Energy 3D printing

Our expertise in the energy industry ultimately drives innovation and cost-effective solutions within the industry, with our ability to accelerate design and production timelines, and reduce part cost and weight. Get instant quotes for high-quality energy 3D printed parts in as little as 24 hours, and receive immediate DFM feedback on your designs.

Energy 3D Printing Service Provider

At Elimold, we provide energy 3D printing services. Digital technology and its innovations have transformed the applications and the materials used for them. Improvements and changes in such applications have helped reduce production costs and provide smooth surface finish materials for the prototyping phase of energy product development. Our professional energy 3D printing services will allow you to create functional parts for a wide range of energy applications. We are an additive manufacturing production center that produces a wide range of parts for a wide range of energy applications using a wide range of materials. Upload your file online with your requirements and we will 3D print it and send it to you. If you don’t have a 3D model or STL file for your prototype yet, we can also design a custom 3D model for you based on a 2D CAD file drawing. Our team of experts has deep design knowledge and is able to provide adequate advice for prototyping and small-scale production.

Custom Projects for Every Need

We leverage the latest advancements in energy 3D printing technology to ensure exceptional print quality and accuracy. Our wide selection of materials gives you the flexibility to choose the perfect material for your project, whether it’s for prototyping or production. We understand that every energy project is unique, and we offer personalized solutions to meet your specific requirements and deliver tailored results. Our team has extensive knowledge and experience in 3D printing for the energy industry, guaranteeing professional guidance and support throughout the entire process. We pay meticulous attention to detail to ensure that every print meets the highest standards of quality and precision. We value your time and work hard to deliver your prints in a timely manner, ensuring fast turnaround times without compromising quality. Our prices are competitive, offering cost-effective solutions without sacrificing the quality of the end product. We prioritize customer satisfaction and aim to exceed your expectations with our reliable service and exceptional results.

Energy 3D Printing Services Capabilities

Using Elimold to manufacture production parts for the energy industry is a cost-effective and flexible option for manufacturers worldwide. We are providing 3D printing processes for the energy industry to build innovative components layer by layer, creating designs that are too expensive or impossible to manufacture through machining or casting. Tolerances up to +/- 0.002 are maintained, allowing precision and post-processing to achieve tighter tolerances. All production is completed within China to protect customer designs and improve speed to market and product testing costs.

3D Printing Services for the Energy Industry

As the demand for cleaner, greener energy production grows, so too does the need for energy companies to reduce carbon emissions from fossil fuels and move to more renewable alternatives. Against this backdrop, technological innovations such as 3D printing are becoming game-changers, providing unprecedented opportunities for the industry to grow and adapt. As a leader in additive manufacturing, Elimold has been at the forefront of this transformation, providing cutting-edge 3D printing solutions that are tailored to the unique challenges and needs of the energy industry. Whether you need 3D printed metal parts or 3D printed high-performance polymer parts, Elimold can provide additive manufacturing consulting advice to guide and help you.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex and high-quality parts.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused DepositionModeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

Rapid Prototyping of Energy Parts

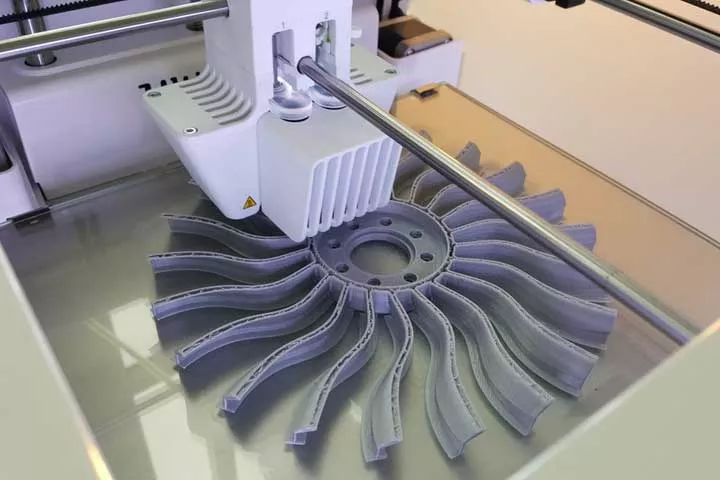

Rapid prototyping, whether it is a simple mockup or a detailed scale model, is an important part of energy product development. Early concept models allow engineers to validate designs and understand the interactions between different energy components. This helps identify potential problems early in the manufacturing process and ensures that the final project meets design specifications. Prototypes used to be handmade or made using molds, which also needed to be designed and manufactured, a costly process that could take weeks or even months. Energy 3D printing can design and print energy industry parts in a fraction of the time and cost required by traditional manufacturing methods, shortening product development cycles. Shortening the time between design improvements allows more testing to be performed in the same or less time. Accelerate time to market and maintain competitive advantage.

Efficient 3D Printing Solutions for Energy with Tangible Benefits

Adoption of additive manufacturing in the energy sector improves efficiency, reduces costs, and supports sustainability initiatives, making it a valuable tool for the industry’s future.

Rapid Prototyping

Additive manufacturing can quickly design and test components, shortening innovation cycles. Engineers can create prototypes of tools and parts, evaluate them, and make adjustments without the long lead times associated with traditional manufacturing methods.

Spare Parts Production

In remote locations of energy operations, spare parts logistics can be challenging and costly. Additive manufacturing enables companies to produce parts on demand, reducing inventory costs and minimizing downtime. This is especially useful for obsolete parts that may no longer be produced.

Lightweight Components

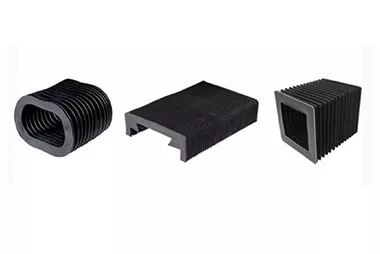

Additive manufacturing can create complex geometries, reducing weight without sacrificing strength. This is critical in the oil and gas industry, as lighter components can simplify operations, reduce transportation costs, and improve energy efficiency.

Material Options

Plastic

- ABS

- PLA

- PET

- TPU

- ASA

- PEI

- PC

- UV Curvable

- Carbon Fiber

Metal

- Aluminium

- Steel

- Cobalt Chrome

- Inconel

- Stainless Steel

- Tool Steel

- Maraging Steel

- Nickel

- Titanium

Surface treatment and post-processing options

Elimold has a variety of tools and machines to remove support material from energy 3D printed parts. We use soluble support materials that allow for the creation of complex geometries. We can handle light 3D print post-processing including sanding, polishing, clear coating, marine epoxy coating (for waterproofing FDM) and adding thermoset inserts. For larger printed parts or more specific post-processing techniques, we can also cater directly to your needs.

- Unfinished

- Natural

- Standard

- Clear Coat

- Painting

- Plating

- Dyeing

- Decaling

- Polishing

- Heat Treatment

- Machining

- As-machined

- Colouring

- Inserts

- Shot Peening

- Vibro Polishing

- Final Assembly

- Welding

Our advanced 3D printing revolutionizes component production through rapid prototyping, custom design, and streamlined supply chains, resulting in significant cost savings, improved efficiency, and enhanced sustainability in the energy sector. 3D printing plays a key role in reshaping and streamlining the energy industry supply chain. By transitioning from multi-step, geographically dispersed manufacturing processes to more direct, localized production methods, 3D printing minimizes reliance on complex global supply networks. This can reduce transportation needs, lower storage costs, and shorten delivery times. By transforming raw materials directly into finished products, the energy industry can respond to demand faster, mitigate potential disruptions, and achieve significant operational efficiencies, resulting in a more resilient and adaptable supply chain framework.

Advantages of 3D printing in the energy sector

- Simplify product development

- Greater design flexibility

- Accelerate time to market

- Produce lighter, better-performing parts

- Minimize raw material waste

- Combine previously separate parts into a single unit

- Optimize inventory and supply chain management

Why 3D print replacement parts?

Spare parts printing supports Elimold’s move to digital supply chains, addressing local supply, scrapping, just-in-time inventory and other material supply chain opportunities for energy companies. Managing spare parts is a major logistical challenge. Too few and your facility may need to shut down. Too many can result in a waste of money and storage. The challenge is even greater at sea because storage capacity is limited and the cost of sending spare parts can be high. Parts availability and obsolescence are also a challenge.

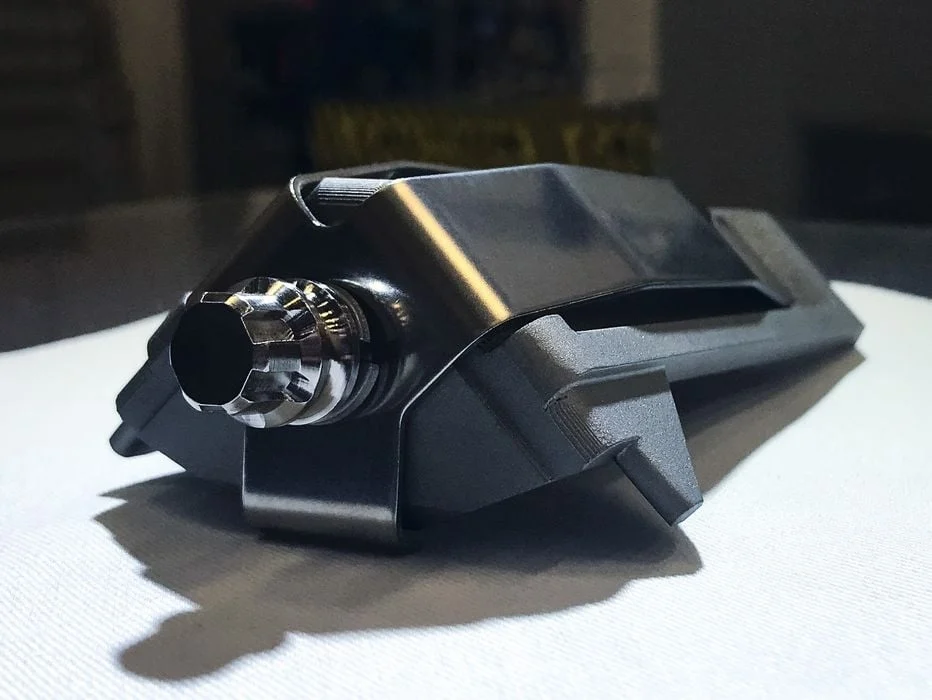

Additionally, most assets in the energy industry are aging and reaching the end of their useful lives. Some major components like pumps determine the lifespan of an asset as they are very expensive and critical. Without 3D printing, if a compressor became obsolete and stopped working, the entire compressor would need to be replaced because the individual components within it cannot be manufactured. 3D printing has the potential to radically simplify supply chains and potentially extend the life of obsolete equipment because we can produce parts that are no longer manufactured.

3D Printing Energy Parts Reduces Costs and Emissions

In energy-related industries, it can quickly become expensive if a part fails and impacts operations. But so is duplicating all the parts that could break. The solution is inventory and 3D printing. Additive manufacturing saves costs, production can be done closer to where the part is needed, and the process often produces lower CO2 emissions than traditional manufacturing. Combined with a digital inventory, we can produce parts on demand.

Supply Chain Simplification

Engineers can now produce parts or products precisely when and where they are needed, without having to maintain large inventories and long, complex supply chains. This shift brings many benefits, such as reduced warehousing costs, reduced risk of overproduction and waste, and the ability to respond quickly to changes in demand or design modifications. Direct digital manufacturing with Elimold enables localized manufacturing, reducing the environmental impact of shipping goods over long distances. This on-demand production not only improves supply chain efficiency, but also provides greater flexibility to meet customer needs, making it a valuable solution for industrial designers and energy companies looking to streamline operations and reduce resource consumption.

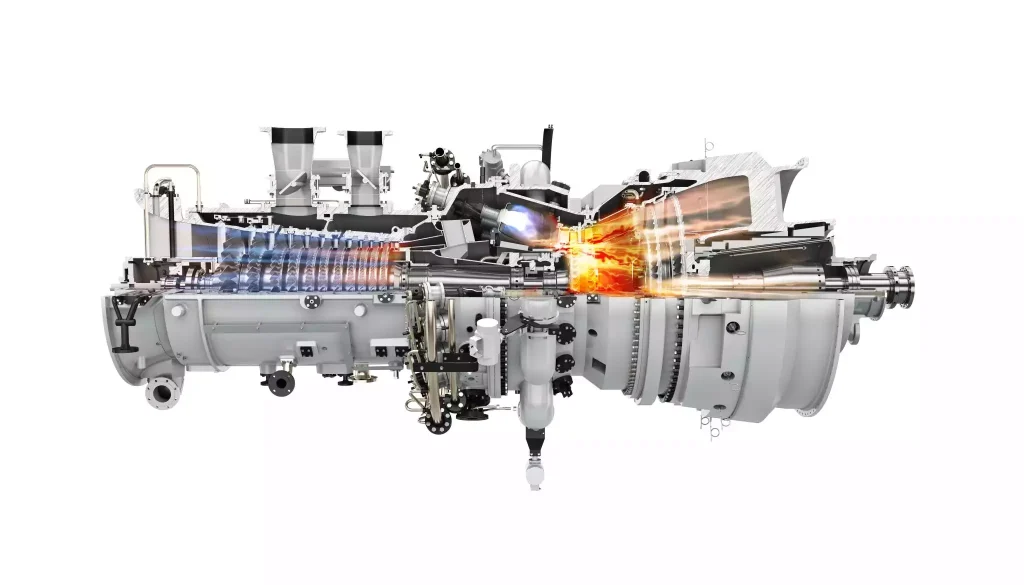

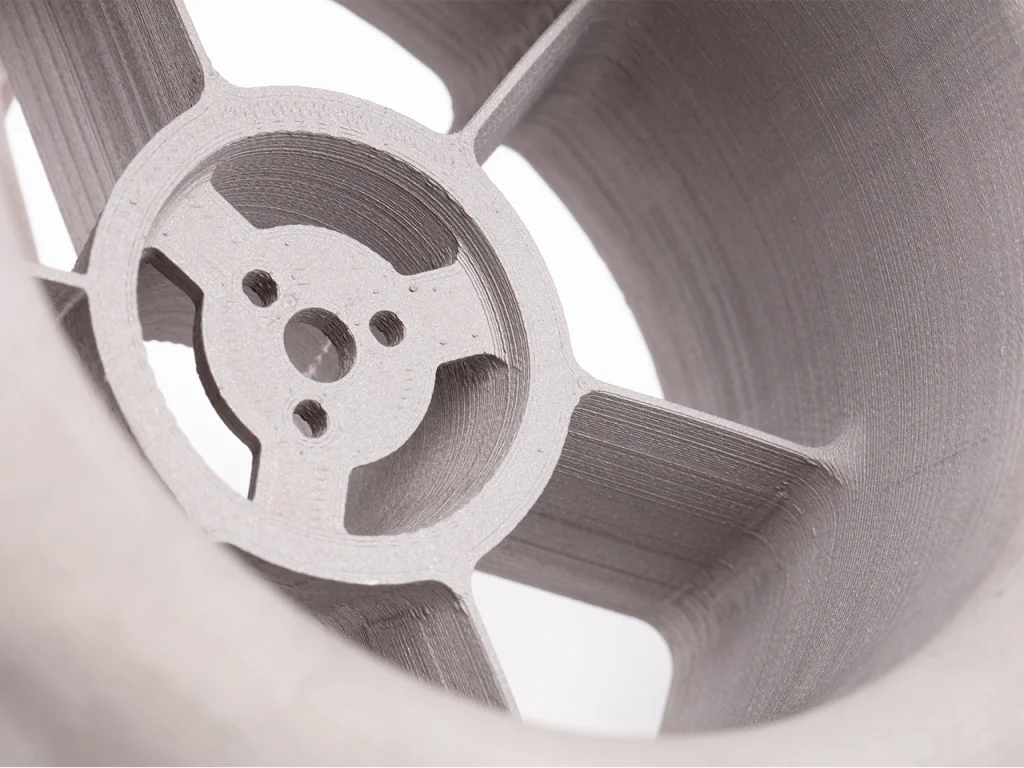

Complex Geometries and Lightweighting

3D printing excels at making complex designs that are impossible with traditional manufacturing methods. In the energy sector, this capability enables the manufacture of components with advanced geometries to optimize performance, such as turbine blades with internal channels to improve aerodynamics or heat dissipation. 3D printing can create lightweight structures using lattice or honeycomb designs that reduce material usage while maintaining structural integrity. This lightweighting is critical in industries such as transportation, where reducing component weight can lead to significant energy savings and efficiency gains, which directly impacts the operational efficiency and environmental footprint of energy systems.

Repair and Maintenance

3D printing can be used to quickly manufacture replacement parts, especially those that are discontinued or rare. This is particularly important for older energy infrastructure, where sourcing spare parts can be a challenge, thereby reducing downtime for energy facilities, ensuring uninterrupted energy production and minimizing losses. Instead of maintaining a physical inventory of spare parts, energy companies can maintain a digital inventory. When a part is needed, the corresponding 3D model can be retrieved and printed. The energy industry around the world is slowly relying on 3D printing to produce replacement parts on-site, reducing downtime caused by equipment failure or maintenance. This is especially valuable at remote drilling and extraction sites, where shipping parts can be time-consuming and expensive. Simply replacing damaged parts and extending the life of equipment, rather than replacing entire assemblies, can save significant costs while reducing environmental waste.

3D Printing Applications in the Energy Sector

A key application of 3D printing in the energy sector is in the face of rapid prototyping. Time to market is one of the most critical issues facing any industry, and the longer a concept stays in the design cycle, the less potential profit a company has. With pressure to create solutions quickly, engineers and designers must make fast, accurate decisions during the concept phase. Rapid prototyping is a critical step in design validation, but can become a barrier to release if it is not performed quickly and cost-effectively. Rapid prototyping and 3D printing complement each other. 3D printed prototypes enable engineers to fail fast, perform multiple iterations, and change design components overnight to meet deadlines. Utilizing 3D printing to manufacture end-use parts has also become a pressing and popular operation in the energy sector. 3D printing can often create custom complex parts faster than traditional manufacturing processes, making it a perfect solution for low-volume projects. 3D printing does not require additional tooling, and the production of lightweight structures with complex internal features is a key element of the next generation of energy components.

Energy application type

- Fluid/water flow analysis

- Jigs & fixtures

- Rotors

- Stators

- Mud motor modules

- Flow meter parts

- Pressure gauge pieces

- Pump manifolds

- Plastic impellers

- Casings

- Connectors

- Wind turbine components

- Solar panel frames & supports

- Junction boxes

Request your free energy 3D printing quote now

Once we receive your drawings, our engineers will immediately analyze your custom energy 3D printed parts. We will actively work with you to clarify all details and then provide a quote that is both economical and accurate.