Electronics 3D Printing

From housings to sheaths and tooling, additive manufacturing is a reliable manufacturing technology if you want to innovate, evolve and bring more adaptability to your products and processes. Do you want to benefit from a production process tailor-made for your electronics project? Accelerate prototyping and production processes by implementing additive manufacturing

Electronics 3D Printing Manufacturer

The electronics manufacturing industry has high requirements for product development cycle, development cost, confidentiality, etc. In order to meet these requirements, the cost of enterprises is very high, resulting in a significant increase in product costs. Additive manufacturing provides great help in the development and production stages of electronic products, such as assembly and functional verification, appearance and performance testing, ergonomics, rapid prototyping, rapid tooling, etc., which can reduce the manufacturer’s R&D and time costs and increase product profits. Elimold provides industry-leading online services for 3D printing in the electronics industry. Whether you need a prototype or a production part, we can produce it on demand. We are your one-stop shop for accurate, precise, and custom 3D printed parts for electronic products at an affordable price. Upload your 3D CAD file to get a 3D printing quote and delivery time in seconds. We can provide the entire manufacturing process from a single prototype to thousands of production-level parts.

Elimold 3D Printing Services Accelerate Electronics Innovation

Electronics have become ubiquitous in our daily lives, sparking a revolution from smart home devices to connected wearables. For your company to stand out in this extremely competitive industry, you need to bring breakthrough products to market faster and continuously create unique customer experiences that deliver value. This level of consumer demand drives the need for design flexibility, prototype performance, rapid iteration, supply chain continuity, sustainable solutions, and operational efficiency from prototyping to bridge production and mass customization.

Elimold’s 3D printing solutions for the electronics industry give you a competitive advantage to meet these challenges. With a dedicated team of experts and decades of industry experience, we work with you on application development and leverage the industry’s largest suite of additive manufacturing solutions to meet your specific needs.

3D Printing in the Electronics Industry

3D printed electronics are becoming a viable alternative to traditional manufacturing processes. This is especially important as electronics become smaller, more tightly packaged, and subject to more demanding conditions. Miniaturization, increasing number and density of electronic components, and faster data speeds that generate more heat are just some of the challenges facing today’s electronics designers.

Speed is a key requirement in electronics manufacturing, and this is the biggest advantage of 3D printing. With Elimold’s 3D printing services, engineers can reduce the barriers between creativity and functional anti-static safety parts. Whether it’s shortening design cycles, conducting more iterations, accelerating tool development, or building more optimized final parts, improving efficiency has powerful downstream benefits throughout the electronics manufacturing process.

Our 3D Printing Capabilities

Our online electronics industry 3D printing services provide customers with efficient, precise, custom 3D printing solutions. As a leading electronics 3D printing company. Elimold utilizes cutting-edge 3D printing technology to produce high-quality 3D printed electronic parts with exceptional precision. Our competitive 3D printing service costs can be tailored to each customer’s unique needs, ensuring they get the best value for their investment. Trust us to be your reliable partner to turn your 3D designs into reality.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused DepositionModeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

Develop your electronics projects using additive manufacturing

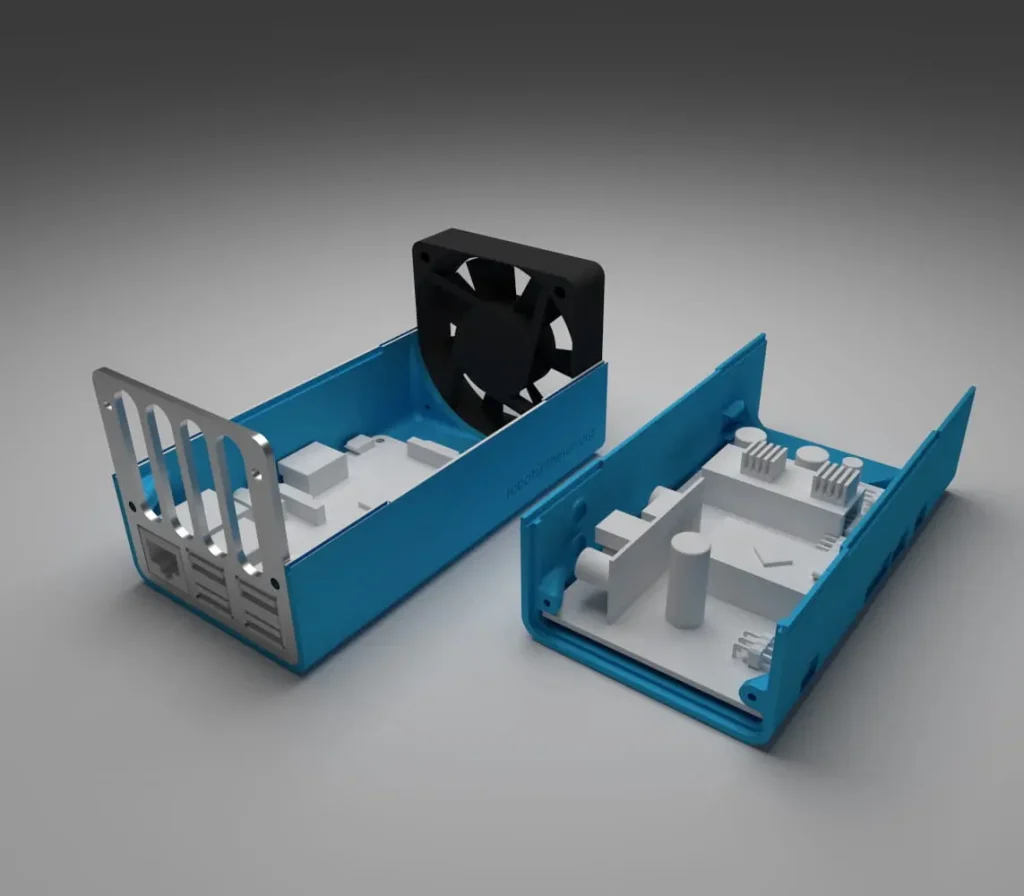

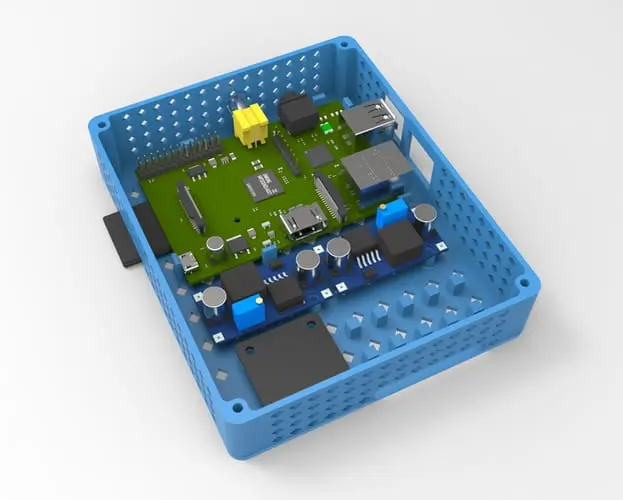

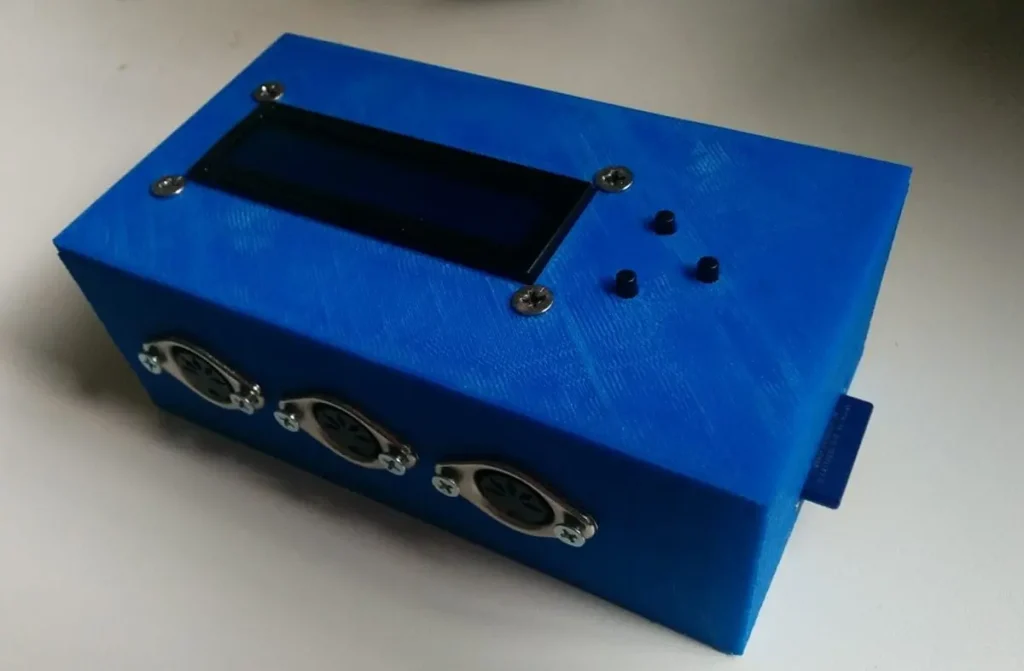

3D Low-Volume Production

Print strong and durable electronic parts with our engineering and ESD-safe thermoplastics. Thanks to our industrial 3D printing technologies, you can design parts with complex geometries. You can also produce small series or limited edition products or even manufacture replacement parts in no time.

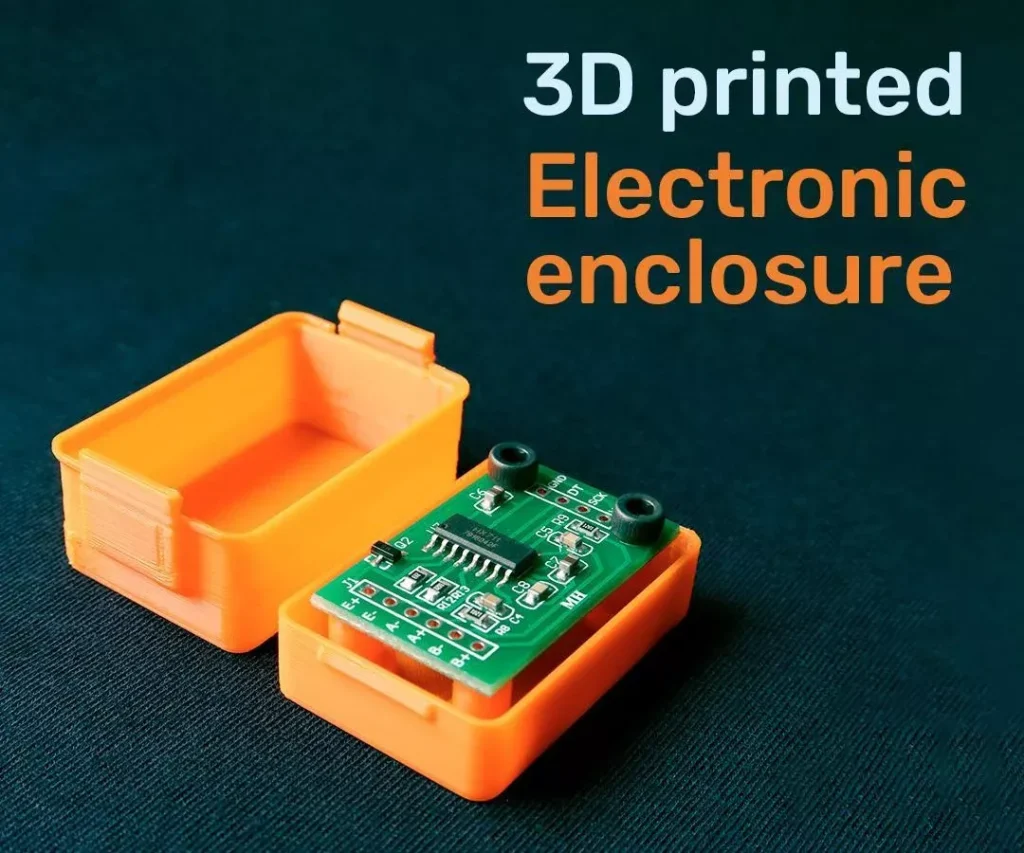

3D-Printed Functional Prototypes

Elimold specializes in 3D printing services for electronic product prototyping. Utilize our advanced technology and engineered thermoplastics to easily and quickly test your electronic parts at a fraction of the usual cost.

3D-Printed Tooling and Jigs

Manufacture stable and lightweight tools that are easy to handle and meet the requirements of electronic applications. Our additive manufacturing experts are there to support you from start to finish, to help you obtain the result you want.

Find your ideal solution

We’re here to help you take advantage of all the advantages of additive manufacturing in the electronics industry.The speed and ease of use of our machines also means you can quickly move from design to manufacturing, allowing you to modify and custom your parts as needed, giving you unparalleled flexibility.We will support you in the process of redesigning your components and selecting the materials best suited for your application.

3D Printing Electronics Rapid Prototyping

Physical prototypes, whether simple mockups or detailed scale models, are an important part of product development. Early concept models can be used to validate designs, test functionality, and understand the real look and feel of a product. Prototyping helps identify potential problems or improvements early in the manufacturing process and ensures that the final project meets design specifications. The downside is that it takes time and cost. Prototyping and testing are the most time-consuming parts of product development.

3D printing can design, print, and test parts in a fraction of the time and cost required by traditional manufacturing methods, shortening product development cycles. Shortening the time between design iterations allows more testing to be done in the same or less time. This enables manufacturers to optimize and release new products faster, which is critical in the highly competitive consumer electronics market.

On-demand production

3D printing allows electronic parts to be produced on demand with fixed lead times and a limited cost structure, significantly reducing the time to design and launch a product. It also allows both new and existing devices to be easily produced in small batches directly from the manufacturer’s digital inventory or the customer’s CAD model using a wide range of 3D printing materials. This is a major advantage that will transform the supply chain for electronics, allowing manufacturers to meet customer needs immediately.

3D printing also tends to be more cost-effective than traditional manufacturing techniques in small-scale production of electronic products. This makes small-batch production of a specific electronic device or product more affordable than subtractive manufacturing. With lower unit manufacturing costs, you don’t need to produce and sell as many devices to make the manufacturing process worthwhile.

Streamline supply chain with on-demand manufacturing

The global electronics supply chain can be riddled with inefficiencies, from inventory challenges to logistics delays. 3D printing offers a compelling solution because it enables local, on-demand manufacturing. With 3D printing services, companies can produce electronic parts on demand, significantly reducing inventory costs and mitigating supply chain risks.On-demand manufacturing is particularly beneficial for small and medium-sized businesses that may lack the resources to invest in large-scale production. It enables companies to respond quickly to market demands or changes, providing customers with timely upgrades and replacements that would otherwise be impractical.

Why choose to use Elimold?

Product compliance management

- Dimensional inspection

- Conformity of raw materials

- Conformity procedure

High-quality production

- Understanding phase

- Design and programming phase

- Production phase

- Quality phase

Quality assurance

- Continuous improvement program

- Elimold’s quality policy

- Efficient and automated quality system

- Focus on industry 4.0: innovation, automation and excellent reliability

Advantage

- Rapidly create functional parts

- Precision machines can create high-precision parts with complex features

- Geometric complexity is no longer limited, simplifying conformal tooling and workholding manufacturing

- Continuous fiber reinforcement provides metal strength parts for a variety of applications

Accelerate Product Development

In the fast-paced electronics industry, speed is critical to maintaining a competitive advantage. 3D printing has revolutionized product development by drastically reducing the time and cost required for prototyping. With advanced FDM and PolyJet technologies, manufacturers can create production-grade prototypes that look, feel, and perform very similar to the final product. This allows for rapid iteration and testing, enabling designers and engineers to efficiently refine their designs, gather consumer feedback, and identify and fix potential issues early.

Customization and Personalization

Electronic products are becoming increasingly personalized, with customers seeking products that reflect their unique preferences and lifestyles. 3D printing enables mass customization, allowing manufacturers to efficiently produce custom products that meet individual consumer needs. By leveraging the flexibility of multiple 3D printing technologies, companies can design and create products with specific fit, functionality, and aesthetics, increasing customer satisfaction and brand loyalty. Whether it’s a personalized smartphone case, a custom wearable, or a unique audio accessory, 3D printing enables the consumer electronics industry to offer diverse and personalized options.

Streamline Production and Supply Chain

Traditional manufacturing processes in the electronics industry often involve complex tooling and long production cycles. 3D printing disrupts this paradigm by introducing additive manufacturing technology to streamline production and reduce waste. 3D printing enables agile manufacturing by printing molds and producing small to medium batches of parts such as connectors, housings, and buttons, eliminating the need for expensive tooling and retooling. This can shorten lead times, reduce inventory costs, and increase supply chain efficiency. Additionally, keeping production in-house minimizes the risk of intellectual property theft, giving companies greater control over their designs and innovations.

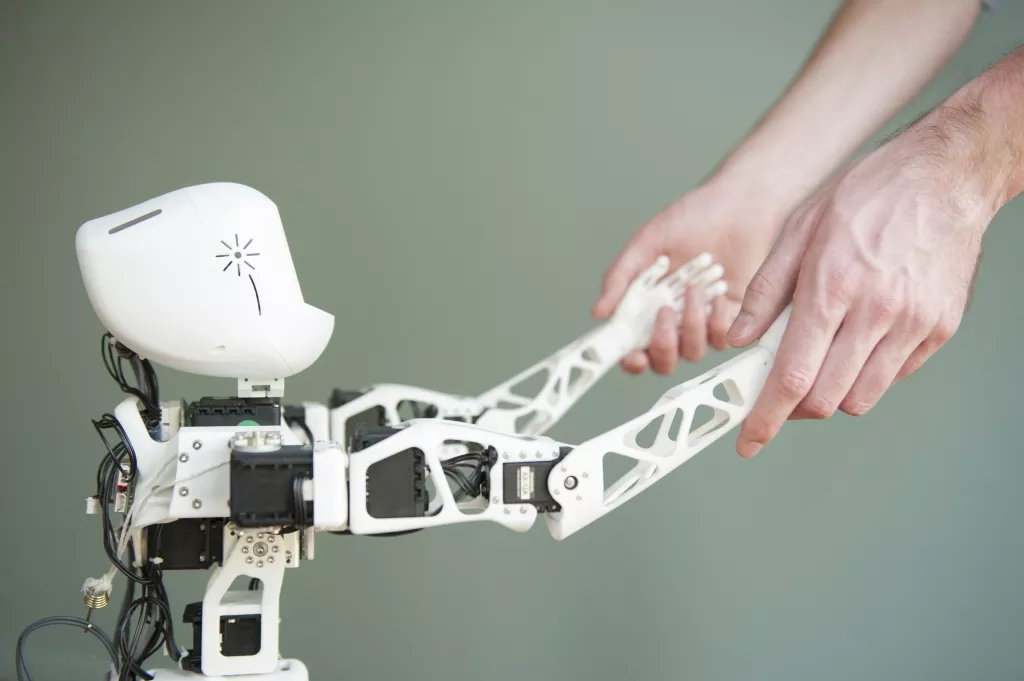

Product Innovation is No Longer Limited

Engineers can custom electronic components to meet the precise specifications of a specific application, which is ideal for industries that require high-performance custom solutions. Whether it is a custom-shaped antenna to improve signal reception or a custom connector to optimize space within a device, 3D printing can enable these inventions without the need for expensive molds or tooling. Designers are no longer limited by traditional manufacturing methods, as they are now able to create organic shapes and complex internal structures. These capabilities facilitate miniaturization, a trend that is shaping the future of electronics. With 3D printing, producing smaller, more compact devices does not mean sacrificing performance or complexity.

Materials suitable for electronic applications

Plastic

- ABS

- PLA

- PET

- TPU

- ASA

- PC

- PP

- Carbon Fiber

Metal

- Aluminium

- Steel

- Copper

- Stainless Steel

- Tool Steel

- Nickel

- Titanium

Key Benefits of 3D Printed Electronics

- Streamlining and simplifying product development

- Greater design freedom

- Faster time to market

- Producing lighter and better-performing components

- More customer personalization options

- Increased cost and resources efficiencies

- Consolidating previously separate parts into a single unit

- Optimizing inventory and supply chain management

Application of 3D printing services in the electronics industry

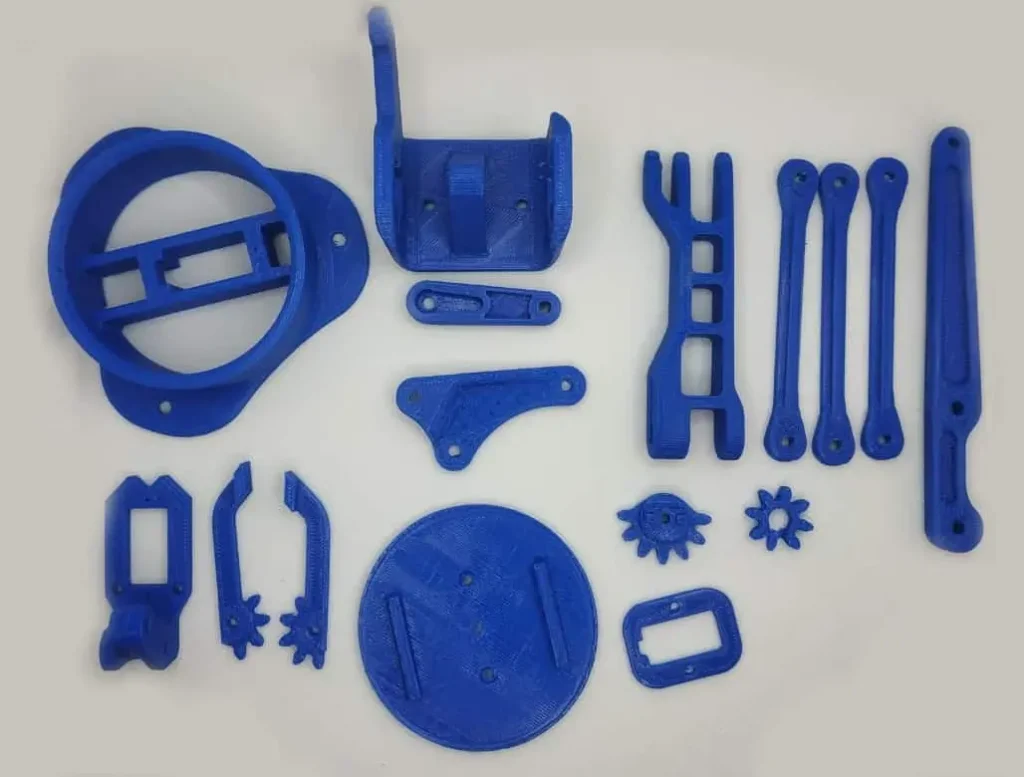

Applications of electronic 3D printing can be classified based on the type of printing and the specific components being manufactured.

- High-quality enclosures housings

- PCB holders

- Electric connectors

- Jigs and fixtures

- Wire guides and organizers

- Battery holders

- Elevator buttons board

- Braille Elevator buttons

- Light Fixture support

- Components, heat exchangers, electric motors

- Jet parts

- Plastic injection molds

- Robot parts

- Metal printing

- Vehicle batteries

- Printed electronic circuits

- Sensors

- Tooling

Ready to start your next electronics 3D printing project?

Additive manufacturing is an effective solution for the electronics industry, both in terms of material utilization and process flexibility. It can produce electronic product parts of any size from a variety of different plastic or metal materials without wasting raw materials. . Explore the potential that 3D printing has for you in the electronics industry with us and upload your files to get a quote now.