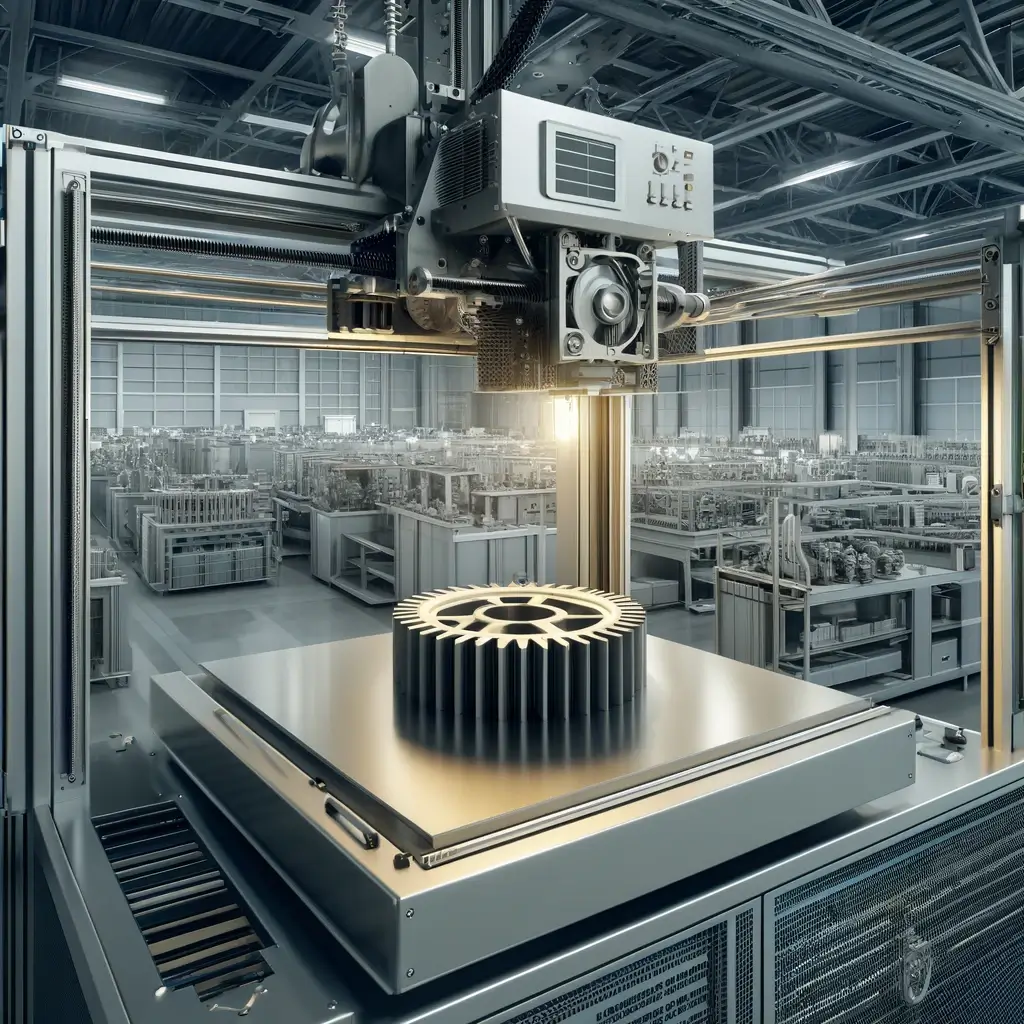

Industrial Application 3D Printing

Shorten time to market, accelerate product development and improve manufacturing with Elimold’s true 3D printing additive manufacturing technology for industrial parts. Contact us today for a free quote.

Industrial Product 3D Printing Solutions

3D printing, as an additive manufacturing method, is suitable for prototyping and low-volume production of industrial parts, producing industrial product parts with complex configurations that are difficult to manufacture using traditional manufacturing methods. It allows for rapid design iterations, allowing you to reduce time to market without sacrificing quality, and also helps reduce material waste and tooling costs.

Elimold’s professional industrial parts 3D printing services ensure an effective turnkey solution for precision industrial products and detailed designs. Our team is experienced in using a variety of materials and multiple 3D printing technologies, working closely with customers to select the best combination of materials and production methods to provide high-quality results and optimal versatility while helping you reduce turnaround time. Whether it is an initial prototype or an end-use part, we use cost-effective 3D printing to change the way new industrial products are brought to market.

Challenging the Limitations of Traditional Manufacturing

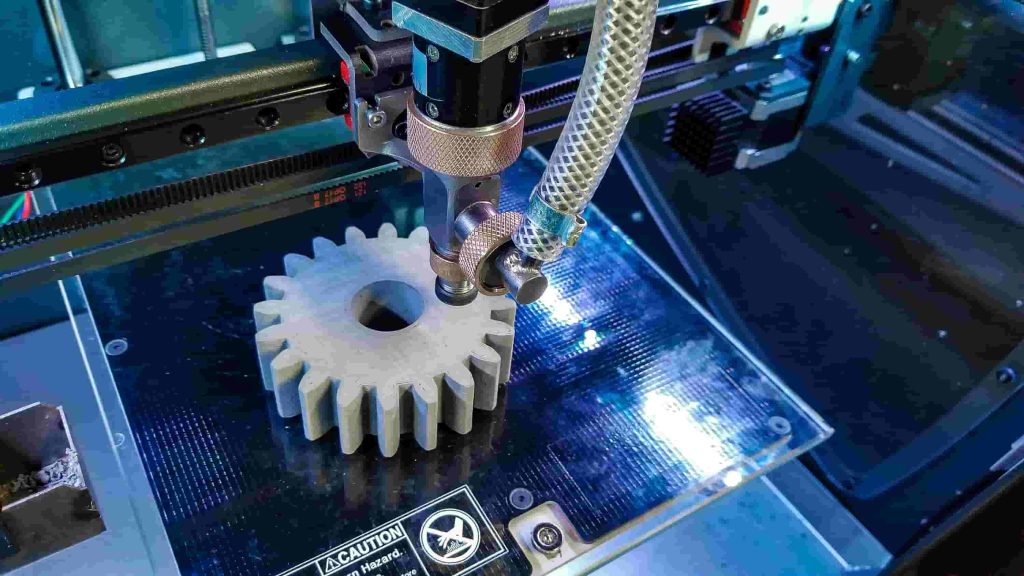

From prototyping to production parts, Elimold’s 3D printing services can provide industrial product manufacturers with more options for bringing industrial products to market. 3D printing is an integral part of Industry 4.0, overcoming the limitations of traditional machining, forming and joining technologies. This technology increases rather than subtracts material and does not require support tools, which improves efficiency and minimizes waste. It helps to produce optimized manufacturing tools faster and allows components that traditionally need to be bolted or welded to be printed as a whole. As a result, 3D printing in manufacturing can significantly improve time and cost efficiency while increasing design flexibility.

Innovative 3D Printing of Industrial Parts

Explore the world of additive manufacturing with our diverse offering of 3D Printing of Industrial Parts for Industrial Applications, with services to meet industry needs at every stage of the industrial product lifecycle. From innovative prototyping to the manufacture of end-use parts, our technology is reshaping the way industrial product manufacturers design and produce. Discover Elimold’s specialized solutions for industrial applications, custom jigs and fixtures to streamline workflows, and industrial equipment manufacturing that offers unmatched custom. We are at the forefront of custom industrial equipment part manufacturing, demonstrating our commitment to driving innovation.

3D Printing Can Change Your Business

As 3D printing technology becomes more advanced, more popular, and more powerful, 3D printing is redefining the way we think about manufacturing industrial products and running a business. 3D printing is much more than just prototyping. It has the power to change business models and distribution models. The biggest impact comes from enabling entrepreneurs to enter the market at a low cost, creating more opportunities for innovation. By incorporating 3D printing into industrial equipment manufacturing and design processes, engineers can shorten the time to market for related products, reduce waste, and deliver results on a larger scale. 3D printing does not require tools or molds, and allows customization of each output, which can be customized for different customers. Enterprises can develop their business in a more diversified way.

Design

Design, print, test, and iterate models with unmatched realism throughout a seamless industrial product lifecycle Leverage 3D printing for accurate and reliable industrial product development, facilitating optimal design communication for faster time to market.

Rapid Prototyping

Quickly transform ideas into precise, high-fidelity prototypes with advanced 3D printing rapid prototyping technology. Revolutionize prototyping in design and engineering for industrial applications with 3D printing solutions Increase efficiency, reduce costs, and accelerate time to market.

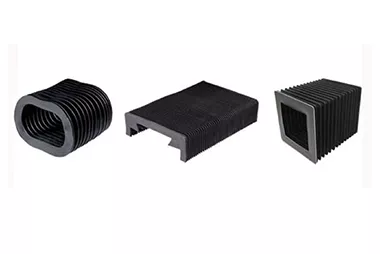

Jigs and Fixtures

Modernize and improve your jig, fixture, and inspection tool manufacturing process. 3D printed jigs, fixtures, and other manufacturing tools offer time, cost, and weight advantages over traditional metal tooling.

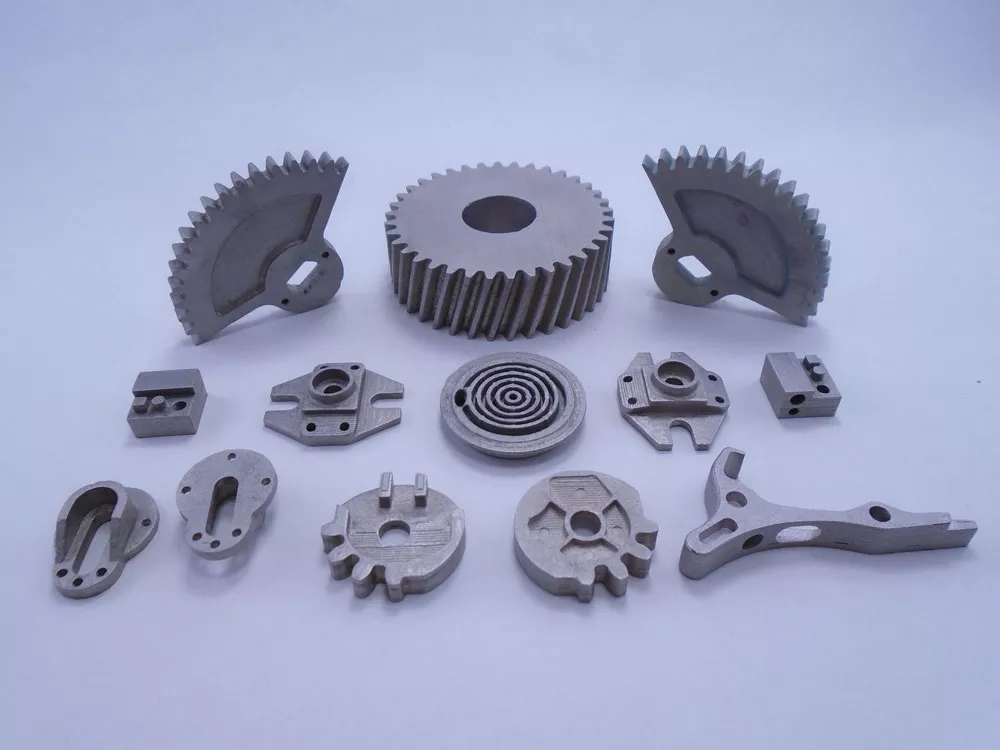

Production Parts

3D printing production industrial parts offers an effective alternative to standard manufacturing methods. Produce end-use parts for custom industrial applications on demand without the high costs and long lead times of traditional manufacturing.

Common 3D Printing Technologies for Industrial Parts

Elimold offers the following 3D printing technologies that are commonly used to manufacture industrial parts.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused DepositionModeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

Why work with Elimold?

Based in Shenzhen, China, Elimold has been committed to building a reputation as a trusted partner for customers around the world since its inception. We specialize in prototyping and low-volume manufacturing for mission-critical applications in the industrial industry.

At Elimold, supporting industrial product development is more than just a service, it’s part of our DNA. Our dedicated team is at the heart of our success, passionate about driving growth and ensuring 100% customer satisfaction. We are committed to quality and safety, with ISO 9001 and ISO 27001 certifications. Our goal is to provide the best in-house 3D printing services, from stereolithography to FDM 3D printing, to give our customers quality components that give them a competitive advantage.

Our advanced 3D printing technology ensures precision, enabling the most intricate details in the final product. From real prototypes and 3D printed models for proof-of-concept applications to high-resolution printed final industrial products, we aim to meet the needs of your budget and project timeframe. Elimold emphasizes the affordability and efficiency of our 3D printing services, with lead times as short as 72 hours for prototypes and production.

We work your way

Whether you’re creating a one-off prototype or low-volume production, we’ve got you covered. From complex industrial product projects developed with our team to parts you print online at your own pace, we can help you in the way that works best for you. We offer the industry’s most comprehensive selection of metal and plastic 3D printing technologies and materials for any industrial application, small or large, simple or complex, prototype or production. Our experts work closely with your team on everything from identifying and evaluating 3D printing candidates to exploring design improvements and cost savings.

Make it better, no matter what you produce

Almost every modern manufacturer can directly benefit from implementing industrial 3D printing. Bring the modern convenience of digital parts to your factory today and unlock unprecedented improvements in processes and end-customer products tomorrow. With industrial 3D printing services, you can turn process inefficiencies and logistical challenges into competitive advantages.

Implementing industrial 3D printing allows you to streamline production processes, reduce costs, and improve product quality. By adopting industrial 3D printing, manufacturers can quickly prototype new designs and iterate on them faster than ever before. Additionally, industrial 3D printing enables on-demand production, minimizing waste and reducing the need for large inventories.

Challenging the Limitations of Traditional Industrial Applications

From prototyping to production parts, 3D printing offers manufacturers more options for bringing products to market. 3D printing services for industrial applications are an integral part of Industry 4.0, overcoming the limitations of traditional technologies such as CNC machining, injection molding, and die casting. The technology adds rather than subtracts material and does not require support tooling, which increases efficiency and minimizes waste. It helps produce optimized manufacturing tools faster and allows components that traditionally require bolting or welding to be printed as a single unit. Essentially, 3D printing in industrial equipment manufacturing can significantly improve time and cost efficiencies while increasing design flexibility.

Advantages of 3D Printing in Industrial Applications

- Reduce Machine Costs: Industrial application 3D printing services help reduce overall product manufacturing costs. With it, complex parts or components can be developed in one step. 3D printing are less expensive than large injection molding.

- Reduce Waste: Additive manufacturing technology produces minimal waste compared to outdated methods. 3D printing use the required amount of material to shape the printed model, thereby improving production efficiency.

- Free Custom: One of the biggest advantages of 3D printing is the freedom to custom items. This makes it more reliable to get the desired output, and the industrial equipment industry has adopted this concept to produce custom parts and components for products. It helps shape ideas and concepts and provides endless possibilities to pave the way for innovation.

- Reduce Weight, Improve Strength: Industrial application 3D printing can create lightweight but strong components by optimizing the internal structure. Lightweight components can improve machine efficiency and overall performance.

- Complex Geometries and Internal Structures: Industrial application 3D printing allows the creation of complex high-performance designs, including components with complex internal channels, lattice structures, and custom features.

- High Precision and Surface Finish: 3D printing services for industrial applications excel in producing parts with high dimensional accuracy and high surface finish.

Wide range of material options

Working with Elimold, you’ll have access to China’s largest 3D printing factory for industrial parts, as well as a wide range of technologies, materials, and finished products. You’ll find dedicated production lines and ready-to-use prototyping services, as well as AM design experience and consulting services. All of our services are under one roof, and you only have to manage one supplier.

Plastic Materials

- ABS

- PLA

- Nylon

- PETG

- TPU

- PVA

- PC

- PEEK

- ULTEM

Metal Materials

- Stainless Steel

- Titanium

- Aluminum

- Inconel

- Tool Steel

- Cobalt-Chromium

- Bronze

- Copper

- Tungsten

Post-Processing and Surface Finishing

Elimold has a wide range of tools and machines to remove support material from 3D printed parts. We use soluble support materials and can create complex geometries. We can also handle a wide range of 3D printed industrial part post-processing and surface finishing. For large printed parts or more specific post-processing techniques, we can also meet your needs.

Metal 3D Printing Industrial Parts

- Shot Peening

- Electropolishing

- Grinding

- Machining

- Heat Treatment

- Coating

- Polishing

- Plating

- Laser Ablation

- Passivation

Plastic 3D Printing Industrial Parts

- Sanding

- Vapor Smoothing

- UV Coating

- Dyeing

- Spray Coating

- Thermal Smoothing

- Polishing

- Plating (for Conductive Plastics)

- Chemical Smoothing

- Surface Sealing

Industrial Applications

- Structural Components

- Heat Exchangers

- Engines and Turbines

- Machinery Parts

- Housings

- Brackets

- Connectors

- Tools and Jigs

- Parts for Aerospace

- Automotive Components

- Custom End-of-Arm Tools

- Casings and Covers

- Mounting Fixtures

- Prototypes

- Housings for Electronics

- Connectors and Plugs

- Handles and Grips

- Gaskets and Seals

- Internal Components

- Packaging and Containers

- Fluid Handling Components

- Decorative Parts

Ready to start your project?

Elimold’s team of application engineers and industry experts are here to help. We can answer any of your questions, from detailed information on relevant material properties to building an additive transformation roadmap for your business.