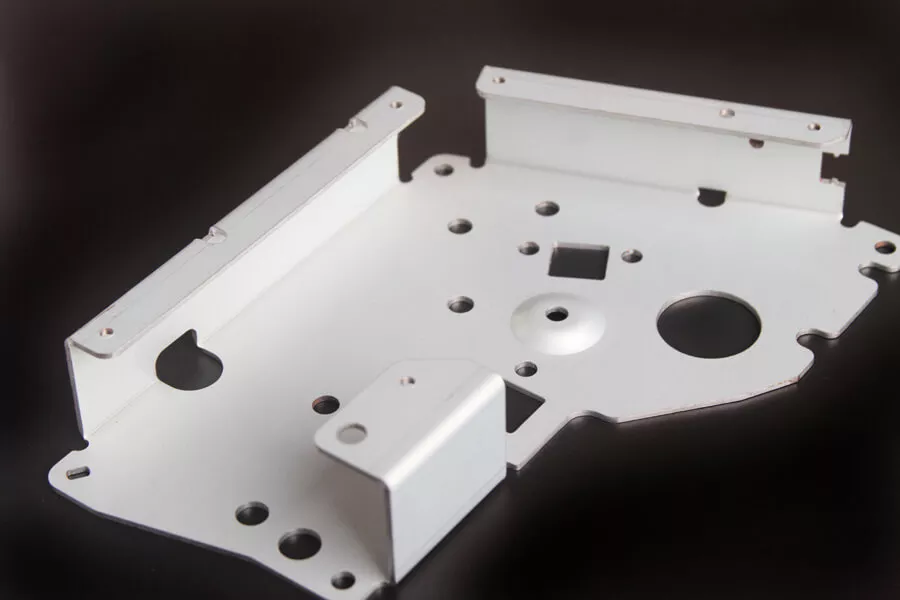

Agriculture Sheet Metal Fabrication

Elimold supplies a wide range of deep drawn housings and stamped parts as well as prefabricated parts to some of the world’s leading agricultural OEMs. Major industry-leading OEMs trust us to provide high-quality, high-precision deep-drawn housings, custom stampings, and other components for their agricultural equipment. Our manufacturing capabilities allow us to meet any OEM’s strength, stiffness and precision standards. With advanced manufacturing equipment, innovative technology and experienced production personnel, we provide parts that meet each customer’s unique requirements. And we also offer flexible scheduling and fast turnaround times to deliver the parts you need, when you need them.

Custom Metal Agriculture Parts

The agricultural industry requires timely responses, so having a reliable metal fabrication manufacturer is more important than ever. As a reliable and responsive supplier, we are committed to consistent, on-time production of parts. Quality suppliers maintain farm and agricultural machinery production by producing quality metal parts and delivering them on time.

Elimold is a comprehensive manufacturing facility that provides practical solutions for innovative ideas. We help develop and manufacture complex designs with a wide range of essential services. Our product portfolio includes metal fabrication, metal spinning and precision laser cutting, and experts will work with you every step of the way. So, use our expertise to ensure the best results at breakneck speed.

We are committed to becoming an industry leader in supporting agricultural manufacturing. That’s why our team specializes in manufacturing agricultural equipment and agricultural components, regardless of lead times or tolerances. We use beautiful materials and an ISO-certified approach to help land developers stand out from the competition. Our dedication to quality and customer service combined with a strong passion for our work means we exceed our customers’ expectations every time.

Importance of Metal Fabrication Services in Agriculture

Investing in custom agricultural metal tools and parts is critical to increasing productivity. Metal manufacturing helps farmers increase yields while reducing operating costs. When equipment is custom and professionally built, components last longer. Custom-designed equipment will also allow for duplication if equipment needs to be replaced, thus reducing costs. When your equipment is custom-made, the metal components are also designed to withstand the elements, increasing corrosion resistance and extending the life of the disparate metal components. Custom also allows farmers to work with our team to create custom parts that best fit their needs during the harvesting process. This not only improves the quality of the equipment but also improves operator comfort. When all of these advantages are combined and applied to machines such as tractors, combines, hay balers and more, businesses will have more efficient, longer-lasting equipment.

A one-stop shop tailored for your industry

At Elimold, we can manage the entire manufacturing process on your behalf – from initial design and prototyping to fabrication, finishing and assembly.

This means you can leave your product development and implementation to us, from concept to completion, without having to hunt around for the skills you need to get it done.

Whether you are a large agricultural machinery manufacturer or need one-off components, contact us today to discuss your needs and request a quote.

Our Facility and Equipment

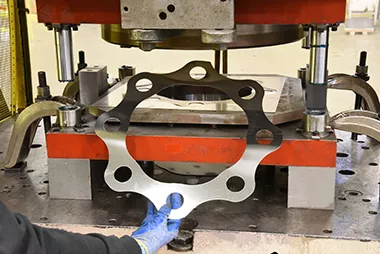

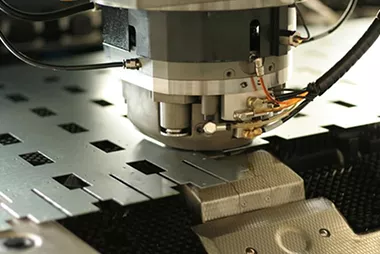

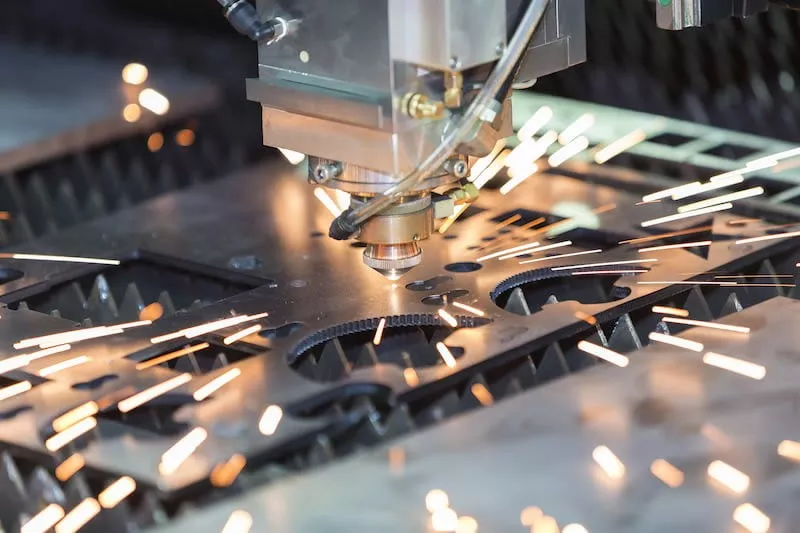

Quality, advanced equipment is crucial for complex metal fabrication products. Our facilities provide us with over 130,000 square feet of space and house state-of-the-art equipment that we can use to meet the needs of even the most complex jobs. We have access to a robotic panel bender, high-speed Trumpf and Amada lasers, Virtek scanners, robotic welders, and Strippit and Trumpf rail turret presses. And, while technology is wonderful, some jobs need a more hands-on approach. For those instances, we also have you covered with press brakes, MIG and TIG welders, hardware insertion machines, and various surface finishing processes.

Sheet Metal Fabrication Techniques

Sheet Metal Laser Cutting

Sheet Metal Stamping

Sheet Metal Robotic Welding

Sheet Metal Punching

Sheet Metal Plasma Cutting

Sheet Metal Bending

How can Elimold help you with your agricultural sheet metal component needs?

- Providing you with engineering assistance to help you optimize the manufacturability, reliability, and durability of your agricultural sheet metal fabricated part designs.

- Supporting your needs for iterative product development with rapid prototyping so you can bring new product innovations to market faster.

- Helping you select the best material for each component to ensure it provides optimal performance and longevity in your critical applications.

- Supporting you throughout the product lifecycle: from rapid prototyping of new part designs to bridge and production manufacturing.

Your Trusted Business Partner

We are a Chinese company headquartered in Shenzhen, China, and can provide technical support to businesses in all regions of the world. Since then, we have invested heavily in our factories and employees to leverage our industry expertise and pass this knowledge on to our customers. We are an ISO-certified sheet metal parts manufacturer for agricultural equipment and can produce any part you may need, including mechanical parts such as tractors or skid steers, irrigation components for sprinklers, sprayers and irrigation valves, etc. Our excellent relationships with suppliers mean that we can help solve product shortages or supply lead times, ensuring you get the products when you need them. Finally, our technical support team is committed to your satisfaction, working with our engineers to create high-quality design layouts and transfer them to our machines for seamless production.

Full-Service Agricultural Industry Manufacturer

You can trust Elimold to provide a comprehensive solution for your agricultural equipment manufacturing needs. Design, sourcing, manufacturing, and finishing are all done under one roof, streamlining your supply chain. Customer satisfaction is of utmost importance to us. Quality control personnel use sophisticated testing and inspection equipment to verify that each product exceeds the requirements. All orders are evaluated for accuracy prior to delivery.

- Saw Cutting

- Shearing

- Drilling and Tapping

- CNC Machining

- Folding and Bending

- Bending and Rolling

- Metal Inert Gas Welding, or MIG Welding

- Tungsten Inert Gas Welding, or TIG Welding

- Straightening

- Sandblasting

- Hot Extrusion

- Water Jet Cutting

- Metal Spinning

- Metal Finishing

- Crating and Packaging

- Shipping and Delivery

Materials

Whether it’s parts for equipment that help crops stay healthy or fencing to safeguard livestock and personnel, our team manufactures products from your designs with precision, efficiency, and quality. Materials we work with commonly are:

- Abrasion Resistant Plate

- Aluminum

- Architectural Metal

- Beryllium

- Brass

- Bronze

- Carbon Steel

- Copper

- Exotic Metal

- Exotic Metal Alloy

- Hastelloy®

- Heat Resistant Metals

- Heat Resistant Steels

- High Temperature Alloy

- Incoloy®

- Inconel®

- Invar®

- Iron

- Kovar®

- Lead

- Light Metal

- Molybdenum

- Nickel

- Nickel Alloy

- Perforated Metal

- Platinum

- Sheet Metal

- Stainless Steel

- Steel

- Steel Plate

- Structural Steel

Why Custom Sheet Metal Parts for Agricultural Equipment

Often, you can use standard items to make your business work. However, when you work with a well-trained, professional sheet metal fabricator like Elimold, you know that the quality of the product you are getting is much better. When you have an expert design and build the irrigation product, plumbing, or tubing you ordered, any defects or problems will most likely be discovered before the item actually reaches you. Additionally, there are cases where a standard irrigation or ventilation product will not work properly. If this is the case, then you must have someone else build the item for you. Contact Elimold today to find out how our experienced and well-trained team of technicians can help you.

Parts manufactured by Elimold include

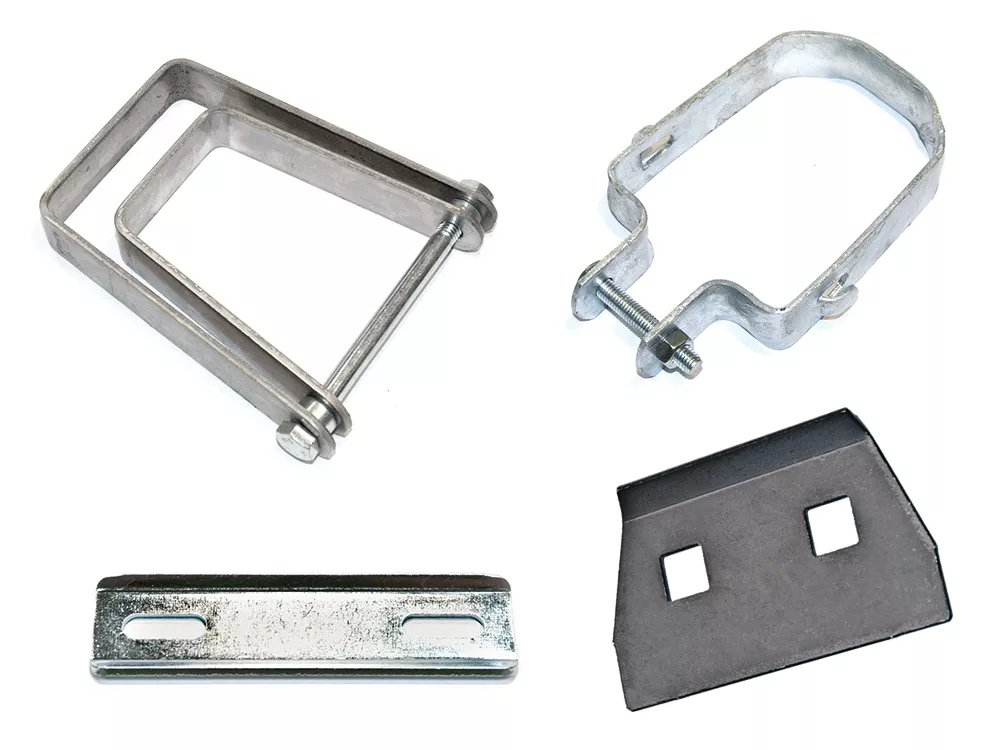

Elimold specializes in manufacturing custom products for agricultural customers. We achieve this by combining experienced tradesmen, advanced equipment and innovative engineering. While our team can manufacture almost any product, the following are typical products manufactured:

- Safety Fencing

- Staircases and Ladders

- Safety Platforms

- Stands and Racks

- Machine Bases and Robot Risers

- Material Handling Equipment

- Cable Tray Covers

- Operator Platforms

- Robot End Effectors

- Sheet Metal Enclosures

- Laser Booths

- Brackets

- Light Screen Brackets

- Weld Timer Stands

- Columns

- Vent Hoods

- Handrails

- Machine Guards

- Weldments

- Maintenance Platforms

- Gravity Conveyors

- Custom Fabrication

Why choose Elimold

Elimold is a precision sheet metal parts manufacturer, which means we have the expertise and equipment to deliver smoothly according to your requirements. We are always committed to improving production and customer experience.

We understand that the agricultural industry has strict timelines that must be adhered to. We can guarantee clear communication and accurate timelines (including delivery times) as well as high quality every time.

Our services are scalable, so whether you need a single part immediately or have a regular order of thousands, we can meet your needs.

Contact us today for a free quote

You can rely on Elimold to provide comprehensive solutions for your agricultural equipment manufacturing needs. Design, sourcing, manufacturing and finishing are all under one roof, streamlining your supply chain.

For us, customer satisfaction is of the utmost importance. Quality control personnel use precise testing and inspection equipment to verify that each product exceeds appropriate requirements. All orders are evaluated for accuracy before delivery. Let’s talk about your next project