Motorcycle Die Casting Services

Elimold specializes in designing and manufacturing high-quality motorcycle die-cast parts using advanced die-casting technology. We provide durable, lightweight, and high-performance components that exceed customer expectations. With our advanced technical expertise, extensive experience, and diverse tooling and equipment, we can meet a wide range of casting needs.

Motorcycle Die-Casting Parts Manufacturer

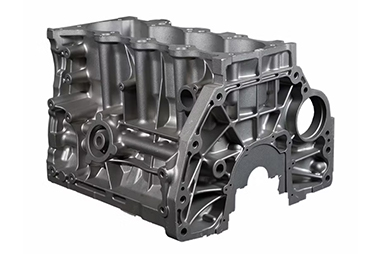

Elimold is one of China’s leading manufacturers of motorcycle die-casting parts. Whether designing and mass-producing motorcycle engine parts or gearbox parts, we ensure the highest tolerances and customized manufacturing processes for motorcycle parts. Elimold is committed to improving motorcycle design and performance across the industry. Our motorcycle die-casting product line covers a variety of manufacturing processes, such as die casting, CNC machining, grinding, and coordinate measuring machine (CMM). Our die-casting machines are available in various configurations, such as 280-ton and 3000-ton machines, capable of producing a wide range of complex motorcycle parts. As a motorcycle die-casting parts manufacturer, factory, and supplier from China, Elimold firmly believes in a bright future and hopes to establish long-term partnerships with motorcycle manufacturers worldwide.

China's High Quality Die Casting Company

As an original equipment manufacturer (OEM) supplier in the motorcycle die-casting industry, we face a highly challenging task. These large OEM clients require strict adherence to their specific project data systems. To build a state-of-the-art integrated production facility, we have an experienced team including operators, mold makers, engineers, quality control personnel, and front-office staff. The key to our project success lies in our unwavering focus on meeting customer needs. We are committed to achieving every goal, striving for customer satisfaction in every project. To achieve high supplier ratings, we consistently adhere to these project objectives. Every employee in our company will do their utmost to meet your product requirements. Elimold is your one-stop shop for lean sourcing of die-cast parts.

Our Advanced Parts Manufacturing Capabilities

Our molds are manufactured independently, without additional profit margins, resulting in moderate costs and short lead times, with samples available in as little as 20 days.

1. Drawing Design

DFM (Design for Manufacturing) is one of the best methods Elimold engineers use to optimize the manufacturability of castings while maintaining their functionality. Elimold has a team of over ten professional engineers who provide effective advice on material structure and find a balance between design, cost, and part performance.

2. Mold Design

The mold design phase simulates the filling flow and solidification process, predicts potential defects in die castings, forecasts the microscopic and mechanical properties of the metal, and the strength of the mold ejector pins. This optimizes runner and gate design, improves production process parameters, reduces R&D and production costs, and improves the quality of cast products.

3. Mold Manufacturing

Elimold's motorcycle die-casting mold manufacturing technology allows us to integrate the part structure into the mold during the molding process, achieving one-time molding of parts and reducing the cost of multi-part production, assembly, and secondary processing.

4. Die-casting Capabilities

Elimold is one of the few companies capable of expanding its casting range, possessing die-casting machines ranging from 58 tons to 3000 tons, capable of producing parts weighing from 5 grams to 35 kilograms. Each die-casting machine is equipped with an independent furnace, enabling us to offer a variety of aluminum, zinc, magnesium, and their alloys to meet the unique needs of our customers.

5. CNC Machining Capabilities

Elimold boasts an experienced and technically proficient CNC machining team, with over ten imported machining centers and lathes dedicated to machining motorcycle die-cast parts, providing reliable precision. To meet part requirements and customer assembly specifications, minimum tolerances are controlled within 0.22mm.

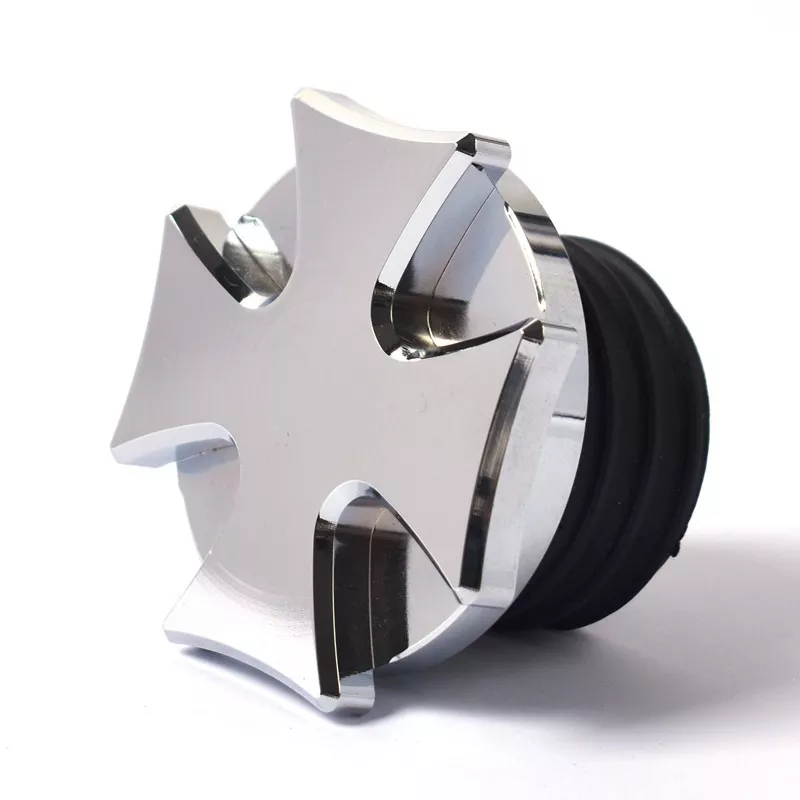

6. Surface Treatment Capabilities

Elimold can perform physical surface treatments such as shot peening, fine sandblasting, and coarse sandblasting, as well as powder coating. Meanwhile, we have cultivated the Chinese supply chain for over 10 years, strategically integrating dozens of chemical surface treatment suppliers. Through the management of this complex supply chain, we provide customers with surface treatment services such as plastic spraying, painting, anodizing, electrophoresis, and chrome plating.

7. Assembly Capabilities

Elimold's in-house die-casting plant can provide customers with a variety of mechanical assembly and sub-assembly services. We have extensive experience in hardware assembly, including screws, bolts, pins, inserts, gaskets, and O-rings, and perform pressure seal testing to ensure product functionality.

8. Quality Inspection System

Elimold places great emphasis on quality control during mass production and has established a comprehensive quality inspection process and system. Five commonly used inspection tools are employed: PPAP, APQP, PFMEA, SPC, and MSA. All products undergo comprehensive inspection or manufacturing according to standards. Testing equipment includes: spectrometers, tensile testing machines, coordinate measuring machines, conform/nonconform gauges, parallel gauges, and various calipers, to achieve effective quality system control.

Establishing a Strong Partnership with Elimold

Elimold not only has its own die-casting plant but also a comprehensive casting supply chain network across China to collaborate on the manufacturing of machined casting prototypes and produce high-quality motorcycle metal casting prototypes. By integrating the supply chain, we seamlessly combine our expertise and industry-leading technology with the capabilities and human resources of our in-house plants and smaller foundries. This allows us to not only control the production processes in our in-house plants but also optimize the processes in our partner supply chain plants, ensuring precision in the casting of complex components. Our real strength lies in our flexibility; we are not limited to a single metal or alloy. Instead, our supply chain network offers diverse capabilities, enabling us to meet the specific needs of each motorcycle project, regardless of its complexity or scale.

Rapid Prototyping

Our professional team utilizes cutting-edge technology and industry-leading processes to bring your ideas to life through parts manufacturing prototyping services. From rapid prototyping and iterative testing to small-batch production and other scales, we tailor solutions to your unique needs and timelines. Our unwavering commitment to quality, reliability, and customer satisfaction makes us a trustworthy partner on your innovation journey, accompanying you every step of the way to success.

Low-volume Production

Elimold is proud to support Original Equipment Manufacturers (OEM) at every stage of the product lifecycle. Whether you are in the early stages of prototyping, scaling up production, or need to reverse engineer repair parts, our team has the skills to produce high-quality parts in low-volume batches.

Casting Tools and Support

At Elimold, we’re not just focused on manufacturing; we’re committed to helping you succeed. Our casting support services are designed to improve the efficiency of your motorcycle custom parts casting operations, propelling you towards success. With cutting-edge technology and a team of experts, we provide bespoke precision molds to meet your unique needs. We optimize your production efficiency while ensuring superior casting quality through rigorous quality assurance and cost-effective solutions. Partner with us to streamline your processes and stand out in the competitive motorcycle market.

Custom Your Motorcycle Parts Today

Fast And Accurate Prototypes Shipped in 1-3 days. First time to purchase casting service online? Don’t worry! Elimold offers you a one-stop metal casting service from design, manufacturing, to shipping.

We Provide Die Casting Services

Elimold’s casting services cover a variety of casting processes, including sand casting, metal casting, investment casting, and lost foam casting.

An Experienced Team of Die-Casting Engineers

Elimold’s team of die-casting process designers has an average of over 15 years of die-casting experience. They set the die-casting parameters to achieve optimal product results. From initial concept to final production, we offer comprehensive services including design consultation, prototyping, mold making, die casting, machining, and metal surface treatment. We also provide designs based on your specific model or CAD drawings.

Our team’s collaborative approach ensures that parts are not only manufactured but also that they are both performance- and cost-effective. They are renowned for producing parts with precise tolerances and complex geometries, combining advanced manufacturing technology with attentive customer service. Whether it’s small-batch prototyping or large-scale production orders, the company’s focus on quality and precision extends to every stage.

In-house Casting Mold Workshop

We have extensive experience in designing and producing die-casting molds for custom motorcycle parts. All our designs, engineering, CNC machining of molds, and CNC machining of castings ensure that we can complete casting work quickly, accurately, and efficiently. The first casting produced using a new casting mold is immediately inspected and then sent back to the CNC machining workshop to complete the mold machining, thus quickly manufacturing CNC-machined castings while the foundry begins producing qualified mass-production castings. Furthermore, Elimold has its own mold manufacturing workshop, providing you with a one-stop service from mold making to die casting. We can manufacture high-pressure die-casting molds suitable for 160-3000 ton die-casting machines. Our mold designs are rationally structured and highly efficient. Good molds produce high-quality products.

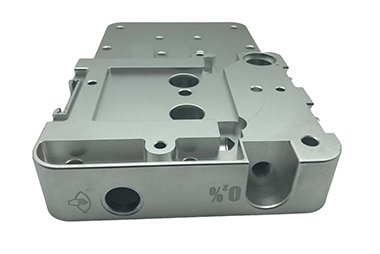

CNC Machining After Motorcycle Die-Casting

Elimold utilizes CNC machining to perform secondary processing on motorcycle die-cast parts, creating high-quality, durable, and reliable components. In addition, we offer surface finishing services such as deburring, conversion chromate treatment, and painting, providing a one-stop solution for your motorcycle die-cast parts procurement needs. We have 20 CNC machining centers used for manufacturing casting molds and castings, including 10 vertical machining centers (with 4-axis and 5-axis capabilities) and 3 horizontal machining centers, with a maximum machining size of 7 feet x 12 feet x 24 inches. Our rapid mold improvement mechanism ensures continuous improvement. Our customers trust our expertise and experience; we assess their application needs and deliver high-quality, high-reliability parts that meet or exceed their specifications.

Our Advantages

Our quality control team develops a control plan for each part number. This plan clearly defines all critical part dimensions and the corresponding inspection methods. Our adherence to industry standards has made us a NAFTA-certified supplier to Fortune 500 Original Equipment Manufacturers (OEM). Our experienced team of engineers and production personnel continuously receives training in industry practices. We guarantee to provide you with high-quality parts at economical prices.

Materials and Surface Treatment Capabilities

Elimold offers a variety of high-quality materials for custom die-cast parts for motorcycles, including aluminum, zinc, and other metals.

Die Casting Materials for Motorcycle Parts

- AL360

- AL380

- AL383

- AL413

- ZA-8

- ZA-12

- ZA-27

- Aluminium A356

Surface Finishing Ability of Motorcycle Parts

- Sand Blasting

- Shot Blasting

- Polishing

- Anodizing

- Oxidation

- Electrophoresis

- Chromate

- Powder Coating

- Painting

Custom Colors

- Black

- White

- Silver

- Red

- Natural

- Blue

- Green

- Different colors as client requirements

Quality Control

Our quality control begins with the mold dimensions. Before die casting, we use a coordinate measuring machine (CMM) to check the critical dimensions of the mold cavity to ensure the dimensional accuracy of the die castings. After die casting is completed, we check dimensions, strength, porosity, etc., depending on the end use of the parts and customer requirements. A complete set of inspection documents and material certificates will be sent to the customer along with the goods.

The Elimold Case Studies Of Motorcycle Parts Casting

Get Your Custom Quote Today

Ready to discuss your forging requirements? Our engineering team is standing by to provide expert consultation and competitive pricing.