Power Generation Die Casting

Elimold manufactures high-quality power generation castings that withstand extreme conditions and provide reliable performance in turbines, generators, and related equipment. With extensive experience and flexible processes, we offer a wide range of products to meet your diverse needs.

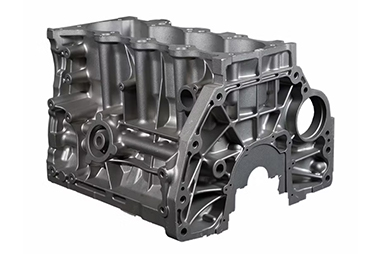

Die Casting Services for Precision Power Generation Components

Do you need high-quality, high-precision die-cast parts to meet your power generation equipment production needs? Look no further! Our die casting services for the power generation industry can produce complex, precision metal parts from a variety of alloys in a cost-effective manner.

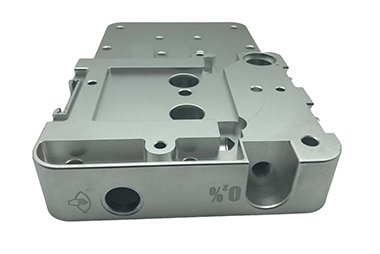

Our in-house factory boasts advanced equipment and a highly skilled team of engineers and technicians, enabling us to produce parts with extremely fine tolerances and exceptional surface finishes. We utilize the latest die casting technologies, such as vacuum die casting and low-pressure die casting, to ensure the highest quality and consistency in every part we produce. We also offer value-added services such as machining, surface treatment, and assembly, providing you with ready-to-use finished products. Elimold’s extensive production capacity allows us to handle projects of all sizes, from small, high-precision parts to large, complex components. Furthermore, we offer highly competitive prices and fast lead times, making us ideal for mass production and prototyping.

A Full-Service Supplier with High-Level In-House Manufacturing Capabilities

As a full-service supplier of custom die-cast parts for Power Generation, Elimold possesses a high level of in-house manufacturing capabilities. Customers can purchase low-value-added die-cast parts at reasonable market prices or customize highly complex, precision components to meet their specific needs. Our full-service model ensures the required precision and machining quality. This model covers the entire process from design, prototyping, and mold making, to production, CNC machining, surface treatment, and parts assembly.

Advantages of Partnering with Elimold

We see ourselves as partners with our clients, providing comprehensive support from product development and manufacturing to logistics and assembly services. Our strengths lie in our superior aluminum, magnesium, and zinc die-casting processes, combined with integrated die-casting and CNC machining technologies. With innovative approaches, we offer value-added solutions and contribute to reducing CO2 emissions.

By introducing “Low Carbon Z410” into our die-casting process, we have set a benchmark for sustainability, significantly reducing our CO2 emissions impact across the supply chain. As a Power Generation die-casting supplier, Elimold has been an ideal partner for our clients for many years thanks to its regional, mature, and reliable supply chain. Direct communication with our experts and convenient shipping routes ensure greater sustainability and proactive climate protection.

Full Production Support Team

We have a team of manufacturing experts working behind the scenes to fulfill your production order, we manage the entire process and keep you updated along the way.

Account Manager

Applications Engineers

Logistics

Quality Control

Extensive Metallurgical Knowledge

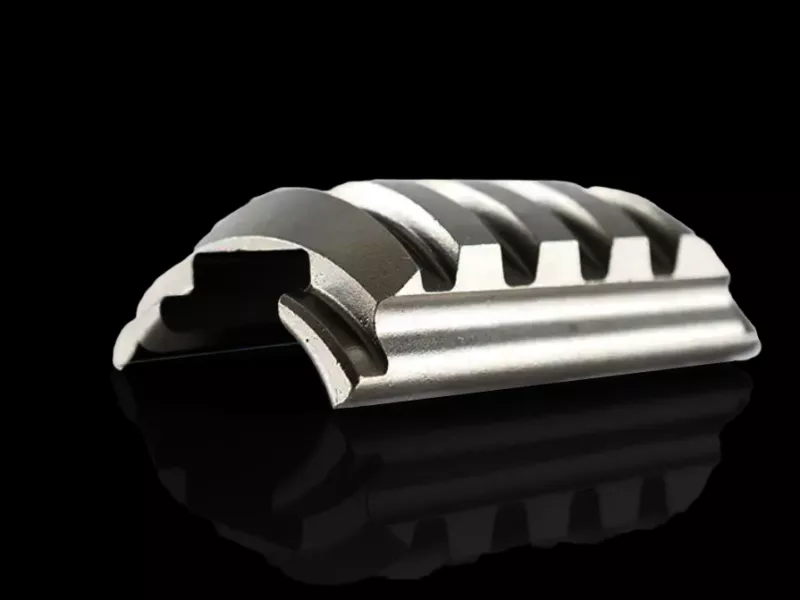

Leveraging our team’s extensive metallurgical knowledge, Elimold has participated in numerous R&D projects within the power industry. We have developed expertise in manufacturing large-section castings that are resistant to high temperatures and creep. Through continuous investment in materials and process development, we have developed casting materials that make a significant contribution to emissions reduction. Because these materials can operate continuously at higher temperatures, turbines can operate at higher temperatures, thereby improving efficiency and ultimately reducing CO2 emissions.

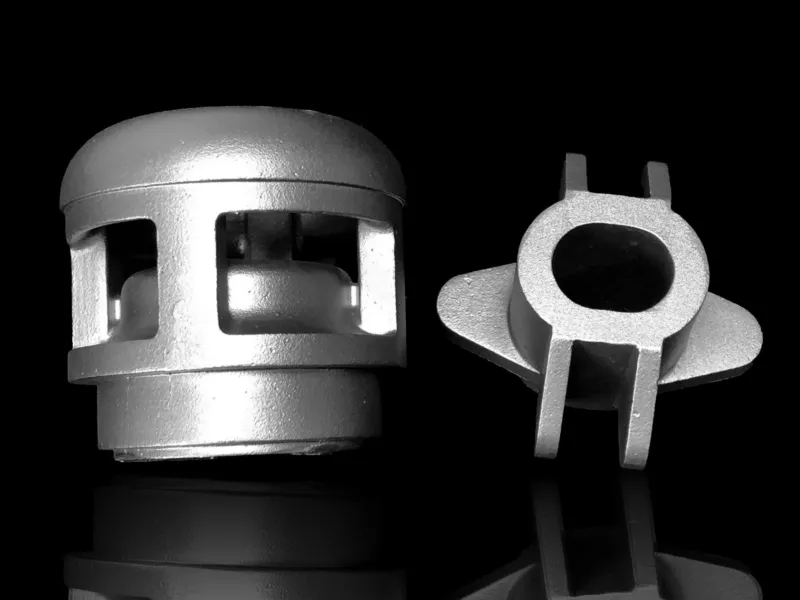

We Manufacture Components

Looking for custom die-cast parts for the Power Generation industry? Choose Elimold for superior quality and performance. Contact us today!

Our Production Capabilities

If you need assistance with material selection or design optimization for the best casting results, our experienced engineering team can support you. Our comprehensive production capabilities include prototyping and mold design, small-batch and high-volume production, CNC machining, surface treatment, and coating. We have die-casting machines ranging from 600 to 1200 tons, capable of producing near-net-shape castings weighing from 8 ounces to 20 pounds and measuring up to 20 inches long x 20 inches wide x 20 inches high. Furthermore, our in-house testing and quality assurance system further ensures you get the parts you need when you need them. Whether your project is at sea or on land, we can build the high-quality, reliable Power Generation product components you require.

Die Casting Service Types

Elimold prides itself on its core casting processes that lead the Power Generation industry, including die casting, sand casting, precision casting, and gravity casting. These processes form the basis of our diversified services, ensuring product quality and meeting the needs of every customer.

Ready to Start a New Die Casting Project with Elimold?

Whether you’re looking for precision, efficiency, or innovative solutions, Elimold’s team will help you turn your die-casting projects into reality with their exquisite craftsmanship and cutting-edge technology.

Our Expertise in Power Generation Castings

Elimold has extensive experience in producing castings for a wide range of power generation applications, including steam turbines, gas turbines, generators, auxiliary systems, and many other systems related to power generation and transmission. We are a leader in this field, and we also utilize 3D printing technology, employing additive manufacturing techniques to produce sand molds and multi-molds, with printing times of just days, rather than weeks or months. Our process flow is highly flexible, allowing us to customize casting solutions to your specific needs.

Designed for Performance

Elimold’s in-house engineering team ensures we do more than just cast parts; we’re committed to helping you improve performance. During the design and prototyping phases, we work closely with your team to optimize part geometry, cooling paths, and tolerance targets. Our team provides design reviews and manufacturing-oriented design support for your projects. Our professionals will evaluate your designs and offer cost-reduction recommendations. Furthermore, we offer design-to-manufacturing (DFM) services and perform mold flow analysis to facilitate efficient production.

In-house Mold Design and Manufacturing Capabilities

Mold design is one of our strengths. We comprehensively consider all aspects of the design, including the flow of metal within the mold, based on customer specifications, to manufacture molds capable of producing complex geometries that closely approximate the final shape. Leveraging our long history of innovation, we design molds for complex parts with variable wall thickness, holes, threads, internal features, and other necessary elements to avoid secondary machining. We manufacture high-precision molds using premium tool steel and employ strategies such as predictive wear analysis, enabling these molds to withstand production volumes of 75,000 to 250,000 pieces without maintenance.

Comprehensive Manufacturing Solutions and Reverse Engineering

We provide original equipment manufacturers (OEM) with mechanical and metallurgical materials data support from the early stages of Power Generation product development, and offer complete manufacturing solutions, including casting, non-destructive testing, welding/surfacing, final machining, and pressure testing.

As a trusted advisor to our clients, Elimold can provide reverse engineering services for original parts, design castings, and deliver the required components to the site before downtime. Our comprehensive services in our own facility enable us to complete these tasks within very short lead times and deliver on time.

Power Generation Die Casting Material Options

By leveraging the unique properties of each material, die casting can optimize strength, weight, and thermal properties, making it suitable for demanding applications in the Power Generation industry.

Aluminum Alloys

It is known for its strength, durability, and resistance to corrosion. It’s used in industries like aerospace, automotive, and medical devices for parts that need to withstand tough conditions.

Zinc Alloys

Zinc alloys are renowned for their superior strength and dimensional stability. With a high resistance to deformation and excellent casting properties, they are often used for parts requiring precise dimensions, such as automotive components and consumer electronics. Alloys like Zamak 3 and Zamak 5 provide excellent surface finishes and are perfect for high-volume production, ensuring durability and longevity.

Magnesium Alloys

Magnesium alloys are the lightest structural metals available, offering significant weight reduction without compromising strength. They have excellent machinability and good resistance to stress corrosion cracking. Common grades such as AZ91D are ideal for aerospace and automotive applications. Their superior thermal properties also make them suitable for heat-sensitive applications.

Copper Alloys

Copper alloys, including brass and bronze, provide outstanding electrical conductivity and thermal resistance. They are often used in applications that require excellent thermal management, such as electrical connectors and heat exchangers. Their high strength and corrosion resistance make them ideal for specialized industrial components, although they are less common in high-volume die casting due to higher material costs.

Lead Alloys

Lead alloys are primarily used in applications where high density and corrosion resistance are essential, such as in battery manufacturing and radiation shielding. While they offer excellent protection against radiation, their use is becoming limited due to environmental regulations. High-quality lead alloys ensure longevity and reliability in specific applications, although they are not as versatile as other materials in the die casting process.

Power Generation Die Casting Parts Surface Finish

Die-cast components, especially zinc and aluminum parts, naturally have smooth surface. To improve aesthetics, durability, or corrosion resistance, explore the surface finishes Elimold offers. For special request, feel free to contact us.

As Cast

Anodizing

Chromate Passivation

Painting

Sand Blasting

Manufacturing High-Alloy Steel Power Generation Casting

The power industry is the cornerstone upon which all other industries operate, and the foundation upon which the modern world functions and evolves. We cast high-alloy steel power generation castings that many other foundries are unwilling to undertake. Hastelloy, Monel, Inconel, and duplex steel are just some of the many specialty materials we process for this technically complex and demanding market. We utilize induction melting furnaces and unbaked sand casting processes to produce steel, stainless steel, nickel, and iron castings weighing up to 3,500 pounds. Whatever your application, Elimold has the right casting solution for you.

Metal Prototyping Casting for the Power Generation Industry

Our diverse range of metal casting processes offers high flexibility, enabling component customization and optimized design for specific energy systems, thereby improving efficiency. Customers can further enhance efficiency by quickly obtaining physical wax model prototypes for design reviews when choosing our rapid casting prototyping service.

Metal castings possess inherent high strength, ensuring the longevity of critical components in demanding applications within the power generation industry. The high precision of our metal casting processes minimizes material waste, aligning with the industry’s sustainability goals. Furthermore, we offer the aforementioned prototyping services or utilize castings for renewable energy applications, further supporting this goal.

Quality Control and Risk Mitigation

At Elimold, quality control is integrated into every stage of the die-casting process. Our team utilizes advanced metrology equipment, coordinate measuring machines (CMM), and statistical process control (SPC) to verify accuracy and consistency. Each part undergoes first-article inspection, material certification, PPAP (Production Part Approval Process) submission, and final review, based on customer requirements, to ensure full compliance with specifications. This rigorous approach minimizes risk, reduces defects, and guarantees reliable and repeatable performance for every Power Generation die-cast part we produce.

Inspection Equipment

The high-end, high-precision testing equipment owned by Elimold not only helps meet diverse size and precision testing requirements but also provides crucial support in quality control. This assists the Elimold in maintaining a high level of product quality, enhancing customer satisfaction, and staying competitive.

- X-ray Digital Radiography Inspection System

- X-ray fluorescence spectrometer

- Stationary Metal Analyzer

- Programmable Temperature and Humidity Test Chamber

- Cleanliness Inspection System

- 2D/3D CMM

Solving Your Power Generation Die Casting Manufacturing Challenges

With high precision and tight tolerance control, you can meet the exact specifications required for your projects, minimizing costly rework. Rapid production capabilities ensure on-time delivery without sacrificing quality, while material diversity enables customized solutions for different applications. Furthermore, advanced surface treatment processes reduce post-processing time, streamline production processes, and improve overall operational efficiency. This comprehensive approach allows you to optimize performance and deliver high-quality products to your customers.

Explore Your Next Power Generation Casting Project

Metal foundries like ours consistently provide reliable and durable components to the Power Generation industry through efficient processes. The flexibility of our casting methods, combined with the inherent advantages of our materials, ensures high-quality parts can be reliably integrated into the complex machinery powering modern Power Generation infrastructure.

We are ISO 9001:2015 certified, demonstrating our commitment to the highest international standards of quality and service. From ferrous to non-ferrous metals and other specialty metals, we can design and mass-produce precision castings to a wide range of specifications. Contact us to learn more about our popular metal casting services and explore how they can support your next Power Generation project.

FAQ

Alloys A380 and ADC12 are typically used for optimal durability and corrosion resistance.

It provides a lightweight, weather-resistant structure, improving ease of installation and overall efficiency.

Due to its high strength and corrosion resistance, turbine blades, impellers, valve bodies, and structural supports are all made of this material.

Due to the superior corrosion resistance of aluminum parts, their lifespan in corrosive environments is typically 25-40% longer than that of steel parts.

Yes, aluminum is 100% recyclable, and the recycling process reduces energy consumption by approximately 95%.

Meets ASTM B117 standards, with salt spray resistance up to 480 hours.

Precision up to ±0.02mm, making it ideal for high-precision power generation components.

Aluminum components are 60% lighter than steel components, thus improving turbine efficiency.

Typically, it can save 20-30% in costs due to the lighter material weight and reduced processing costs.

Yes, we offer comprehensive design assistance to optimize component efficiency and manufacturability.

Complies with ISO 9001:2015 and industry-specific standards such as ASTM and ISO 14001 environmental management systems.

Die-cast aluminum components have excellent thermal conductivity (approximately 150-200 W/mK), improving the cooling efficiency of inverters and modules.

Yes, due to their high corrosion resistance and suitability for marine environments (compliant with ISO 9227:2017).

It is lightweight, corrosion-resistant, and reduces rotational inertia, thereby improving turbine efficiency and reducing energy loss.

Typically, turnaround time is 4-6 weeks, depending on design complexity and order volume.

Yes, aluminum components maintain mechanical integrity over a wide temperature range from -40°C to 300°C.

Reducing energy consumption, minimizing production emissions, and the recyclability of aluminum all contribute significantly to achieving sustainable development goals.

Yes, we offer high-precision rapid prototyping for design verification and testing before mass production.

The lifespan is typically over 25-30 years, with very low maintenance requirements.

We employ rigorous testing methods, including X-ray inspection, dimensional checks, tensile testing, and corrosion testing, to ensure the highest quality standards are met.

Searching For Power Generation Custom Casting Solutions?

Submit an inquiry or contact our team whether you need to produce high-integrity aluminum castings for an upcoming project or need rapid prototyping for a new application. Elimold can help. Contact our power casting experts today, or submit your inquiry now.