Motorcycle 3D Printing Services

With additive manufacturing and rapid prototyping technologies, you can turn your initial idea into a fully functional motorcycle in just 12 weeks. Elimold offers 3D printing services for both metal and plastics, producing all motorcycle parts. Learn how to save time and money with 3D printing.

Motorcycle Parts 3D Printing Company

Elimold is a professional motorcycle 3D printing service provider located in China. We are committed to providing project management and support for all stages of motorcycle product development using state-of-the-art additive manufacturing technologies. To date, we have collaborated with numerous motorcycle R&D and manufacturing companies worldwide, completing over 2,300 projects.

To best meet our clients’ evolving needs, in 2021, Elimold added Selective Laser Sintering (SLS) 3D printers and other metal 3D printers to our existing lineup of stereolithography (SLA), fused deposition modeling (FDM) 3D printers, and CNC machines.

Therefore, customized motorcycle parts in small batches and rapid prototyping can be delivered in as little as 24 hours. Contact the Elimold team now, and we’ll help you solve your key motorcycle parts challenges with greater flexibility.

Custom Motorcycle Parts 3D Printing Service

Elimold’s in-house factory uses a variety of 3D printers for prototyping, functional testing, and manufacturing the final parts for custom motorcycles. By using 3D printers, we significantly accelerate the iterative design and prototyping process, enabling the production of unique, finished parts.

3D printing services play a crucial role in the motorcycle design cycle, allowing motorcycle parts design and manufacturing teams to expand their creativity to limitless possibilities. The rapid prototyping advantages of 3D printing significantly shorten the design cycle time for manufacturing custom parts in the motorcycle industry.

Our custom motorcycle parts manufacturing plant in China leverages the immense potential of 3D printing technology for the motorcycle industry. If you want to design unique parts and find traditional manufacturing methods difficult and expensive, contact the Elimold team to start experiencing our 3D printing services.

3D Printing Directly to Production

The Elimold team is capable of custom-manufacturing motorcycle parts using a variety of 3D printing methods. Our clients’ favorite printing material is carbon fiber PLA (Plastic Composite), as its texture and surface quality are perfectly suited to the parts they print. Additionally, surface patterns can be directly printed onto the motorcycle, with quality sufficient to meet client production needs. Every part we design and print is designed to solve a client’s problem, whether it’s an engineering or aesthetic issue. 3D printing services will dramatically change the amount of custom metal and plastic motorcycle products that end up being discarded. If you don’t want to spend a lot of time creating something that ends up as junk, Elimold’s 3D printing services specifically for the motorcycle industry will revolutionize that.

3D Printing Processes

We offer an online 3D printing service specializing in custom motorcycle parts, allowing you to print custom parts on demand. We offer six 3D printing technologies to transform your 3D files into plastic, metal, and elastomer parts. With over 120 3D printers, our unparalleled capacity ensures reliable parts delivery within days. In addition to a wide selection of materials, we also offer various post-processing options to improve appearance or enhance mechanical properties.

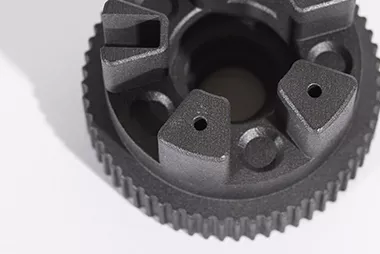

Metal 3D Printing

Selective Laser Sintering (SLS)

Stereolithography (SLA)

Multi Jet Fusion (MJF)

PolyJet

Advanced Photopolymers

Development of 3D-Printed Motorcycles

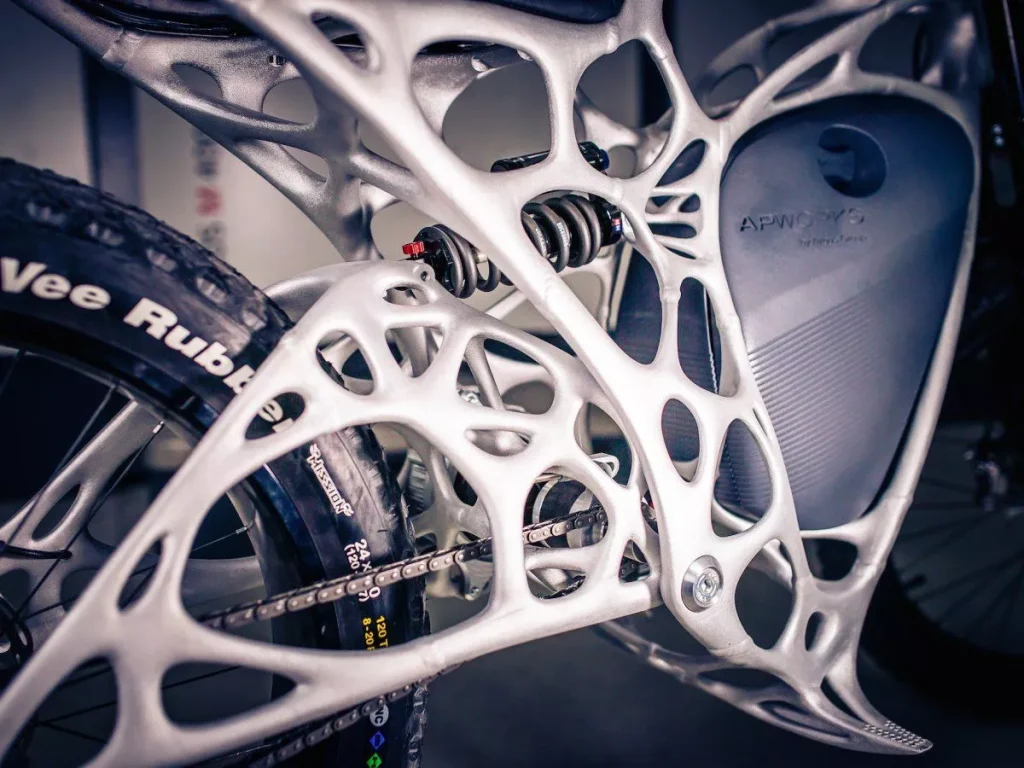

In rapid prototyping, our goal is small-batch production with a requirement for rapid delivery. Manufacturing motorcycle parts with complex geometries requires machining multiple components and creating molds, which increases development cycle costs. Additive manufacturing (3D printing) eliminates the need for mold making. It provides open-minded designers with the opportunity to create motorcycle structures with minimal material. Therefore, 3D printing technology makes it possible to manufacture unique, custom motorcycle parts, such as gearshift levers and linkage mechanisms. It also allows manufacturers to fully utilize existing resources and expand their creative possibilities. Simultaneously, using 3D-printed motorcycle parts can shorten production cycles and reduce manufacturing costs.

Custom Motorcycle 3D Printing Parts

Using 3D printers to manufacture parts allows for customization and unique designs. You can design parts of various shapes, which is impossible with traditional industrial processes. Furthermore, this avoids mold costs, which are difficult to recoup in the short term. Another advantage of 3D printing production is the ability to manufacture parts simultaneously on different printers. You can break down components into multiple parts and print them concurrently, further accelerating production.

Design and Engineering Team

Elimold specializes in providing custom parts design services for motorcycles and scooters to other companies, and has assembled a team of designers and engineers. Our team provides external consulting services to companies looking to create innovative motorcycles. Elimold has already developed projects for the Italian, American, European, and Vietnamese markets.

We believe design is always at the heart of production, so we utilize clay models, sketches, and renderings, combined with state-of-the-art technologies such as 3D printing and robotics, to provide custom parts design services for motorcycle manufacturers. Furthermore, we leverage advanced precision scanning technology and the latest 3D printing technology to manufacture precise and durable replacement parts for motorcycles. This is a perfect example of the integration of craftsmanship and automation.

Full Production Support Team

We have a team of manufacturing experts working behind the scenes to fulfill your production order—we manage the entire process and keep you updated along the way.

Account Manager

Applications Engineers

Logistics

Quality Control

3D Printing Reduces Motorcycle Part Manufacturing Costs

Many of Elimold’s clients are opting for 3D printing instead of traditional manufacturing and outsourcing methods for rapid prototyping. This has helped them reduce raw material costs by 90% and save thousands of dollars on design. The tested “Prototype Zero” motorcycle consists of several 3D-printed parts: the body, dashboard bracket frame, windshield, saddle base plate, and saddle (including rubber components). Other 3D-printed parts include covers, electronic insulators, cable clamps, front and rear fenders, and other less stress-bearing components such as the chain guard and headlight.

Motorcycle 3D Printing Solutions

As you may know, rapid prototyping (and 3D printing) is widely used in the manufacture of custom motorcycle parts. Many industrial-grade 3D printing technologies used for custom manufacturing can be applied to motorcycles. Utilizing SLS 3D printing technology and different types of wind molds, Elimold completed the prototype, manufacturing, and launch of an electric superbike in just two weeks. A full 1:1 scale master model was manufactured for testing assembly, overall dimensions, space optimization, raceways, and validating various static and partially dynamic components and electronics.

3D Printed Motorcycle Parts to the Rescue

Elimold’s 3D printing technology, specifically designed for the motorcycle industry, accelerates the creation of custom parts at every stage, from design and testing to manufacturing. Teams are now able to iterate faster and refine designs through a streamlined workflow. This helps our customers overcome design limitations imposed by previous manufacturing technologies. Furthermore, thanks to the versatility of Elimold’s 3D printers, engineers at motorcycle manufacturers are now able to create end-use parts from various materials, such as nylon, PET-G, or ABS, for a wide range of applications.

Material Options

Elimold is printed with BigRep TPU, BigRep ProHT, BigRep PLA, and BigRep PETG materials. While we use ProHT for rigid parts, PLA for color details and PETG for the light reflectors, TPU allows us to embed functionalities in a unique way. Tires, bumper, seat and handles are printed with the flexible material and fulfill functions that usually require complex mechanical constructions such as hydraulic, shock absorbing suspension systems.

In addition, for motorcycle metal parts, we can also provide aluminum alloy, titanium alloy, stainless steel and other metal materials to manufacture custom structural parts.

Why use metal 3D printing to manufacture motorcycle metal structural parts?

Metal 3D printing technology provides motorcycle manufacturers with more precise, customized components, as well as the flexibility to rapidly iterate on fork geometry to match specific chassis and kinematic requirements. Metal 3D printing can reduce the weight of fork arm components and bypass traditional weight transfer phenomena and ‘brake dive’ problems. Furthermore, it allows for the design of components that are not only lighter but also more rigid. In one Elimold customer case, the titanium alloy Ti6Al4V, processed using additive manufacturing, achieved an ultimate tensile strength exceeding 1100 MPa and a near-perfect density of 99.7%. The resulting new fork arm was significantly more rigid than the original multi-part, hand-assembled steel component.

Motorcycle 3D Printing Partner

Designers can create more complex parts with significantly less effort, time, and cost than ever before. Previously, many companies spent considerable time handcrafting parts; now, they can focus on higher value-added components.

Elimold’s application of 3D printing technology in custom or non-aesthetic parts has opened up new solutions and design strategies for motorcycle OEM, enriching their design processes and final deliverables while shortening time-to-market and reducing overall labor costs. Are you interested in learning how Elimold’s 3D printing services can benefit your business? Contact us; we look forward to your inquiry!

Elimold offers 3D printing services for custom motorcycle parts and prototypes

At Elimold, we use high-quality 3D printers throughout the entire process, from design to production. You can also fine-tune your design to ensure the best final result. Upload your CAD files now and let us bring your 3D printed motorcycle design to life!