Robotics 3D Printing

Elimold offers on-demand robotic 3D printing and manufacturing from prototyping to production. Instant quotes, rapid manufacturing, and in-house production ensure high-precision, production-ready, high-quality robotic parts. Our industry-leading manufacturing speed and reliability, tight tolerances, and superior material properties deliver quality you can count on, every time. Contact us now for a free instant quote.

Robotic 3D Printing Manufacturer

Elimold is a professional solution provider for robotic 3D printing, providing everything from part design, project management and batch manufacturing to part post-processing and part installation, commissioning and service. We develop and build custom solutions for additive manufacturing of custom robotic parts to achieve large-scale additive manufacturing of custom robotic parts. We offer a variety of cutting-edge, high-quality 3D printing technologies and services to meet the needs of professional robotic manufacturers and the commercial sector around the world. Our team specializes in robotic applications and is ready to tackle the most stringent manufacturing requirements. Whether you need precision prototypes or production-level components, we provide on-demand solutions and technical support to ensure your project stays ahead of the curve. As your trusted partner, Elimold is the first choice for providing high-precision custom robotic 3D printed parts designed for professional and commercial use.

Providing Custom Robot 3D Printing Solutions

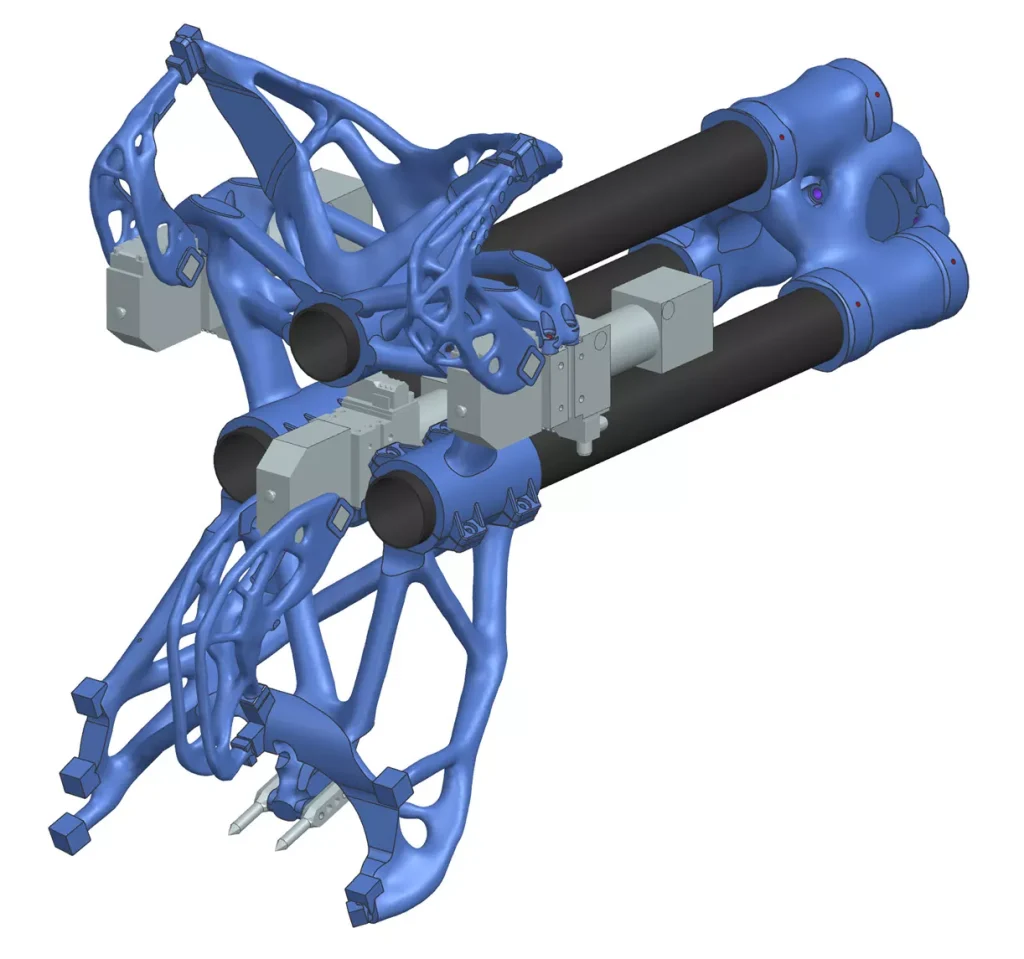

The development and production of robots varies from industry to industry. Many robot manufacturers develop custom robots based on the precise needs of customers to promote corporate market and performance growth. Therefore, robot development engineers must explore ways to design and develop custom robot parts solutions with unique functions and excellent performance. 3D printing technology helps engineers design and test robot parts. Engineers can use 3D printed part prototypes to ensure that the robot solution can meet the operational requirements specified by the customer. When custom robot parts are needed, they can use Elimold’s robot 3D printing service to custom the parts and deliver a custom robot solution in a short time based on the prototype approved by the customer. If you need to create a custom robot solution, you can use our robot 3D printing service to design and manufacture the robot.

Advanced Digital Robotic 3D Printing Manufacturing Services

Elimold combines speed, precision, and reliability at every stage of robotic 3D printed parts production. From instant online quoting and seamless digital workflows to 24/7 industrial manufacturing and exceptional part quality, we ensure an effortless experience from concept to completion. Our advanced technology and strict quality control produce production-ready robotic parts directly from the machine, and our professional finishing services improve components to meet the most demanding specifications. Plus, time is of the essence in robotic product development, and Elimold delivers speed without sacrificing precision. Our instant quoting system allows you to upload your designs, get instant quotes, and order with confidence anytime, anywhere. Whether you need a rapid prototype or full production, our automated systems ensure fast turnaround times while maintaining the highest industry standards. Our manufacturing facility in Shenzhen, China operates 24/7, ensuring no reliance on external suppliers for ongoing production. By bringing all manufacturing technologies in-house, we minimize lead times, eliminate supply chain delays, and maintain comprehensive quality control. With 24/7 operations and expert technicians, we deliver precision-engineered robotic parts on time every time, whether it’s a one-off prototype or full production.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused DepositionModeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

Application of 3D printing in the field of robotics

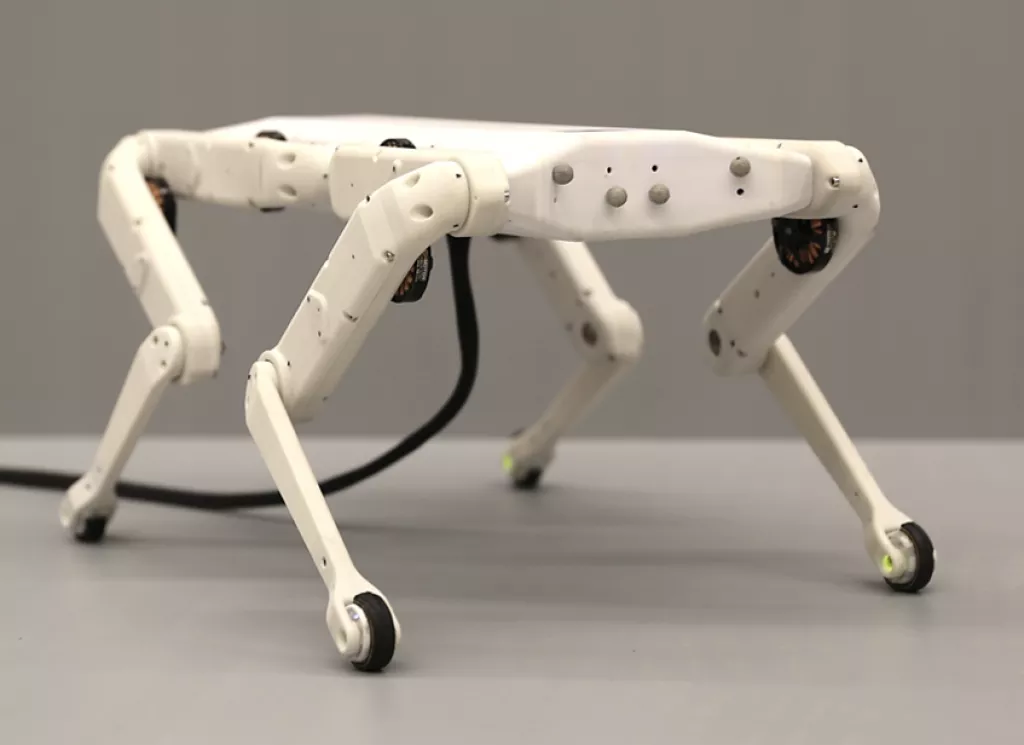

Robotic Design

From a rapid prototype to a finished product, 3D print custom robot designs, choosing from over 90+ materials and finishes.

- Affordable, industrial-grade prototypes

- No minimum orders

- Perfect for complex designs that integrate multiple functions into one part

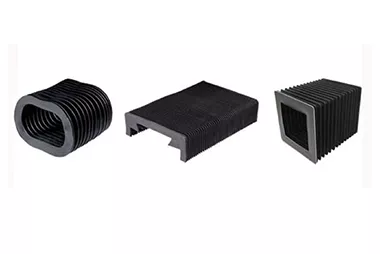

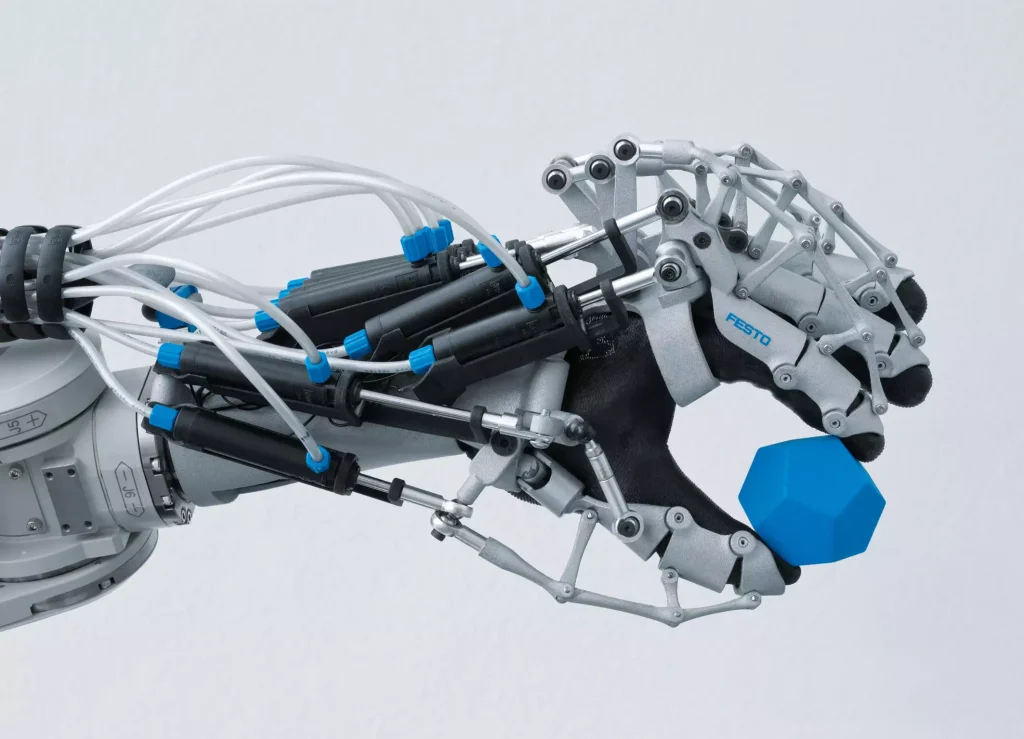

Robotic Modifications

Develop unique modifications for your robotic needs.

- Custom housings and parts

- Tooling and jigs

- Replacement parts

- Durable and long-lasting materials from steel to nylon

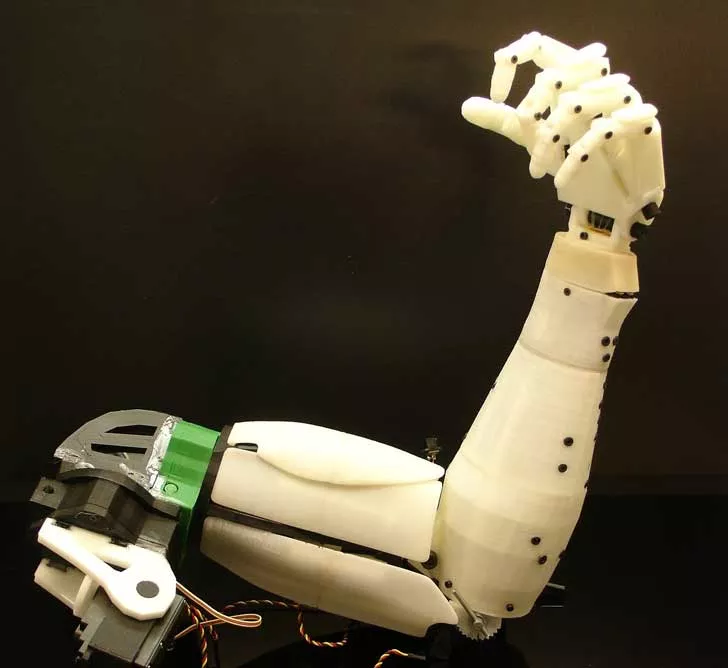

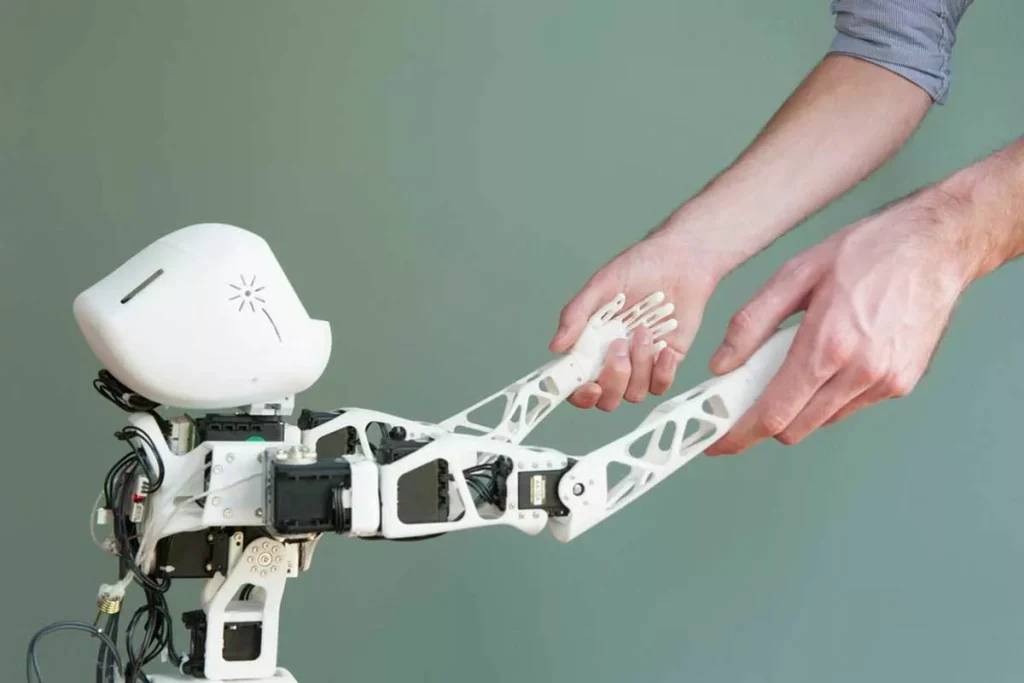

Robotic Prosthetics

Develop custom 3D printed robotic limbs designed for a perfect fit and ergonomic design.

- Human prosthetics

- Animal prosthetics

- Robotic attachments and parts

Your Robotic 3D Printing Partner

Robotic 3D printing technology is the perfect choice for custom robotic parts, bringing endless opportunities to robotic design and product development. Elimold has long been committed to supporting robotic engineers and designers, encouraging customers to transform concepts and designs into high-performance robotic products. This is all possible with Elimold’s state-of-the-art robotic 3D printing materials and technologies.

Elimold provides robotic 3D printing services for large-scale production of robotic parts for performing identical tasks. Our production ensures the accuracy and repeatability of robotic parts, and each 3D printed robotic part is exactly the same, ensuring consistency for each project or task. Regardless of the size or complexity of the 3D printed robotic custom parts project, our services make the process faster and more efficient. As a result, robotic designers and engineers enjoy great freedom in design, custom parts as needed, and endless iteration opportunities during the robotic product development process.

Reverse Engineering Services

Our dedicated team of engineers can reverse engineer and remanufacture critical consumable parts and tooling, providing our customers with a reliable, low-cost source for custom robotic parts. Once your part design is complete, we create the associated 3D print files, and you can reorder as needed at any time. We will ship in as little as two days, typically with no minimum order quantity. On-demand part production reduces your costs by reducing your inventory, shipping, and warehousing costs. If your robotic 3D printed parts and tooling are underperforming, Elimold can communicate with your team of designers and redesign your robotic critical parts using new materials and new 3D printing technology to improve performance.

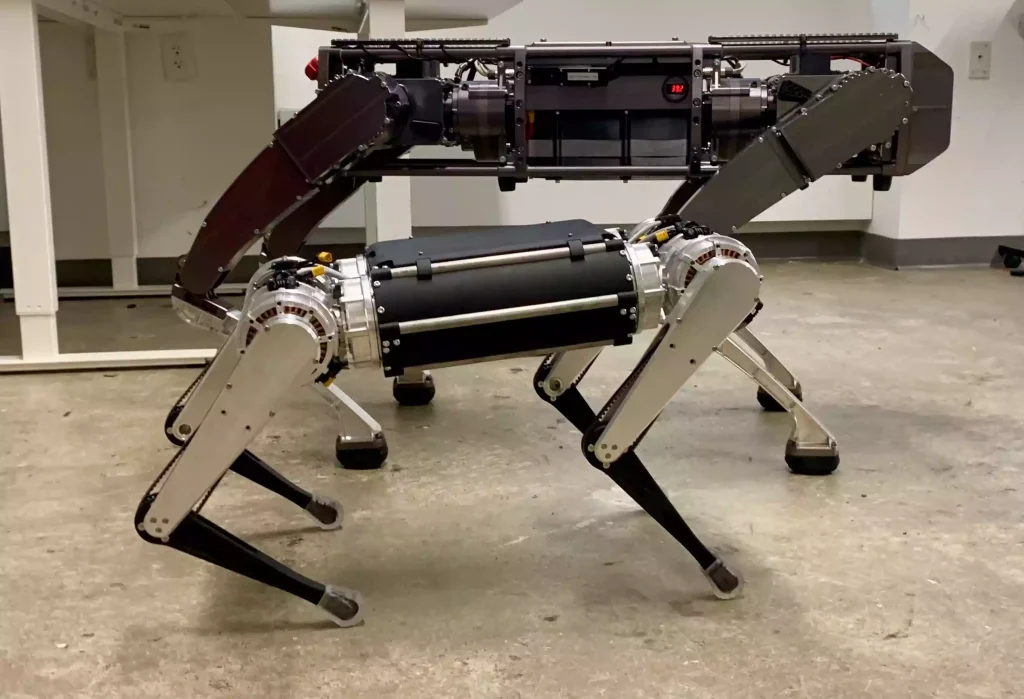

3D Printed Robot Parts Rapid Prototyping

When creating custom robotic custom parts rapid prototyping solutions, engineers must fine-tune the concept and play with many design parameters. In addition, they must meticulously evaluate and assess the design based on different requirements and design parameters. By working with Elimold, engineers do not need to invest extra time and effort to make robotic 3D printed prototype parts, and they can also evaluate and test multiple versions of the prototype without increasing material costs. As a result, engineers can take prototypes into production with our advanced printers. Currently, many robotics manufacturing companies have taken advantage of Elimold’s robotic 3D printing technology to carry out small batch custom production of robotic parts based on precise business needs.

Due to the efficiency of 3D printing, rapid prototyping is simpler and is conducive to using 3D printing design processes to determine every detail of the robot before the robot is put into mass production. Startups and innovators in the robotics industry benefit from the affordability and accessibility of Elimold 3D printing. We can provide a cost-effective way to prototype and test new robotic concepts. Entrepreneurs can quickly iterate their designs, attract investors and accelerate the development of new robotic solutions.

Contact us today and let our professional team bring innovation to your robotics project!

Are you curious about how to use 3D printing to improve your robotics project? Our team of experts is ready to provide advice and guidance. No matter the size of your project, no matter how complex your design needs, Elimold is confident that we can provide you with a satisfactory solution. Contact us now for a free instant quote.

Our Manufacturing Quality Commitment and Certifications

Elimold’s robotic 3D printing services cover a wide range of additive manufacturing technologies for the production of plastic and metal robotic parts. As an ISO 9001:2015 certified company, we produce high-quality robotic parts using the finest materials with full traceability, including material certification and dimensional reporting, in compliance with industry standards. And each of our parts is inspected both in-house and on-site to ensure unmatched precision and reliability. Our QA team ensures that every order meets strict manufacturing standards and customer specifications, so you get a part that performs as expected, every time. Elimold’s advanced printer and material options support rapid prototyping, functional testing, and even low-volume production, meeting the robotics industry’s need for speed and innovation. Elimold’s robotic 3D printing services meet a wide range of robotic parts needs.

Exceptional Customer Experience

From the moment you contact Elimold, we will help you achieve excellence every step of the way in your custom robotic parts. Our team of experts will guide you through the process to ensure you find the perfect 3D printing technology and manufacturing process for your unique part needs. Our comprehensive service offering includes prototyping, part design optimization, mass production and assembly to ensure you fully utilize the potential of our advanced technologies and services. Whether you need to prototype a robotic part or mass custom a single robotic product, Elimold has the manufacturing technology and services to meet your needs.

From prototyping to production, we have you covered

From concept to creation, we turn your ideas into reality. From prototyping to full production, at every stage, our team of experts ensures precision, efficiency, and unmatched quality. Whether it’s a single model or a complete product line, we can provide you with a tailor-made solution to meet your unique part needs. Robotic projects involve hundreds or thousands of parts working together perfectly. Additive manufacturing provides the opportunity to produce these unique parts while meeting the tight tolerances and perfect finishing you expect.

At Elimold, we firmly believe that 3D printing can push the limits of the field of custom robotic parts. Our advanced, large-scale 3D printing technology is designed to redefine the way the robotics industry creates and innovates product development. From robot manufacturing giants to small businesses, our 3D printing services for robots meet a variety of robotic application needs with unparalleled precision, speed, and flexibility. Elimold’s robotics 3D printing services offer a variety of materials to meet any robotics project specifications and are the ideal solution. Ready to power your robotics project with 3D printing?

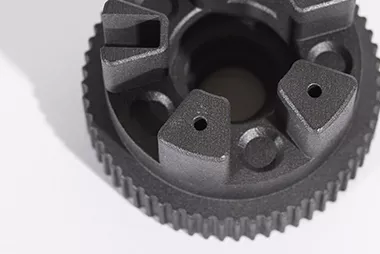

Parts design and repair replacement

The assembly and production of robots requires a large number of fine parts, which are difficult to produce with traditional manufacturing methods. 3D printing can well complete the production of these fine parts. 3D printing has a large degree of design freedom, and robot parts of all shapes can be manufactured by 3D printing. Therefore, robot 3D printing technology can not only make the simplest robot parts, but also complex parts. Moreover, 3D printing can not only provide fine parts production for robot manufacturers, but also be used to repair robots. Replacement parts and spare parts can be manufactured as needed to repair robots that are not working properly due to lack of accessories. This process does not require ordering and preparing inventory of replacement parts, because it can be quickly manufactured at Elimold’s factory. The entire supply chain and the maintenance and repair of robots can be solved with the help of 3D printing.

Materials Adapted To Robotics Applications

Elimold offers a variety of 3D printing materials to custom the functionality and performance of robotic parts and produce custom robotic components in plastic or metal.

Metal

- Stainless Steel

- Aluminum

- Titanium

- Inconel

- Cobalt-Chrome

- Tool Steel

- Copper

Plastic

- PLA

- ABS

- PETG

- Nylon

- TPU

- PEEK

- PEI

Surface Treatment Capabilities

We go beyond manufacturing to ensure that every robotic component meets the highest standards of durability, aesthetics and performance. We offer a range of advanced post-processing technologies to enhance mechanical properties and surface quality. Whether you require a flawless high-gloss surface or a wear-resistant functional finish, our finishing expertise ensures your parts meet precise specifications and visual requirements.

Robot Metal Parts

- Sandblasting

- Tumbling (Vibratory Finishing)

- Polishing

- Bead Blasting

- Anodizing

- Powder Coating

- Electroplating (Nickel, Chrome, Gold, etc.)

- Heat Treatment

- Shot Peening

- Chemical Etching

- PVD (Physical Vapor Deposition)

Robot Plastic Parts

- Sanding

- Vapor Smoothing (Acetone, MEK, etc.)

- Priming and Painting

- Epoxy Coating

- Bead Blasting

- Tumbling

- Electroplating (Metal Coating)

- UV Curing

- Clear Coating (Polyurethane, Acrylic)

- Chemical Smoothing (Dichloromethane, Tetrahydrofuran)

- Dyeing

Bring 3D printing to your automation and robotics projects

3D printing is revolutionizing the world of robotics, offering previously unimaginable customization, precision and affordability. The ability to create complex geometries, microrobots, custom end effectors and spare parts on demand is changing how robots are designed, manufactured and maintained. As 3D printing technology continues to develop, it will play an increasingly critical role in driving innovation, improving robot performance, and expanding the application of robots in different industries. The synergy between 3D printing and robotics is ushering in an exciting era where robots will become smarter, more adaptable, and highly specialized and will continue to reshape our world.

Robotic 3D Printing and CNC Milling

Elimold can also offer a unique option that combines 3D printing and CNC milling into one manufacturing process. For mold making and tooling applications, it is ideal for achieving the desired surface finish. For robotic end-use parts, CNC milling capabilities can ensure high tolerance mounting flanges and holes. Our combined process is tailor-made for robotic part manufacturing. Therefore, we can use different processes as well as custom services to meet your specific part customization needs, and our engineering team can work with you to find the on-demand manufacturing service that best suits your robotic application.

Start 3D Printing Your Robotics Project Today

At Elimold, we pride ourselves on our fast turnaround times, making it easy for you to meet project deadlines. Our streamlined processes and advanced technology allow us to provide a seamless experience for all your robotics 3D printing needs. Choose our robotics 3D printing services for exceptional results, unmatched quality, and a reliable partner for your robotics parts 3D printing needs.