Consumer Products Die Casting

If you have a complex die casting design for a consumer product, Elimold can help you turn it into reality. With the right equipment, strong technical knowledge and a focus on quality. From tool design to finishing to shipping, we ensure that every consumer product die casting project is completed to a high standard and your order is delivered on time, every time.

Consumer Goods Die Casting Services

The consumer goods industry encompasses the vast majority of products we use in our daily lives. In a market where customers want to stand out, Elimold can help you create unique and tailored consumer goods products to meet the needs of different categories of consumers. Our die casting services support mass customization and personalization, helping companies diversify their product lines and SKU, and meet seasonal demand and inventory management goals.

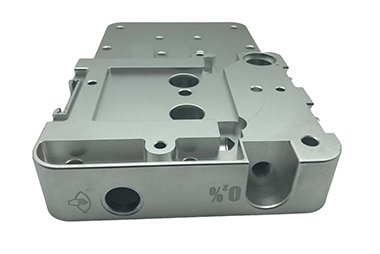

Whether it is a new design or an existing tool, we provide customers with the highest quality consumer goods die castings. Our capabilities include die casting equipment up to 3,500 metric tons, and with multi-slide mold technology, we are able to produce complex castings to meet the specific needs and requirements of products in the consumer goods industry. We also assist in the design of new high-quality die castings and can provide fast turnaround, custom finishes, and product assembly services. So when you submit your design to Elimold, we use the die casting manufacturing process to create the perfect mold for you. We are precision consumer goods casting experts located in China, serving the world!

Consumer Product Die Casting Manufacturer

At Elimold, we are proud to offer a wide range of production expertise and services to cast high-quality alloy components for consumer products. Every industrial and consumer component we produce is made to your design specifications, quality expectations and timelines.

We produce die castings for many of the industry’s leading manufacturers and companies. Every component we make is tailored to your specific die casting design requirements, specifications and end use. We understand the importance of keeping your designs confidential; the tools, dies, designs and final products are your property. By using state-of-the-art equipment supported by our dedicated engineering, process technicians and production teams, we can produce quality industrial products to your exact needs. Each product is of very consistent high quality, so when combined and assembled with other components, it is a beautiful finished product ready for you to sell to your customers. We are committed to providing you with the best value.

Providing you with a competitive advantage starts with our own in-house manufacturing facility. We continually invest in advanced equipment and a talented team, using cutting-edge technology and operational practices that enable us to exceed your expectations at every turn.

Turnkey service

Our team pays special attention to detail, including linear dimensions, parting lines, and moving die component tolerances. With years of experience, our team is sure to provide you with the consumer die casting products you need. We have our own die casting facility designed to produce a wide range of consumer products for our customers.

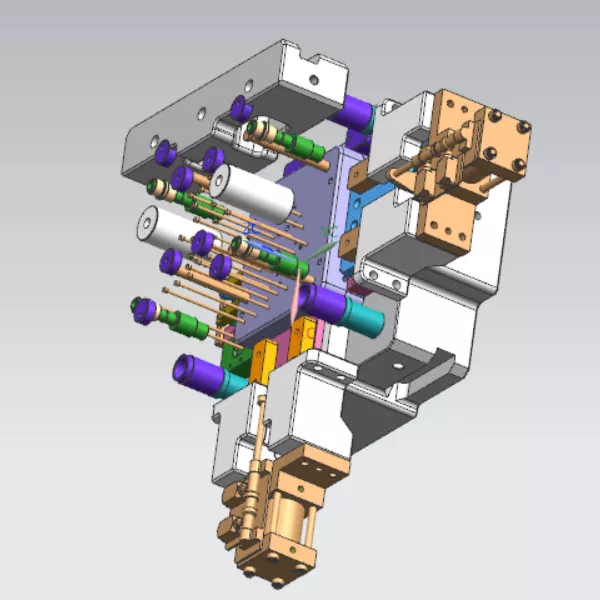

Elimold makes it easy to incorporate precision machining of consumer die castings into the production of finished exterior parts. To meet your exact design standards, each of our facilities is equipped with a full complement of secondary operations with tolerances as low as 0.0020 inches. Equipment includes multiple vertical and horizontal CNC machining centers, drilling and tapping stations, high-speed horizontal and vertical CNC lathes, and finishing equipment.

During a design review of your die casting program, we will determine the additional processes required and provide a complete solution to produce the components. We will not hesitate to build a dedicated cell, or reconfigure additional processes and CNC machining to exactly meet your design. To meet your additional quality standards, in-cell automated inspection, including pressure testing and vision systems, can also be integrated into the operation.

Manufacturing Capabilities

- Under normal circumstances, cold chamber die casting machines can die cast 50 to 90 times per hour.

- Hot chamber die casting machines can die cast 400 to 900 times per hour.

- The general tolerance grade of consumer die castings is IT13~IT15 in GB/T 1800-2009, and the higher precision can reach IT10~W 1 1. The surface finish (Ra) is 3.2~1.6μm, and can reach 0.8μ locally.

- High mechanical properties of die castings

- The minimum wall thickness of consumer die castings is 0.5mm.

- The minimum wall thickness of consumer die castings can be 0.3mm.

- Parts of other materials can be embedded in consumer die castings – complex fasteners or inserts can be included in the final assembly. Therefore, it saves valuable material costs and processing costs.

- Parts with complex shapes can be obtained, improving the performance of parts and reducing assembly workload.

- Die castings with durable and dimensionally stable shapes can be obtained, so no or less processing is required.

- Consumer die castings can be finished using a variety of finishing techniques and surfaces. The process can achieve either a smooth or textured part surface.

Types of Die Casting Services We Provide

If you have a complex part design, Elimold can help you turn it into reality. With the right equipment, strong technical knowledge and a focus on quality. From tool design to finishing to shipping, Elimold ensures that each project is completed to a high standard and your order is delivered on time every time.

Sand Casting

Investment Casting

Die Casting

Low Pressure Casting

Permanent Mold Casting

Lost Foam Casting

Centrifugal Casting

Vacuum Casting

Build and Test Faster with On-Demand Die Cast Manufacturing Solutions for Consumer Products

Speed of development, accuracy, and user-centric design optimization are at the heart of the consumer goods industry. That’s why your prototype shouldn’t take days to make. With Elimold, you can now accelerate your product development cycle from design to first build, prototype, and final part manufacturing in just hours!

We believe in versatility and scope, which is why we’ve perfected the art of combining multiple manufacturing options with a wide range of raw materials to create finished consumer die cast parts that are both functional and beautiful in the shortest lead time. Our options are particularly well suited for designers and companies looking to expand their SKU and product range without investing high capital costs for rapid prototyping, small batch units, and rapid market testing.

Our in-house capacity proves Elimold is a great fit for the fast-moving consumer goods industry. On-Demand Die Cast Manufacturing and production volume flexibility also means we’re ready to work with you to produce one piece, ten thousand pieces, or anything in between, with no minimum order quantity restrictions.

Stay ahead of the competition and get to market faster by choosing our Rapid Prototyping and On-Demand options, unfettered by any production volume. Backed by extensive engineering experience and leading-edge technology. Elimold is your one-stop center for custom consumer die casting products, providing you with exceptional value to accelerate your product development and market entry.

Quality Standards

Elimold can meet your die casting needs from mass production to precision parts and mold processing to end-use production. With our state-of-the-art equipment and highly trained professionals, Minghe meets or exceeds the quality standards of the world’s most demanding industries. These include:

- ISO 9001:2015 certification

- Fully compliant with customers’ stringent requirements

- Compliant with DFARS material sourcing requirements

- Strict compliance with automotive customers’ PPAP and process FMEA

- Proficiency in KanBan and other customer-driven quality and inventory management systems

- ITAR registered

Full-Service Consumer Goods Die Casting Manufacturer

You can count on our decades of expertise in die casting technology, our skilled manufacturing management team, and our well-organized management system. You can count on our high-quality, efficient production capabilities. We excel in developing the right manufacturing strategy to meet stringent product quality standards, optimize costs, and reduce delivery times.

Casting upto 3500T

When manufacturing large and complex components for the consumer goods industry, we use machines with clamping forces up to 3500T.

One-Stop Manufacturing Service

By offering a one-stop manufacturing service, we simplify the supply chain for our customers, reduce lead times, minimise logistical complexities, and ensure consistent quality throughout the production process.

Experienced Techincal Team

Our experienced team ensure the efficient and high-quality production of die-cast components. Elimold’s expertise contributes to achieving consistent results, minimising defects, and optimising the whole manufacturing process.

Specialising In Complex Parts

We manufacture parts for the consumer goods industry with complex shapes and tight tolerances, often requiring advanced manufacturing techniques that can be used to manufacture parts for a variety of industries.

Full Quality Control Reporting

We follow a comprehensive process that involves the documentation and reporting of all aspects of QC measures in manufacturing. This process ensures that every step of our production is monitored, evaluated, and documented to meet specific quality standards and requirements.

Over 15 years experience

With over 15 years in manufacturing, our long-standing experience is often highly regarded and can be a valuable asset in delivering quality work and providing guidance to our customers.

Die Casting Materials

- Aluminum

- Zinc

- Magnesium

- Titanium

- Copper

- Bronze

- Steel

- Stainless Steel

- Foundry Iron

Finishing Operations

At Elimold, we also ensure that our finished consumer die castings meet quality standards. We provide high-quality results by finishing the workpieces through secondary operations. Our team uses in-house techniques such as grinding, shot peening, deburring, and other types of precision work to ensure customer satisfaction.

Our attention to detail and quality assurance leads customers to choose us to supplement their supply chain by sourcing products through quality partners. We have an excellent track record to provide you with the right customer service and parts, and stay informed about our dedication to the various products provided by consumer product companies.

Our Finishing Services

Elimold’s production services are further enhanced by our finishing services. Consumer products place special emphasis on appearance and appeal. Our finishing is decorative, aesthetic, and in some cases functional. Here is a list of the finishing options we offer for components in the consumer products industry:

- Texturing

- Anodizing

- Polishing

- Blasting

- Painting

- Electroplating

- Passivation

- Heat treatment

- Powder coating

- Custom

Consumer Product Applications

Die casting is ideal for creating intricate consumer electronics components. Check out some common applications:

- Smart Home Devices

- Virtual Reality Equipment

- Automotive Electronics

- Smartphones and Tablets

- Wearable Technology

- Gaming Consoles

- Digital Cameras

- Personal Care Devices

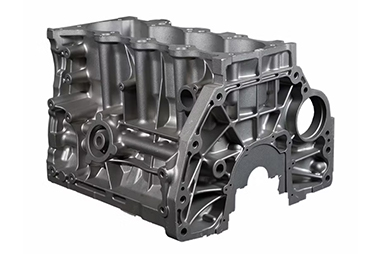

The Rise of Die Casting for Consumer Products

The future of manufacturing is always changing, and die casting is becoming an increasingly popular choice for the consumer goods industry. This manufacturing method has proven to be cost-effective, efficient, and versatile, making it an ideal choice for many businesses looking to produce consumer goods products quickly and efficiently. Die casting is known for its ability to produce large quantities of high-quality, precision parts. This makes it ideal for the consumer goods industry, where batch production is key.

From electronics to home appliances. This casting method is a fast and automated process that can produce a large number of parts in a short period of time. The fast turnaround time of this method is not only cost-effective, but it also ensures consistent quality for all parts produced.

The growing demand for environmentally friendly manufacturing techniques has driven the development of die casting. Compared to other manufacturing techniques, die casting produces minimal waste and consumes less energy, making it a more sustainable choice for the future.

Ready to start your next project?

Start your next project by uploading your CAD file and requesting a quote. Our engineers will provide you with a free quote and design for manufacturability analysis to start production discussions immediately.