Optics Injection Molding

Elimold is a leading provider of optical injection molding services, with plastic parts that meet international quality standards. Our optical molding experts can guide you through the entire process, including important decisions about parts, materials, and mold construction. Elimold’s service is unmatched, leveraging decades of experience in optical engineering, tooling, performance verification, and lifetime mold maintenance. Contact us now for a free instant quote.

Optical Injection Molding Manufacturer

Elimold is a plastic molding company that helps every customer make optical components. Our team of engineers will work closely with you to understand the application, evaluate tolerances, establish necessary quality metrics, and create molds that deliver molded optics in a consistent manner.

We combine decades of experience and advanced equipment to mold precision plastic optics in-house. Elimold serves customers around the world by providing unparalleled expertise in optical injection molding. So when your design defies traditional molding design rules, our team of engineers can provide you with a solution. Sure, we use basic principles like Taguchi Design of Experiments (DOE), window treatments, and decoupled (scientific) molding, but we have a secret recipe that has been used for over 30 years to ensure that your molded optics are fully functional works of art.

Precision injection molded plastic optics require special knowledge and capabilities. Because tolerances are tight and mold processing conditions are often extreme, injection mold design and manufacturing techniques require special knowledge and skills. Injection molding equipment should have advanced control capabilities and care must be taken to ensure cleanliness.

In-house Optical Injection Molding Shop Manufacturing Capabilities

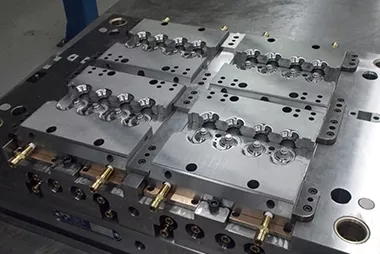

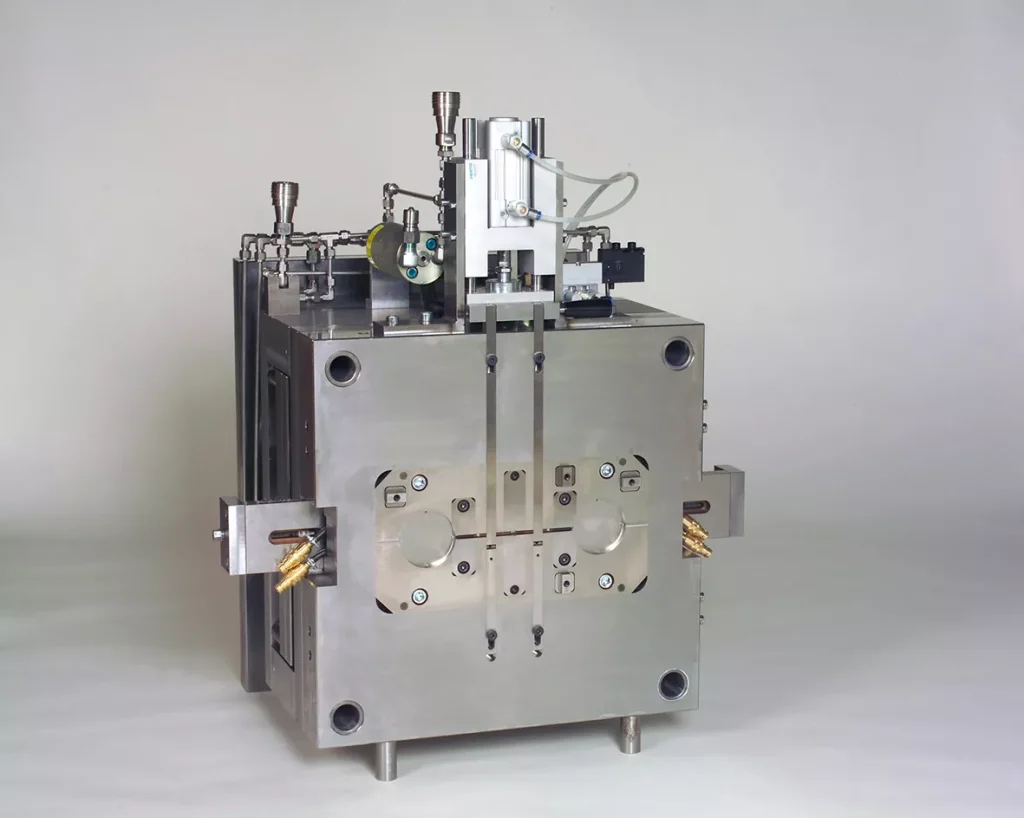

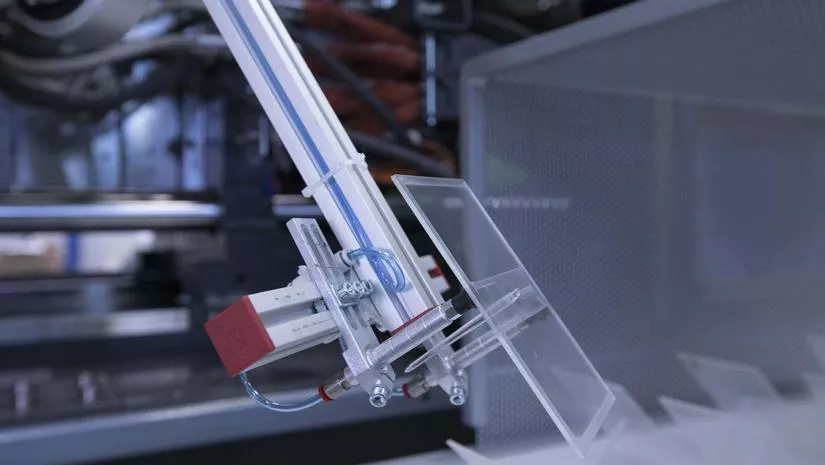

The cleanroom of our in-house injection molding plant is equipped with dozens of advanced injection molding machines ranging from 85 tons to 2500 tons for optical injection molding. Components with diameters ranging from 2.5mm to 350mm and weights ranging from 0.05 grams to 10KG can be produced. In the mass production of precision plastic optical components, high-precision plastic optical components weighing from a few tenths of a gram to thick-walled components can be provided, all of which are achieved through injection molding. In addition, we can also provide injection compression molding services, which is an improvement on the injection molding process for the production of thin-walled large-area plastic optical components, microstructures and low-stress plastic parts. And the robots, conveyors, tool storage and palletizing systems equipped in our in-house factory enable automated and cost-effective mass production of plastic optical components. Elimold’s on-demand manufacturing service can provide flexible production plans that enable us to produce up to millions of components per year as well as small batches of a few thousand plastic optical components.

Optical Injection Molding Tolerances

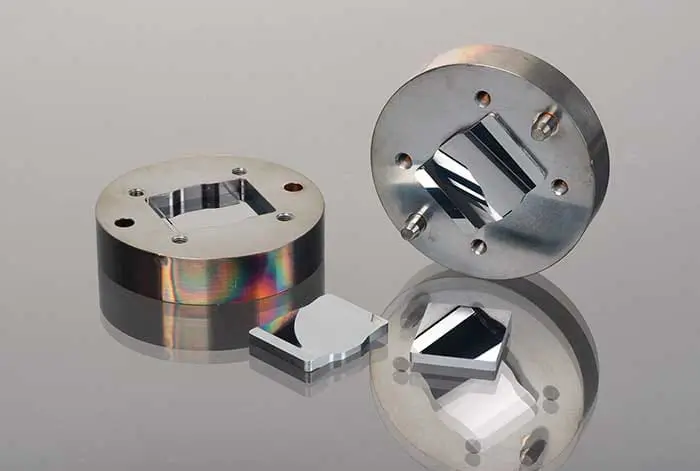

Our optical injection molding process begins with our DFM engineers and expert moldmakers who have decades of experience in optical molding. Our technicians use highly precise metrology tools to maintain micron and even half-micron tolerances.

At Elimold, standard optical projects require a P/V tolerance of 1 micron and a surface finish of 100 angstroms. On recent projects, we have achieved P/V tolerances of 200 nanometers and a surface finish of 20 angstroms. Position tolerances are tight to +/- 1 micron, with repeatability to 0.5 microns.

When your optical assembly or part is ready to scale quickly, our custom automation and vision systems ensure that the part is exactly the same from start to finish. Since no one in the world can operate within our known micron tolerances, we had to create our own in-house functional test system.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

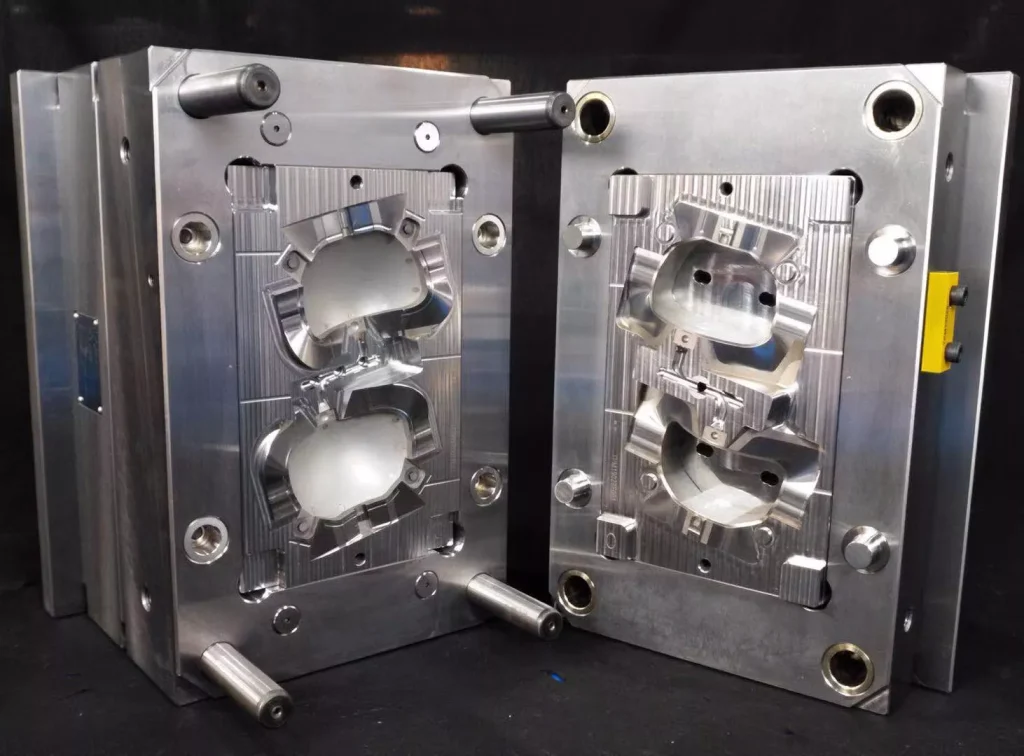

Optical Injection Mold Solutions

Each project to develop custom optical plastic parts needs to be managed by a project engineer who is responsible for monitoring and controlling deliverables and providing regular status updates. Elimold not only provides custom optical plastic parts services, but also optical injection mold manufacturing services. Our team of mold design and manufacturing engineers are proficient in the design and manufacture of various injection molds. We can design and manufacture single-cavity R&D molds with steel insert areas. Interchangeable plates, inserts and sub-inserts in the mold can achieve faster design iterations at a lower cost, rather than creating a new mold for each functional change. In addition, the cold runner, hot gate and hot runner injection molds we design and manufacture can be designed with up to 128 cavities.

Packaging and Cleanrooms

Our in-house custom packaging process not only protects and ships critical components, but also guarantees that the parts are well received in your manufacturing process. Our micro mold packaging capabilities include tape and reel, tray and gel pack as a starting point, but we can also custom design a packaging process to meet the unique needs of each customer. Our custom packaging is the perfect complement to our micro mold cleanrooms. Our cleanrooms meet ISO standards, 100k (ISO Class 8) and 10k (ISO Class 7).

Comprehensive optical parts custom manufacturing services

Our vertically integrated production facilities accelerate your time to market for new or existing optical products. At Elimold’s in-house facility, part design, DFM, mold design, in-house cnc machining, injection molding, and QA are all done under one roof. From rapid optical plastic part prototyping to mass production, we streamline production lines with automation when necessary to achieve the optimization you need. Elimold’s global supply chain enables us to meet your production needs at our in-house optical plastic part injection molding manufacturing facility. Our optics will deliver the same performance no matter where you need us to send your optics.

Explore Elimold's injection molding solutions for a wide range of optical components

We would be happy to provide a free evaluation and quote to help you produce your optical parts. Let us show you how we can start saving your company time and money.

Quality Control in Action

Quality control in action at Elimold is a comprehensive inspection and testing process that ensures that each part meets strict quality performance standards. Rigorous inspections are performed at every stage of the manufacturing process, from initial design to final product. Our quality control staff continuously monitors the injection molding process. Operators perform 100% optical and appearance inspections during the process to ensure that customers receive only the highest quality products. Optical inspection equipment and testing processes are designed and executed to meet the performance standards of each product. And utility molding is provided to simplify the customer’s build process. Internally molded trim rings, concealed gaskets, and other assembly parts reduce the customer’s workload. Elimold analyzes each step of the manufacturing process to provide customers with greater efficiency. Recommendations such as multi-cavity tools or turnkey assemblies can save customers money.

Optical metrology close to production

Strict adherence to the tightest tolerances is essential. Throughout the entire production process, in addition to our test engineers, our experienced assemblers and process technicians monitor all relevant parameters in order to be able to react to deviations as quickly as possible – upon request, this is done via statistical process control (SPC) within a 100% test range and frequently via functional tests on customer-specific test benches. In projects with very large quantities, in addition to the checks by our highly qualified team, we also offer solutions for 100% checks by automated test systems. In this way, components can be produced piece by piece with the highest precision.

Measurement equipment

- interferometer

- 3D Coordinate Measuring Machine

- contour measuring machine

- Luminance Camera

- spectrometer

- Integrating sphere

- MTF tester

- Focal length tester

- Center impact tester

- Series-accompanying, customer-specific function and camera test benches

Our experts will provide you with a wide range of services

- Optimization of your construction element design for more cost-efficient serial coating

- Selection of suitable materials and processes

- Feasibility studies

- Development of optimized coatings and coat designs according to customer requirements

- Process optimization ranging from cleaning and coating right through to packaging

- Development of suitable measurement and testing procedures according to ISO, DIN, or MIL

Excellent optical performance

As a bulk supplier of optical plastic parts, Elimold provides customers with a steady supply of high-precision optical lens parts for a variety of light transmission and control applications with precise, flexible optical performance. With proprietary optical design, tool design, and scientific injection molding processes, mass production of complex optical lens part designs is possible.

Not ready for mass production yet? Our flexible lens production meets customer needs, from small batch prototypes to fast ramp-up and stable mass production.

Produce your optical lenses at scale where you need them and ensure on-time product delivery: our global production network provides flexibility to optimize your supply chain.

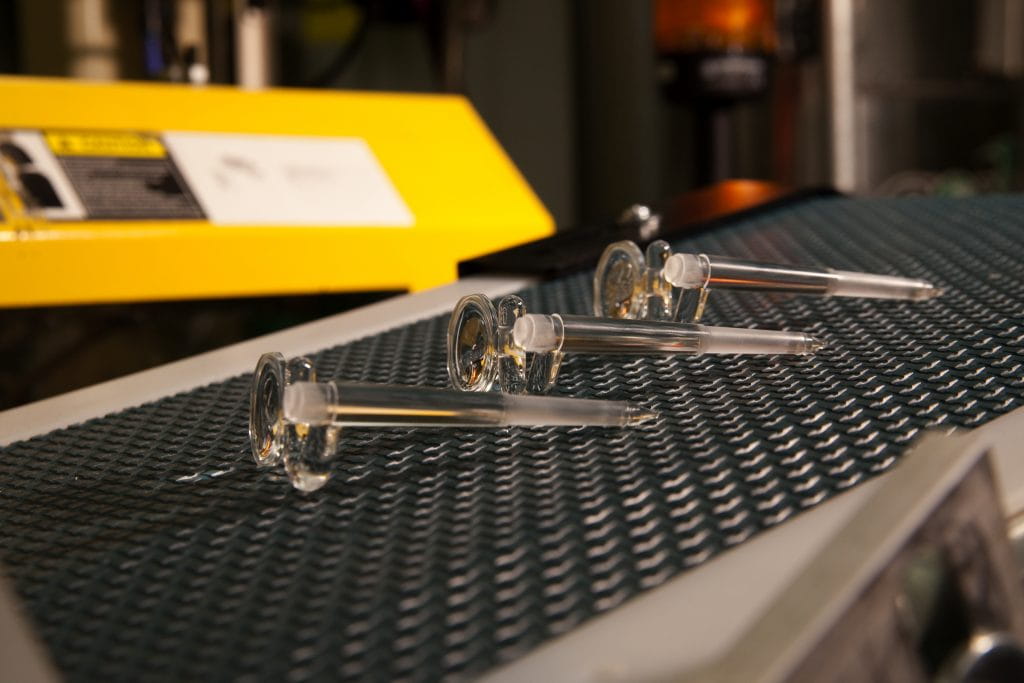

Injection Molded Nano-Scale Lenses for Reliable Optical Performance

Elimold injection molds precision optical products such as lenses for optical communications. With our specialized injection molding processes and in-house produced ultra-precision molds, complex lens features such as tiny dimensions (e.g., lens pitch is sub-micron), high transparency, and mirror surfaces can be injection molded. Enplas’ high-quality lens molding not only enables precise lens dimensions for lens optical performance, but also provides easier alignment when assembling the molded lenses into devices such as optical transceivers. This is because the quality of injection molding affects point quality and other important factors.

Making lenses in large quantities with stable optical performance

Elimold customers get precision plastic lenses that consistently deliver the optical performance they need, no matter how large the production volume. We supply LED backlight lenses to high-end TV manufacturers to meet the needs of the huge global consumer market. This is a testament to the quality of our high-volume products. While some manufacturers may only meet the dimensional specifications of the lenses produced, Elimold ensures the optical performance you need. Our engineers work closely with customers to meet their specific optical performance needs by solving lens design, production and assembly procedures. We are by your side throughout the process.

Injection Molded Freeform Lenses

Enplas can injection mold the next generation of optical components, such as freeform and aspheric lenses. With our proprietary optical design, tool design and scientific injection molding process, large-scale production of complex lens designs is possible. If you are looking for a manufacturing partner who can design, prototype, test and ultimately achieve large-scale production of new optical components used in AR/VR or sensing applications, please contact us for more details.

Optical Component Materials Options

Our experienced team of designers, technicians and engineers use their in-depth knowledge to produce a range of plastic optical components with different application consistency. We use high-quality materials to ensure that the manufactured parts are of the highest quality. We can design parts composed of various materials, such as:

- Teflon

- Kynar

- ABS

- Styrene

- Delrin

- Acrylic

- HDPE

- Acetal

- Polypropylene

- PMMA

- Polycarbonate

- PTFE

- Zeonex (COC)

- Optical Silicone

- Engineering Thermoplastics

Optical coatings

Optical coatings are used to reflect, direct and filter light, prevent reflections, protect surfaces and improve the quality of optical components. Elimold is your expert partner for the design, manufacture and coating of polymer-based optical components and systems. Plastics have become the material of choice for optical components. LED reflectors, medical technology components and many other components can be produced in large quantities at low cost. Optical coatings improve the physical properties and functionality of plastic lenses. Not only can the optical properties be controlled (e.g. anti-reflection or reflection), but also the mechanical and chemical properties can be influenced. With optical coatings, plastic optical components are resistant to gases and moisture. For the coating of optical components, we use physical vapor deposition (PVD). Modern software tools and coating systems from Elimold calculate and optimize optical properties and characteristics.

The following optical functions can be achieved by optical coating

- Antireflection (AR) for anti-reflection

- reflex increase (HR) for reflections and filters

- Hard coating to increase the scratch resistance, for example glassy hardness of coating with SiO2

- Topcoat for chemical function alization

Application

Our plastic injection molded optical products are designed with precise dimensions, contours, edges and curves. Our capabilities allow us to provide component solutions for the following applications:

- Internet and telecommunication

- Optical disk drives

- Laser cutting

- Contact lenses and eyeglasses

- Electronic image sensors

- Image processing

- X-ray imaging

- Magnetic Resonance Imaging (MRI

- Computer and television manufacturing

- Semiconductor lasers for optical storage devices

Integration of lens molding and optical molding

In the field of optics, the convergence of optical molding and lens molding is reshaping the industry. Optical molding facilitates large-scale, cost-effective production of durable non-glass lenses, overcoming historical issues of fragility and cost. This collaboration enables the manufacture of high-quality lenses with perfect optical surfaces, positioning plastic optical lenses as a resilient alternative in a variety of applications.

The integration of optics and lens molding prioritizes efficiency and innovation in the field of optics. Plastic optical lenses made with precision molding processes become durable alternatives that meet the needs of modern applications. This collaborative approach not only ensures large-scale production, but also marks a strategic shift towards a future of advanced and accessible optical solutions. The journey of combining optical molding with lens molding heralds a transformative future where optics will seamlessly combine durability, precision and cost-effectiveness.

Ready to get a quote for your optical injection molded parts?

We have years of experience in optical injection molding, and our team of experts can deliver high-quality results quickly and efficiently. Contact us now for a quote.