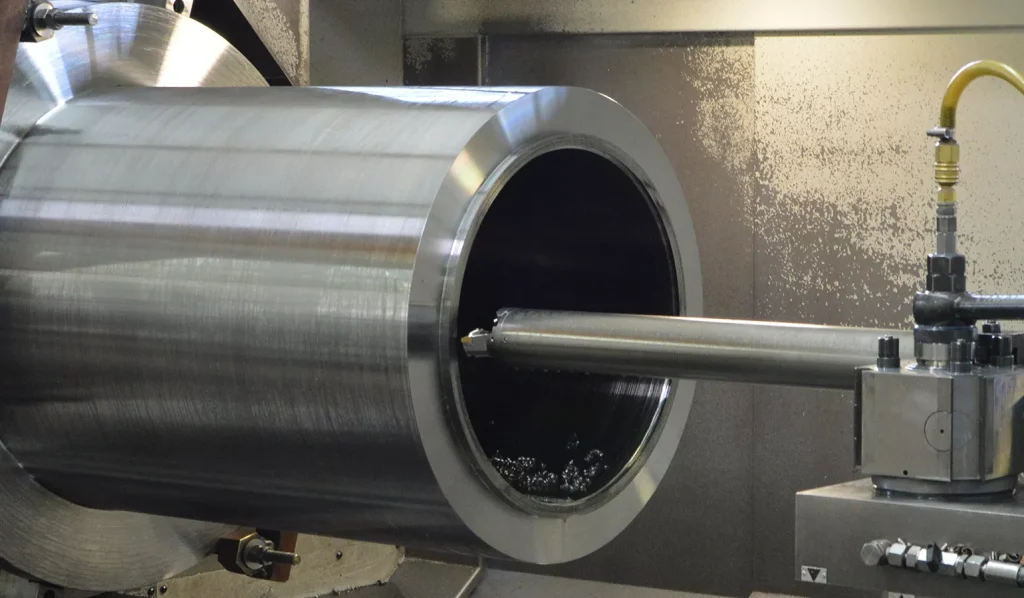

CNC Boring Services

Elimold offers a variety of CNC boring services, including horizontal boring, vertical drilling, and single-point drilling. Our team of experts is equipped with the latest technology, training, and capabilities to provide the best size, straightness, and overall accuracy for any application. Contact us now for a free instant quote.

CNC Boring Manufacturers

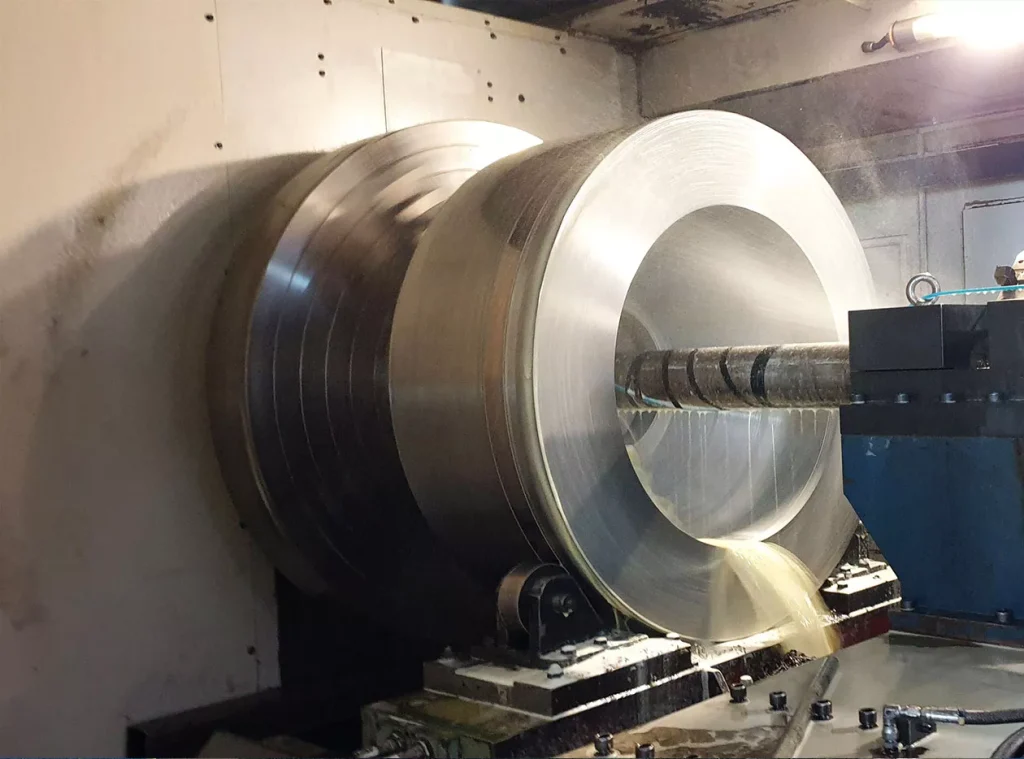

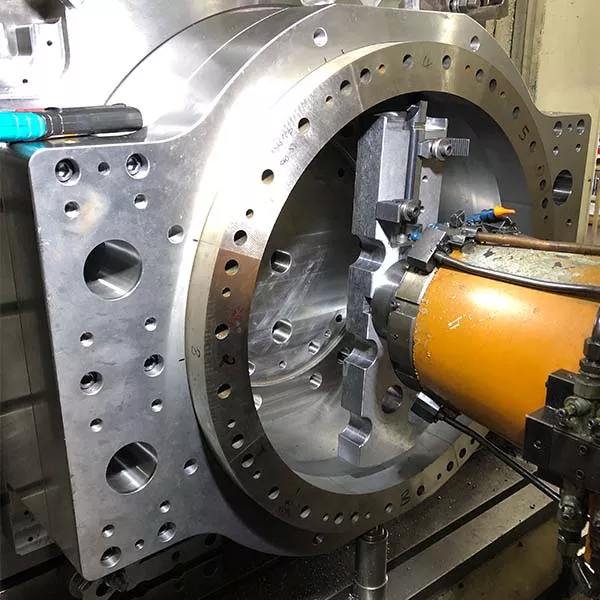

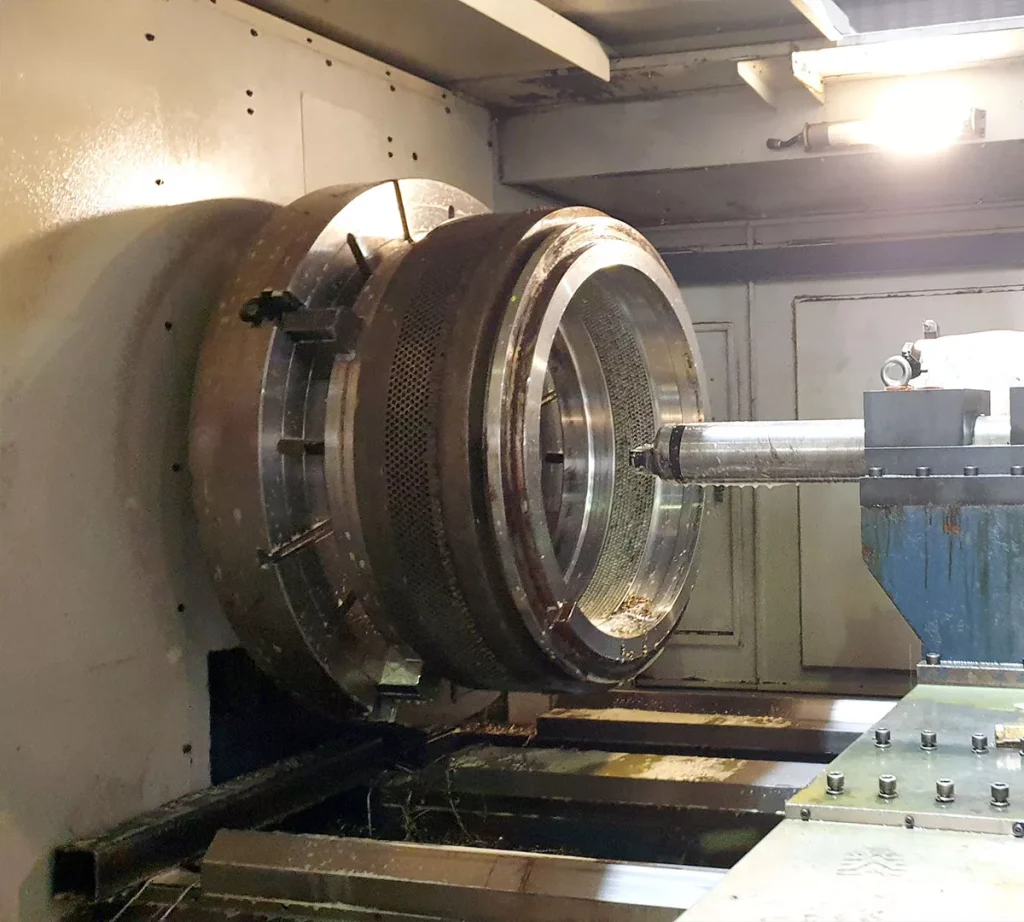

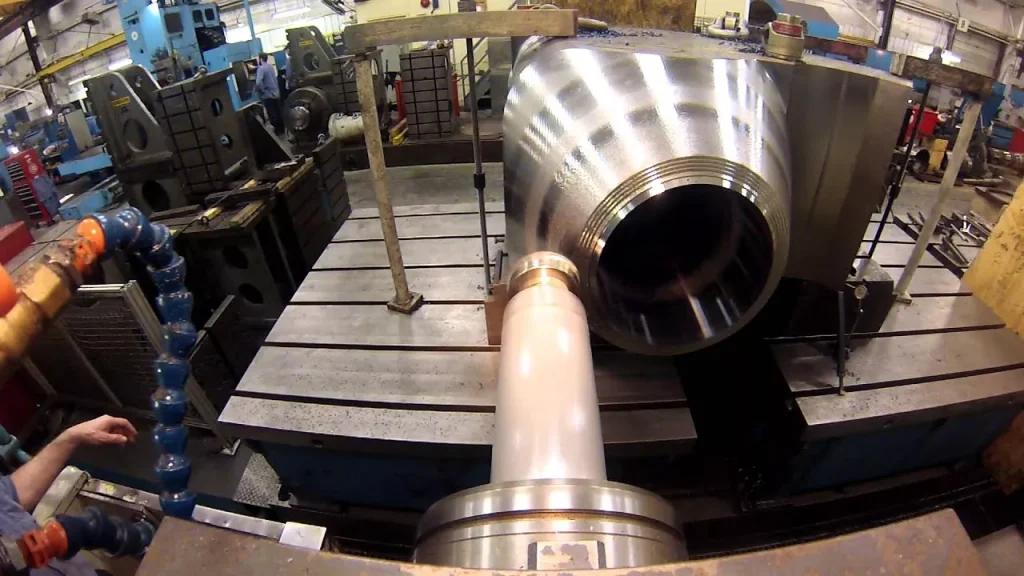

Elimold’s expertise in CNC boring services stems from its comprehensive approach to precision machining. With a foundation of advanced technology and skilled craftsmanship, our expertise in CNC boring services is the result of the company’s commitment to the highest standards of excellence. With a foundation of advanced technology and skilled craftsmanship, custom solutions can be provided to meet the needs of a wide range of industries. From large industrial projects to complex precision components, Elimold has the resources to handle large-scale machining needs in-house. We have a large fleet of state-of-the-art machinery, skilled machinists, and the ability to provide you with quality boring mill services and precision parts. We utilize a variety of horizontal boring mills that can easily handle parts that require a working envelope as large as 60 inches x 80 inches x 120 inches. Using our precision boring mills, we can quickly and accurately machine parts to meet your unique and exacting specifications. Even if our largest vertical machining center cannot meet your requirements, we will provide another option to meet your unique needs. Our line of horizontal boring bars accommodates parts up to 80” x 100” and weighing up to 10,000 lbs. In addition, Elimold’s in-house large-part CNC machining factory incorporates the latest technological advances in CNC boring, using state-of-the-art equipment and advanced machining strategies, as well as the use of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software to ensure meticulous planning and execution. So, whether you just need a prototype or large-scale production, Elimold has the perfect CNC equipment to meet your needs. In addition, we offer expedited service on top of our already fast 2-3 week turnaround time. Contact us now for assistance and a quote for an upcoming project.

Large Part CNC Boring Factory

We provide CNC boring machining services for the fabrication of a wide range of large, high precision, high accuracy products. We can also achieve cost-effective manufacturing for both one-off and mid-volume production runs. With a large number of available machines in our 40,000 ft. in-house facility, we are fully equipped to handle all of your CNC boring machining and fabrication needs, including rush jobs at an additional cost. The state-of-the-art equipment in our in-house facility is vertically integrated, and our value-added capabilities extend well beyond machining, offering a range of services from cutting to painting and powder coating. Our machining and fabrication capabilities and tooling, along with ISO 9001:2015 and AS 9001 certifications, make us an ideal choice for nearly all CNC boring machining needs. Feel free to contact us for assistance and a quote for an upcoming project.

Large CNC Boring Capabilities

Our drilling equipment includes automatic lathes and horizontal boring mills. We are able to machine workpieces as large as 48″L x 24″H x 24″W with a workpiece load of 6,600 lbs. Typical tolerances are 0.0001″. Our production capabilities include full-volume production, low-volume production, and rapid prototype production – all to our high quality precision standards. Our custom machined parts meet standards across a variety of industries around the world, ensuring your parts will meet your exact requirements and perform as expected in the finished product. Elimold is known for manufacturing the highest quality custom CNC boring parts to our customers and is committed to providing each customer with a custom boring solution for their application.

CNC Boring Process Types

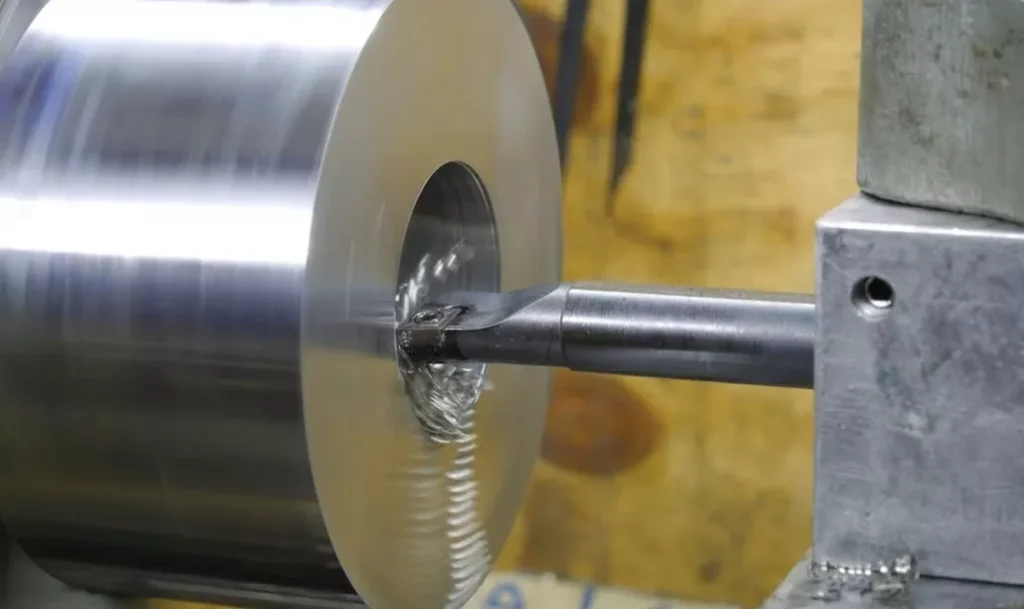

When you need to enlarge and refine an existing diameter for your next project, Elimold’s boring services are the solution! Our horizontal and vertical boring machines allow us to provide both long and short hole services to meet your specific needs.

Horizontal Boring

Vertical Boring

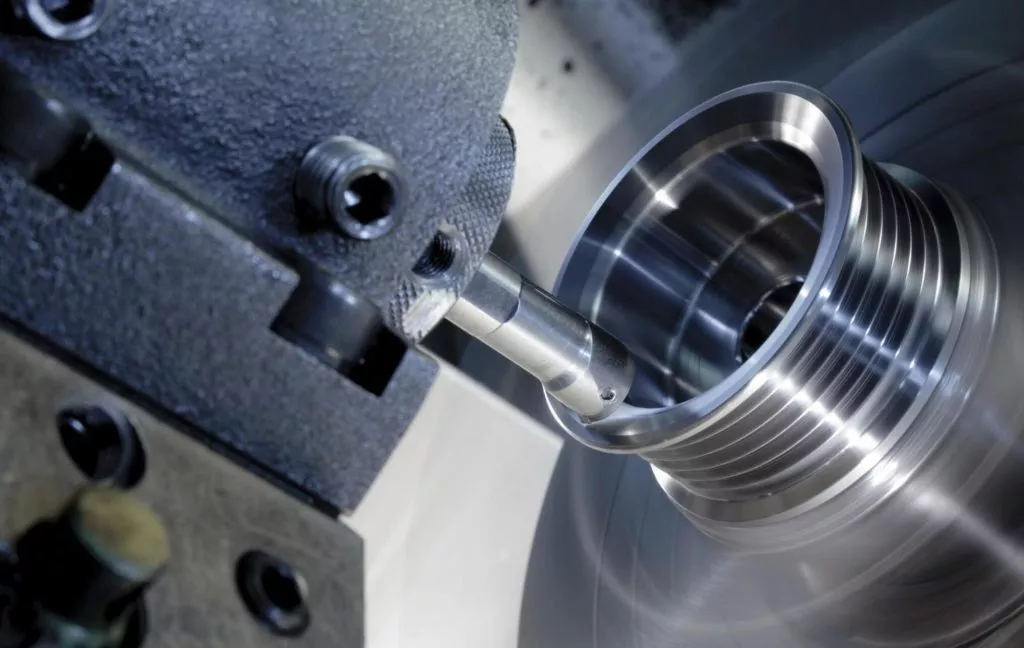

Precision Boring

Full Range of CNC Boring Services

Elimold’s team of engineers specializes in CNC boring technology to achieve maximum cuts and efficiency in our ISO 9001:2015 certified CNC boring machine shop. Our engineers are equipped to drill various grades and sizes of material, up to 45 Rc steel, and will leave 0.050 inches of excess stock to hone to meet all standard, metric or oversize requirements. Our machines can handle boring operations on parts of nearly any shape, size and material. They provide precise positioning, accurate round holes and the high-quality surface finish that our customers demand. Elimold is capable of performing many types of drilling operations such as straight holes, tapered holes, conical holes, eccentric holes and more. Our process can also achieve the straightest inside diameters, better wall thickness and better surface finish by enlarging and finishing the hole with greater precision. The process also removes all stock faster in one pass, is ideal for smaller diameter applications, and leaves a high-quality surface finish. Our team that performs drilling operations on lathes has many years of experience to meet your requirements. We keep up with the ever-changing technological advancements and diverse customer needs to ensure that your greatest needs are always met.

Comprehensive CNC Boring Capabilities

Long Drilling Capabilities:

- 36″ diameter, 28′ long

- 40″ diameter, 30′ long

- 27.5″ diameter, 38′ long

Large Diameter Boring Capabilities:

- Up to 50″ inside diameter (ID)

- Up to 12′ long

- We can also perform single point drilling up to 41″ deep

- Custom fixtures designed and manufactured in-house

- Prototyping of new parts and reverse engineering of replacement parts

Quality Control Measures

- Pre-processing inspection: Check raw materials for defects such as voids, inclusions or misaligned pre-made holes.

- Tool monitoring and calibration: Ensure drilling tools remain sharp and accurately calibrated.

- Process monitoring: Use sensors and feedback systems to maintain consistent cutting speeds and feeds.

- Post-processing inspection: Perform a comprehensive dimensional and surface inspection of all critical holes.

- Non-destructive testing (NDT): Includes ultrasonic and penetrant testing to detect hidden defects.

- Compliance with standards: Comply with ISO 9001 and other industry-specific quality standards.

- Traceability: Record dimensional data, material properties and process history of each part for accounting purposes.

Dimensional Inspection Equipment

- Precision Bore Gauges: Measure inside diameters with high accuracy.

- Coordinate Measuring Machines (CMM): Verify hole size, alignment, and concentricity.

- Dial Bore Indicators: Check for taper, roundness, and diameter variation.

- Laser Measurement Systems: Capture high-precision data on hole geometry and surface profile.

- Ultrasonic Thickness Gages: Measure wall thickness around drilled holes.

- Surface Finish Testers: Ensure hole smoothness meets specifications (e.g. Ra value).

We can provide inspection reports

- First Article Inspection (FAI): Verifies initial hole size, surface quality, and alignment.

- Geometric Dimensioning and Tolerancing (GD&T) Report: Confirms hole location, concentricity, and roundness.

- Runout and Alignment Report: Verifies hole straightness and alignment with mating components.

- Surface Finish Report: Documents roughness and polish.

- Material Certification Report (MTR): Ensures cast or forged material properties meet project specifications.

Are you ready to use Elimold's CNC boring services?

We are able to manage both prototypes and mass production, ensuring we can meet the needs of different customers. Combined with our ancillary services, we strive to provide a comprehensive, one-stop solution to serve customers around the world. Contact us now for a free instant quote.

What is CNC Boring?

CNC Boring is a precise and accurate process that involves enlarging a pre-existing hole in a workpiece using a single-point cutting tool or boring bar. The technique is used to achieve high levels of dimensional accuracy and surface finish, making it an essential technology for industries where precision is critical. Unlike drilling, which creates an initial hole, boring can improve the accuracy and size of an existing hole. The process is performed using a boring machine, which can be configured to bore horizontally or vertically as required. This technique is fundamental to the manufacturing industry, where precision and accuracy are critical to ensure that the machining process meets industry standards and specifications. Through the application of CNC machining and advanced technology, boring can produce highly precise and accurate results, and this versatility makes boring an indispensable machining technology in today’s manufacturing industry.

Materials for Precision CNC Boring

CNC boring is commonly used for a variety of materials, each with unique properties.

- Titanium

- Aluminum

- Copper

- Brass

- Bronze

- Carbon steel

- Stainless steel

- Inconel alloy

- Monel alloy

- Hastelloy alloy

- Stellite alloy

- Nimonic alloy

- Rene Alloys

- Alumina

- Zirconia

- Aluminum-based Silicon Carbide

Surface Finishes for CNC Bored Parts

Surface finishes for CNC bored parts enhance the functionality and aesthetics of machined components. Options include polished, ground, and smooth surface finishes that ensure tight tolerances, reduced friction, and optimal performance. These surface finishes are critical for precision parts across a variety of industries.

- Thermal Coating

- As Machined

- Painting

- PVD (Physical Vapor Deposition)

- Sandblasting

- Electroplating

- Polishing

- Anodizing

- Powder Coating

- Electropolishing

- Passivation

- Brushing

- Black Oxide

- Heat Treatment

- Thermal Barrier Coating (TBC)

- Tumbling

- Alodine

- Chrome Plating

- Phosphating

- Nitriding

- Galvanizing

- UV Coating

- Lacquer Coating

- Teflon Coating

CNC Boring Industries and Applications

CNC boring machining is widely used in multiple industries and can be used in a variety of precision applications to achieve precise results, utilizing its ability to create accurate holes and achieve tight tolerances. The following industries are common precision applications that require CNC boring manufacturing.

- Aerospace and Aviation: Aircraft engine components, Turbine housings, Landing gear assemblies

- Power Generation: Steam turbine shafts, Generator housing bores, Gas turbine components

- Oil and Gas: Drill pipe connections, Valve body bores, Pump casing bores

- Consumer Products: Motor housings, Appliance components, Gear assemblies

- Medical Device: Surgical instrument shafts, Implant channels, Medical device housings

- Agricultural Machinery: Hydraulic cylinder bores, Gearbox components, Engine block components

- Automotive: Engine blocks, Transmission housings, Differential housings

- Robotics: Actuator housings, Robot arm joints, Gearbox components

- Automation: Pneumatic cylinder bores, Actuator housings, Control valve housings

- Industrial Equipment: Gearbox housings, Pump casings, Compressor bodies

- Nuclear: Reactor pressure vessel openings, Fuel rod channels, Control rod housings

Other CNC Machining Processes

At Elimold, our extensive experience in boring operations allows us to serve a variety of industries with exceptional precision and quality. Additionally, we can offer 3 to 5 axis CNC milling, CNC turning, and Swiss lathe machining, and our dedicated and skilled team can achieve tolerances up to +/- 0.0002 inches (±0.005 mm).

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Boring vs. Other Machining Methods

Boring vs. Drilling

Boring and drilling are both drilling processes, but they differ greatly in their execution and application. Drilling requires a rotary tool to drill the hole, while boring machines combine automation and precision control, making them ideal for workpieces that require high precision. Drilling requires a rotary tool to drill the hole, while boring uses a single-point cutting tool to refine an existing hole, ensuring precise dimensions and excellent surface finish. Drilling is best suited for simpler holes, while boring excels at achieving higher precision and desired surface quality in existing holes. Existing holes.

Boring vs. Turning

Boring and turning are both machining techniques that involve rotary motion, but they differ in their methods. CNC turning processes primarily the outer surface by removing material from the surface. Turning processes primarily the outer surface by removing material from the outer diameter of the workpiece, while boring focuses on refining the inner surface, improving the accuracy and finish of existing holes. Despite their differences, both processes help achieve specific dimensional and surface requirements. Despite their differences, both processes help achieve specific dimensional and surface requirements.

Boring vs. Countersinking

Boring and countersinking have different functions. Boring involves enlarging or thinning a hole to a precise size to ensure the best fit and function of a component. Countersinking, on the other hand, creates a tapered recess at the top of the hole to accommodate the screw head, enhancing the flushness of the fastener with the workpiece surface. Each method meets different needs in machining and assembly.

Request a Quote on your Machining Project Today

Whether you are manufacturing components for machinery, aerospace or other industries, boring technology provides the precision and versatility needed to meet demanding requirements. You can leverage Elimold’s precision CNC boring service capabilities to improve the quality of metal processing and drive innovation across a variety of applications. Contact us today to help you.