Drone(UAV) Injection Molding

We provide custom injection molding solutions for the drone market, allowing them to innovate new solutions quickly. We offer a range of UAV plastic injection molding services, from prototyping to small, medium and large batch production with fast lead times, allowing our customers to focus on their business. We manufacture parts using a variety of aerospace-grade plastic materials and can also provide weight reduction solutions through 3D printing or carbon fiber parts.

Provide comprehensive solutions for drone companies

Elimold is a leading supplier of custom plastic injection molded components for the unmanned systems industry, including Unmanned Aerial Vehicles (UAV), Unmanned Ground Vehicles (UGV), Remotely Operated Vehicles (ROV) and Unmanned Underwater Vehicles (UUV). Plastic injection molding processes (vacuum forming and pressure forming) are particularly suited to the emerging needs of the unmanned systems and vehicle industries, providing extremely lightweight and durable materials, precision manufacturing and low-cost production of unmanned system components. Plastic thermoforming also offers a high degree of design flexibility, enabling the production of large components at a very affordable cost.

UAV Molded Component Manufacturing

The Elimold team is known for its evolving engineering expertise and technical proficiency, especially in product and process design. For UAV components, we provide design support and frequently use our injection molding services. We also use 3D printing services for rapid prototyping, custom, and production of complex parts for UAV plastic components.

We also offer our customers on-site tool manufacturing services, which is also a great benefit. Completing this process in-house offers significant advantages in terms of speed, cost, quality, custom, and reliability. We also offer our customers a wide range of resin options, including high-end engineering resins. These materials ensure the efficiency and reliability required for effective UAV operation, even with stringent requirements for performance, durability, and weight.Elimold wants to help UAV manufacturers produce reliable and high-performance products, and to do this, we have incorporated 5-axis CNC machining technology into our manufacturing process. 5-axis CNC machining significantly improves precision, efficiency, flexibility, and quality. Leveraging this technology is particularly important in the rapidly evolving UAV industry, providing our customers with a valuable competitive advantage.

Precision Mold Manufacturing Capabilities

In order to maintain the best possible supply chain (for each project, including UAV components), Elimold has established global sourcing connections. Leveraging our domestic and international connections, our in-house mold manufacturing facility has established long-term relationships with global manufacturing partners, and our shop can produce custom molds with tight tolerances of 6/10,000 for a 140-inch span and 14/10,000 for a 23-foot span. We also offer additional value-added services such as CNC machining, mold sampling, etc. to save you time and money. After the mold is made, we also provide value-added services including pad printing, heat staking, ultrasonic welding, assembly, kitting, packaging, and inventory management. We know that the UAV market is highly regulated, so we ensure that the quality requirements of the parts are met through the Production Part Approval Process (PPAP). We are also proud of our AS9100D certification, which is a total quality management standard essential to the aerospace industry. With this certification, customers can rest assured that Elimold’s work meets the stringent requirements of the aerospace industry, including its high standards of safety, quality, and reliability. Elimold is your partner for outstanding solutions and peace of mind, combining our deep expertise in plastic, rubber and polyurethane production with our extensive technical knowledge and commitment to quality. Create a partnership and let us develop the custom products you need for your drone.

On Demand Injection Molded Plastic Parts for Drones

Using injection molding services, drones can also be personalized and custom to any individual need, while offering an unrestricted manufacturing process that allows for modifications and upgrades through testing and design iterations. We can also get your drone to perform at its best with the production of lightweight components as well as easily accessible spare parts. That’s where the on-demand manufacturing services provided by Elimold come in to help you mass produce all the drone parts you need to a high standard, with a variety of options to ensure you get the exact product you need to produce your drone. With the injection molding services provided by Elimold On Demand Manufacturing, you can easily produce high volumes of drone parts. We have currently helped several drone companies produce high volumes of parts. They use our on-demand manufacturing services to mass produce drone parts to their exact needs.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

Testing Tolerances with Prototypes

Elimold’s UAV injection molding service offers the option of low-volume prototype part production using low-cost, fast-cooling aluminum molds, an excellent solution for rapid prototyping. You can quickly complete prototypes of varying complexity for testing.

Elimold’s streamlined digital infrastructure also helps accelerate the design and development of UAV parts, helping UAV injection molding engineers meet specifications without sacrificing development time or cost. We also provide technical DFM feedback with both automated and human support. This service allows you to detect and fix part manufacturability issues early in the development process, helping you avoid costly roadblocks, optimize designs, and increase efficiency.

Ready to start your UAV injection molding project?

Contact our knowledgeable engineers for expert guidance and solutions. Let our experienced experts guide you through a seamless process to achieve a successful project.

What we can do

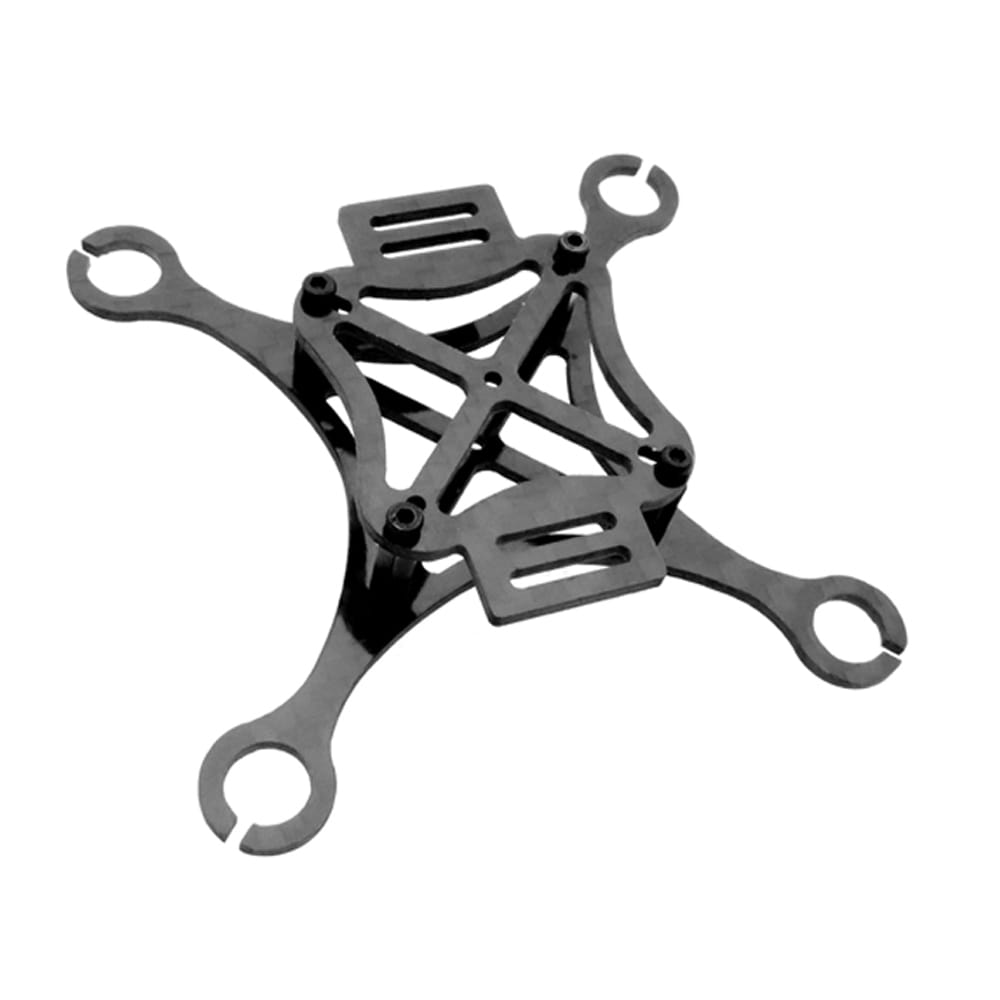

A drone consists of a fuselage, wings, tail, landing gear, automatic flight control system, and power system. The drone fuselage is generally made of PC and ABS, the wings and tail are PP, and the landing gear is PA. As the requirements for drones become higher and higher, composite materials such as PC, GF, PC or ABS have become the first choice for drones. We can manufacture drone fuselages, wings, and landing gear according to the specific needs of our customers.

Elimold has made a series of investments in developing new injection molding technologies to optimize the process. We are good at providing custom services and mold manufacturing services such as injection molding, insert molding, multi-cavity molding, etc. to customers, and have a group of trustworthy customers. Therefore, Elimold has very mature technology and rich experience in manufacturing injection molds and molding. Leading drone parts manufacturers trust that we can maintain the integrity of their designs and have already cooperated with us to start their projects as planned.

Material Options

Elimold’s drone injection molding experts can produce custom molds for a wide variety of plastic and metal materials. No matter what material your application requires, you can count on us to turn your ideas into reality. Explore the plastic materials we manufacture drone plastic injection molding for:

- ABS Plastic

- Polycarbonate

- Nylon

- Polypropylene

- PVC

- Polystyrene

- TPE

- Glass-Filled Resins

- TPO

Precision Drone Plastic Parts on Demand

Whether you are custom a racing drone for competition or a quadcopter for cinematography, Elimold has the equipment and expertise to manufacture your custom parts to specification. Create custom drone parts to improve performance, enhance the appearance, replace damaged or defective components, or personalize and make your drone unique. Choose from a variety of high-strength and lightweight materials to optimize the functionality and appearance of your project. Contact Elimold to easily design your custom parts from scratch.

We manufacture custom parts for a variety of drone applications

Plastic injection molding services are ideally suited for the production of a variety of drone applications, and Elimold currently manufactures custom plastic components for leading unmanned systems original equipment manufacturers (OEM) such as:

- Military

- Delivery

- Film & Production

- Racing & Competition

- Quadcopters

- Airships

- Micro Air Vehicles

- Propellers

- Wings

- Rotors

- VTOL

- UAVs

Why use plastic injection molding for UAV plastic parts?

Capable of manufacturing complex geometries and thin-walled parts, plastic injection molding has proven its ability to accommodate complex designs while maintaining structural integrity. While initial mold costs can be high, the efficiency of plastic injection molding is extremely cost-effective for large-scale production.

The process is able to achieve tight tolerances, thereby achieving precision, and its consistency and repeatability keep all molded parts consistent. In addition, plastic injection molding can accommodate a wide range of materials, making it a top choice for a variety of requirements, especially for applications that require high material strength and stiffness.

Advantages of Plastic Molding for Unmanned Systems Components

Plastic injection molding offers an economical and lightweight solution for UAV plastic parts. Injection molding can produce parts comparable to structural foam molding at a fraction of the total project cost. In addition, industrially formulated thermoplastic materials can meet the most stringent global safety standards and performance requirements of your application. Combine these properties with the incredible design flexibility of thermoplastics, and the advantages are numerous.

Lightweight Materials

Thermoplastics are 40% lighter than fiberglass, 6 times lighter than stainless steel, and half the weight of aluminum

Reduce costs and improve efficiency

Lightweight materials mean greater fuel or battery efficiency and reduced maintenance costs

RTL, EMI and RFI Shielding

Thermoplastic material options available with RTL, EMI and RFI shielding properties, additives or applied films

UV and Extreme Temperature Protection

Thermoplastic material options available with high UV resistance to withstand harsh environments and temperatures

Durable and Impact Resistant

Tough thermoplastics can withstand impacts and are less likely to dent, chip or crack

Aesthetic Design

Modern, streamlined design capabilities and flexibility at a lower cost

Multiple surface finishes

Material and tooling options for overall color, texture, pattern or branding

Large, low-cost parts

Large plastic parts up to 96″ x 120″ can be produced with low upfront tooling investment

Medium Volume

Ideal production process and competitive cost for 250-3000 drone plastic parts

Your trusted manufacturing partner

We always pay attention to market trends, continuously develop new UAV mold development and fixed-wing UAV aircraft processing to meet customer needs, focus on product quality, and improve customer satisfaction. Our company’s platform uses big data mining technology to deeply mine and analyze industry information, and summarize and refine to form business opportunities. We use scientific operation models and high-tech products to guide the market to improve consumption quality as our own innovative concept, and win many market shares with perfect after-sales service and complete marketing network.

We firmly believe that people’s character makes a career. Our company extends the value of products to consulting and after-sales service, and makes up for the similarity of product core value by improving the overall value of UAV plastic injection molding services and mold customization. After years of continuous and rapid development, we have consolidated our brand advantages in the industry and accumulated rich and valuable experience and high-quality customer base. We vigorously promote quality, efficiency and power changes, and drive industrial modernization with innovation. We focus on the balance between short-term and long-term interests, and do everything possible to give shareholders a reasonable and stable return on investment. The company has always adhered to the policy of “keeping pace with the times, pioneering and innovating, striving for excellence, and striving for innovation”, and has achieved remarkable results. At present, it has established extensive business relations with many domestic and foreign UAV companies and enterprises. We focus on meeting your requirements, focusing on customers, striving to create competitive advantages for customers, and have the courage to assume social responsibilities. We hope to stand out in the industry with excellent technology, unremitting pursuit of innovation, excellent quality, and outstanding reliability.

Ready to explore how Elimold can help make your project a success?

We urge you to contact us when you have manufacturing needs. Our team is ready to provide manufacturability assessments, design recommendations, and molding solutions based on your needs. Elimold will only start the production process after we are fully connected to the entire project and there are no issues. We will maintain close contact with the customer’s design team and procurement team throughout the production process, and the corresponding experts will be involved in each stage to ensure that the products we produce can meet customer requirements on time and within budget.