Oil & Gas 3D Printing

Elimold’s extensive experience in oil and gas 3D printing services means we can offer the industry’s most comprehensive selection of metal and plastic 3D printing technologies and materials for any oil and gas application, whether small or large, simple or complex, prototype or production. Our experts work closely with your team to identify and evaluate 3D printing candidates to explore design improvements and cost savings. Contact us now for a free instant quote.

3D Printing Manufacturer for Oil and Gas Industry

Elimold provides industry-leading online Oil & Gas 3D Printing services. Whether you need a prototype or a production part, we can make it for you in one day. We are your one-stop shop for accurate, precise, custom Oil & Gas 3D printed parts at a low cost. Elimold uses the latest additive manufacturing processes to manufacture affordable functional prototypes and end-use parts in all metals and plastics. With our global supplier network and a team of engineers with extensive expertise and experience to support you, you can meet or overcome the challenges of Oil & Gas Additive Manufacturing/3D Printing. We provide a wide range of services, including rapid part prototyping, part design analysis and optimization, product prototype testing and inspection, and high-volume production. Whether you are an Oil & Gas parts supplier, technology developer, designer, or equipment manufacturer for the Oil & Gas industry, our professional engineering and technical team can provide you with a complete solution based on your needs.

Our Digital 3D Printing Manufacturing Process

On-demand digital manufacturing services from our in-house 3D printing facility can greatly increase flexibility for custom parts in the oil and gas industry, helping to quickly move custom parts from design concept to tangible prototypes for immediate testing and adjustments. Our just-in-time online 3D printing manufacturing platform for oil and gas supports on-demand production, minimizes customer inventory costs, and enables custom part solutions without extensive re-tooling. Elimold’s services can decentralize manufacturing capabilities, ensuring faster, more efficient, and more cost-effective delivery of custom part solutions for oil and gas customers.

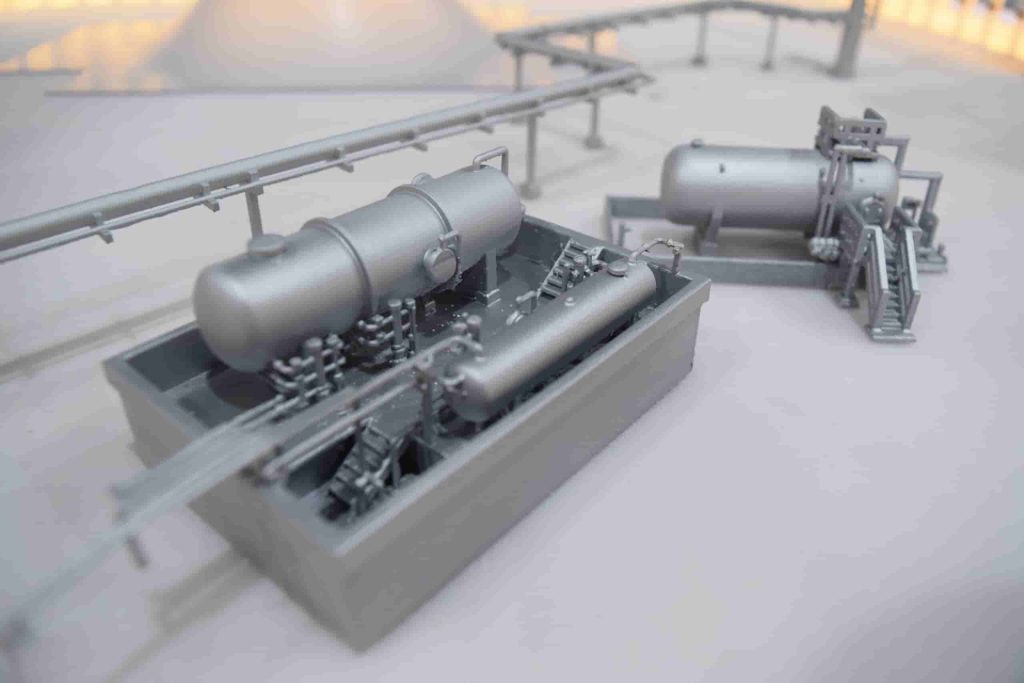

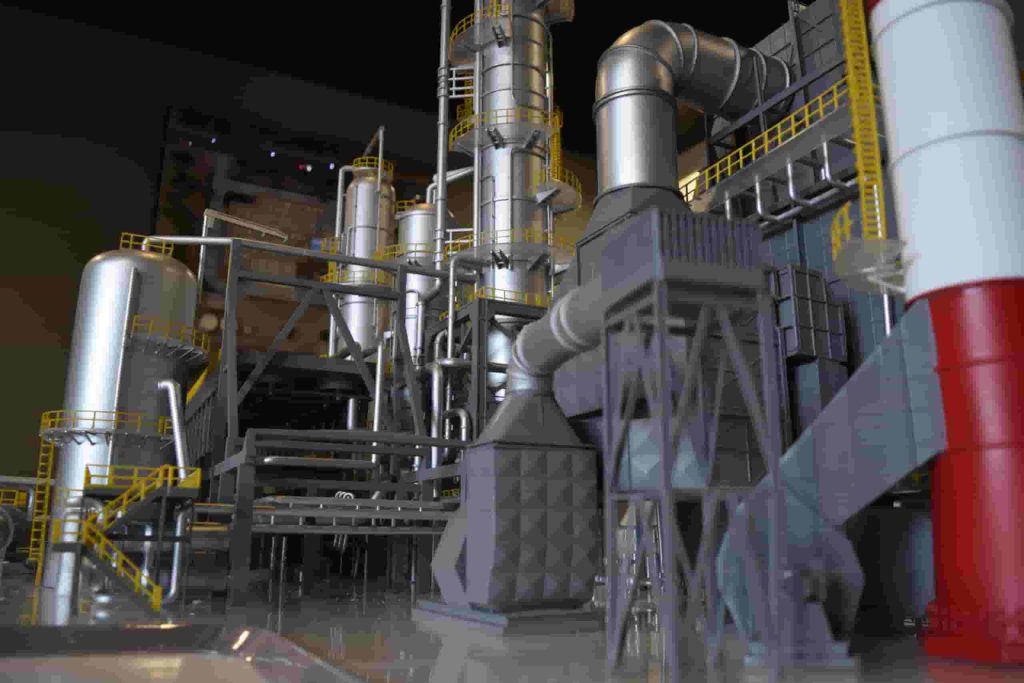

Large-Scale 3D Printing Services

Elimold also provides high-quality large-scale 3D printing services (also known as large-format 3D printing) to the Oil & Gas industry. We can provide metal or components up to 20 inches, theoretically enabling custom parts of any size. Our large-scale 3D printing is endless in its capabilities, with the most common uses being full-scale models, single printed components, large prototypes, and other applications that would be laborious and expensive to produce using other manufacturing methods. Therefore, with Elimold’s large-scale additive manufacturing technology, designers can produce full-scale prototypes and save printing time, allowing designers to improve prototypes faster and more accurately. And with large-scale additive manufacturing, parts that are completely custom to customer needs can be produced quickly, and the labor and material costs associated with custom manufacturing can be reduced.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused DepositionModeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

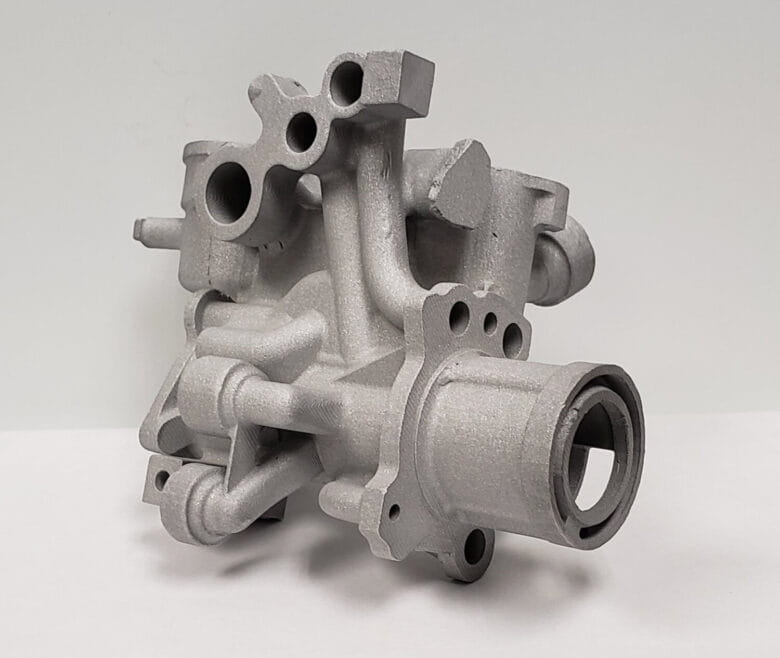

Part Reverse Engineering Services

Elimold can provide reverse engineering technology to customers in the Oil & Gas industry. And we specialize in low-volume, highly custom parts, which is exactly in line with the needs of the Oil & Gas industry. We have helped many customers re-manufacture old service parts that they no longer have CAD drawings for through scanning and reverse engineering. Experienced technicians and materials engineers use a set of analytical techniques to determine the material composition of the part, the materials it is made of, and how to re-design the part to make it lighter and more efficient. We can then produce limited quantities of parts to keep important production equipment running and minimize expensive downtime. Some of our advanced manufacturing techniques do not require tooling. Parts can quickly go from CAD to finished metal or plastic, ready for use in your equipment. All of this is done in weeks, not months. Elimold can help you streamline your supply chain.

Rapid Prototyping for Custom Oil & Gas Parts

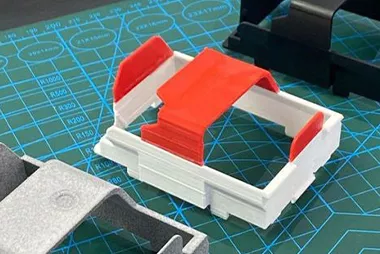

A key application of our Oil & Gas 3D Printing Services is in the provision of rapid prototyping services. Time to market is one of the most critical issues facing the Oil & Gas industry, and the longer a product stays in the design cycle at the concept stage, the less potential profit a company makes. Faced with pressure to create solutions quickly, engineers and designers must make fast, accurate decisions during the concept phase. Rapid prototyping is a critical step in design validation, but can be a potential barrier to release if not performed quickly and cost-effectively. Our Rapid Prototyping and 3D Printing Services for the Oil & Gas industry complement each other. 3D printed prototype parts can enable engineers to quickly make multiple iterations and change component designs overnight to meet deadlines.

Ready to get started on your next Oil & Gas 3D Printing project?

Experience a seamless, turnkey service process with our advanced manufacturing facility, design and engineering teams, and 3D scanning capabilities to ensure high-quality results and exceptional customer satisfaction every step of the way. Contact us today for a free instant quote.

Key Benefits of Optimizing Oil and Gas with 3D Printing

Learn how 3D printing can improve efficiency, safety, and sustainability in the oil and gas industry through innovative applications.

Quicker Prototyping Of Parts

Produce Complex Geometries

Manufacture Parts On Demand

On-demand additive manufacturing for custom parts for the oil and gas industry

Using additive manufacturing and superior performance improvements to revolutionize the way the energy, oil and gas industry custom parts, Elimold helps manufacture engineered tools and components for the oil and gas industry. Whether it’s a spare part or a new component to support new component assembly, we use additive manufacturing to create parts that can’t be made through die casting or cnc machining. And by applying DFAM technology to product design, we guarantee you that the part will outperform all previous versions, allowing you to maintain a competitive advantage. Adherence to strict ISO 9001 requirements also ensures that mass-produced parts exceed all quality requirements and are reliable. We also provide assistance with part consolidation, spare part production, and topology optimization.

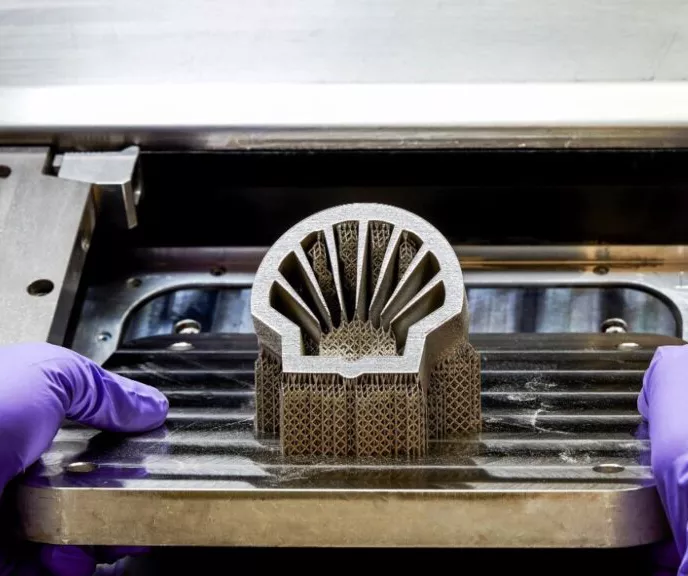

Complex Geometries and Lightweighting

3D printing excels at creating complex designs that are impossible with traditional manufacturing methods. In the oil and gas sector, this capability enables the manufacture of components with advanced geometries to optimize performance, such as turbine blades with internal channels to improve aerodynamics or heat dissipation. 3D printing can create lightweight structures using lattice or honeycomb designs, reducing material usage while maintaining structural integrity. This lightweighting is critical in industries such as transportation, where reducing component weight can lead to significant energy savings and efficiency gains, directly impacting the operational efficiency and environmental footprint of oil and gas systems.

Supply Chain Simplification

Designers can now produce parts or products precisely when and where they are needed, without having to maintain large inventories and long, complex supply chains. This shift brings many benefits, such as reduced warehousing costs, lower risk of overproduction and waste, and the ability to respond quickly to changes in demand or design modifications. Direct digital manufacturing with Elimold enables localized manufacturing, reducing the environmental impact of shipping goods over long distances. This on-demand production not only improves supply chain efficiency, but also provides greater flexibility to meet customer needs, making it a valuable solution for industrial designers and businesses looking to streamline operations and reduce resource consumption.

Looking for large-scale 3D printing services to manufacture oil and gas parts?

To expedite the quote request process, our experienced staff is ready to work with you to ensure all details are addressed and your project is accurately quoted.

AM technology promotes part innovation

AM technology can help engineers in the oil and gas industry to quickly realize physical objects and quickly iterate product designs during the R&D process to support innovation. Combining it with Elimold’s other manufacturing technologies, part designers and original equipment manufacturers (OEM) in the oil and gas industry can collaborate more efficiently no matter where they are. And our additive manufacturing services can also handle more complex designs and use unconventional and new materials better than traditional manufacturing methods. It requires little or no re-equipment of manufacturing equipment. It can also enable novel repair methods, such as building new layers of material in eroded areas. This can extend the safe and efficient operation time of aging assets and reduce the life cycle cost of equipment.

Material Options

We offer the oil and gas industry’s most comprehensive selection of 3D printing materials, which are frequently used in a variety of demanding applications including prototyping, production parts, tooling, and more.

- Aluminium

- CobaltChrome

- Copper Alloy

- Nickel Alloy

- Stainless Steel

- Stainless Steel 316L

- Titanium

- Tool Steel

- PLA

- ABS

- PETG

- TPU

- Nylon

- PET

- PA

- PEEK

Applications

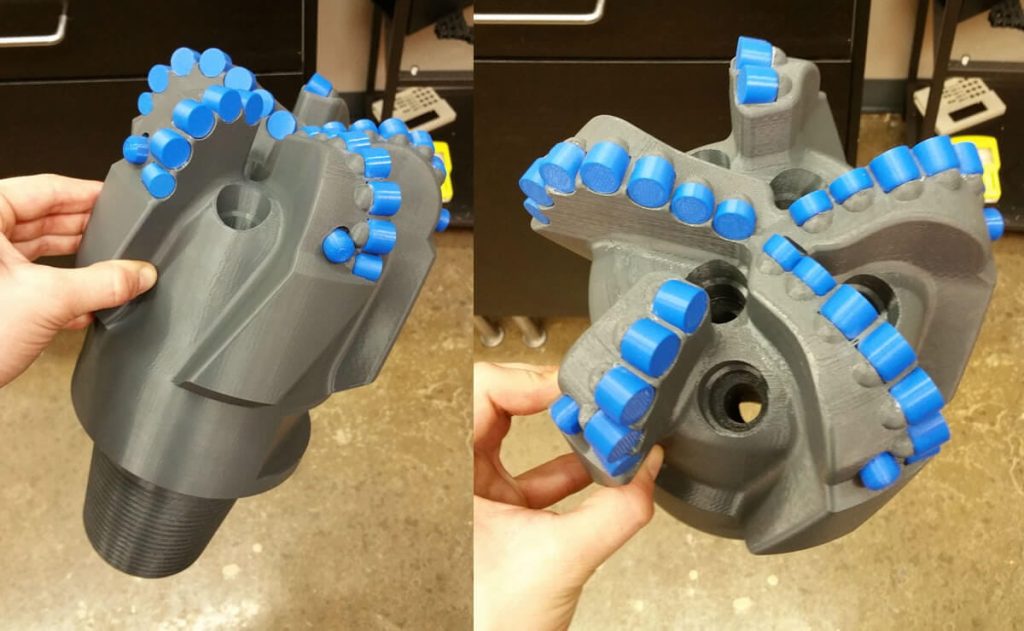

- Custom Drill Bits: 3D printing can create drill bits with unique geometries and configurations, optimized for specific drilling conditions.

- Replacement Parts: 3D printing can be used to quickly produce replacement parts for equipment, reducing downtime and maintenance costs.

- Flow Nozzles: 3D printing can be used to create complex and precise flow nozzles for oil and gas pipelines.

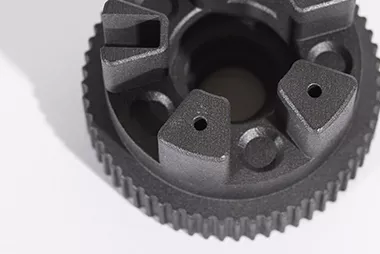

- Valve Components: 3D printing can be used to produce custom precision valve components, such as valve seats and balls, for oil and gas operations.

- Production Molds: 3D printing can be used to create molds for casting complex and custom parts, such as manifold systems and pump components.

Fast and efficient maintenance

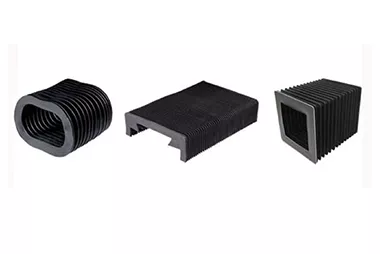

Equipment in the oil and gas industry needs to be kept up and running. Equipment downtime can be a huge expense for companies, so downtime needs to be minimized. When equipment is located in remote areas such as oil rigs, the cost of downtime is even more prominent. 3D printing in the oil and gas industry can change this situation. When maintenance operations need to be carried out efficiently, 3D printing with Elimold can create custom tools and fixtures to ensure smooth and flexible maintenance operations.

Some stages of maintenance operations are repeated. For such operations, 3D printing in the oil and gas industry offers the possibility to create fixtures and tools that will make the process safer and more efficient. With it, the work of maintenance operators becomes more ergonomic, so the level of work safety can be improved.

Decarbonizing Component Manufacturing and Component Supply Chains

Understanding the complexities of oil and gas industry standards is only part of the story we solve for our clients. Net zero, or achieving carbon neutrality in the hydrocarbon and energy sectors, is one of the world’s most important challenges. Elimold can help!

Many oil and gas companies are looking to achieve net zero emissions from the activities they control. But those who really want to make an impact understand that it’s not just about evaluating and improving the existing value chain; it’s doing the same with supply chain suppliers. There is no single solution, but rather multiple solutions that require change from consumers to governments to businesses. A carbon neutral approach may also allow large organizations to encourage and support smaller suppliers on the path to net zero.

Supplying parts using wire additive manufacturing reduces carbon footprint and emissions. The Elimold process reduces carbon intensity by printing in near-net shape using wire feedstock, producing significantly less material waste than billet machining. 3D printing parts using Elimold also has a significantly reduced carbon footprint compared to traditional casting and forging manufacturing methods.

Ready to dive deeper into your project?

Speak with an expert in 3D printing for the oil and gas industry today! Our team is standing by and ready to answer questions or provide a quote for your project.