Tungsten CNC Machining Services

Elimold’s tungsten CNC machining services efficiently and precisely machine tungsten parts with tight tolerances and complex geometries to your project specifications, making it the preferred partner for various industries. Contact us for more information or a quote.

Looking for a Tungsten CNC Parts Supplier?

Looking for a company that provides tungsten machining services? Due to tungsten’s extremely high hardness, many machinists cannot supply tungsten and other powder metallurgy parts. However, Elimold possesses strong machining capabilities, enabling the customization of precision tungsten parts to meet your most demanding application and performance requirements. Furthermore, we can combine multiple processes to create dimensionally accurate parts that conform to your design specifications. If you are planning to use this material to manufacture parts and have encountered difficulties in the past, or have never worked with tungsten before, Elimold’s team, with years of practical experience, will guide you through the entire machining process.

Custom Tungsten Alloy Parts Machining

Elimold boasts a fully equipped machining workshop capable of machining parts to customer specifications. We accept custom-machined parts orders of all sizes. We also have a comprehensive inspection department to ensure your parts meet standards. Certification of chemical composition and physical properties is provided free of charge. Dimensional inspection reports are also available upon request.

Our process-centric approach strives for optimal results, meeting all specifications and exceeding your expectations through our tungsten machining services. When you send a project to the Elimold team, we analyze your design and customize fixtures and machining solutions to meet your specific needs, producing your parts at a very reasonable cost.

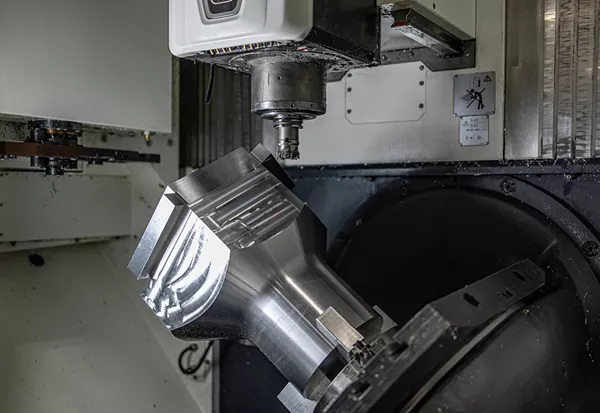

Tungsten Parts CNC Machining Factory

Our state-of-the-art 7,000-square-foot facility is equipped with state-of-the-art 5-axis machining, CNC turning, CNC milling, and multi-axis machining centers, capable of processing both small and large parts. With this massive machining capacity, Elimold can complete the production of tungsten machined parts in extremely fast batches, from small to large quantities. We are renowned nationwide for our on-time delivery, budget control, and tolerance control. We understand that every project is unique, therefore we offer bespoke manufacturing services to meet specific client needs. Furthermore, Elimold’s rigorous quality assurance and inspection processes ensure that every precision tungsten CNC machining service we provide meets the highest standards.

Full Production Support Team

We have a team of manufacturing experts working behind the scenes to fulfill your production order, we manage the entire process and keep you updated along the way.

Account Manager

Applications Engineers

Logistics

Quality Control

What is Tungsten?

Tungsten, originally named “wolfram,” is a rare earth metal known for its high hardness, high density, and high tensile strength. It is naturally corrosion-resistant and has the highest melting point of all metals, exceeding 3000°F (approximately 1593°C). Pure tungsten also possesses considerable ductility even in its unalloyed state.

Furthermore, tungsten is one of the hardest naturally occurring elements on Earth. Although its melting and boiling points are among the highest of all known elements, it almost always exists in compounds with other elements. Tungsten is a versatile and environmentally friendly metal, but its high hardness and brittleness can make processing tungsten products relatively difficult.

Like other metals such as niobium, molybdenum, tantalum, and rhenium, tungsten is chemically stable. It is also very stable, possessing the lowest coefficient of thermal expansion of all metals, and exhibits strong resistance to creep, the tendency of a metal to undergo plastic deformation under stress and high temperatures.

What are Tungsten Alloys?

Tungsten alloys are primarily composed of tungsten, mixed with small amounts of other metallic elements such as nickel, copper, titanium, or iron. These alloys typically conform to industry standards ASTM-B-777, AMS-T-21014, and AMS-7725. Because tungsten has a high density, extremely high hardness, and a high melting point, like other refractory metals, it cannot be cast, forged, or rolled like other metals. Instead, it must be pressed into powder form and then sintered. It is frequently alloyed with other metals, such as super duplex steel, tool steel, and high-speed steel.

Challenges of Tungsten Machining

Tungsten and other hard, brittle materials are notoriously difficult to machine. Machining tungsten requires years of trial and error to master and demands rigid fixtures and minimal spindle runout. Only the most skilled machinists can effectively machine tungsten. Careful adjustment of feed and cutting speeds is crucial to balancing tool life and machining time. Too high a machining speed can cause tool breakage or damage to the part; too low a speed results in inefficiency and high costs. Our team meticulously studies the client’s project design before machining to determine the optimal manufacturing process.

This process involves close collaboration and communication with the client’s engineering team to identify the most suitable design and manufacturing approach for your project, meeting the required part design requirements. Our experienced team can keep the cost and delivery time of tungsten CNC part projects within reasonable limits.

Tungsten Alloy Grades

Comprehensive selection of ASTM B777 compliant tungsten alloys for diverse applications.

Tungsten Carbide (Cemented Carbide)

Tungsten carbide is a composite material made of tungsten carbide (WC) particles and a binder phase (usually cobalt (Co) or nickel (Ni)). Known for its extremely high hardness, cemented carbide is suitable for manufacturing cutting tools, drill bits, and wear-resistant parts.

Heavy Tungsten Alloys (W-Ni-Fe, W-Ni-Cu)

These alloys are typically composed of tungsten, nickel, and iron or copper. They have high density and are used in ballasts, vibration dampers, and aerospace components.

Tungsten Nickel Copper (W-Ni-Cu)

This tungsten alloy is typically composed of tungsten, nickel, and copper. It combines density, machinability, and electrical conductivity, making it suitable for manufacturing electrical contacts, radiation shielding, and aerospace components.

Tungsten Nickel Iron (W-Ni-Fe)

Alloys of tungsten with nickel and iron are used in a variety of applications, including counterweights, balances, and rotating inertia components.

Tungsten-Rhenium (W-Re)

Tungsten-rhenium alloys combine tungsten and rhenium (Re) to improve their high-temperature strength and ductility. They have applications in aerospace and electronics, such as in thermocouples and high-temperature heating elements.

Ready to Get a Quote?

Ready to transform your CAD file into a custom part? Upload your design to get a free, precise quote.

High-Precision CNC Machining of Tungsten Parts

Elimold is a trusted brand for providing advanced tungsten machining services. With CNC technology and cutting-edge equipment, we are capable of performing complex machining operations on a wide variety of tungsten alloys suitable for CNC machining. Our advanced machining capabilities encompass four-axis and five-axis milling, Swiss-type lathe machining, and even micro-machining. This allows us to manufacture parts with the highest precision and smallest tolerances. We can achieve tolerances as small as 0.0005 inches. Five-axis machining accuracy reaches ±0.005mm. Laser-cut micro-milling cutters can machine grooves as fine as 0.1mm. Precision guide bushings achieve a mirror-polished inner hole roundness of 0.001mm.

From Prototype to High-Volume Production

Our production process is flexible and efficient, capable of meeting the needs of mass production or customized single-piece prototype parts. We can supply tungsten alloy materials according to specific customer requirements, or our experienced team of engineers can provide mechanical design advice and guidance to meet various complex customer needs. For customers who wish to perform their own machining, we can provide rough-machined tungsten alloy bars or blanks, with all dimensions allowing for at least 3 mm of machining allowance. For more information, please contact us today.

More Tungsten Alloy Machining Services and Solutions

Elimold offers not only the aforementioned machining services, but also a wide range of machining capabilities including sawing, multi-axis CNC milling, boring, threading, tapping, and grinding. Our team of machinists utilizes advanced tools and techniques to ensure superior machining results. We excel at machining parts for demanding industries and provide certification and dimensional inspection reports to ensure your parts meet specifications and quality standards. Whatever type of tungsten alloy parts you need, we can meet your customized requirements.

Precision Tungsten Alloy Grinding Services

We specialize in precision machining of tungsten alloys using high-precision optical grinding machines, ensuring ultra-high dimensional control and superior surface finish. Leveraging advanced optical positioning and grinding technologies, we provide micron-level machining accuracy for a wide range of carbide parts, meeting the most demanding industrial requirements. We offer optical grinding specifically designed for ultra-high precision forming of carbide, with micron-level dimensional tolerance control and a surface roughness Ra ≤ 0.1μm, enabling precision grinding of carbide parts with complex geometries.

Surface Finishing of Tungsten Alloy CNC Parts

As Machined

Anodizing

Brushed Finish

Sand Blasting

Heat Treatment

Teflon Coating

Black Oxidize

Electroless Plating

Electroplating

Painting

Powder Coating

Electrophoresis

Tumbling

Alodine

Electropolish

Passivation

SPI Finish

Launch Your Project With Rapid Prototyping Services

Don’t let your project stall while waiting for prototype parts and components. Elimold utilizes computer-aided machining technology to quickly and accurately manufacture test parts with extremely fast turnaround times. Our test parts are so precise that we can directly use the actual tungsten metal that will be used in your final product to create real parts, accelerating your time to market. Moreover, testing and producing complex-shaped parts is one of our most frequent projects. No matter the complexity of your project, we can provide the high-precision prototypes you need to complete it. If you’re ready to get started, contact us today for a quick quote on tungsten alloy prototyping.

Reduce Tungsten Alloy CNC Prototype Costs

Lowering production costs is crucial to your profitability. Elimold offers consulting services on design and material usage to help clients achieve the structural integrity required for their parts at the most cost-effective price. Our experienced engineers will work with you to help you reduce production costs by suggesting improvements to machining and manufacturing processes.

Quality Assurance and Integrity Testing

We provide high-quality components and ensure customer satisfaction. Utilizing 3D CAD models, we can manufacture prototype parts according to your specific requirements. We also employ rigorous inspection measures. Each unique prototype is sent to our inspection department for testing, where they measure with extremely high precision. Furthermore, we use alloy analyzers to test materials, ensuring the reliability of material usage and product quality.

Technological Synergies

Elimold positions itself as a comprehensive supplier of high-value-added finished products, utilizing a variety of industrial technologies, including machining, assembly, welding, and laser marking, to provide full-process support for its clients’ projects. Our expertise lies in combining our own technology with local partners who are proficient in specific machining and surface treatment processes. Additionally, we can customize packaging specifically for tungsten parts. Custom tungsten alloy parts are carefully placed in wooden crates or cartons and extra-supported with soft materials to prevent shifting during transportation. This packaging method ensures that the product remains intact throughout the entire shipping process.

Industry Applications

Tungsten components play a crucial role in demanding industries.

- Radiation therapy collimators

- X-ray tube targets

- CT scanner components

- Radiotherapy shields

- Brachytherapy sources

- Aircraft counterweights

- Helicopter rotor balancing

- Satellite components

- Rocket nozzles

- Gyroscope rotors

- Nuclear shielding

- Counterweight systems

- Ballast applications

- High-speed spindle weights

- Vibration dampers

- Crankshaft balancing

- Flywheel components

- Drilling equipment

Why Choose Elimold for Your Tungsten Machining Needs?

Elimold provides high-performance tungsten and tungsten alloy machining and finishing services to various industries. We understand that in many cases, using Elimold’s machining capabilities can reduce costs and shorten delivery times. Our experienced team of machinists and in-house machining workshop make tungsten turning, roughing, milling, and finishing ideal. With years of experience in tungsten alloys, we can manufacture a wide variety of tungsten alloy products, covering various shapes, sizes, and alloy parts. Furthermore, we can undertake projects that other companies refuse, proving our ability to handle the most challenging materials and specifications.

If you are looking for a CNC machining plant that pushes the boundaries of CNC machining, we are ready to serve you. Whether it’s tungsten or any other challenging material, our team possesses extensive knowledge, advanced technology, and unwavering passion to transform complex problems into precision engineering solutions.

FAQ

Machined tungsten alloy parts will conform to ISO 2768-m (Medium) or ISO 2768-f (Fine). We guarantee that all CNC-machined parts and other components conform to ISO 2768 standards, excluding parts with specific tolerance requirements. For shafts with higher tolerance requirements, we offer free customized quotations.

We have no minimum order quantity limit. Our solutions include: one-time rapid prototyping, customized small-batch CNC machining, and high-volume production with short lead times.

For production, our usual lead time is 20-30 days. However, the lead time may vary slightly depending on the product and quantity. If your order is urgent, please contact us and we will do our best to solve your problem. For shipping, we usually use express and air freight. Express takes approximately 7-10 days, and air freight takes approximately 3-5 days. If the customer requests sea freight, we will ship by sea, which usually takes 40-50 days. Intellectual Property and Confidentiality Agreements?

We understand that your 3D data and designs are crucial to your business. Therefore, we place great importance on protecting your intellectual property. We use SSL encryption to encrypt all transmitted files, ensuring they are not intercepted during upload to our servers. All information and files you upload to our platform are securely stored and shared only internally with employees who need access to this information to produce the parts you require. We guarantee absolute confidentiality throughout the entire order process; as all production is completed in-house, original drawings are not shared with third-party suppliers. If you require further protection, we can sign a confidentiality agreement.

First, we ensure we fully understand all customer requirements. Then, we place the order with the production and inspection departments. Each production stage undergoes self-inspection to ensure everything is in order. Before shipment, all products must be inspected by the inspection department to confirm they meet customer requirements before entering the packaging department. If they do not meet requirements, the products will be sent back to the production department for repair or rework.

All our products undergo rigorous inspection and secure packaging before shipment. Each production stage is inspected to ensure good product quality. The inspection department will conduct a re-inspection to ensure everything is perfect. However, if a quality problem does occur, we sincerely apologize and will take full responsibility. We will do our best to repair or remanufacture the product to properly resolve all issues.

Due to the material's high hardness, it is best to use a carbide drill bit or a solid carbide drill bit.

Use a straight flute high-alloy tap. For small holes, a thread-forming tap can be used. Considering the difficulty of machining tungsten, thread milling may be more suitable than tapping.

This material has an extremely high density, therefore a high-torque CNC machine tool is required. It is highly wear-prone to tools, so high-quality carbide tools must be used, and tool life should be checked frequently as it wears out quickly.

Get Your Custom Tungsten Parts Quote

Ready to start your precision tungsten project? Our experienced team is here to help you select the right materials and processes for your specific requirements.