Oil & Gas Die Casting

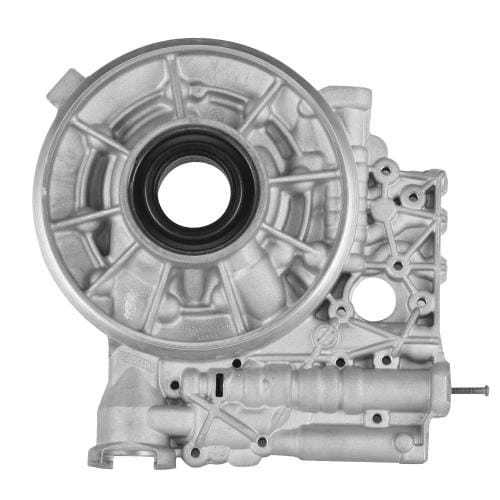

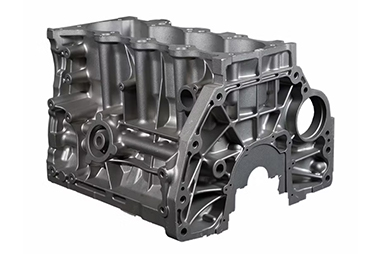

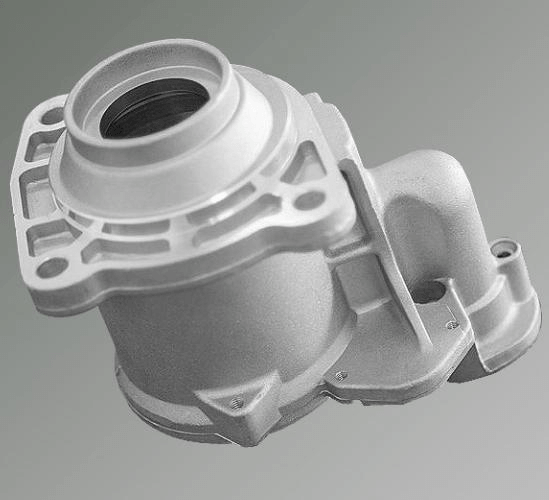

Elimold provides die casting solutions for the oil and gas industry. We work with a variety of materials including aluminum, brass and bronze. We specialize in casting components with complex core passages and thin walls, and provide tight tolerances to meet your design specifications.

Oil & Gas Precision Casters

Elimold is a NACDAP-accredited and AS9100-certified foundry with many years of experience in die casting. Our die casting experts can help you with everything from troubleshooting your design to selecting the right alloy for your operating environment.

We specialize in casting parts with complex core channels and thin walls, and provide tight tolerances to meet your design specifications. Other services for oil and gas castings include NADCAP-accredited heat treatment and welding and non-destructive testing to ensure the integrity of the casting.

A Team of Oil and Gas Industry Experts

The Oil and Gas industry specifies some of the most carefully engineered components for volatile, high-pressure applications due to the risk of catastrophic failure. We and inexperienced suppliers are not an option. For centrifugal oil and gas castings, Elimold has earned the trust of most major OEM for its ability to meet the material needs specified by engineers. Buyers know they can trust our staff to understand, review and adhere to their specifications for oil and gas castings, whether industry standard or customer specific. We have the flexibility to manufacture a one-off prototype, a few repair spares, or a large production run for a new product launch. All orders receive the same level of professional attention that Elimold’s loyal customers demand. In this industry, a perfect product is essential. From liquid metal to finished component, every step of production is monitored through Elimold’s highly regarded quality program.

Our Capabilities

Elimold has extensive experience working with oil and gas equipment manufacturers. We manufacture large nickel aluminum bronze pump casings for deep sea oil production, with castings weighing up to 870 pounds and pour weights up to 2400 pounds. Air molds weigh over 8000 pounds. Our castings operate in harsh acidic and alkaline environments that would destroy steel in two weeks. The aluminum bronze will show no signs of wear or corrosion after years of use. They pump fluids at 3000 psi. We have developed a special high pressure static mold design that produces flawless, completely non-porous castings that can withstand these pressures. These castings range in size from 275 pounds to 870 pounds. They are complex castings that other foundries cannot do, but are standard product for us.

We also produce thousands of valve casting parts used in the storage, transmission and production of oil and gas. Specified alloys include C83600, C83450, C95400, C95500, C90300, C92200, etc.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Sand Casting

Investment Casting

Die Casting

Low Pressure Casting

Permanent Mold Casting

Lost Foam Casting

Centrifugal Casting

Vacuum Casting

Precision Castings for the Oil and Gas Market

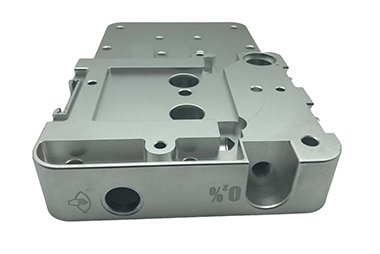

Elimold manufactures precision products for the oil and gas industry. Our custom products are made from a variety of materials including aluminum, stainless steel, tool steel, cobalt, Inconel and Hastelloy, and are durable enough to withstand high temperatures and high cycles of use. Using precision die casting, sand casting or multi-step investment casting processes, we provide castings including instrument housings, ball and needle valve assemblies, impellers and flanges with precise details and tight tolerances.

Elimold offers low-volume and high-volume production, as well as rapid prototyping to develop custom products. We also offer a range of non-destructive testing to ensure we meet or exceed stringent quality and performance standards, including X-ray, magnetic particle and dye penetrant testing.

In-house Design and Fit-out Services

In addition to die casting, Elimold also offers early design engineering development and prototyping services as well as complete in-house secondary solutions including cnc machining, finishing and assembly. Our quality management system is certified to ISO 9001:2015 and we employ all forms of technology including:

- Visi-Trak process monitoring

- MAGMA casting simulation

- X-ray: Digital radiography (real-time), computed radiography (CR) and traditional film

- CAD systems: Pro/ENGINEER and SOLIDWORKS

- Full metallurgical and non-destructive testing labs

Why Choose Elimold for Your Oil Industry Castings

In the oil industry, component failure is not an option, and quality is not just an added benefit, but a necessity. That’s why we’ve invested in quality certifications that set us apart in the field. Our certifications are more than just badges; they demonstrate our unwavering commitment to delivering excellence:

- ISO 9001:2015: As an ISO 9001:2015 certified supplier, we adhere to international quality management standards. This means our operations are rigorously externally audited and we continually meet and exceed customer expectations through continuous improvement.

- Heat Treatment: Our heat treatment certification guarantees that we have the in-house capability to modify the physical properties of our materials to meet your specific requirements. Through heat treatment, we can increase durability, improve corrosion resistance, and optimize performance in extreme conditions.

- NDT (Non-Destructive Testing): Our certified non-destructive testing methods, including radiography and penetrant techniques, allow us to meticulously inspect the structural integrity of each component without causing any damage. This ensures that every product that leaves our facility meets the highest standards.

- Welding: Our welding certification ensures that our welded components can withstand the tremendous pressures and extreme environments common in oil industry applications. Each weld is made with unrivalled technology, ensuring maximum durability and reliability.

We Make Oil Industry Castings Different

Our goal is not just to provide you with products; we aim to provide you with solutions that bring unparalleled efficiency and reliability to your operations.

We are masters of investment casting, capable of manufacturing parts with complex core channels and ultra-thin walls. These complexities, often seen as challenges in the industry, are opportunities for us to showcase our craftsmanship. Our state-of-the-art technology and skilled engineers ensure that these complex structures do not compromise the integrity of oil industry castings.

When it comes to tolerances, we know that oil industry castings have no room for error. That’s why we go to great lengths to meet (and often exceed) your design specifications. Our quality control protocols ensure that every casting we produce meets the closest tolerances, ensuring not only a fit, but a perfect fit.

Die Casting Manufacturing Solutions for a Wide Range of Applications

Elimold has extensive expertise in serving a wide range of industries, working with long-standing OEMs, Tier 1 suppliers and other supply chain members. We work closely with industries such as Oil & Gas, Aerospace, Defense, Renewable Energy and General Engineering. Our castings meet Baseefa and Atex standards.

Our facility in China includes a premium commercial grade investment casting and high integrity aluminum casting production line. Utilizing our innovative die casting casting process, we can provide precise, high integrity aluminum parts to meet your requirements, working closely with customers in the Oil & Gas, Aerospace, Military, Electronics and Motorsport industries.

We are proud to provide outstanding engineering services to the industry. At Elimold, we have some of the best minds in the industry working behind the scenes to provide the most appropriate and economical engineering solutions to meet the demanding needs of the industry. We have worked with many of the industry’s leading operators and understand the importance of tight machining tolerances, accurate lead times and timely delivery.

We also have the equipment, processes and quality standards required to produce castings and components for this industry. Our components are quality checked under the ISO 9001:2015 quality management system and comply with the international quality standards specified by our customers.

Oil & Gas Die Casting Applications

We have the capability to manufacture different Oil & Gas castings for the Oil & Gas industry as listed below:

- Cylinders

- Aluminum housings

- Heatsinks

- Cover

- Electrical boxes

- Power transmission equipment

- Fan blades and hubs

- Gear boxes

- Gearboxes

- Hubs

- Hydraulic cylinders

- Impellers

- Manifolds

- Marine components

- Oil pans

- Pistons

- Pressure housing

- Pump components

- Suspension components

- Transmission channel plate

- Valve body

- Valve body

- Wind power generation equipment

Ready to get die casting solutions for your next oil and gas project?

Elimold specializes in complex, pressure-resistant aluminum castings and thermoplastic injection molded parts. We offer complete in-house precision machining, finishing, and assembly services. Contact us to learn more about our capabilities and discuss your die casting project!