Energy Sheet Metal Fabrication

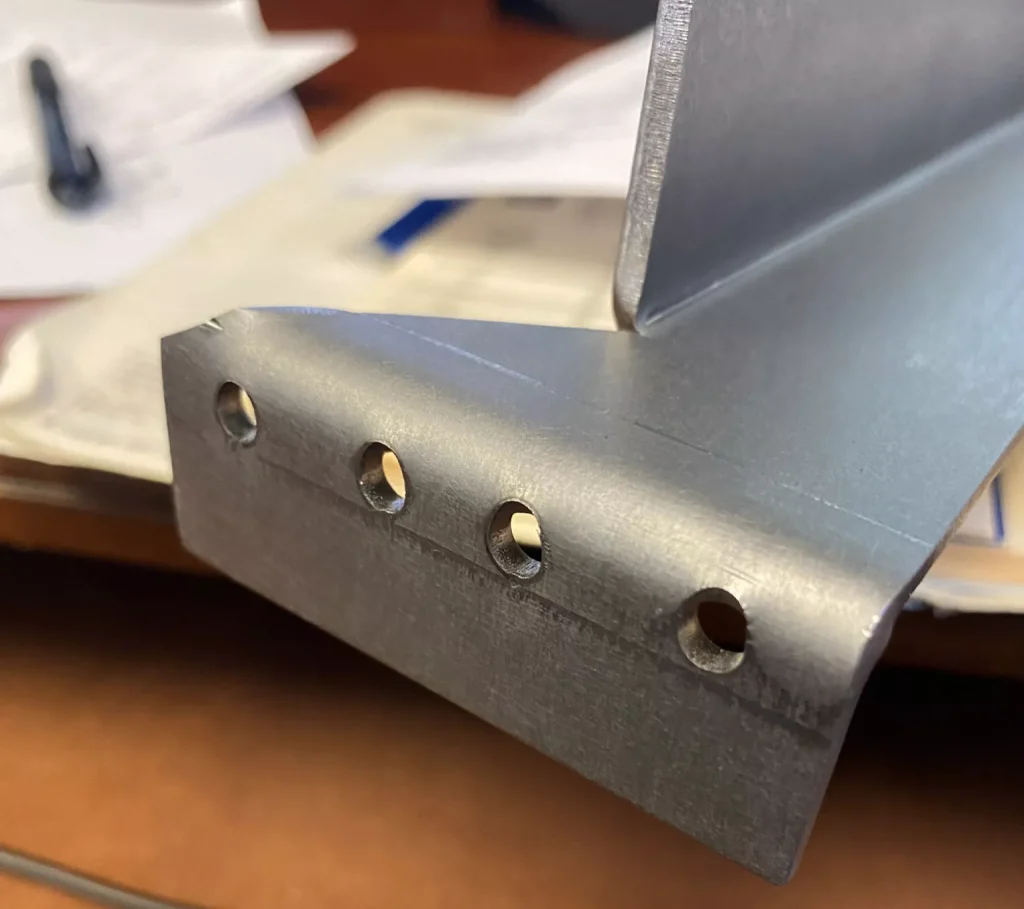

Elimold is a high-precision sheet metal manufacturer of medium to large energy parts and mechanical assemblies. We provide the energy industry with a competitive advantage through state-of-the-art metal cutting and forming, extensive experience in welding a variety of metals, precision CNC machining, complete assembly services, on-time delivery and unparalleled customer service. Our manufacturing capabilities and inspection services meet or exceed the requirements of the most demanding projects.

Energy Industrial Metal Manufacturing

At Elimold, we understand the need for high-quality, durable materials to create long-lasting renewable energy applications. Renewable energy components are subject to harsh conditions in nature. These parts need to be durable enough to withstand sunlight, precipitation, wind, temperature fluctuations and any other weather conditions. The metal components used to generate electricity can withstand these harsh conditions without damage or corrosion.

Furthermore, the energy industry requires very specialized equipment that relies on precision-made metal components. Wind turbines, generators, solar panels, and more all require high-quality metal components to operate at full capacity for long periods of time.

Communities and economies are built on the energy industry, so it’s important that all involved parts are properly maintained. Because the energy industry is in the midst of a long-term transformation, it is imperative to find a reliable metal parts supplier that can keep up with future changes.

Elimold’s goal is to become a leading metal parts supplier. Innovation and customer service are at the forefront of our work. We work with countless energy companies to help build durable, high-quality metal parts and machinery. Our CNC machining services and sheet metal fabrication services are truly unparalleled. We have worked with a variety of power generation industries such as solar, wind, coal, natural gas and geothermal. Every time, we produce parts that are perfect for their purpose.

With years of experience in metal fabrication, we ensure that we provide the energy industry with precisely manufactured metal parts and machinery to help deliver energy to locations across the globe. Our precision manufacturing and manufacturing capabilities span all renewable energy industries around the world.

Elimold's Custom Energy Sheet Metal Fabrication Services

We have an in-house sheet metal fabrication shop. Our state-of-the-art fabrication facility is located in our 36,000 square foot facility and is equipped with a wide range of advanced sheet metal fabrication equipment and the latest technology in sheet metal fabrication. This allows us to manufacture custom energy equipment sheet metal parts with outstanding quality. Our team of highly trained professionals has the expertise to customize energy sheet metal parts to your drawing standards and designs.

Our Capabilities

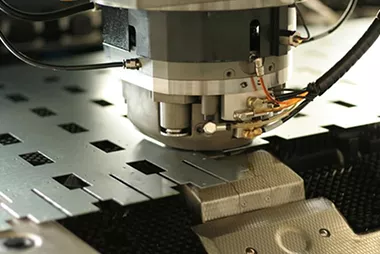

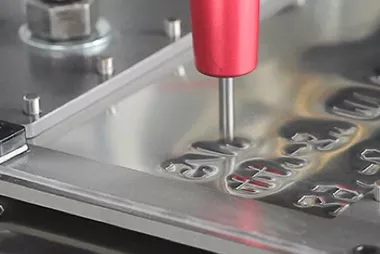

Elimold provides precision sheet metal fabrication services to the energy industry. In our ISO 9001:2008 certified facility, we utilize modern turret punch presses and press brakes to fabricate small to medium sized components and meet MIL-I-45208A inspection system requirements. We can process material up to 80 feet in length, 30 feet in width, 20 feet in height, 2.5 inches in thickness, and 75 pounds in weight. Our presses can generate up to 3000 tons of force while maintaining tolerances of ±.002” to ±.005”. Specializing in prototypes to high volume production, with a typical turnaround time of 2 – 4 weeks, we offer a 1 week “quick turn” lead time. All of our products and processes meet the highest industry standards. Our customer-centric approach includes dedicated representatives and access to engineers. We are prepared to custom design projects or re-engineer existing product lines for better performance and cost-effectiveness.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Stamping

Die Cutting

Bending and Forming

Laser Cutting

Plasma Cutting

Punching

Welding

Extrusion

Embossing

Providing Reliable Sheet Metal Fabrication Services to the Energy Industry

When you work with Elimold, you’ll take advantage of all the relationships we’ve built with our suppliers over the years. We work tirelessly to find ways to help our customers meet their project needs by utilizing the best technology and most modern methods to source materials, schedule production runs, and manage shipping and delivery schedules. We offer kitting services to optimize how you package and deliver parts, and we provide smaller customers with the option to consolidate orders and achieve economies of scale when sourcing materials. When it comes to inventory, we can store parts and products on-site or change production schedules to meet your inventory needs. No matter what parts you need, the size of your business, or the schedule you operate on, Elimold offers you the flexibility and expertise to complete your energy fabrication projects with peace of mind.

Our energy sheet metal fabrication services include but are not limited to

- Carbon Steel Fabrication

- CNC Plasma Cutting

- Specialty Steel Fabrication

- Steel Bending & Rolling

- Steel Fabrication Designing/Drafting

- Steel Laser Punching/Cutting

- Custom Steel Fabrication

- Large Capacity Steel Fabrication & Machining

- Steel Machining

- Steel Piping & Tubing Fabrication

- Steel Plate, Bar & Sheet Fabrication

- CNC Control Carbon Steel Fabrication

- CNC Plasma Cutting System

- Delivery on Site

- Designing

- Detailing

- Engineering

- Full Automatic Fabrication Equipment

- Stainless Steel Fabrication

- Steel Bending

- Steel Curving

- Steel Cutting

- Steel Punching

- Steel Rolling

- Steel Welding

- Mig Welding

- Tig Welding

- Robotic Control Welding Equipment System

- Arc Welding

- Structural Steel Fabrication

- Timely Completion Date

Quality Energy Equipment Sheet Metal Parts Manufacturer

We manufacture a wide variety of energy sheet metal parts products. Our customers rely on our manufacturing expertise and flexible production, inventory, and delivery options to meet the growing demands of the energy industry. We are proud to be a part of energy efficiency initiatives that will further grow our economy and support our local business partners. As their only energy equipment sheet metal parts manufacturer, our contract metal fabrication and powder coating services truly make Elimold your one-stop shop for your energy equipment needs.

Services for the energy sector

The energy industry demands real-world performance from its parts and machines. Each component is made with industrial strength to withstand weather elements and corrosion. The production of reliable parts starts with the metal used. Our engineers have a wealth of skills and knowledge that helps them create high-quality, cost-effective solutions for your energy company. Submit your CAD files now and one of our engineers will provide a quote and show you how Elimold provides the best metal fabrication solutions for the energy industry.

Rapid manufacturing services

Elimold’s engineers ensure your parts are fully optimized before the production process begins, meaning you save time and money during the manufacturing process. We work closely with you to ensure you get the best product. Our rapid manufacturing services provide quick turnaround for projects through our automated production lines.

Sheet metal services

With a wide range of services, Elimold is ready to solve all your precision sheet metal services. We provide laser cutting, metal forming, machining and painting services to the renewable energy industry, giving you the highest quality, durable, corrosion-resistant metal parts for your power generation needs.

Metal surface treatment services

At Elimold, we don’t just stop at the production of metals. We want your product to go well all the way. Our quality metal finishing services can complete your project. With our innovative powder coating and screen printing capabilities, we can complete your metal project to your specifications.

Metal assembly services

Elimold provides professional sheet metal assembly services to complete your interior projects. We always strive to provide high quality products, and we’re happy to assemble metal components so you can save time and money. Our assembly services ensure your product is assembled with the highest precision to meet your specific requirements.

Elimold Energy Solutions

The energy industry requires reliable, high-performance equipment. At Elimold, we use leading technologies in laser cutting, bend forming and welding to create products to tight tolerances using highly durable metals. Our welders are AWS D1.1 certified, ensuring optimal quality and performance for a variety of energy applications.

In addition to being an ISO 9001:2015 certified manufacturer, Elimold can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

Our Certifications

Elimold is an advocate of Lean Management and Six Sigma efficiency and quality drives. Elimold holds these certifications and uses the following quality standards:

- ISO 9001: 2015 Registered

- Reach Compliant

- RoHS and Lead-Free Process Certified

- AS9100 Certified

- ITAR, TUV, FCC, UL, CSA Agency Certifications

- IPC-A-610 Process Certification

- IPC-A-620 Process Certification

- J-Std-001 Welding Certification

- AWS D1.2 and AWS D1.3 Certified Welders

Materials

- Aluminum

- Aluminized Steel

- Brass

- Cold Rolled Steel

- Copper

- Galvannealed Steel

- Galvanized Steel

- Hot Rolled Steel

- Stainless Steel

- Carbon and Alloy Steel

Material Forms

- Sheet

- Plate

- Circle Blank

- Expanded

- Perforated

- Rod

- Bar

- Tube

- Pipe

- Strip

High-Grade Metal Finishes

- Standard

- Shot Blast

- Powder Coat

- Zinc Plating

- Chemical Coat

- Hot-Dip Galvanizing

- Heat Treating

- Wet Paint

- E-Coating

- Custom Finishes

Heat Treating, Thermal Stress Relief and Annealing Services

Many customers require heat treating, annealing or stress relieving processes to improve part strength and processing. We can process parts up to 105 inches in length, 60 inches in width, 72 inches in height, and weighing 5 to 10 tons. We offer subcritical annealing services in the 500-1400°F range, as well as a variety of stress relieving processes.

- Standard (1100-1200°F)

- ASME Section I (900-1300°F)

- ASME Section VIII (900-1300°F)

Custom Blanchard Grinding Services

Blanchard grinding is a high-powered finishing technique that utilizes the rotation of an abrasive on a vertical spindle to rapidly remove metal from the surface of a part. A magnetic chuck holds the component in place during machining. The resulting surface has a unique, beautiful surface finish with tolerances of ± 0.005 inches or tighter. We process all types of steel, castings, and other metal parts with dimensions up to 84 inches corner to corner and weights up to 10,000 pounds. Our custom Blanchard Grinding services achieve a standard finish of 125 and a surface finish up to 63.

Fabricated Products

- Angles

- Air Movement

- Cans

- Channels

- Fan Casings

- Frames

- Exhaust Stacks

- Foodservice

- Panels

- Plates

- Sanitary

- Shells

- Spun Parts

- Tooling

- Tubes

- Tubing

Combining the right parts makes all the difference

If you’re evaluating new ways to maximize product performance, you need to look at the parts you’re using. When it comes to your energy equipment, it’s always a good idea to conduct a reflective analysis of your efficiency. Asking yourself the right questions isn’t everything—it’s the only thing.

This is what sets Elimold apart. We always try to find the next answer to a question before it is asked. We know how quickly things change and how important it is to use parts that make sense for the products and equipment you make. We are always moving forward.

Ready to start your next project?

If you are looking for a full-service energy metals contract manufacturing solution, Elimold is ready to help. With our advanced capabilities, we are able to deliver high-quality, high-value results. Contact us to learn how we can be the best part of your supply chain.