Energy Injection Molding Service

Elimold provides free quotes, part design reviews and manufacturability analyzes for tooling and engineering services for the energy industry. We provide fast, cost-effective short-term injection molding services. From start to finish, we can deliver most projects in 30 days or less.

Energy Injection Molding Manufacturer

We offer a wide range of services in the field of plastic injection molding for the energy industry, laying the foundation for a variety of custom innovative solutions for different applications. Our customer-oriented agile organizational structure, short decision paths, efficient process environment and our modern technical equipment support your energy projects with result-oriented solution implementation. Elimold has more than 20 years of injection molding experience, 120 injection molding machines with pressures ranging from 28 tons to 4000 tons, and our injection molding plant covers an area of 120,000 square feet, running in three shifts six days a week, and equipped with CNC machining and 3D printing capabilities. Moreover, we are experienced in solid injection molding, structural foam, secondary molding, gas assist and two-color molding, and have processed a variety of performance materials from commodity grade to heat-sensitive PVC resins to conductive and engineering polymers.

Not only do we provide advanced molding technology, we can also work with your team through every stage of the manufacturing process, from initial design and prototyping to full production. We also offer services that can streamline shipping and sales, from kitting and assembly to product marking, custom packaging or bagging and labeling.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

Tooling and engineering services

Elimold is a custom injection molding manufacturing company that provides fast, low-cost molding and processing services for a variety of plastic custom parts for the energy industry. We produce custom plastic parts for many parts manufacturers in the energy industry. Our team has decades of industry experience, and we are committed to providing high-quality parts that meet our customers’ unique needs.

We understand the importance of reliable, durable and efficient parts in the energy industry. That’s why we work with energy industry companies and parts manufacturers to produce custom plastic parts that meet their specific needs. We work closely with our customers to understand their needs and provide them with solutions that suit their needs.

However, no matter the industry and no matter how complex the part, we can deliver the part quickly. If you have your CAD files ready, we can provide you with a quote in just a few hours. If not, our expert engineering staff can develop a CAD file for you.

Our expert engineers and moldmakers allow us to turn your 3D CAD model into a fully functional prototype or production part using real engineering-grade resin, more consistently and affordably than any other rapid injection molding company.

Process and Quotation

Start your project with Elimold’s experience and capabilities. Simplifying the injection molding process allows us to offer you the lowest possible prices and get your products to market faster than you ever thought possible.

You can submit documents via our website, email. Our experienced engineers will quickly provide a comprehensive quote along with manufacturability analysis. Modify quantities, materials, finishes, and more to find the perfect combination for your project and budget.

Competitive pricing and advanced processes allow you as a designer to quickly compare prices and find the best option for your manufacturing requirements.

Once approved, your files are sent to our injection molding shop and we begin creating your mold to exact dimensions. Years of experience allow us to improve our processes and develop long-lasting precision molds for injection molding processes, ensuring you get consistent manufacturing and high-quality precision parts.

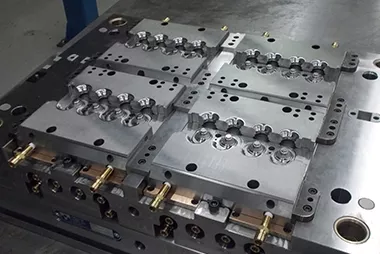

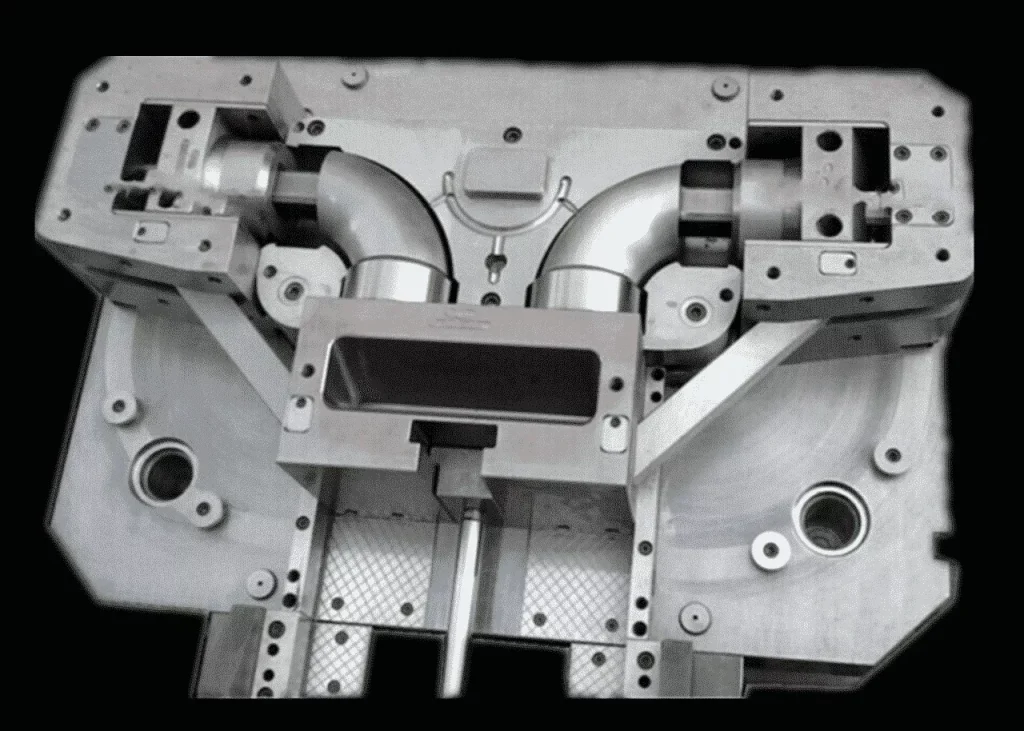

Our mold making

Once your design is complete, it is sent to our precision moldmakers where we begin the milling process on your tooling. Using high quality aluminum blocks and advanced machining processes allow us to create your custom tooling quickly and efficiently. A mold is only considered complete when detailed inspection confirms that your tooling has captured every detail of your custom plastic part.

Custom design

Elimold not only provides simple materials and machines, but also provides comprehensive custom design services for plastic injection molding. Recognizing that every customer has unique needs and each product has unique features, we work with our customers to create custom plastic parts that perfectly match their specific requirements. Using CNC machining and advanced software, we can create complex mold tooling from durable materials like steel, an important step in the manufacturing process.

The mold design takes into account details such as parting lines and is also capable of producing complex plastic parts. Our team of professionals work tirelessly to ensure precise control of the injection process, resulting in consistent quality of custom molded parts. Even though the initial cost of creating a custom mold is higher, the ability to mass-produce parts can result in significant cost savings in the long run.

Prototyping services

Elimold also provides advanced prototyping services for plastic injection molding. Elimold utilizes state-of-the-art equipment and technology to create prototypes of injection molded parts before committing to a full-scale production process. The first run provides customers with a concrete example of the final product, allowing critical evaluation and testing before series production begins. By integrating tools like Scientific Molding into the prototyping process, we are able to maintain precise control over the variables in the plastic injection molding process, ensuring optimal quality and energy efficiency.

This process is a critical step in process optimization to address potential material shortages, evaluate the efficiency of the injection unit, and ensure that molten plastic flows into the mold in the most efficient manner.

From electrical equipment to major components of large assemblies, our prototyping services facilitate the production of high-quality, cost-effective and energy-efficient plastic products while increasing the growth rate of plastic injection molding jobs.

Produce energy parts with Elimold injection molding services

To help create parts that can withstand extreme operating demands, Elimold offers a variety of high-performance injection molding materials, including engineering-grade plastics, thermoplastics and specialty plastics, as well as overmolding services. This gives energy companies the flexibility to produce parts with multiple performance properties, such as greater mechanical strength, corrosion and chemical resistance, UV and heat resistance, and more—all in a single part.

Our injection molding services combine computer-aided design with high-quality injection molds and can also develop robust equipment parts with complex geometries in a very repeatable manner. To further ensure repeatability and deliver high-quality parts that comply with energy industry regulations, we also offer a wide range of injection mold manufacturing options and have strict quality management systems and inspection protocols in place.

Material Options

Materials should be selected based on their properties, manufacturing characteristics, cosmetic appearance, and cost. We have 300 engineered thermoplastic grades of materials in-house:

- EPDM

- PEBA

- PVC

- TPE

- TPU

- TPV

- LSR

- POM

- ABS

- ASA

- CA

- HDPE

- LCP

- LDPE

- PA 6

- PMMA

- PARA

- PBT

- PC

- PE

- PEEK

- PEl

- PES

- PET

- Bioresins: reclaimed, biodegradable

- Chemical-resistant: Isoplast™

- Filled: carbon, glass, metal, mineral

- High-density: EcoMass™

- High-heat: PEEK, Radel™, Stanyl™, Ultem™

- Thermally-conductive: Electric and dielectric

High-Tech, Certified Solutions

The Elimold team is dedicated to using the latest technology and techniques to create the best parts for our customers. We use state-of-the-art equipment and tools to ensure that our parts are of the highest quality. We also have a team of experienced engineers who work closely with our customers to design parts to their exact specifications.

In addition to our commitment to quality, we also prioritize sustainability. We are proud to say that we are RoHS and REACH compliant. By complying with these regulations, we are able to provide our customers with high-quality, safe, and environmentally friendly plastic products.

At Elimold, we are passionate about what we do and are committed to providing the best service to our customers. Our team is always available to answer any questions or concerns you may have, and we are committed to meeting all of your plastic part needs in a timely and efficient manner.

Energy Applications Injection Molding Finishes

Painted

Painting offers a wide range of color options. Furthermore, different painting techniques and high-quality coatings can achieve various effects, such as glossy, matte, metallic, or textured finishes.

Polishing

This process involves gradually smoothing the surface using abrasive materials or compounds, resulting in a glossy finish that highlights the fine details of the printed object.

Surface texturing

Surface texturing techniques create specific patterns or textures on the surface of injection-molded parts, enhancing their functionality, aesthetics, or grip.

Pad printing

Pad printing applies detailed designs, logos, or markings on the surface of injection-molded parts. This process is done by transferring ink onto the part using a specially designed printing pad.

Energy injection molding applications

Wind

- Blades (and support)

- Motors

- Gear Boxes

- Brakes

- Accumulators

Solar

- Panel & Chip Manufacturing

- Load Centers

- Combiner Boxes

- Load Centers

Hydropower

- Valves

- Turbines

- Gates

- Transformer

- Motors

Biomass

- Generators

- Turbines

- Condensers

- Boiler Feed Pumps

Geothermal

- Flanges

- Pumps

- Heat Exchangers

- Well & Casing

Powering the injection molding production process

From prototype to final part production, Elimold takes the guesswork out of the injection molding manufacturing process. Regardless of the application, or whether you work with renewable or non-renewable energy sources, the Elimold team will work closely with your company to help design and manufacture high-quality equipment components, achieving fast and repeatable results while meeting the stringent energy industry requirements Ask for request. Upload your files now to request a free quote.