Electronics CNC Machining

Elimold provides high-precision CNC machining services for the electronics industry, producing complex components that meet stringent performance standards. Our advanced technology and expert engineers accelerate product development, providing support from prototyping to mass production while ensuring top quality at every stage.

CNC Electronic Parts Manufacturer and Supplier

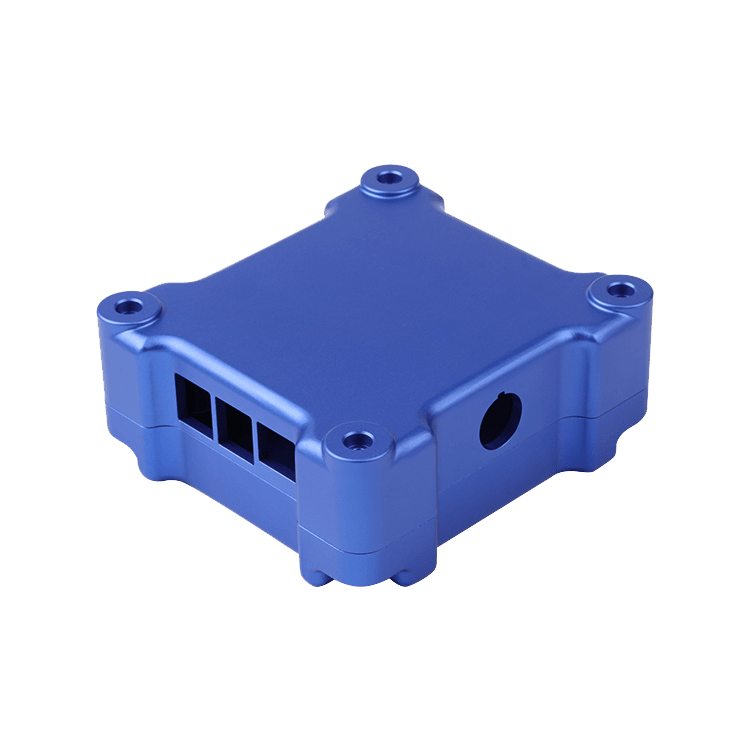

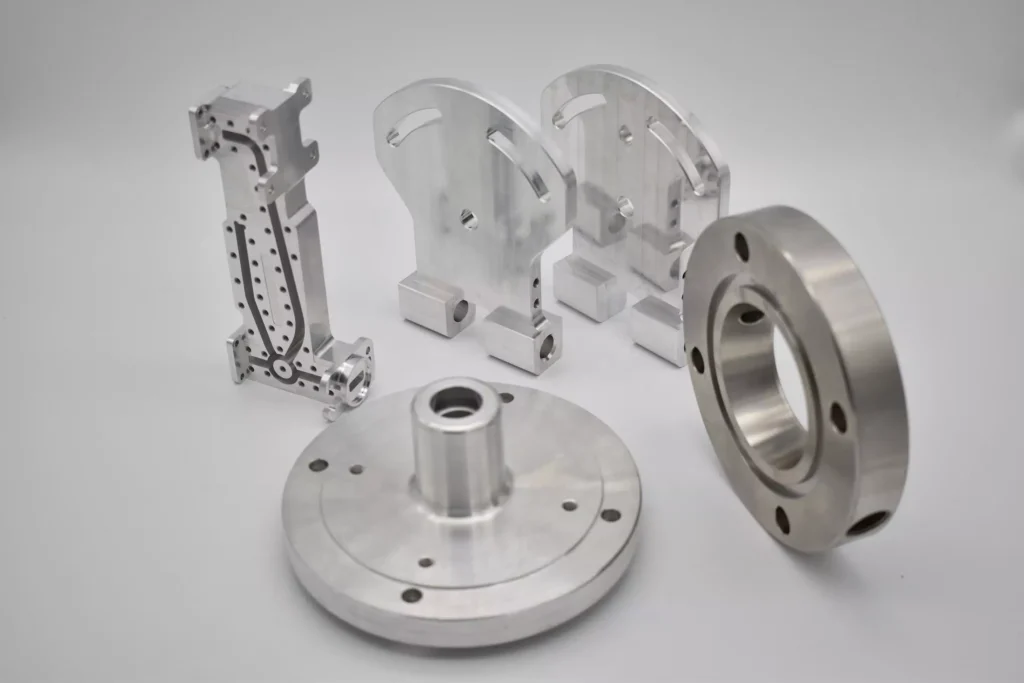

In this fast-paced, competitive electronics industry, components are becoming smaller and more powerful. And these components need to remain lightweight and compact. At Elimold, we understand the unique challenges and demands of the electronics industry. Our custom machined parts are carefully designed and manufactured to meet our customers’ specific requirements, ensuring they integrate seamlessly into electronic devices. From prototyping to full production, Elimold has the resources to supply turnkey components, from simple flat metal parts to sophisticated functional parts, our advanced production equipment and extensive experience enable us to maintain fine tolerances in demanding applications. We can provide excellent dimensional accuracy and repeatability for even the most complex part designs. We work closely with our customers to develop parts that enhance the functionality and reliability of their products. Whether it is a custom one-off part or a large-scale production, our commitment to quality ensures that every part we deliver is perfectly suitable for its intended use.

Your Electronics CNC Machining Partner

At the core of Elimold’s operations is an unwavering commitment to producing high-quality CNC machined electronic parts that meet the most stringent electronics industry standards. Notably, Elimold specializes in manufacturing custom parts based on drawings or samples provided by customers. In addition, we commit to a signed Non-Disclosure Agreement (NDA) to protect its customers’ intellectual property, ensuring the highest degree of confidentiality and security. Elimold’s comprehensive expertise, advanced technology, and commitment to quality make it a trusted choice for electronics companies that need a reliable partner to produce complex electronics industry CNC parts. The company’s focus on customization, precision, and confidentiality ensures that it can meet its customers’ unique manufacturing needs and contribute to the continued advancement of electronic devices and technology.

We maintain a dedication to exceeding our customers’ needs. We will do everything in our power to ensure the successful completion of your project on time and on budget. We take pride in every component we produce.

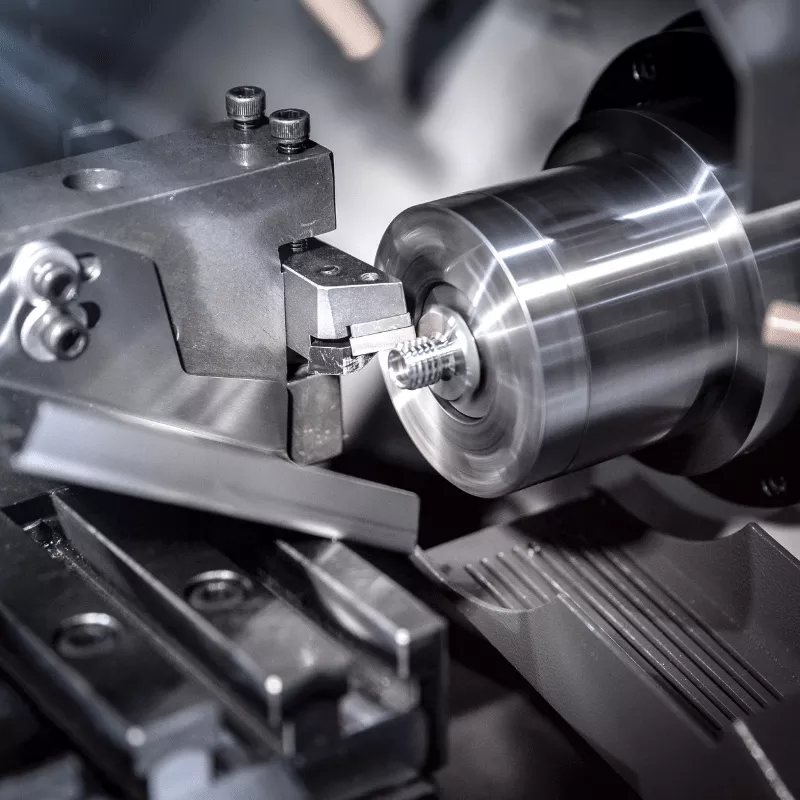

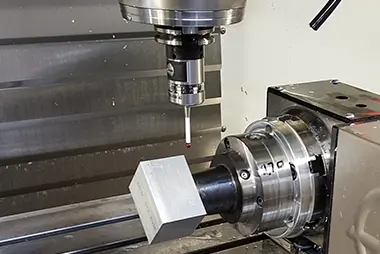

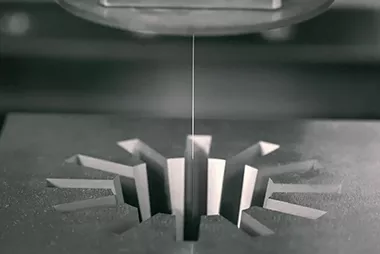

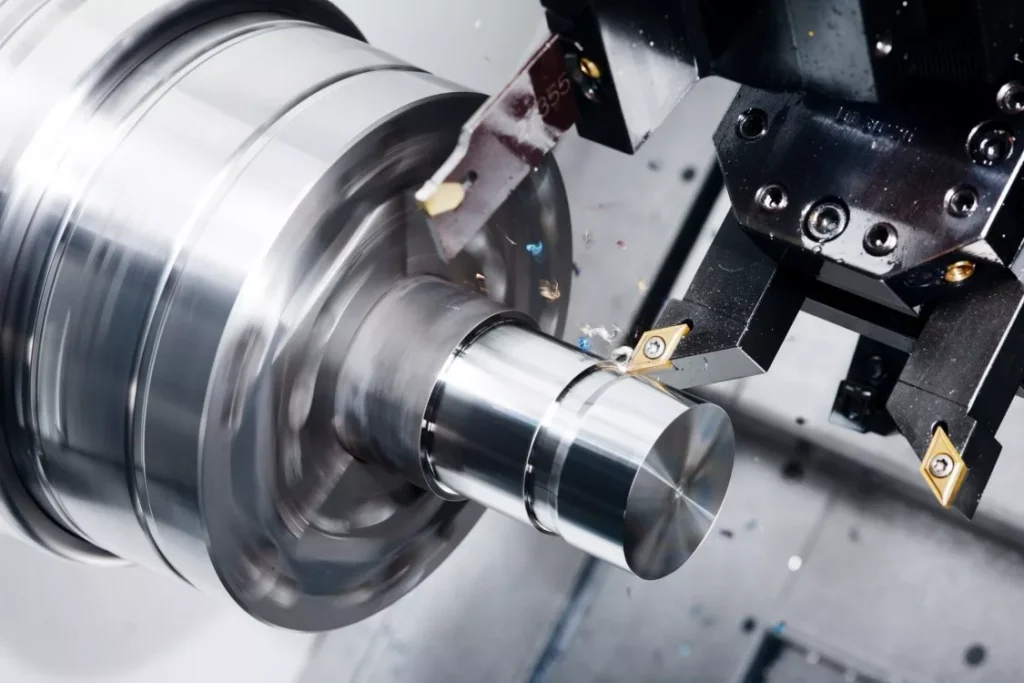

CNC Electronics Machining Service Capabilities

As a precision electronic component manufacturer, whether your company needs large quantities of parts made from a variety of metals with tolerances of +/- 0.050mm, or single-piece prototypes, Elimold has solutions for your unique electronic problems. Our manufacturing processes are ISO 9001:2015 certified, demonstrating our commitment to strict quality control standards, no matter the size of your part. When fractions of a thousandth of an inch matter, customers trust us to thoroughly inspect every batch to ensure that every product meets customer specifications.

We work with customers on projects at every stage of the product lifecycle, from the early R&D stages to full production and launch. With our precision electronic parts machining, we are able to produce not only single-piece rapid prototypes, but also up to 100,000 units per order. With lead times of just 8 weeks, our customers never have to wait for production and can rest assured knowing that their products are delivered on time, every time.

Our Manufacturing Services for Electronic Applications

Elimold specializes in providing custom parts to the precise specifications of electronics manufacturers, from prototype development to full production. Our advanced CNC machining capabilities and commitment to quality make us a trusted partner in the industry, ensuring that each component is not only fully functional, but also looks outstanding.

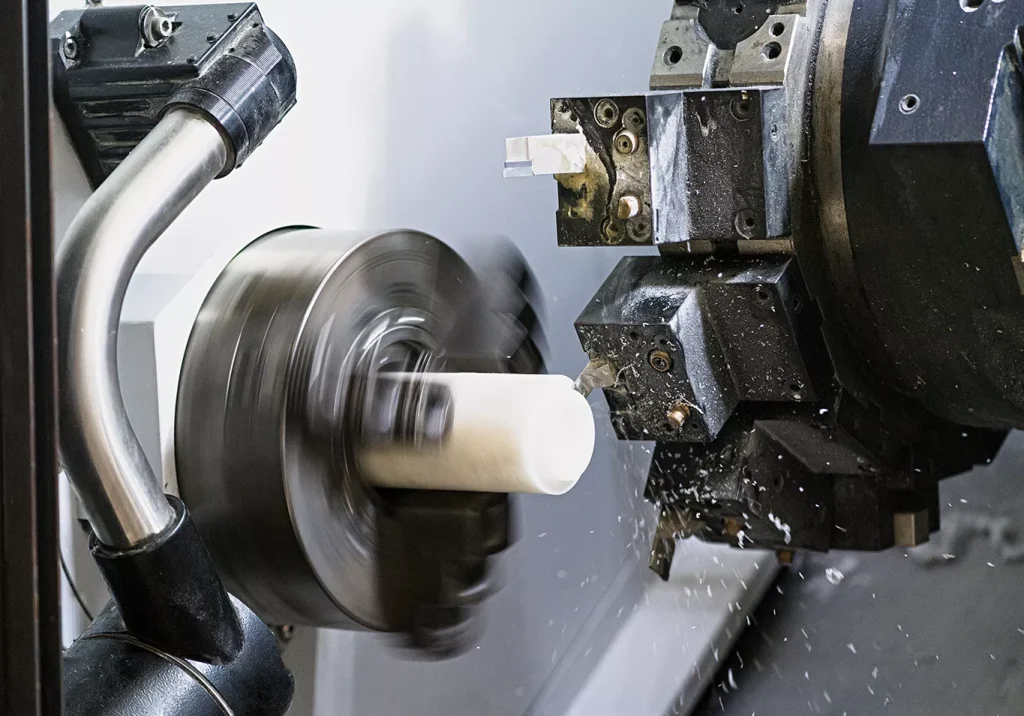

CNC Milling

CNC Turning

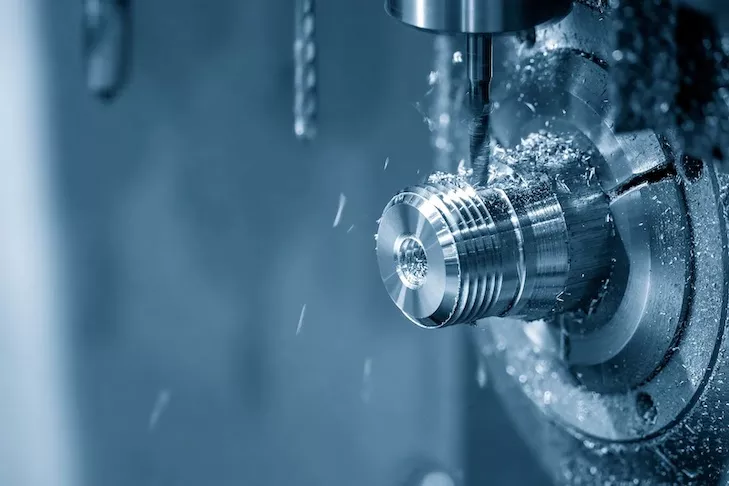

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

EDM Machining

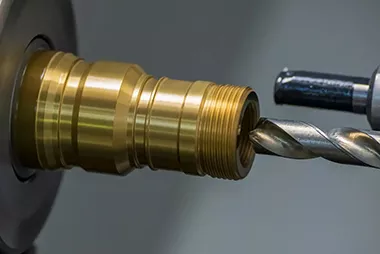

CNC Threading and Tapping

CNC High-Speed Drilling

Certifications

- ISO 9001:2015 certified

- Fully compliant with stringent customer requirements

- Compliant with DFARS material procurement requirements

- Strict PPAP and process compliance

- FMEA for automotive customers

- Expertise in KanBan and CMM inspection and inventory management systems

- ITAF 16949 certified

We machine electronic parts to your specifications

We use the latest CNC technology and equipment to precisely manufacture your electronic components. Our team of experts ensures that your components meet your specific requirements. We also offer a wide range of services to our customers, including assembly, packaging and shipping. We provide the best service to our customers. Contact Elimold’s certified experts for precision electronic parts machining. Our skilled experts have industry-specific knowledge and certifications, ensuring that electronic components are produced to the highest standards. Working with us, you will benefit from cutting-edge technology, superb craftsmanship and a commitment to providing custom solutions that meet the stringent requirements of your electronic applications.

Ready to start your next electronic CNC parts project?

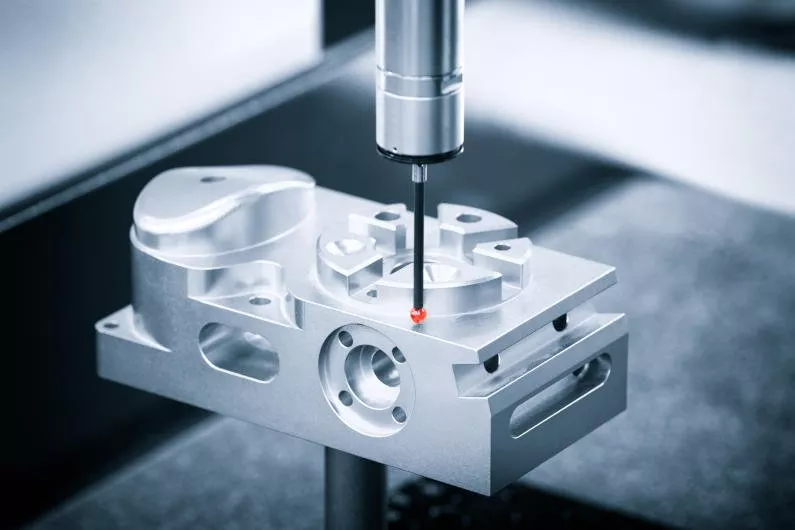

Quality Inspection

With deep roots in the electronics industry, we have created systems around part handling, automated deburring/surface finishing, non-contact dimensional inspection, and QC inspections related to standardized appearance and assembly. Our dmu 5-axis machines and Swiss machines allow us to form mission-critical components with tight tolerances with high repeatability, and our experience working with large electronic parts companies gives us the knowledge needed to form parts that meet your expectations.

In addition, Elimold uses an ISO9001:2015 REV D certified, ITAR registered machining process to manufacture electronic parts. We have worked hard to develop a robust ISO9001:2015 certified quality system, which includes the use of a custom ERP system throughout the company to enhance quality control.

Custom Machined Parts for the Electronics Industry

We provide precision CNC machining services tailored to the electronics industry. Our expertise in rapid prototyping and on-demand production helps you bring innovative electronic products to market quickly. With state-of-the-art capabilities, we produce high-quality components with tight tolerances. Our team ensures precision-engineered solutions that meet your design specifications. We focus on fast turnaround and superior engineering support, leveraging cutting-edge technology and industry best practices to optimize your production process.

If you need custom CNC components for the electronics industry, Elimold is your best choice. We specialize in manufacturing custom electronic parts and will determine materials, produce components, and ship them all from one location. Simply provide us with your specifications. You can also send us parts, drawings, or research materials. We focus on quality and precision, and will find innovative ways to meet the unique needs of your project. Every product is carefully considered, which allows us to work with some of the most renowned electrical and electronic OEM in the world.

CNC Prototyping and Production Solutions for the Electronics Industry

By efficiently transitioning from rapid prototyping to full production, our expertise in CNC machining of electronic parts ensures a seamless process, accuracy and timely delivery to meet industry needs with superior quality.

Prototyping

Through Elimold’s years of experience in electronic parts machining, precision and innovation merge to shape the future of high-performance and reliable electronic components. As a leader in custom CNC parts for the electronics industry, Elimold employs a meticulous prototyping process that includes design conceptualization, computer-aided modeling, and precision manufacturing. Initial concepts are transformed into digital models that are carefully analyzed by a team of engineers to ensure efficiency and structural integrity. These designs are then brought to life through advanced manufacturing technologies such as 3D printing combined with CNC machining, and thoroughly tested to ensure the production of high-performance, reliable rapid prototypes of electronic components.

Design Testing

Explore Elimold’s meticulous design testing for custom CNC parts for the electronics industry to ensure that each component meets the stringent standards of accuracy, durability, and performance required by the design. Elimold’s design testing of CNC parts for electronics products is a detailed process that involves a thorough inspection of each component. Initial digital models undergo rigorous simulations to evaluate mechanical efficiency and structural integrity. Advanced testing methods, such as experiments in controlled environments, evaluate performance under a variety of conditions. Material durability is scrutinized to meet stringent electronics industry standards. Continuous improvements based on test results ensure precision, durability, and optimal performance of the final electronics parts.

Engineering Testing

Elimold offers comprehensive electronics parts engineering testing, dedicated to meeting the highest engineering standards for electronic CNC parts, ensuring optimal functionality and superior performance. At this stage, we help you create prototypes based on your product requirements and design files. Based on your needs, we will use low-cost materials and processes to develop parts similar to the final product. This enables you to check specifications and functional testing. Our advanced technology also helps us ensure a fast turnaround for these prototypes.

Production Testing

Production testing is a critical stage in the process of preparing electronics for high-volume production, where electronic components undergo rigorous scrutiny to guarantee quality, reliability, and optimal performance for mass production. Elimold uses a rigorous electronics production testing process to ensure top quality. This includes a comprehensive inspection of components to evaluate materials, structural integrity, and performance under simulated conditions. Precision testing methods are used to verify reliability and compliance with industry standards.

High-Volume Production

Elimold’s final production phase of electronics is seamlessly integrated with meticulous precision and rigorous quality control processes throughout the production process, ultimately creating flawless electronic components that exceed the most stringent industry standards. Elimold’s final production process for high-volume production of electronic CNC parts embodies precision and excellence. Our in-house factory utilizes a variety of cutting-edge technologies throughout all production processes to ensure that each component meets strict industry specifications. Rigorous quality inspections evaluate structural integrity, materials, and performance to ensure that our custom-made parts for our customers exceed electronics industry standards.

Let’s discuss your project needs

Experience the Elimold difference, where precision, reliability, and end-to-end management combine to streamline your manufacturing process. Whether you need CNC machined electronic components, custom accessories, or advanced machining services, we can handle your project from start to finish. Not only does our team deliver high-quality results, but we also work closely with you on Design for Manufacturability (DFM) to ensure your design is optimized for production. Partner with Elimold for a comprehensive electronics machining solution. Contact us today to learn how we can manage and support your entire manufacturing process.

Advantages of CNC Machined Electronic Parts Production

A few of the advantages of partnering with Elimold for CNC machined electronic components include:

- In-depth expertise in Swiss machining, CNC and multi-spindle turning, ensure tolerances of +/- .0002 accuracy.

- Quality assurance standards in compliance with the most stringent requirements set by the International Organization for Standardization.

- Procurement expertise that allows for the acquisition of the highest quality materials at competitive rates.

- Reliable turnaround ensured by lean processes and Kanban inventory management solutions

Materials We Work

We work with a wide range of metals and non-metals for CNC electronic parts production. The materials we work with are listed below.

Plastics

- Ultem®

- PEEK

- Polyethylene

- PTEF (Teflon)

- Derlin/Acetal

- ABS

- Nylon

- G-10 Garolite

Metals

- Copper

- Aluminum

- Bronze Alloys

- Stainless Steel

- Brass

- Alloy Steels

- Zinc and Zinc Alloy

- Titanium Grade 2 and 6Al-4V

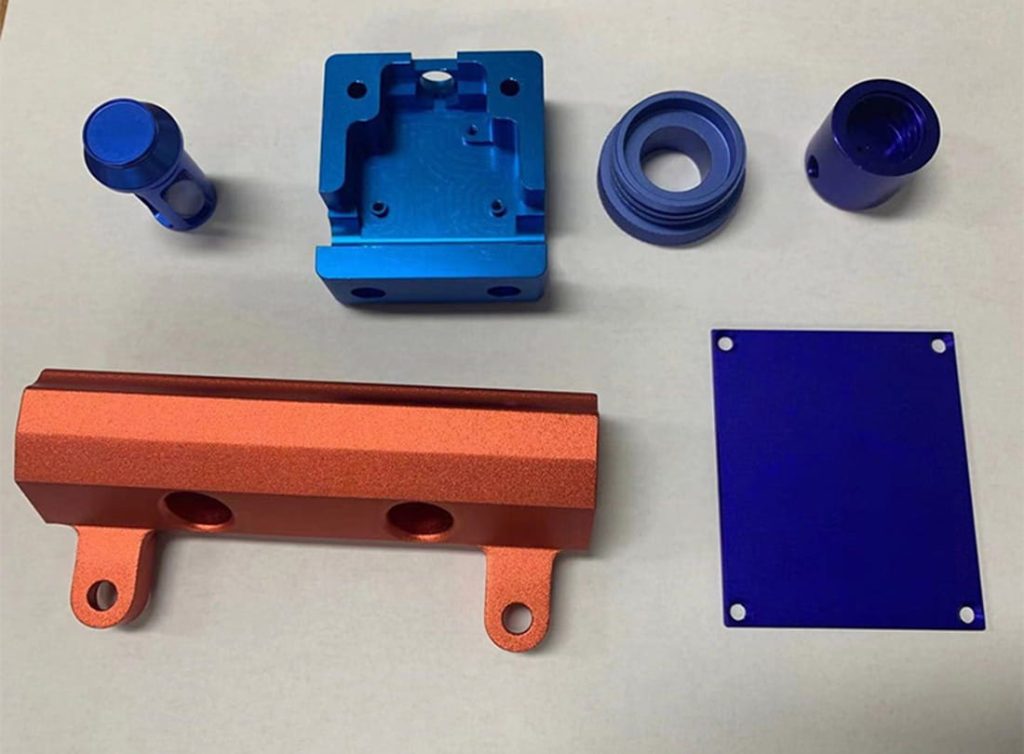

Surface finishing options

Our finishing services further enhance our range of production technologies. Electronic products place particular emphasis on appearance and appeal. Therefore, our finishing is decorative, aesthetic and, in some cases, functional.

- Texturing

- Anodizing

- Polishing

- Blasting

- Painting

- Electroplating

- Passivation

- Heat treatment

- Powder coating

- Custom

Applications of electronics cnc machining

Electronics machining is a challenging sector owing to the diversity involved. Every project is quite different and sometimes comes with extra requirements. We can fulfill them quite easily and have been successfully delivering on time all these years. The following are some common parts that we regularly machine at our facility.

- Printed Circuit Boards

- Casings and Enclosures

- Heat Sinks

- Semiconductors

- Sockets and Connectors

- Fixtures

- Brackets, Tools, and Chassis

Why Choose Our Electronic CNC Machining Services?

The manufacturing of parts for the electronics industry requires definite precision and experience to build a high-quality product to enhance the functioning of the end product. The make and break of an electronic machine depend on the perfection of these little parts. A slight difference in their manufacturing—and the whole final product can collapse.

Semiconductors, electronic and mechanical components, circuit boards, and any part that fits in an electronic assembly must be well designed and tested before sending out for application.

Elimold’s experts with many years of combined experience use modern methods to manufacture reverse engineered machine parts for electronic assembly support and various other functions in the electronics industry.

Reverse engineering is a smart method of working backward from a design and making relevant adjustments in the component design of semiconductors—improving the whole structure of the component altogether.

Whether you need a single prototype or many reverse engineered machine parts, we promise to deliver quality every time. We use modern technology in our services—integrating design, jig & fixture manufacturing, CAD model and prints, precision CNC machining, Precision grinding and various other tested-for-quality methods in our manufacturing. With CMM inspection, we make sure every part that leaves our place is perfect for your industry.

The Electronics Manufacturing Industry

The electronics manufacturing industry is a broad term that covers the production of a wide range of electronic products, from small components to large consumer appliances. The industry is a major contributor to the global economy, accounting for more than US$1 trillion in annual shipments.

The electronics manufacturing industry is highly fragmented, with a large number of small and medium-sized enterprises accounting for a significant share of global production. The top 10 electronics manufacturers account for less than 30% of global production, while the top 100 account for less than 60%.

The electronics manufacturing industry is also constantly changing, with new technologies and products being introduced on a regular basis. It has seen a major shift in recent years with the introduction of CNC machining. This technology has allowed for greater precision and accuracy in the manufacturing process, as well as increased efficiency and productivity. CNC machining has become an essential part of the electronics manufacturing process and has helped to improve the quality of products and reduce costs.

The Status Quo of CNC Machining in the Electronics Industry

CNC machining is currently a widely used manufacturing process for metal and plastic parts. It is known for its accuracy, repeatability and ability to produce durable parts by extruding blocks of material.

It can also produce precision metal parts in a short time because it does not require tools, but can produce higher quality parts than other short-cycle technologies such as 3D printing.

For these reasons, CNC machining is very suitable for the prototyping and production of electronic device components, from simple handheld devices to expensive industrial equipment.

Large and small parts, simple and complex parts can be processed by CNC, and CNC processing is widely used.

Request a Free Electronics CNC Machining Quote Now

Ready to start your next project? Upload your CAD design prototype and contact us. Our engineers will provide you with a free quote and design for manufacturability analysis to start production discussions immediately.