Laser Engraving Services

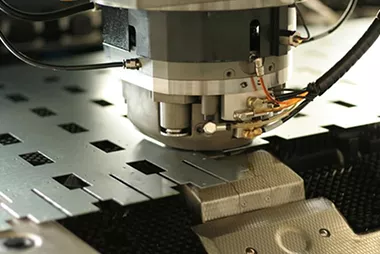

Are you looking for high-precision laser engraving services? Our in-house facility has a wide range of laser engraving machines capable of processing a wide range of materials, including delicate surfaces. We are a trusted provider of laser marking and engraving services with many years of experience. Request a quote to learn more about our laser engraving services.

Laser Engraving Service Provider

Elimold is an excellent laser engraving service provider committed to providing the highest quality products. Laser engraving is a precise and adaptable technology that can etch patterns or marks on a variety of materials. To meet the needs of a wide range of customers, Elimold offers a variety of laser engraving services, including deep engraving, surface engraving, and rotary engraving.

We use modern laser technology to ensure excellent accuracy and fine details. Permanent marking, high precision, and the ability to engrave complex patterns or text are just some of the many advantages of laser engraving. We can undertake engraving jobs of all sizes, even large-scale production. We have complete facilities to meet all your engraving needs. Our service value is extraordinary and the craftsmanship is unparalleled. We pride ourselves on excellent service, reasonable prices and on-time delivery. Welcome to contact us to discuss your specific engraving application and our team will guide you every step of the way.

Types of Laser Engraving

Whether our customers’ projects require decorative designs, or essential product markings such as measurement lines, we can meet their needs with high-quality engraving. We are committed to continuously improving and expanding our engraving capabilities, which also enables us to provide customers with a wider range of project options.

Micro Engraving

Deep Engraving

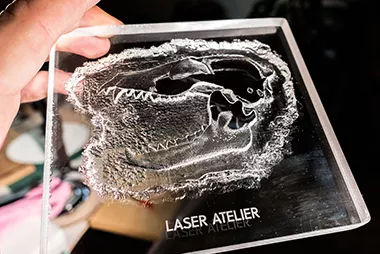

3D Engraving

Custom Laser Engraved Parts Manufacturer

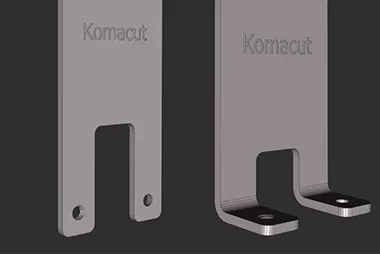

Elimold’s laser engraving services have produced custom parts for engineering and artistic applications, hobbyists, and well-known American brands. CNC engraving is a subtractive manufacturing technology that produces excellent results for parts with tight tolerances and fine details. Using laser engraving to produce custom parts that require engraving, such as text or patterns, can provide our customers with unparalleled cost savings and improve material utilization throughout the production process. The processed parts are ready for the consumer market after the operation is completed. Each order goes through a mature pre-production process, including testing and setting processing parameters, cutting optimization, and material utilization optimization. We implement a comprehensive quality assurance program to ensure high-quality parts with high geometric accuracy, burr-free edges, and a factory-smooth surface finish. Our laser engraving service has unparalleled repeatability and fine feature tolerances of +/-.0001 inches, which is more stringent than many industrial standards.

Our team of highly trained laser operators not only have extensive backgrounds in laser processing technology, but also have extensive experience in the aerospace, medical technology, and gasket manufacturing industries. CNC laser engraving has disrupted some of our traditional manufacturing processes and significantly improved our ability to meet customer needs. Additional services we can provide include drawing assistance, material selection, packaging and a variety of processing capabilities.

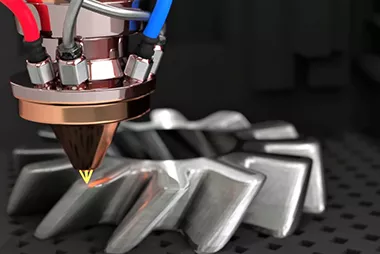

Laser Engraving Technologies

A variety of laser machine types are employed for laser engraving services. These are the three primary categories:

LED Laser

CO2 Laser

Fiber Laser

Rapid Prototyping & Design Optimization

Design assistance includes drawing updates and revisions, cost-saving strategies, kitting, and toolpath planning. Our design team has extensive experience with 2D and 3D CAD software and is proficient in laser cutting processes. It has never been faster or easier to provide assistance and expertise at every step of the production process. And with an in-house factory, dozens of industrial suppliers, and extensive warehousing capabilities, Elimold is your ideal partner for a wide range of laser engraving services and storage of manufactured parts and consumables. Our services include custom laser engraved parts, rapid prototyping and mass production, certification, and warehousing. Our wide range of materials makes it easy to source custom products, simplifying your supply chain and increasing profitability.

Custom Packaging Services

Laser engraved parts are often unique, complex, and precise, requiring unique packaging solutions to ensure safe storage and transportation. Our team designs and manufactures custom solutions for the aerospace, medical, technology, and packaging industries. Once the right packaging solution is developed, it is immediately used for subsequent orders.

- Damage protection

- Individual packaging

- Rust protection

- Bulk packaging

- Custom labels

- Instructions

Quality Management

At Elimold, we emphasize the importance of quality in all of our laser engraving projects. We consistently meet our high quality standards and customer specifications by:

- Paying close attention to each project’s requirements and restrictions

- Employing a team approach to every project

- Thoroughly inspecting and measuring every part

- Performing monthly environmental testing

- Committing ourselves to Continuous Process Improvement (CPI)

- Using in-process controls

Have a special request or creative laser engraving idea?

Elimold will work with you to develop and refine concepts, conceive new ideas and proposals, design artwork, or create custom graphics for your custom products. We are known for turning visions into reality and are committed to adding brilliance to projects that need to stand out. To get a free quote on laser engraving or ask questions about laser engraving materials, contact us now.

What is Laser Engraving?

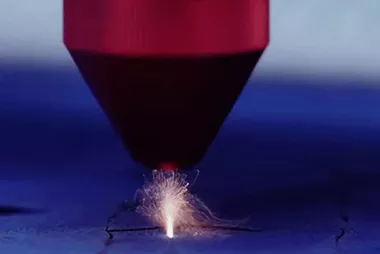

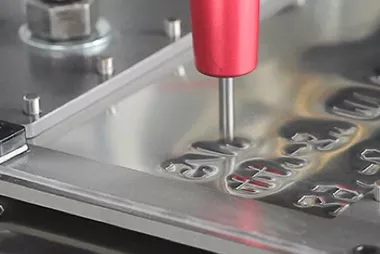

Laser engraving is a popular option that provides a permanent and legible marking on an object through etching, ablation, or deep laser engraving. It is similar to laser marking, but the resulting appearance differs due to the depth of laser penetration. Laser engraving vaporizes a small amount of material with pulses of high heat light, quickly creating a cavity that provides texture with a sharp and contrasting appearance.

Laser engraving can reach depths of 0.125 inches in material like graphite but is limited to 0.020 inches in metals, making it ideal for parts that may become worn but not for parts where safety is crucial.

Differences Between Laser Engraving and Laser Marking

The major difference between laser marking and laser engraving is the amount of material lost in the process and the depth of laser penetration. Unlike the quick, high heat laser engraving process, laser marking is a slow, low energy, low temperature process that discolors the surface of the object without leaving a notable texture.

Laser Marking is the most versatile of all marking methods. Laser Marking is a non-contact form of marking in which a CNC machine directs a laser beam as small as 0.002” in diameter to cut through a part to a desired depth. Laser Markings with depths greater than 0.002” are considered to be Laser Engraved, while Laser Markings with depths 0.002” or shallower are considered to be Laser Etched.

Laser Engraving is ideal for parts that require a deep mark (over 0.030” deep), but cannot withstand the high stress that results from other marking methods, such as Engraving or Impression Stamping, which put the part in direct contact with a cutter or a die.

Material Options

The laser engraving process is suitable for a wide range of materials. Below is an overview of the materials we typically work with.

- Acrylic

- Alloys

- Aluminum

- Anodized Aluminum

- Brass Bronze

- Carbon & Carbon Fiber

- Ceramic

- Circuit Boards

- Coated Metals

- Cork

- Copper

- Fiberglass

- Galvanized Steel Glass

- Leather

- Mylars

- Paper

- Rubbers

- Stainless Steel

- Steel

- Tile

- Titanium

- Wood and Composites

Benefits of Custom Laser Engraving

Laser engraving may just be the solution you need to take your project to the next level. Benefits of using laser technology for industrial applications include:

- Highly efficient

- Compatible with a range of materials and depths

- Provides excellent quality and repeatability

- Produces zero wasted material

- Cost-effective option for lower production volumes

Alternatives to Laser Engraving Service

Some alternative Elimold capabilities that can be used instead of laser engraving service include:

CNC Machining

3D Printing

Waterjet Cutting

Laser Engraving Applications

Despite its limitations in terms of versatility, laser engraving remains a highly adaptable technology with extensive applications. Here are a few typical applications for laser engraving, along with some examples of industries that profit from them:

- Automotive parts

- Barcoding

- Bicycle Parts

- Flashlights

- Firearm Components

- Hardware tools

- Hunting equipment

- Machine parts

- Medical components and devices

- Product branding and personalization

- Protective housings

- Surgical equipment and instruments

Other Sheet Metal Fabrication Services

Elimold provides a variety of sheet metal fabrication services to customers in a variety of industries. These fabrication processes have different principles, they achieve different results and are suitable for different fabrication projects.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

Embossing

Request Your Free Laser Engraving Quote Today

After receiving your drawings, our engineers will analyze your custom Laser Engraving parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.