Sheet Metal Fabrication Services

Elimold offers a wide range of sheet metal fabrication services. Our team of experts can meet all of your fabrication needs, including comprehensive design, engineering and manufacturing services. We are committed to delivering on time, on budget and with great value, no matter the size of your project. As a leading sheet metal fabrication service provider, our team is ready to provide excellent sheet metal fabrication services that exceed expectations. Contact us now for a free instant quote.

Professional Sheet Metal Fabrication Company

Welcome to Elimold Sheet Metal Fabrication, your first choice for quality sheet metal solutions. With a rich tradition of excellence, we have been a trusted partner in a variety of industries. Our state-of-the-art facilities and experienced team ensure that every project we undertake is precise, efficient, and innovative. From design to delivery, we always put customer satisfaction as our top priority and provide tailored solutions to meet your unique needs. With a comprehensive range of sheet metal fabrication services, we are committed to turning your ideas into reality. Experience Elimold’s unparalleled craftsmanship and reliability, your success is our ultimate goal.

Online Custom Sheet Metal Fabrication

Are you looking for a sheet metal manufacturer that can handle everything from new product development and prototype parts to high-volume production and finishing services? Elimold goes above and beyond. Our comprehensive services can help you streamline your supply chain and get your products to market faster. We offer a value engineering approach to every project. We have designed a manufacturing process that ensures your parts can be produced quickly and cost-effectively. Our experts will manage every step of the process. From design assistance and metal fabrication to surface finishing, kitting and assembly, we can provide you with thoughtful services.

Precision Sheet Metal Fabrication Service Provider

Our online sheet metal fabrication services allow you to get quotes in minutes and deliver parts in days. We provide 3D visual design for manufacturability (DFM) feedback to help you manage project costs and gain actionable design insights. With a wide range of machining and finishing capabilities, our powerful combination of technology and skilled operators can produce accurate and high-quality parts, whether your project consists of a single or multiple components. Unlike traditional sheet metal shops, we have unlimited capacity and an easy-to-use online quotation system to ensure on-time shipment every time, whether you need a single part or 50,000 parts. You can also contact our knowledgeable team of engineers to optimize part designs and get friendly production service support. From prototypes to assembly to finishing, choose a professional sheet metal supplier to shorten your production time and launch products faster.

Sheet Metal Fabrication Facility

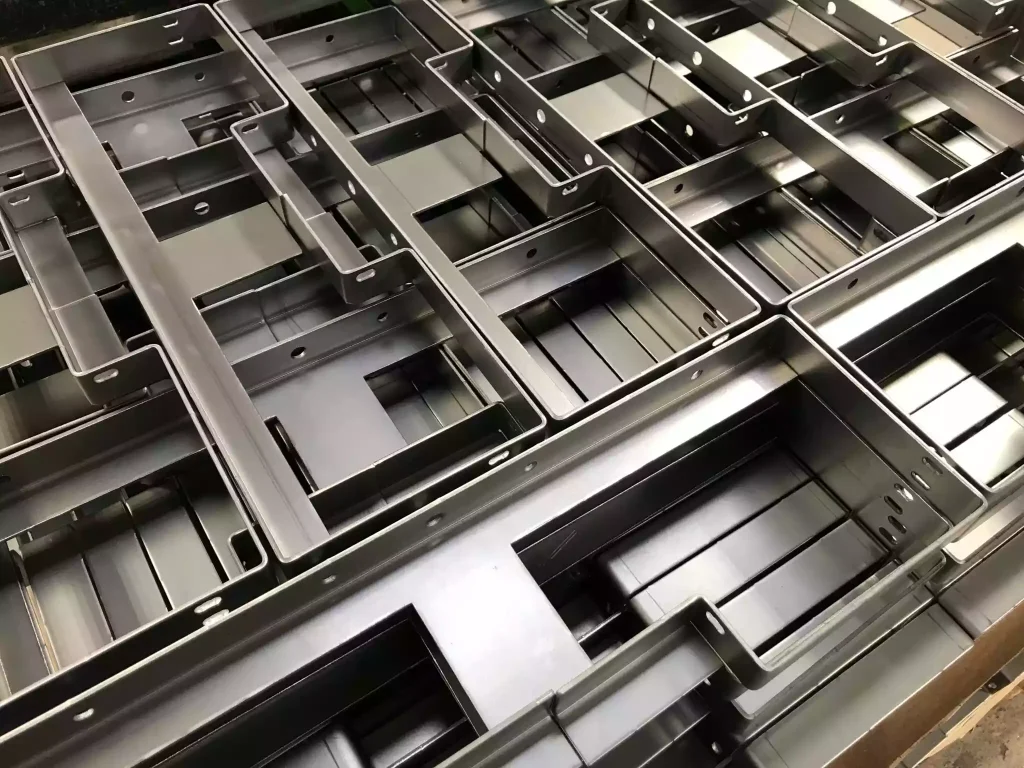

We have a sheet metal parts manufacturing facility in Shenzhen, China that can handle parts of all sizes. Our in-house facility has a staff with decades of experience and expertise to help you with your design, prototyping, and production needs. Our in-house facility’s 135,000 square foot manufacturing facility consists of three buildings, each equipped with state-of-the-art metal fabrication and material handling equipment (including laser cutters, CNC hydraulic benders, automatic seam welders, overhead cranes, and more). This equipment enables our expert craftsmen to handle nearly any metal fabrication project, so you can choose one or all of our metal fabrication services because we have everything you need. We are constantly updating our equipment to provide you with the highest quality metal fabrication services. We use 10 cranes for material handling within the facility.

Our Sheet Metal Fabrication Capabilities

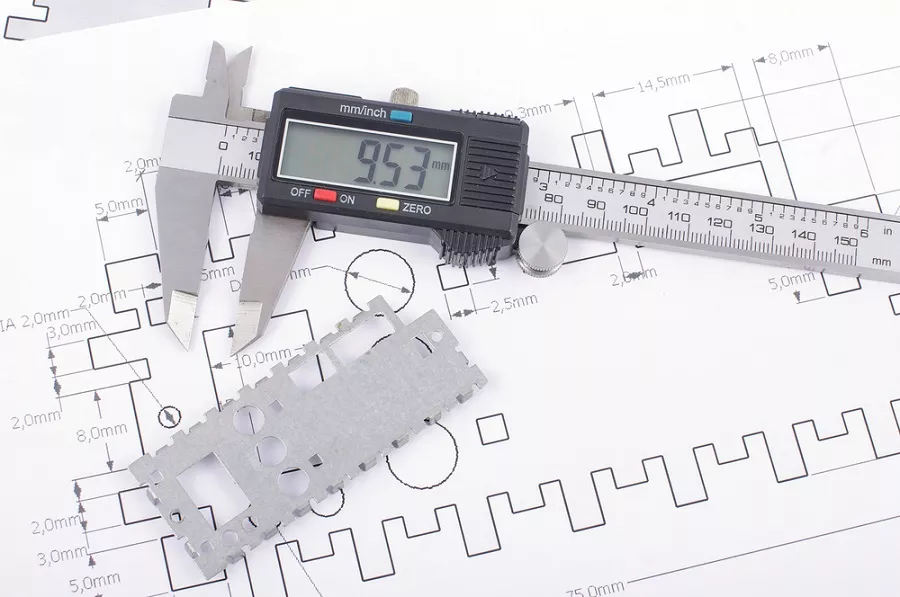

While maximum part size and thickness will vary depending on the sheet metal used, we hold all parts to the same precision. We can process material up to 8 feet in length, 3 feet in width, 2 feet in height, 0.5 inches in thickness, and 75 pounds in weight, maintaining tolerances of ±.002 inches to ±.005 inches. We specialize in prototypes to high-volume production, with a typical turnaround time of 2 to 4 weeks and a 1-week “quick lead” lead time. All of our products and processes meet the highest industry standards. We are customer-focused with a dedicated team of sales representatives and engineers. We are always ready to provide a custom design for a project or re-engineer an existing product line to improve performance and cost-effectiveness.

Custom Sheet Metal Parts Made to Your Specs

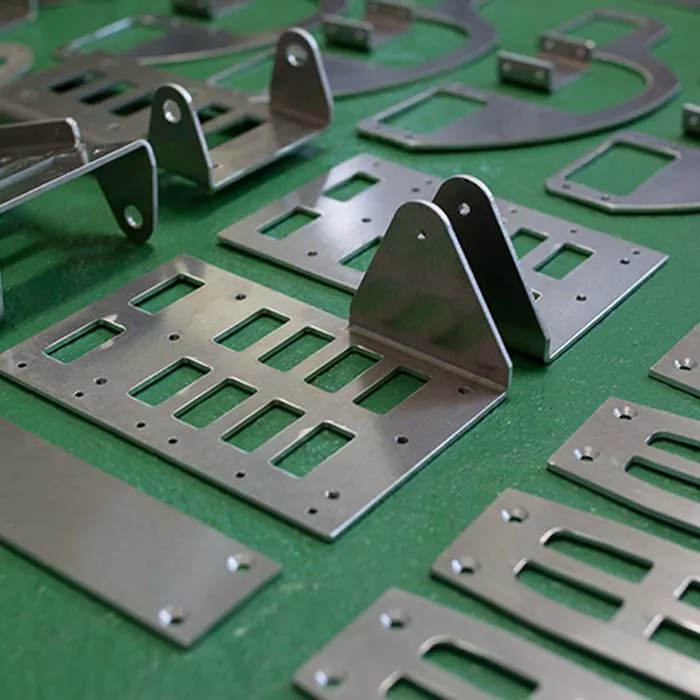

Every client and their project is different. While there are similarities in the industries and the work they do, every company and their work has its own unique nuances that make it unique. So when you need custom metal fabrication, work with a company that understands your needs. Elimold has worked with numerous clients in a variety of industries. We are able to provide custom solutions for a variety of common or special needs. So no matter what type of sheet metal part you are customizing, we are ready to help you. Our team can help you design and manufacture any project. We work closely with you from scope determination to delivery date. Our team maintains open communication and is committed to providing timely updates. And you will get the perfect solution for your project and an experienced partner who can deliver results.

From Prototype to Production

Elimold has the expertise and technology to help you meet your sheet metal fabrication needs quickly and efficiently. We can take on your project from concept to prototype to mass production. Our experts can provide you with suggestions for improvements to help you streamline the production process for your parts. In some cases, we are even able to reduce costs. We integrate lean manufacturing principles to transform innovative designs into high-quality products with superb craftsmanship and cutting-edge technology. From initial concept to final production, our team excels in creating a seamless transition from prototype to full-scale manufacturing, ensuring an efficient, waste-reducing process. This approach enables us to deliver custom and large projects while maximizing value and minimizing waste.

Types of Sheet Metal Fabrication Processes

Choose Elimold for comprehensive online sheet metal fabrication services. Our China-based facility can handle everything from small batch prototypes to high volume production. Our knowledgeable team of engineers ensures that each sheet metal part is manufactured to precise specifications and quality standards.

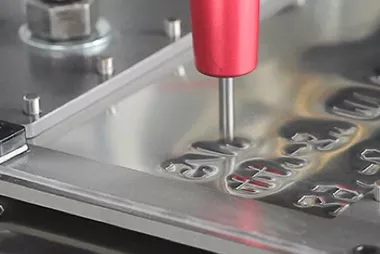

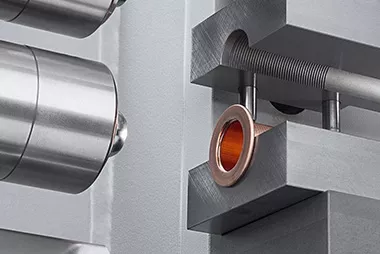

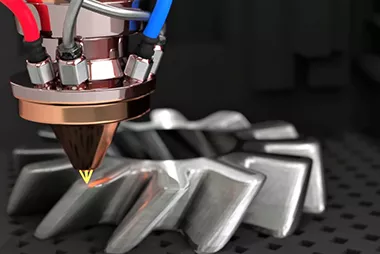

Laser Cutting

Bending

Welding

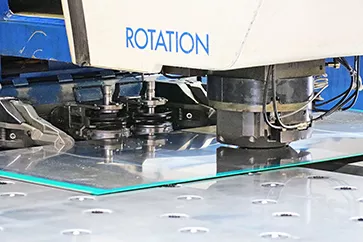

Punching

Riveting

Stamping

Plasma Cutting

Die Cutting

Extrusion

Embossing

Forming

Waterjet Cutting

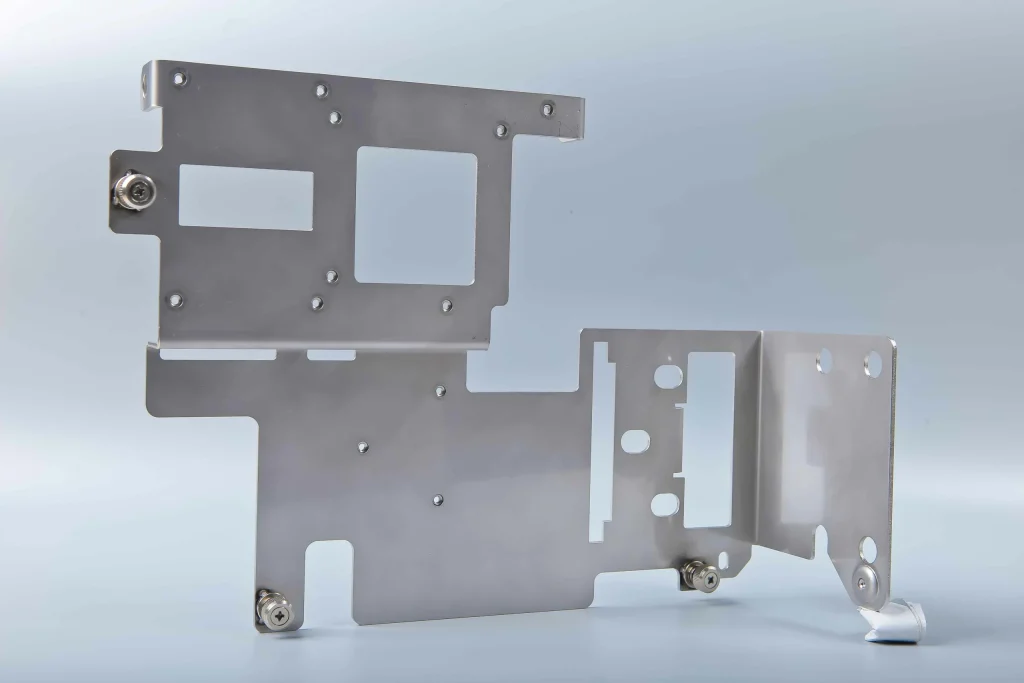

Custom Sheet Metal Parts from Concept to Installation

Our sheet metal fabrication shop can take on your project from start to finish, or step in when needed. If you need guidance on your project, our team can start by designing a custom solution based on your needs. Your ideas will be converted into suitable CAD drawings or 3D models. The design will then be submitted to you for review and approval. Once you sign off, our team will start working on creating the perfect product. Once the product is completed, we will ship it to your location along with all necessary installation instructions. We can even complete the installation according to your requirements.

Sheet Metal Rapid Prototyping Services

Our rapid prototyping services are essential to validate designs and ensure feasibility before full production. Our engineers are hands-on throughout the development process to exceed customer requirements. Using cutting-edge tools and techniques, we create detailed and accurate prototypes that reflect final product specifications. This approach allows for thorough testing and refinement, identifying and resolving potential issues early. Our expertise in complex prototyping ensures fast turnaround times without compromising quality. By providing realistic, working prototypes, we help customers experience and refine their designs, paving the way for successful manufacturing and implementation.

On-time Delivery and Competitive Pricing

Our professional services focus not only on product quality, but also on timely delivery and competitive pricing. We understand the importance of on-time delivery of parts to ensure that your project is completed on time. Our standard order delivery time is 10 business days to ensure efficient production. In addition, we also provide expedited services to meet urgent needs, and parts can be delivered in as fast as 1-2 business days.

In addition, one of the reasons why we are able to offer competitive prices is that we have established strong partnerships with material suppliers. These partnerships allow us to purchase materials at favorable prices and obtain trade discounts, which we pass on to our customers. As a result, you can enjoy a cost-effective solution without sacrificing quality. Therefore, when you choose Elimold for your sheet metal processing needs, you can not only expect on-time delivery and very competitive prices, but also get the excellent quality that meets your expectations.

Design for Manufacturability (DFM) Feedback for Every Sheet Metal Quote

We now offer automated design analysis for all sheet metal components, highlighting features that may present challenges during manufacturing. Now it only takes minutes to get DFM feedback that improves the quality of your sheet metal parts. We work closely with you at the beginning of the design process to help you create the most innovative product solutions. We will combine our expertise with 3D solid modeling software for design and engineering to help you optimize your designs for manufacturability.

Our team of skilled manufacturing engineers is dedicated to improving the manufacturability of your sheet metal components and assemblies. From the moment you step into our company, we will work with you to improve your sheet metal manufacturability and help you achieve the most cost-effective production. With an experienced team of sheet metal engineering experts and decades of proven DFM experience, we will work with you to optimize shape, size, complexity, tolerances, materials, and more.

Personalized Customer Service

We believe in friendly, professional service and honest communication. When you contact Elimold, you will be communicating directly with an experienced sheet metal expert. Our team will listen to your needs, answer your questions in plain language, and provide recommendations that meet your budget and goals. And we know your time is valuable. We have efficient internal processes that can usually quickly transform your ideas from the drawing board to the finished product without sacrificing quality. What do you need? Just talk to us and we will most likely meet your needs. We also provide free quotes and consultations to make it easy for you. Our team will help you refine your concept and give you a clear estimate, without any obligations or pressure. Customer satisfaction is not just a slogan for us, it has been our way of doing business for decades.

Leading Sheet Metal Parts Supplier

As a leading sheet metal parts supplier, we have exceptional custom expertise to manufacture the products you need based on your unique needs. With our advanced sheet metal manufacturing technology, mass production of sheet metal parts is a breeze. Whether your order is 200,000 pieces or just a few dozen, we can deliver on time. We place a high priority on customer service. Our people share the same passion as our company to provide first-class assistance. We are more than happy to discuss your needs with you and provide sound recommendations to minimize your costs. We are extremely pleased to see your business flourish with our best-in-class solutions.

Ready to Get a Sheet Metal Fabrication Quote?

Sheet metal components and assemblies in as fast as 1 day. Get an online quote for your prototype or low-volume production project today.

Custom Metal Fabrication Contract Manufacturing Services

We understand the challenges of manufacturing complex sheet metal products and are ready to help. We provide custom metal fabrication contract manufacturing services, specializing in the production of custom sheet metal parts, complex assemblies, and fully integrated products. With advanced processes, advanced technology, precision engineering capabilities, and best-in-class quality management systems, we ensure that every product is completed accurately, on time, and consistently. You can trust us to provide you with the most reliable, efficient, and cost-effective solutions to meet your manufacturing needs. With expertise in full turnkey assemblies and precision sheet metal manufacturing services including but not limited to forming, bending, rolling, cutting, welding, finishing, inspection, and assembly, we provide the expertise to exceed your expectations for first-class solutions.

One-Stop Sheet Metal Parts Supplier

Working with a one-stop sheet metal parts supplier that offers design, engineering, and manufacturing can expedite the delivery of your project or product. We have extensive experience, advanced equipment, complete facilities, strong manufacturing capabilities, and a passion to design and manufacture high-quality parts, products, and equipment. You have a specific vision that requires custom manufacturing. Or perhaps it’s a problem you’re working to solve that currently doesn’t have a solution. Whatever the case, your organization needs a reliable, high-quality solution. After all, the success of your vision depends on it. You don’t have time to dwell on low-quality results from manufacturers who lack experience, integrity, or follow-through. You deserve better. With superior and lasting craftsmanship and extensive experience in creating innovative custom manufacturing designs, we are always committed to helping you get the job done perfectly. With our commitment to putting your needs first, always maintaining integrity, and communicating upfront, you can rest assured that you are working with trusted manufacturing experts.

Quality Management Standards

At Elimold, we don’t cut corners or take shortcuts. Quality and consistency are key to our success and that of our partners, and our customers can always rest assured that we put quality first. Not only is Elimold NIST compliant and ITAR registered, we exceed the requirements of ISO 9001, ISO 13485, and AS9100D, and continually review and improve our procedures to deliver best-in-class results. Our world-class quality management system allows us to easily meet the most stringent regulatory requirements, ensuring you receive only the highest quality products. We also have laser measurement and portable CMM for in-house inspection of the manufacturing process, including First Article Inspection (FAI).

Testing Equipment

- CMM

- Laser Scanner

- Electronic Height Gage

- Optical Comparator

- Micrometers

- Thread Gages

- Calipers

- Hardness Tester

- Coating Thickness Tester

- Surface Finish Inspection

- SolidWorks

- Spot Weld Pull Tester

- Pin Gages & Gage Blocks

- Custom Gaging

Value-added Assembly Services

We also offer value-added assembly services to help customers save time and money. We will take care of assembling mechanical components into the sheet metal parts you produce. This turnkey process provides customers with a single point of purchase to quickly, flexibly and cost-effectively produce complete, ready-to-use assemblies. Each operation is custom designed based on the product and application. Whether you have a large, complex assembly project or a series of small, precision assembly projects that require specialized technical expertise, we can assemble a variety of products. We can undertake one-off assembly projects or outsource assembly work for your team.

What is Sheet Metal Fabrication?

Sheet metal fabrication is a manufacturing process that involves cutting, forming, and assembling sheet metal parts into desired shapes and structures. This versatile process is used across a wide range of industries due to its ability to produce high-precision and durable parts. Manufacturers can transform flat sheets of metal into complex and useful parts through techniques such as cutting, bending, and welding. The sheet metal fabrication process offers many advantages, including high precision, cost-effectiveness, and the ability to customize designs for specific applications.

The core of sheet metal fabrication involves cutting, bending, and assembling into desired shapes. Flat blanks are transformed into a variety of final shapes through processes such as bending, cutting, and finally forming sheet metal parts. Depending on the complexity of the design and the production volume, a variety of methods can be used, from laser cutting and welding to CNC punching and coining. After the metal sheets are cut and formed into the desired shape, they are assembled and welded to form the final product. Sheet metal bending is a cost-effective process that can be used to deform sheet metal and highlight the features of the bending machine and specific die geometry.

Why Use Sheet Metal Fabrication?

Sheet metal fabrication provides a solution that lasts longer than other products with similar uses. For example, you may get a similar shape and function using casting. However, a cast doesn’t have the same durability and longevity you get with metal.

When you need precision, sheet metal fabrication allows you to cut, bend, and shape the metal the way you need it. Metal gives you a material that not only conforms to its new shape but holds it indefinitely.

In industries that need materials to survive impacts or harsh conditions, metal far outstrips plastics of any kind when it comes to strength. Fabricating sheet metal is also a faster and more cost-effective alternative to other methods of creating similar products.

Benefits of Custom Metal Fabrication

Unique requirements necessitate custom parts that fit and perform exactly as intended. Custom-fabricated and machined parts bring many benefits, including:

- Receiving exactly the parts you need, when you need them, at a competitive price

- Precisely cut, formed, welded, and machined on specialized, advanced machinery

- Inspection with instrumentation calibrated on a regular basis in order to provide consistent quality

- Fine craftsmanship, guided by highly qualified engineers, managers and operators

- Custom metal parts made from materials that comply with your every requirement

- Custom finishes to your exact specifications

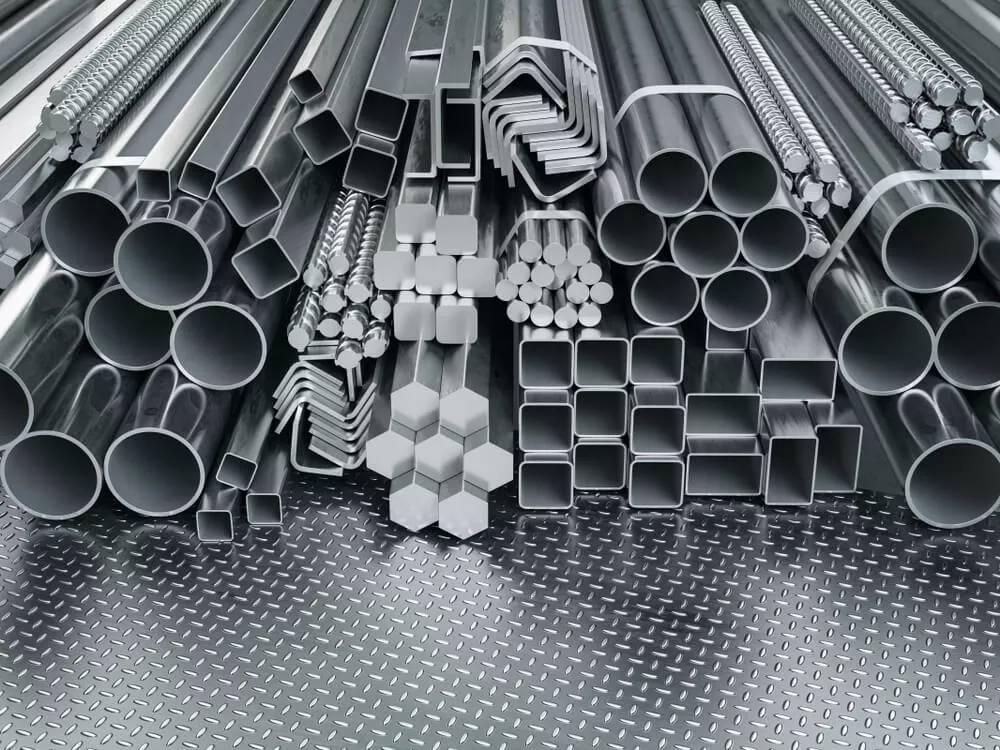

Sheet Metal Materials

- Alloy Steel

- Aluminum

- Aluminized Steel

- Brass

- Copper

- Expanded Metal

- Wire Cloth

- Perforated

- Galvanized Steel

- Stainless Steel

- Plastics

Sheet Metal Finishing

- Linear deburring

- Media blasting

- Brushing (Cosmetic)

- Orbital deburring

- Tumble deburring

- Polishing

- Anodizing type II

- Anodizing type III

- Black oxide plating

- Chromate conversion coating

- Digital printing

- Electroless nickel plating

- Nickel plating

- Zinc plating

- Powder coating

- Silkscreen

- Standard

Industries We Serve

Our sheet metal fabrication services provide customized, high-precision components for a variety of industries, with a focus on quality, durability, and reliable performance. With expertise in specific industries, Elimold provides custom sheet metal fabrication services, backed by competitive pricing and scalable solutions to meet the needs of modern manufacturing.

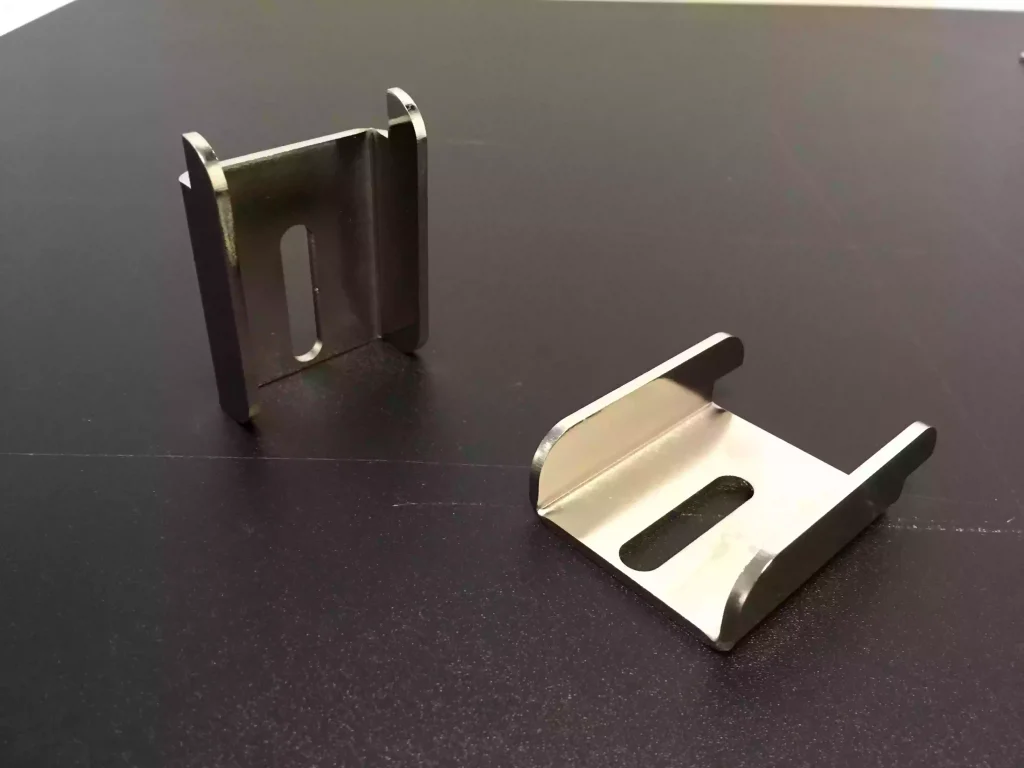

Sheet Metal Applications

Sheet metal is used to manufacture a variety of metal parts, from large-volume products to small-volume, one-of-a-kind applications. Years of experience have taught us the strengths and limitations of various materials, and we know which metal is best for your application. Common sheet metal parts include:

- Enclosures

- Brackets

- Panels

- Chassis

- Mounting plates

- Cabinets

- Ducts

- Covers

- Frames

- Shields

- Clips

- Trays

- Gussets

- Heat sinks

- Housings

- Faceplates

- Racks

- Boxes

- Louvers

- Reinforcements

- Hinges

- Latches

- Supports

- Connectors

- Flanges

- Reinforced corners

- Control panels

- Equipment bases

- Bins

- Battery holders

- Vents

- Drawer slides

- Signage backplates

- Filter holders

- Cable management trays

- Knockout panels

- Electrical enclosures

- Access doors

- Machine guards

- Terminal boxes

High-Quality Custom Metal Fabrication Solutions

Elimold’s manufacturing services are designed to incorporate complex designs into high-quality, functional products. We utilize time-tested manufacturing techniques and cutting-edge equipment to enhance the value of every product we produce. Advanced machinery, state-of-the-art technology, and professional management ensure that every product we produce is produced with precision and excellence. From custom one-off projects to large-scale production runs, our team excels in providing superior, consistent workmanship. We focus on engineering efficient processes to achieve the best results, ensuring that every manufactured product meets strict industry standards and customer specifications. Our staff includes highly skilled fabricators and AWS certified welders, whose skills enable them to provide a level of workmanship that exceeds the minimum quality and integrity standards required by the industries we serve. The Elimold team firmly believes that quality is not just a process requirement, but a part of the corporate culture that is integrated into every area of our organization.

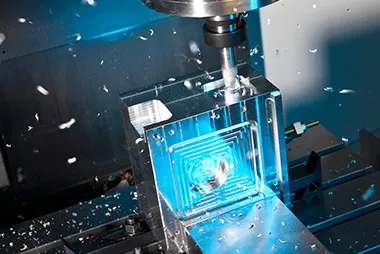

Differences between CNC machining and sheet metal fabrication

Choosing between CNC machining and sheet metal fabrication depends on a variety of factors, including production volume, part complexity, budget, and delivery time. CNC machining particularly shines when high precision and complex geometry are required. This subtractive manufacturing process is able to produce parts with fine details, smooth surfaces, and tight tolerances. CNC machining can handle a variety of materials, including metals and plastics. While CNC machining offers excellent precision and flexibility, it is more expensive and slower to produce in large quantities than sheet metal fabrication.

On the other hand, sheet metal fabrication is very beneficial for the high-volume production of parts, especially those that require high strength and durability. The process is ideal for manufacturing large, sturdy parts. It offers excellent repeatability and high-quality surface finishes, and is able to reduce costs and increase time efficiency when producing in large quantities. However, sheet metal fabrication may not be as flexible as CNC machining for complex designs. Both methods have their advantages, and the decision should be based on the specific needs of the project.

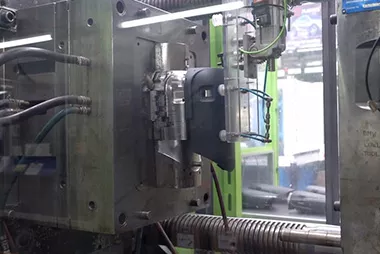

Explore Our Other Manufacturing Services

CNC Machining Services

3D Printing Services

Casting & Molding Services

Why can you trust Elimold to handle your sheet metal fabrication?

Whether you are ordering a single prototype or 100,000 marketable parts, trust in your manufacturer is critical. Parts in the prototyping stage may involve intellectual property and trade secrets that need to be kept away from public attention; while production parts require a high degree of precision to ensure consistency. With over a decade of experience in sheet metal fabrication, more than 2 million parts manufactured, and over 33,000 customers who continue to use our manufacturing services, knowing that every part they order meets our strict capability requirements. At the same time, we provide a 365-day warranty on all parts, regardless of order size, which means engineers can be confident that the parts will last for the life of the part.

Request Your Free Sheet Metal Fabrication Quote Today

After receiving your drawings, our engineers will analyze your custom Sheet Metal Fabrication parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.