Lighting Industry Die Casting

We offer a comprehensive range of die casting services for both indoor and outdoor lighting parts. We can provide a wide range of die casting and related services to companies in the lighting industry. You can trust us to develop the right lighting solution for your needs and budget. Contact us now for a free quote.

Manufacturer of Castings for the Lighting Industry

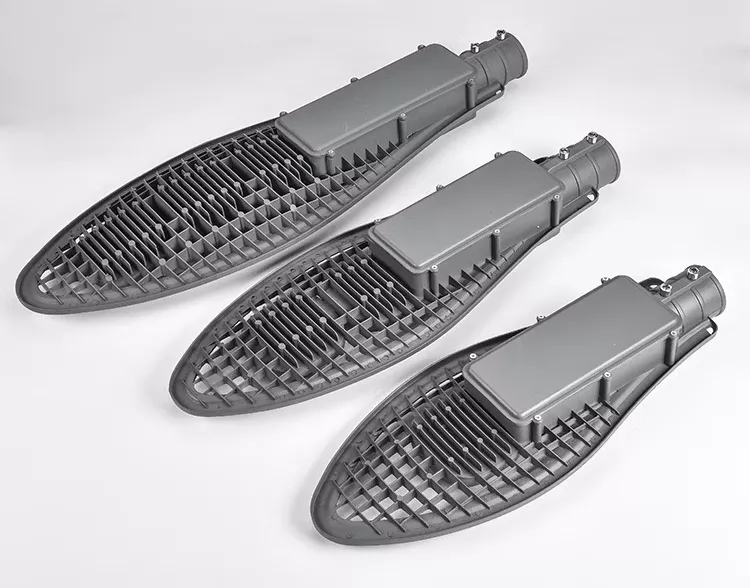

As a vertically integrated manufacturer of custom castings, Elimold is your trusted partner for lighting castings. We have extensive experience in lighting, including streetlight manufacturing as well as fully assembled die-cast components.

We have deep engineering experience, can provide design assistance to improve manufacturing efficiency and reduce costs, and provide world-class die-casting, plating, painting, electromechanical assembly, and warehousing and logistics services.

Elimold offers low-volume and high-volume production, as well as rapid prototyping to develop custom products. We can also provide a range of non-destructive testing to ensure quality and performance standards, including X-ray, magnetic particle and dye penetrant testing.

Strong Productivity

The production rate of die castings is 2,0000 to 3,000 pieces per day. Tooling costs can be high, and our R&D team will do their best to provide you with optimization suggestions, prioritizing your long-term interests. Our molds usually last about 3 years. When the old mold reaches the end of its life, if you choose to continue working with us, we can replicate a new mold, free of charge.

Source and Production Traceability

We promise you a transparent and streamlined manufacturing process. All aluminum alloys are sourced from certified suppliers, which can avoid potential defects. Your order will be under mature project management. In addition, we use digital industrial touch screens for real-time production manufacturing. That’s right, you always get real-time feedback.

Quality Assurance

Elimold adheres to strict quality control practices. We are an ISO 45001, ISO 9001, ISO 14001 and IATF 16949 certified die casting aluminum manufacturer and factory. In addition, our die casting materials are REACH, RoHS and FDA certified to meet various market needs. Upon request, we can provide documents such as PPAP, APQP, FMEA, MSA, SPC, etc., demonstrating our commitment to quality control and production management.

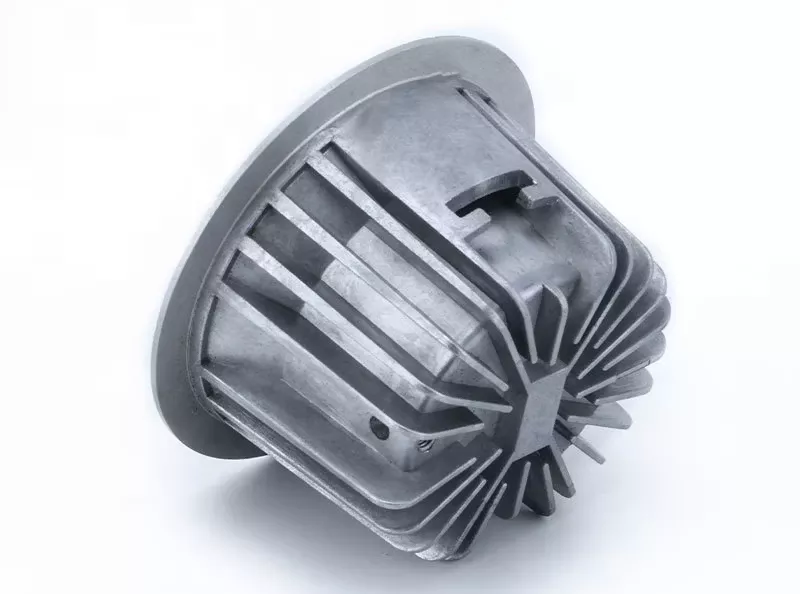

Die Casting Solutions for the Lighting Market

Are you looking to elevate your lighting projects with unmatched precision and quality? Lighting die casting is the key to achieving high-performance and aesthetically pleasing components for a range of lighting applications. At Elimold, we specialize in providing superior die casting solutions to meet the unique needs of the lighting industry. Our expertise ensures your lighting fixtures are fully functional and look great.

Elimold has been at the forefront of the die casting industry, providing innovative solutions with a focus on quality and customer satisfaction. Our extensive experience and state-of-the-art facilities enable us to deliver exceptional lighting die casting products to the highest standards. Whether you require custom components or large-scale production, we can meet your needs.

Find out why Elimold is a reliable choice for all your die casting needs. We are committed to providing precision, competitive pricing and excellent customer service to help you achieve your project goals with ease and confidence.

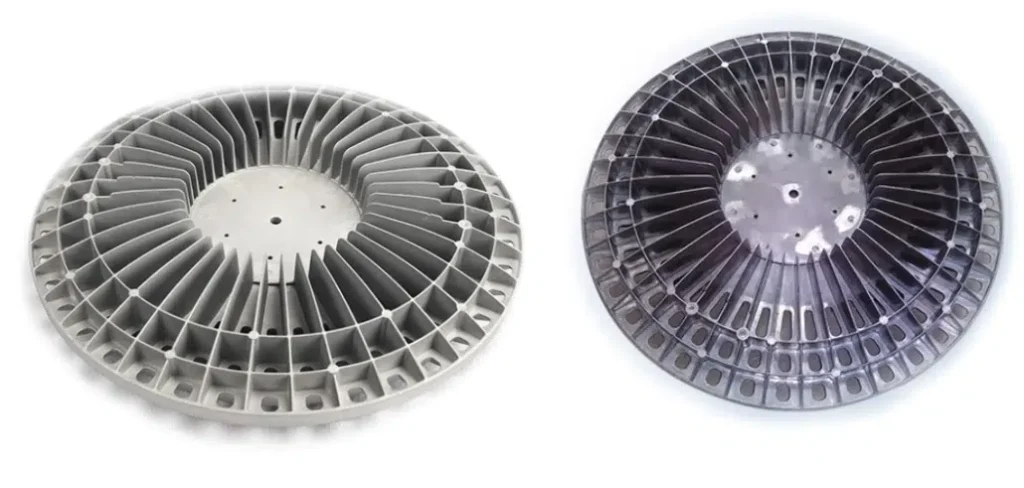

Our comprehensive lighting die-casting capabilities

Elimold is a professional supplier of die-casting parts for the lighting industry, providing complete services including product design, mold manufacturing, die-casting and surface treatment. We have a number of experienced technicians who design die-casting parts with different wall thicknesses and structures to meet the intensity and functional requirements of different lighting. The company has 83 CNC machining centers, including 4 five-axis German HERMLE CNC machining centers, 7 88T-500T die-casting machines, as well as precision mold processing equipment such as AGIE, Sodick EDM machines, Okuma, FANUC, Sumitomo, Sodick injection molding machines, and CMM automatic measurement laboratories, including German GOM blue light three-dimensional detectors, etc.

In addition, various surface treatments such as polishing, sand scraping, powder spraying, painting and electroplating can be selected according to the environment where the lighting is placed to ensure the beauty of the die-casting parts and enhance the corrosion resistance in outdoor environments. For both small-scale and large-scale production of lighting die-casting parts, a variety of die-casting technologies can be selected to meet your special needs.

Elimold has a team of precision mold manufacturing with rich theoretical and practical experience. The key members have more than 20 years of experience in the mold industry and have a number of core technologies and patents in complex mold structure, mold flow analysis, conformal cooling technology, processing thermal deformation management, etc. If you need die casting services, please contact us.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Sand Casting

Investment Casting

Die Casting

Low Pressure Casting

Permanent Mold Casting

Lost Foam Casting

Centrifugal Casting

Vacuum Casting

Strict quality testing ensures part functionality

We will conduct comprehensive quality testing to ensure that die-cast products meet your specific requirements and standards. From die casting to final inspection, our workshop is equipped with a full range of facilities, including:

- Coordinate measuring machine

- Direct reading spectrometer

- Aluminum liquid hydrogen measuring instrument

- X-ray non-destructive testing system

- Airtightness testing equipment

- Vacuum chamber helium leak detection device

- Phase microscope

Ready to start your next lighting die-cast parts project?

Supporting the High-Volume Need of Our Customers

As a custom manufacturing company for lighting die-cast parts, Elimold is unmatched in its capabilities for custom die-cast lighting parts. Not only are we able to provide lightweight metal castings in a wide range of sizes and weights, but we are also able to meet the high-volume needs of our customers. At Elimold, we are equipped with state-of-the-art die-casting machines that are integrated into fully automated casting cells and can be custom to increase productivity and efficiency. With the help of state-of-the-art metal software simulation, our engineering experts will design robust tools and processes to maximize die life and optimize cycle times, thereby reducing program life cycle costs. The Elimold technical team has the skills and expertise to design the best tooling concepts and perform cost evaluations to determine the most cost-effective solution for your lighting application.

Thin-walled die casting parts for lighting products

The most important advantage of die casting for thin-walled lighting products is the ability to create parts that are lighter, less expensive, and have a higher strength-to-weight ratio. With our many years of expertise in thin-walled lighting castings and using our proprietary process control software and state-of-the-art simulation technology, we can produce thin-walled lighting product castings less than 2 mm in die casting. Our expertise in thin-walled castings was developed for pressure-resistant lighting applications that require higher strength and surface integrity at a fraction of the weight of the casting.

Supporting the lighting market with world-class services

Tailored to your needs

We understand that every lighting project is unique. Our die casting services are designed to meet your specific requirements, whether you require a custom design or varying production volumes.

- Custom Designs and Specifications: We work closely with you to develop custom die casting solutions that meet your project goals.

- Flexible Production Volumes: Whether you require low or high volume production, we have the ability to efficiently handle varying production needs.

Collaboration and Consultation

Our collaborative approach ensures that we fully understand your needs and provide solutions that exceed your expectations.

- Working closely with our clients: We conduct detailed consultations to gather all necessary information and develop a comprehensive plan for your project.

- Design and Prototyping Support: Our team provides support throughout the design and prototyping phases, ensuring your components are accurately rendered before full production.

Strict Quality Control

Ensuring the highest quality is a top priority at Elimold. Our stringent quality control measures ensure that every Elimold component meets our exacting standards.

- Inspection Process: We perform thorough inspections at every stage of production to identify and resolve any potential issues.

- Durability and Reliability: Our focus on quality ensures that our components are durable and reliable, meeting the needs of a wide range of lighting applications.

Certifications and Standards

We adhere to industry standards and hold certifications that reflect our commitment to quality and safety.

- Industry Standards Compliant: Our products meet the stringent requirements set by industry standards, ensuring their reliability and performance.

- Certifications Held: We hold relevant certifications to demonstrate our adherence to high-quality manufacturing practices.

Material Options

- Aluminum ADC12、ADC6、A360、A380

- Zinc Zamak 3, Zamak 5, Zamak 2, ZA8

- Magnesium AZ91D, AM60B

- Copper ZQA19-2, ZQA19-4, ZQA19-7, ZQA19-10

Surface Finishing

- As Cast

- Polishing

- Sand Blasting

- Anodizing

- Powder Coating

- Brushed Finish

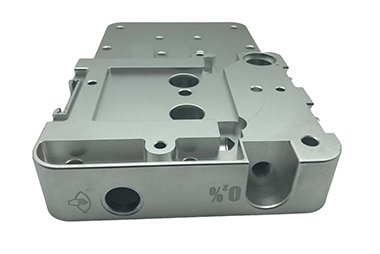

Secondary operations increase availability

Our die-cast LED parts are beautiful and high quality. With our one-stop production capabilities, after die-casting, we carry out CNC machining and subsequent surface treatment according to your requirements. Even for individual components, we pay meticulous attention to every detail to ensure that they are perfectly custom for seamless integration in practical applications.

Advantages of Aluminum Die Casting Lighting Parts

- Corrosion resistance

- Great strength and rigidity

- Low Manufacturing Cost

- Considerable strength-to-weight ratio

- Outstanding EMI and RFI shielding properties

- Excellent thermal conductivity

- Great electrical conductivity

- Strong finishing characteristics

- Full recyclability

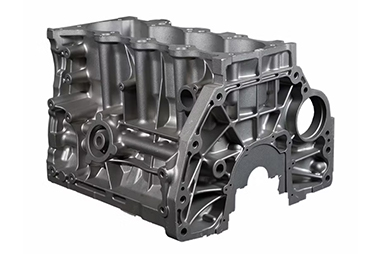

Die casting of many different types of lighting components

As a lighting housing manufacturer, Elimold’s capabilities include precision high pressure die casting of a wide range of lighting components, including:

- Industrial lamp housings

- Outdoor headlights and spotlights

- Wall sconces

- Traffic signal housings

- Parking lot lighting housings

- Office pendant lamps

The lighting industry's preferred custom die casting supplier

At Elimold, we are dedicated to providing exceptional lighting die casting solutions that not only meet your expectations, but exceed them. Our commitment to quality, precision, and customer satisfaction drives everything we do, from initial consultation to final delivery. With our advanced technology and experienced team, including our expertise in large-scale machine die casting, we ensure that every component we produce meets the highest standards.

Ready to take your lighting project to the next level? Contact us today to learn how our lighting die casting can realize your vision with unparalleled quality and efficiency. Whether you need a custom solution or are exploring options for large-scale production, we are here to help. Contact us today and let Elimold light up your success!

Get die-cast parts and services for the lighting industry in one place!

Elimold provides comprehensive assistance for your project, including mold design, die-casting, CNC machining and surface treatment services. Please feel free to contact us!