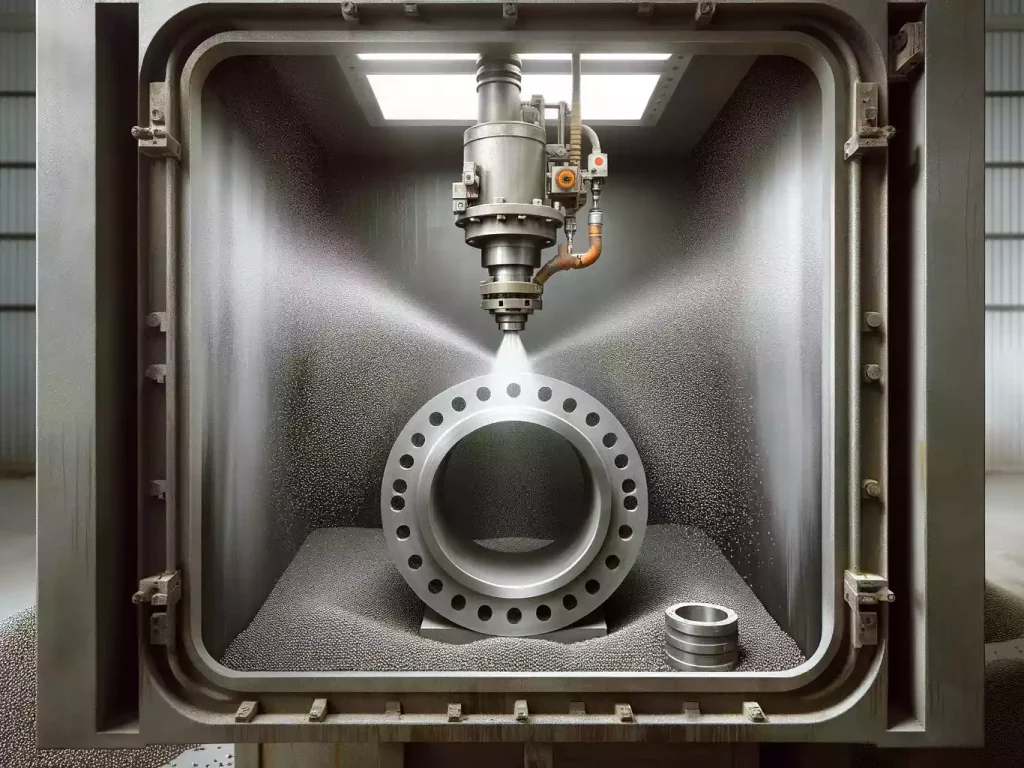

5. Customized surface treatment

To enhance the appearance and durability of your parts, we offer high-quality surface treatment services such as passivation (for improved corrosion resistance), electropolishing (for a smooth surface) and sandblasting (for a sophisticated matte texture).

6. Secure Packaging and Delivery

Once processed, your stainless steel parts will be securely packaged to prevent damage during transportation. We offer global shipping services to deliver top-quality components to your location quickly and reliably.

Trusted Stainless Steel Machining Service Provider

Explore our premium stainless steel CNC machining services, providing precision manufacturing services tailored to your specific needs. Our skilled team uses advanced CNC technology to machine stainless steel into custom parts with unparalleled precision. Whether you need a sophisticated design or a rugged component, our services can meet a variety of project needs. You can rely on us to provide reliable and durable stainless steel parts that meet the highest quality standards. With our CNC stainless steel machining services, experience a seamless combination of technology and craftsmanship to ensure that your project combines quality and durability. We are committed to providing tailored solutions to turn your ideas into reality, ensuring precision and reliability every step of the way.

Types of Stainless Steel CNC Machining Services

Our dedicated team offers a wide range of CNC machining technologies. We look forward to using them on your next project. We deliver on our strict quality standards for every product, from rapid prototyping to high-volume production. Services can also be tailored to the stage of product development, ensuring you get the best value with unmatched fast delivery every time! Our dedicated team of experts is ready to provide customized support when needed, helping you successfully achieve all your project goals.

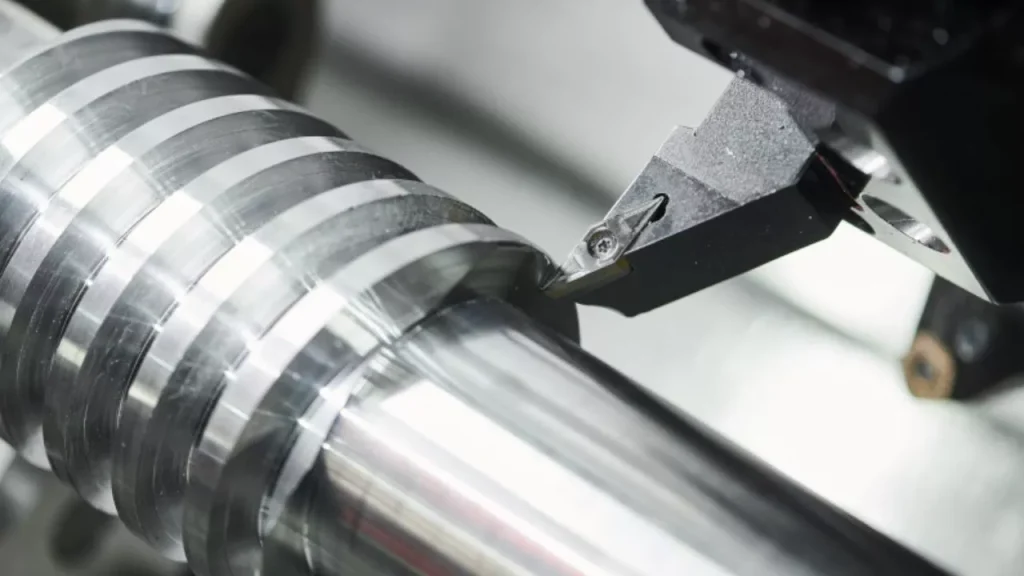

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Types of Stainless Steel

Austenitic

Non-magnetic, highly formable and can be cold worked, but not heat treated. Austenitic stainless steel is corrosion resistant but prone to stress corrosion cracking. Often used to make shafts, valves, bolts, bushings, nuts, aircraft fittings, and cryogenic vessels. Austenitic stainless steels are either 200 or 300 series with common grades including 201, 202, 301, 302, 303, 304, 305, 308, 309, 310, 314, 316, 317, 321, 347, 348, and 384.

Ferritic

Magnetic with lower ductility and corrosion resistance than austenitic grades. Ferritic stainless steel grades have a high resistance to stress corrosion cracking and can be cold worked, but are not heat treated. Often used to make heat exchangers, automotive fasteners, and furnace components. Ferritic stainless steels are 400 series with common grades including 405, 409, 430, 434, 436, 442, and 446.

Martensitic

Magnetic and heat treatable with higher strength but lower corrosion resistance than ferritic grades. Often used to make pump shafts, bolts and screws, valves, bushings, rivets, coal chutes, jet engine parts, aircraft fittings, mining machinery and fire extinguisher inserts. Martensitic stainless steels are 400 and 500 series with common grades including 410, 414, 416, 420, 431, and 440.

Precipitation Hardening Grade

These grades are heat treatable, typically have much higher strength than austenitic stainless steels and retain much of their strength in high temperatures. Often referred to as PH Type stainless steel, and used to make military equipment and aircraft structural components. Common grades include 17-7 PH, PH 15-7 Mo, 17-4 PH, and 15-5 PH.

Duplex

A hybrid of austenitic and ferritic steels, duplex stainless steels are known for exceptionally high strength and stress corrosion cracking resistance. Duplex stainless steels are easily heat treated but difficult to cold form. Often used to make chemical processing equipment, pressure vessels, and heat exchanger components. Common UNS grades include S32101, S32304, S32003, S31803, S32205, S32760, S32750, S32550, S32707, and S33207.

Stainless Steel Grades We Use

If you are ready to choose stainless steel as the material for your custom CNC machined parts, you can rest assured that the material you choose has many advantages. Due to the variety of stainless steel material grades, it can be a challenge for engineers to find the exact material that is suitable for a specific project in the material list. Elimold’s professional design team has decades of engineering experience and welcomes the challenge. We ensure that the material selection is flawless, helping you to easily achieve the expected results. Here is a brief introduction to the main stainless steel grades we have experience with:

201 Stainless Steel

polished without bubbles and pinholes, mostly used in the production of high-quality materials for various watch cases and watchband bottom covers.

301 Stainless Steel

Similar to SS304, Stainless Steel 301 offers good corrosion resistance and is used in applications where higher strength and formability are required, such as in springs and foils.

303 Stainless Steel

An austenitic stainless steel with added sulfur and phosphorus, known for its excellent machinability, good corrosion resistance, and non-galling properties.

303Se Stainless Steel

contains selenium and phosphorous for improved machinability.

304 Stainless Steel

the most common grade, with the base 18/8 composition (18% chromium, 8% nickel); also called A2 stainless steel.

304L Stainless Steel

A low-carbon variant of 304 stainless steel, recognized for its improved weldability and resistance to sensitization, making it suitable for welding applications.

305 Stainless Steel

increased nickel content lowers work hardening properties.

309 & 309S Stainless Steel

higher chromium and nickel content provides greater corrosion and high temperature scaling resistance; 309S contains less carbon to minimize carbide precipitation.

310 & 310S Stainless Steel

greater nickel content further improves scaling resistance; 310S contains less carbon to minimize carbide precipitation.

316 Stainless Steel

A molybdenum-bearing austenitic stainless steel with superior corrosion resistance, especially in aggressive environments, and excellent weldability.

316L Stainless Steel

A low-carbon variant of 316 stainless steel with enhanced resistance to sensitization and improved weldability, suitable for use in corrosive environments.

316LSi Stainless Steel

A variant of 316L stainless steel with added silicon for improved weldability and wetting behavior, known for its excellent corrosion resistance and strength.

321 Stainless Steel

titanium content ties up the carbon and helps avoid chromium carbide precipitation when welding the material.

330 Stainless Steel

ultra-high nickel content provides the highest possible corrosion resistance in most furnace atmospheres; this grade offers a low coefficient of expansion, excellent ductility, and higher strength.

347 & 348 Stainless Steel

columbium-tantalum content ties up carbon and helps avoid chromium carbide precipitation in welding; used for working temperatures from 800° to 1,650°F.

403 Stainless Steel

special high quality stainless steel; ideally suited for high-stress applications, such as steam turbines and jet engine compressors; magnetic.

405 Stainless Steel

contains 12% chromium, as well as added aluminum, to prevent hardening.

410 Stainless Steel

“general purpose” corrosion and heat resistant stainless steel; can be heat treated for additional hardness; magnetic.

410NiMo Stainless Steel

A modified 410 stainless steel with added nickel and molybdenum, providing improved strength, hardness, and corrosion resistance, suitable for high-stress applications.

416 Stainless Steel

A free-machining martensitic stainless steel with added sulfur, known for its excellent machinability, good corrosion resistance, and moderate strength.

416Se Stainless Steel

specialized variations of Type 410; free-machining, non-seizing, and non-galling thanks to additional sulfur or selenium (Se) content; heat treatable.

420 Stainless Steel

can be heat treated to a maximum of roughly 500 Brinell; offers maximum corrosion resistance when fully hardened; magnetic.

430 Stainless Steel

offers good ductility, superior resistance to atmospheric corrosion, and higher scaling resistance than 302.

430F & 430Se Stainless Steel

provide better machinability thanks to their respective added sulfur and selenium content.

431 Stainless Steel

1.252% nickel content; can be heat treated to high mechanical properties; greater corrosion resistance than 410, 416, 420, 430, and 440 stainless steels; magnetic.

440 Stainless Steel

A high-carbon martensitic stainless steel offering excellent hardness and wear resistance, commonly used for cutlery and other applications requiring sharp edges.

440C Stainless Steel

can be heat treated to the highest hardness of any martensitic stainless steel grade.

442 Stainless Steel

added chromium improves scaling resistance.

Type 446: very high chromium content (27%) further improves scaling resistance.

13-8 Stainless Steel

13-8 stainless steel is a type of martensitic stainless steel known for its outstanding strength, high hardness, exceptional toughness, and effective corrosion resistance. Furthermore, 13-8 demonstrates excellent ductility and fabrication properties.

15-5 Stainless Steel

A precipitation-hardening, martensitic stainless steel known for its high strength, excellent corrosion resistance, and good transverse toughness.

15-5 PH Stainless Steel

A variant of 15-5 stainless steel with improved toughness and ductility, characterized by its excellent strength, corrosion resistance, and machinability.

17-4 Stainless Steel

A martensitic, precipitation-hardening stainless steel featuring high strength, excellent corrosion resistance, and good mechanical properties at high temperatures.

17-4 PH Stainless Steel

A variant of 17-4 stainless steel with improved strength and corrosion resistance due to precipitation hardening, known for its exceptional toughness and high tensile strength.

17-4H900 Stainless Steel

A material that offers a good balance of corrosion resistance and strength. It’s magnetic and can be precipitation-hardened with heat treatment. Some applications include aircraft parts, nuclear equipment, food processing machines, and paper mills.

17-4H1150 Stainless Steel

A precipitation-hardened, chromium-copper alloy that exhibits high strength and a moderate level of corrosion resistance. It’s magnetic and heat-treated to add strength. Typical uses are valve components, pump shafts, aerospace parts, turbine blades, nuclear waste casks, offshore applications, food-processing tools, and pulp-and-paper industry equipment.

18-8 Stainless Steel

A general-purpose, non-magnetic stainless steel containing 18% chromium and 8% nickel, recognized for its good corrosion resistance, formability, and weldability.

2205 Duplex Stainless Steel

A duplex stainless steel combining good corrosion resistance with high strength, known for its excellent resistance to stress corrosion cracking and erosion.

A286 Stainless Steel

An iron-based superalloy wexcellent oxidation resistance at elevated temperatures, suitable for use in high-stress applications at high temperatures.

Nitronic 60

Nitronic 60 is an excellent general purpose material with excellent wear and corrosion resistance. Nitronic 60 stainless steel provides corrosion and wear resistance at a very low cost compared to cobalt-containing and high-nickel alloys. Its overall corrosion resistance is superior to Type 304 in most media. It has almost double the yield strength of SS 304 and SS 316 and has excellent oxidation resistance.

What is stainless steel?

Stainless steel is defined as an alloy steel containing at least 10.5% chromium by mass. As the name implies, stainless steel should be non-staining and non-corrosive. It should be non-staining, but not stain-resistant. Stainless steel is often thought of as corrosion-resistant, but given the wide range of grades available, this isn’t actually a very useful defining characteristic, as the quality and grade of stainless steel determines its strength and corrosion resistance. Custom CNC Machined Parts

The basic element of stainless steel is iron (Fe), with the addition of chromium (Cr) making it a corrosion-resistant alloy. Alloys are mixtures of several metals. Small amounts of carbon (C) are often added to increase hardness and strength. Nickel (Ni) is added to stabilize the crystal structure of the iron, which improves its integrity and corrosion resistance in all extreme temperatures. Other alloying elements, such as molybdenum (Mo) or titanium (Ti), may also be added to enhance heat and corrosion resistance.

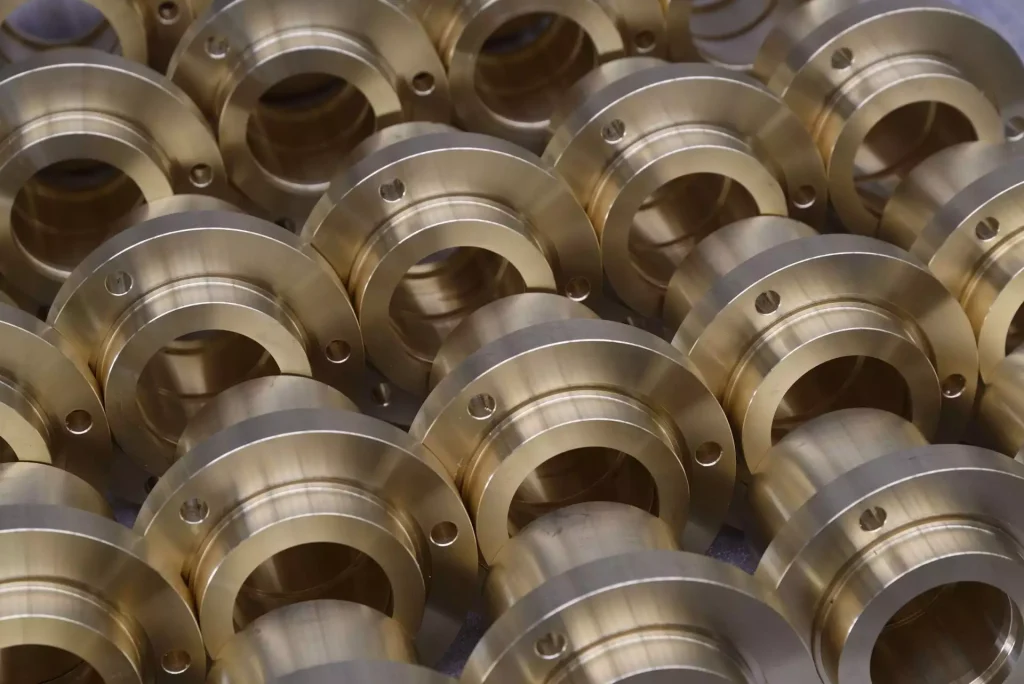

One of the great properties of stainless steel is its ability to self-heal after CNC machining is complete. The chromium element forms an invisible protective film on the surface of the iron through a process called passivation, protecting it from air and water. If the surface is scratched, this protective film quickly repairs itself under the influence of oxygen. This is why high-quality stainless steels do not rust even if they are scratched during machining. Brass parts Most high-quality blanks are stress-relieved to ensure maximum machinability and dimensional stability.

Stainless Steel Properties

Stainless steel has excellent machinability, excellent uniformity, corrosion and oxidation resistance, which prolongs product life and reduces the total cost of machined parts.

- Corrosion resistance

- Designed for improved machinability

- Low cost

- Quick part turnover

- High strength and stable quality.

- Beautiful surface and versatile use.

- High temperature oxidation resistance and high strength.

- Simple and easy maintenance because no surface treatment is required.

- Good welding performance.

- Excellent thermal expansion performance and thermal insulation performance. Improved weldability.

Stable Supply Chain of Stainless Steel Materials

A stable supply chain is critical to your business. You need to be able to trust your suppliers to provide the goods and services you need, when you need them. Elimold can use customer-provided stainless steel materials or source them ourselves. Choosing us to source stainless steel materials can save you time and money. We work with several certified steel mills and distributors to quickly and easily obtain specific grades of stainless steel in the right lengths, thicknesses and shapes. In addition, our experienced machinists and welders are proficient in processing multiple grades of stainless steel, and materials are sourced from reputable suppliers and verified for compliance upon arrival. Calibrated testing and inspection equipment ensures that every part produced exceeds applicable industry standards or customer specifications. All orders are reviewed for accuracy before shipment.

From Prototyping To Full-scale Production

All Elimold employees are highly trained, have the necessary certifications and qualifications, and receive continuous cross-training on equipment and software. This ensures that despite the challenges of stainless steel processing, we are able to meet any challenge. Our expertise covers precision design and complex geometries, ensuring that all components achieve optimal performance. Whether you need rapid prototyping or large-scale production, we can meet your needs. Tight tolerances of ±0.02 mm ensure accuracy, and fast turnaround times ensure a smooth project. Elimold offers competitive pricing, global shipping, and dedicated customer support based on your production requirements to simplify your processing projects.

Custom Stainless Steel Parts Made to Your Specs

Whether you are looking for a simple machined stainless steel part or one with complex, organic geometries and tight tolerances, Elimold can execute your project seamlessly. In addition to our extensive in-house stainless steel fabrication capabilities, we have a strong local supply chain that can provide special surface treatments, non-destructive testing, and nearly any other service we can’t provide ourselves—all supervised by your dedicated project manager and held to Elimold’s exacting quality standards.

Need stainless steel CNC machined parts?

Contact us to discuss your stainless steel machining project or request a quote to design your component.

Full-Service Precision CNC Machining Stainless Steel Company

Our stainless steel CNC machining services are dedicated to excellence and precision for your project. Elimold’s engineering and technical team ensures meticulous attention to detail to turn your ideas into reality through high-quality stainless steel parts machining. Whether you have complex project requirements or need a strong part, we can meet your every need. From design to completion, we prioritize excellent workmanship to provide you with a carefully crafted piece custom made to your specifications. Experience our reliable service, a seamless process that blends expertise and cutting-edge technology to enhance your project. We are trusted to provide reliable and durable stainless steel parts that meet the highest quality standards. Let us turn your ideas into reality with tailor-made solutions, providing superb craftsmanship and reliable performance, making us your trusted partner to provide excellent results for your project.

Our Quality System

At Elimold, we firmly believe that quality is fundamental to the success of every project. Our stainless steel CNC machining services are backed by a strong quality management system, ensuring that every part you receive meets your exact specifications and comes with complete quality documentation.

- ISO 9001:2015 certified processes

- In-process and final inspections

- Dimensional control using CMM, micrometers, calipers

- Surface finish and thread checks

- Material certifications available

- First Article Inspection (FAI) and PPAP support (upon request)

Elimold's quality inspection process

Elimold’s quality management team will strictly implement quality control measures throughout the processing process to ensure the accuracy and consistency of your custom parts. For small and large batch orders, in addition to regular inspections during the processing, a comprehensive inspection of the first piece must be carried out. In addition, our company’s quality management requirements require interval inspections throughout the production process, such as every 10 or 20 pieces, to ensure consistent quality throughout the order batch.

In addition, before shipment, Elimold’s quality management team will use a variety of tools to measure stainless steel workpieces, including calipers, micrometers, plug gauges, ring gauges, thread gauges, projectors, and coordinate measuring machines (CMM). And record the measurement data, and rework any parts that exceed the specified tolerances. After rework, the parts must be inspected again to ensure quality.

Lead Time and Turnaround Time

Lead time for CNC machined stainless steel parts is critical to planning your production schedule. Please confirm the quote and reconfirm after placing the order. You can also ask the supplier to provide a schedule for a specific project, which includes material procurement dates, estimated processing dates, EMD dates, QC dates, and logistics dates. This helps ensure that high-quality parts are produced on time for large and important projects. Elimold’s regular lead time for CNC stainless steel parts is 5 to 7 business days. For fast-delivery projects, lead time can be reduced to 1 to 3 days.

Customer Support and Communication

Clear communication, timely response and mutual collaboration are essential for projects. The project manager or account manager should have a clear understanding of the customer’s part requirements and convey the information to the factory engineer. Any misunderstanding may lead to project failure. Due to the time difference, our business team cannot send only one email a day. This will slow down the project progress. Therefore, Elimold will arrange the work according to the customer’s working hours and respond to any customer requirements in a timely manner. And we also provide customized solutions for each project according to the specific needs of the customer.

At Elimold, our project managers work from 9:00 am to 10:00 pm. We use email, WhatsApp and Skype for instant communication. They will reply within 30 minutes after receiving your message. For each project, we will arrange an engineer to provide technical support together with the project manager. Detailed project schedules are provided for important projects and updated daily.

Packaging & Shipping

Parts are produced on time and pass quality inspection. Don’t let packaging and shipping ruin your project. Stainless steel has a density between 7.75 and 8.05 g/cm³, so stainless steel CNC parts can be heavy. Elimold’s experienced quality management team knows that small and large stainless steel parts require very different packaging methods. Professional and safe packaging is essential.

Therefore, Elimold’s team wraps the parts with white or kraft paper for smaller CNC stainless steel prototype parts to prevent the parts from touching each other. We then wrap the components with multiple layers of pearl cotton and secure them with stretch film. For small CNC stainless steel parts, vacuum-formed packaging boxes are a viable option. For larger parts, we use wooden boxes after proper packaging to avoid damage. We take every measure to ensure that the parts will not be damaged during transportation.

Ready to start your project?

Contact the experts in stainless steel CNC machining today! Our team is standing by and ready to answer your questions or provide a quote for your project.

Surface Treatment of Stainless Steel CNC Parts

We can provide you with the best quality surface treatment to make your stainless steel parts look better and perform better. We select the most suitable surface finishing process according to your project needs and expectations; our experts are very careful in the selection process to ensure that the parts are not only beautiful, but also perform better, thus improving the overall performance and enhancing the overall appearance.

- Heat treatment

- Anodizing

- Deburring

- Painting

- Packaging

- Polishing

- Sandblasting

- Assembly

- Testing

- Kitting

- Coating

- Plating

- Brush Grain

- Spraying

Industries We Serve

We provide the CNC machining for stainless steel parts used in the following industries:

- Oil and gas

- Petrochemicals

- Heavy equipment

- Catering

- Food processing

- Medical

- Agriculture

- Automotive

- Architectural

- Construction

- Electronics

- Renewable energy

- Mining

- Furniture

Parts Made by CNC-Machined Stainless Steel

Stainless steel parts are popular in many industries for their strength, durability, and long-term reliability. Whether you need a prototype or a full production run, we can provide a custom stainless steel part solution. At Elimiold, we specialize in custom stainless steel parts and assemblies to meet your exact needs and specifications. Here are some of our custom CNC stainless steel parts:

- Actuators, arms

- Check valves

- Pivot balls

- Valve seats

- Read heads

- Armature assemblies

- Solenoid valve seats

- Flexures

- Grid clamps

- Night vision goggles

- Brake fluid flow control

- Military aircraft

- Air flow regulators

- Signal encoders

- Pneumatic valves

- Hydraulic piston seats

- Electronic controls

- Satellite components

- Body, columns

- Housings

- Octopole housings

- Nozzle adjustment

- Plate

- Outlet adapters

- Gun bodies

- Drilling slot blocks

- Mix head inserts

- Nozzles

- Optical elements

- Beam direction

- Direction

- Adjustment

- Fluid flow

- Inkjet printer heads

- Ink absorber blocks

- Nozzles

- Urethane applications

- Micro tips

- Hemispheres

- Drive rods

- Nozzle housings

- Instrument covers

- Inkjet nozzles

- Inkjet pistons

- Circuit board manufacturing

Difficulties of Stainless Steel Machining

Stainless steel is very difficult to machine. It has very low machinability compared to many other materials. Stainless steel can be very taxing on tools and machine tools if not handled correctly. For example, if you drill too fast, you can damage the tip of the drill and harden the material in front of the drill. This can make the rest of the hole more difficult or sometimes impossible to complete. This can make your life very difficult. Therefore, when choosing a stainless steel machining shop, you need to choose a machine operator who has the tools and experience to do it right.

Other Steel Materials

Tool Steel CNC Machining

Mild Steel CNC Machining

Alloy Steel CNC Machining

Custom Machining More Materials

Elimold is more than just a custom CNC machined stainless steel parts manufacturer. We can also machine a wide range of materials, providing a complete manufacturing service from concept to production to final realization. In addition to stainless steel machining, we also machine:

- Titanium Alloys

- Cobalt Chrome Alloys

- Tungsten Alloys

- Inconel®

- Plastics

- And more.

CNC Machined Stainless Steel Parts Solutions

Step into the future with our exceptional CNC machined stainless steel parts production solutions. We not only lead the precision production industry, but also revolutionize custom manufacturing to meet precise needs. Our next-generation processes ensure exquisite craftsmanship, while our team of experts master the perfect combination of art and engineering. Your wishes are our blueprints. We excel in quality optimization and provide you with personalized solutions that exceed your expectations. Witness our unprecedented performance, we turn carefully crafted blueprints into practical results. Dominate your field with our customizable stainless steel parts manufacturing services with tailor-made perfection. Your vision and our superior quality work together to create unparalleled precision.

Request Your Free Stainless Steel CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Stainless Steel CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.