- Elimold Slogan: Make One, Made More

Robotics Injection Molding

Elimold is committed to providing the highest quality and most efficient robotic injection molding services. We have an in-house injection molding automation shop and an experienced team to support our capabilities and provide the best service. This ensures the highest quality and repeatability while reducing production time, increasing efficiency and keeping costs reasonable. Contact us now for a free instant quote.

Robotic Injection Molding Manufacturer

Elimold has been dedicated to helping global robotic manufacturing companies get the perfect robotic plastic parts for their needs. With extensive experience, a professional team, and state-of-the-art machines, we are ready to take on the most challenging projects. Our team can help you with everything from initial design and lean manufacturing to secondary services and warehousing. We provide high-quality custom molds of various complexities to produce plastic parts in multiple plastic forms, grades, and any color of your choice. You can save time, money, and hassle when you work with a full-service supplier for all your robotic plastic part development and mass production needs. We guarantee that no matter what the product is, we will pay close attention to ensure it meets your specifications and our high quality standards for precision work. We value our customers and strive to exceed their expectations.

In-House Injection Molding Factory Capabilities

Elimold’s in-house injection molding facility’s highly flexible plastic injection molding capabilities allow us to produce around the clock to meet our customers’ most challenging needs. We help our customers build a stronger supply chain through superior manufacturing solutions. With more than 100 injection molding machines ranging from 20 tons to 32,00 tons, our in-house facility is able to provide the precise force required for your project. Most of our machines are equipped with Star Automation robots, and the facility can operate 24 hours a day to ensure that your robotic plastic part project is completed quickly. In addition, our state-of-the-art injection molding facility not only has precision injection molding machines, but also an in-house tool shop for the production and ongoing maintenance of molds. Elimold has a fully staffed engineering team to conceive and produce high-quality designs, manufacturing capabilities to develop OEM products, and warehouse storage space to maintain customer inventory. And, we can also provide custom injection molding solutions for AI smart robot products to better meet the unique needs of each customer. Our robotic injection molding solutions improve manufacturing consistency, productivity, and overall product quality, and are especially cost-effective for large-volume production.

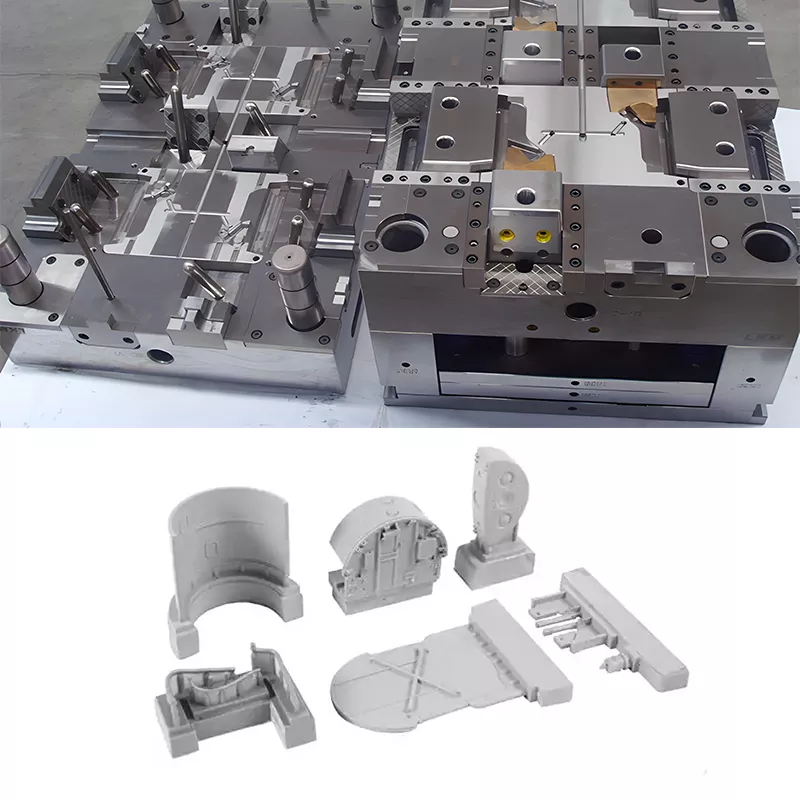

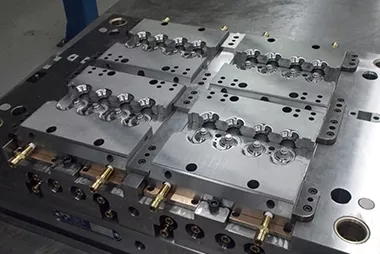

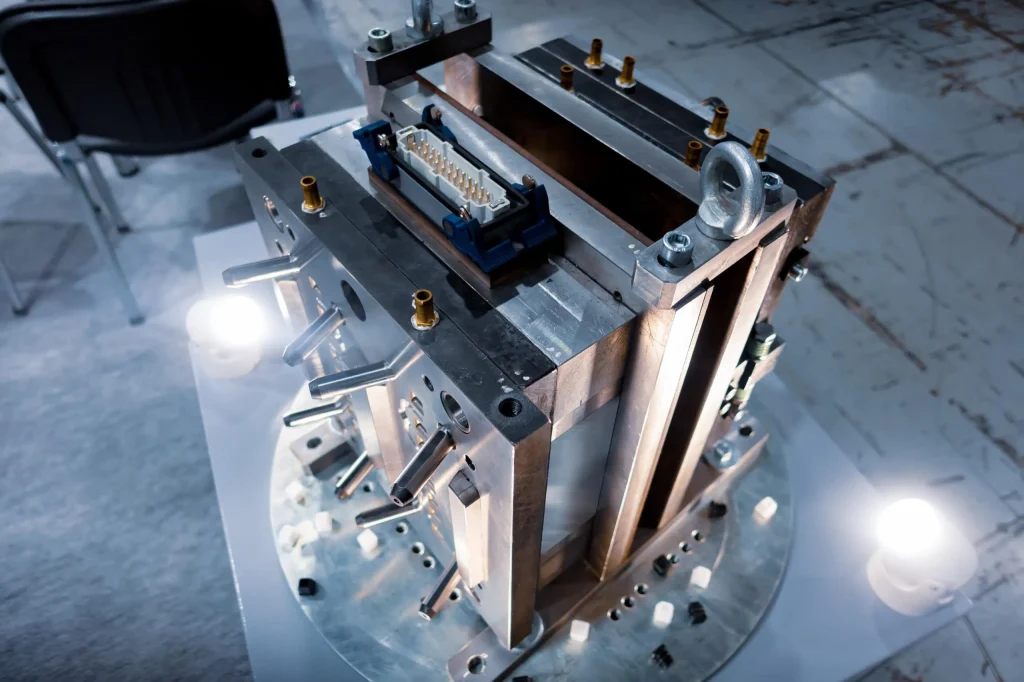

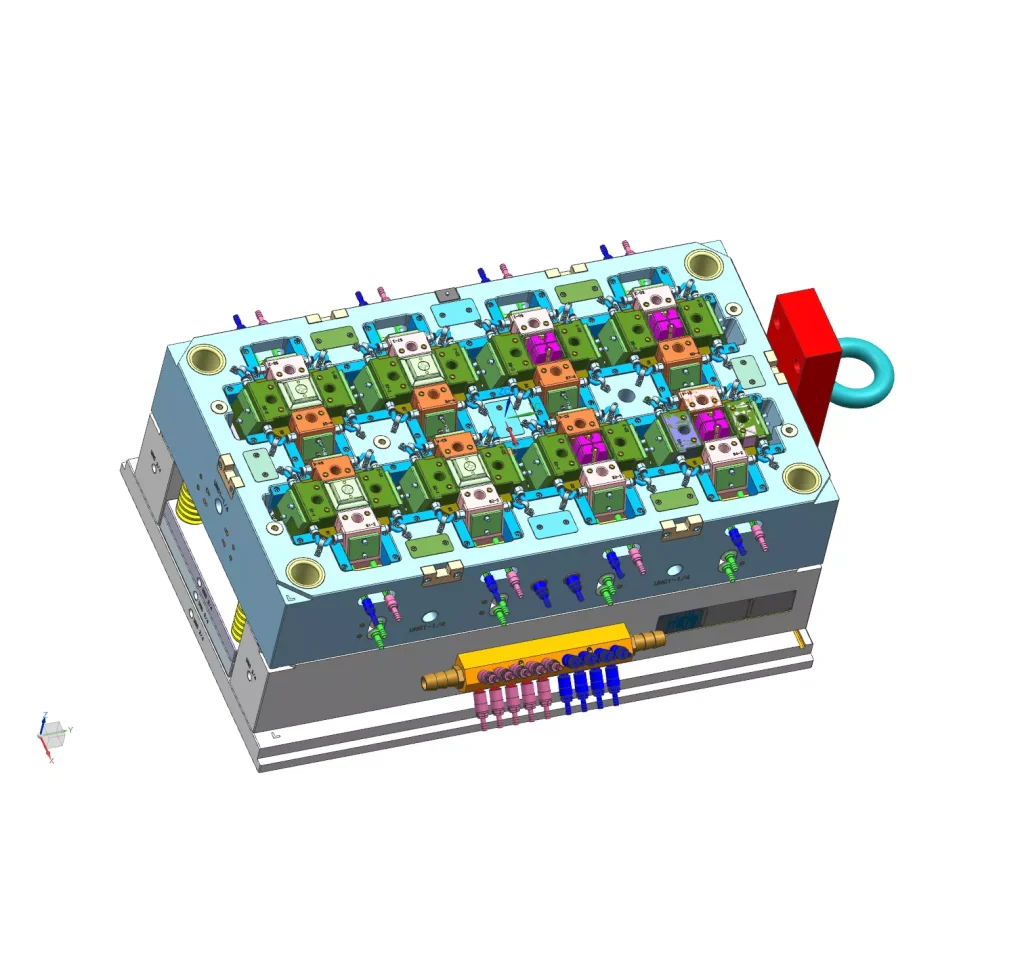

Robotic Injection Mold Design and Fabrication

Elimold has an in-house mold making shop that is equipped with the latest technology and the most experienced personnel to design, develop and maintain molds. From concept to production, our mold shop works closely with production and engineering departments to bring decades of experience in mold design, manufacturing and maintenance to customers. Customers can utilize the advanced machining capabilities of our state-of-the-art tool room to manufacture precision plastic injection molds. The in-house factory has advanced equipment including 5-axis CNC milling centers, CNC Turning machines and precision EDM machines, which puts us at the forefront of custom injection molds. Our philosophy in manufacturing molds is to create precision tools in the fastest and most economical way. With a wealth of experience, our skilled designers and engineers combine expertise with cutting-edge technology to develop efficient and durable solutions that optimize our shop’s productivity and ensure the highest quality for each part.

Robotic Plastic Engineering

Our plastic engineering and design services provide clients with creative ingenuity and highly skilled manufacturing and engineering expertise to achieve the speed to market they deserve. Our engineers work with you from conception to production and develop the final process optimization for overall robotic project success.

- Product Development Services

- Design Engineering

- Technological Innovation

- Design for Manufacturability/Assembly

- Material Selection Assistance

- Mold Flow Analysis

- Prototype to Production Manufacturing

- Tooling and Fixture Build

- Assembly and Verification Testing

- Multiple Engineering Software

- Robotics and Automation

- Cost Savings Ideas/Recommendations

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Plastic Injection Molding

Elimold precision plastic injection molding services is most common manufacturing process to produce quality custom plastic parts at competitive cost.

LSR Injection Molding

The rubber injection molding process is high production efficiency, which allows for the production of complex custom rubber parts with excellent dimensional accuracy.

Overmolding

Overmolding is a process that involves mixing two material parts together.

Gas Assist Injection Molding

A versatile technique, gas assist injection molding creates resilient products and reduces part weight by utilizing pressurized nitrogen to strategically core out thick cross sections.

Insert Molding

Insert molding includes injecting plastic into the mold cavity prior to injection molding.

Structural Foam Molding

A technique that reduces tonnage to create a more stable part. The thicker the part, the more its weight is reduced. Structural foam molding also offers low-cost tooling and a wide range of design flexibility.

Rapid Tooling

Rapid tooling is ideal for quickly making smaller volumes of parts that are suitable for engineering testing, new product development, proof-of-concept, and as a bridge to mass production.

Micro Molding

Micro molding is a specialized service for making unlimited volumes of parts on the small scale. For tomorrow’s advanced micro mechanical devices, micro molding can save both time and money.

Production Tooling

Production tooling is for customers who need high volumes of identical plastic parts and enclosures. Production tools require careful engineering, high performance tool steels, and exacting process control to achieve repeatable results.

Plastic Tooling

Our robust toolroom and experienced toolmakers can support and maintain our client’s tools. Our plastic tooling specialists can work with inherited tooling or build your tools from scratch.

- Project management of tool construction

- Fully equipped tool room

- Domestic and overseas tool sourcing availability

- Computer-aided manufacturing

- CNC milling and EDM machines

- Extensive tool maintenance program

- Short lead times/Speed to market

- Experienced mold makers available 24 hours

Robotic Plastic Part Design & Engineering Services

With decades of experience in the plastic injection molding industry, as well as extensive material knowledge and design innovation, Elimold is the right resource to facilitate every aspect of the robotic product design cycle, from rapid prototyping and testing to production tooling and final assembly. By taking a collaborative approach during the design phase, we can help guide your design to maximize manufacturing efficiency and profitability. No matter what stage you have reached in your product development process, our engineers are happy to assist you in any way you need.

Even when your design is ready, our design team (composed of representatives from engineering, tooling, production, management, sales, and quality assurance) thoroughly reviews the requirements of the part to ensure that the design will produce the expected results with minimal impact on overall project time and cost. When you come to us with your next big project, you can trust us to develop innovative robotic injection molding solutions to turn your ideas into reality.

Robotic Plastic Parts Rapid Prototyping Services

Elimold can create robotic plastic parts rapid prototypes and pre-production samples to help you validate your design and test your product before full production. Choosing the right rapid prototyping manufacturer and method can help reduce the time and cost of your robotic injection molding project. We offer a variety of precision plastic part prototyping options, each with its own advantages. These methods are often used in combination to achieve full-volume production. Whether you need a small batch or to quickly achieve full production, Elimold will work with you to determine the method that best suits your robotic product plastic prototype parts service. And, our rapid prototyping services enable rapid iteration and improvement to ensure your final product meets your expectations.

Manufacturing injection molds with 3D printing

Our expedited service delivers rapid injection molding robot plastic parts in 2-3 weeks. Our injection molding method is also suitable for producing prototypes, small batches or large batch orders, thanks to our ability to custom rapid injection molds with our 3D printing service. Having mold parts made with 3D printing can provide customers with significant cost savings. In addition, these parts can be delivered within two weeks.

Combining 3D printing with mold manufacturing is really beneficial. It helps to shorten the injection mold manufacturing cycle. The key to automation is to prepare tests and make the right adjustments. It reduces errors and speeds things up significantly. Our 3D printed injection molds can always maintain the same quality and save money.

Partner with Elimold for your next robotic injection molding project

We are committed to providing quality robotic plastic products and reliable robotic injection molding solutions. Contact us today to discuss how we can support your plastic robotic parts and product needs.

Metrology and Inspection

In addition to continuously improving the quality management system and team, Elimold continues to invest in advanced metrology equipment to measure tighter tolerances for opaque and optical parts. Our metrology department currently includes:

Injection Molding Process Metrology

- IQMS Quality Management Software

- Omnimark Mark 3 Material Moisture Analyzer

- Zeiss Calypso Servo-driven CMM

- RJG Process Monitoring

- Dynisco Melt Flow Indexer

Optical Metrology

- Optical Gaging Products SmartScope Flash, 200 and 300 series

- Fisba Optik Interferometer

- Zygo New View 7100 White Light Interferometer

- OptiPro OptiTrace 5000 Contact Profilometer

- Stereo Microscopes

- Video and Optical Comparators

Advanced Quality Assurance Testing Capabilities

Quality is a top priority at Elimold. We adhere to strict quality control measures and industry best practices to ensure that every part we produce meets the highest quality and performance standards. Our ISO 9001 certification demonstrates our commitment to excellence in everything we do. From material selection to final inspection, we use advanced testing methods and comprehensive quality checks to guarantee superior performance of our robotic plastic parts. We utilize PPAP, CPK, and Minitab to ensure reliability and compliance with industry regulations. Our state-of-the-art precision testing equipment includes cutting-edge blue light scanners and highly sensitive coordinate measuring machines (CMM). These advanced inspection capabilities utilize the latest technology to ensure that each component meets precise specifications. At Elimold, we maintain industry-leading automated processes to streamline manufacturing and ensure consistent quality for all production volume requirements. We continually strive to improve our quality management system, provide innovative solutions, and operate with integrity.

Committed to Customer Satisfaction

Elimold is committed to providing quality robotic plastic products that meet or exceed customer expectations for on-time delivery and superior customer service. We work closely with our customers to develop custom solutions to meet their robotic plastic part injection molding needs while finding ways to enhance their designs, streamline production, reduce material costs, and improve overall quality. This dedication to quality and exceeding customer expectations allows us to build long-term relationships.

Robotic Plastic Material Options

We offer a wide variety of plastic materials to meet nearly all robotic plastic application needs. If you don’t see the material you need, ask our experts.

- Acetal (Acetal)

- Polycarbonate (PC)

- Polypropylene (PP)

- Acrylic (Acrylic)

- Polyester (Polyester)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyether Imide (PEI)

- Polysulfone (PSU)

- Biodegradable Polymers (Biodeg Polymers)

- Polyetherketone (PEK)

- Polyurethane (PUR)

- Cellulose Acetate (CA)

- Polyethylene (PE)

- Polyvinyl Chloride (PVC)

- Polyamide (Nylon)

- Polyimide (PI)

- Styrene Acrylonitrile (SAN)

- Polyarylate (Polyarylate)

- Polyolefin (Polyolefin)

- Thermoplastic Elastomer (TPE)

- Polybutylene (PB)

- Polyphenylene Sulfide (PPS)

- Thermoplastic Polyurethane (TPU)

Secondary Operations

- Sonic Welding

- Inserting Ultrasonic Inserts

- Tipping

- Hot Stamp Decoration

- Assembly

- Regrinding

- Packaging

- Labeling (Thermal Printer)

- Bar Coding

- Product Pack Out

- Shielding

- Plating EMI, RFI

- Silk Screen Printing

- Pad Printing

Customers We Serve

The robotic injection molding services we provide to our customers can accurately meet the challenges of robotic plastic part manufacturing.

- Direct Robot Manufacturers

- Robotics-as-a-service (RaaS)

- Aftermarket robotic end-effector manufacturers

- Robotic engineers and design experts

- University robotic and engineering departments

- Industrial and general manufacturing

- Automobile engineers

- Robotics software experts

- Medical Robotics

- Autonomous mobile robots

- Service and diagnostic centers

- Aerospace robotics

- Exoskeleton component manufacturers

- Standalone, collaborative, and production line robots

- Articulated, SCARA, Delta, and Cartesian robot engineers

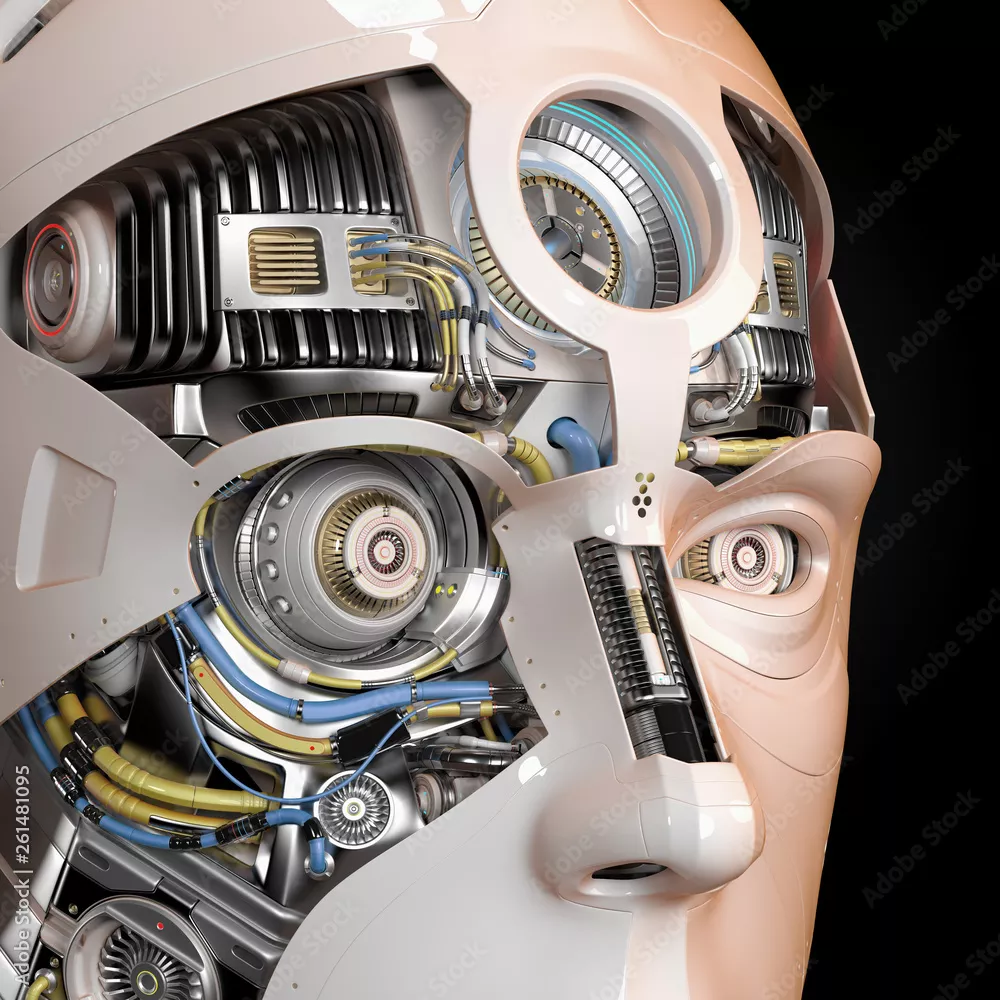

Common Robotic Plastic Parts

Elimold offers a comprehensive range of rubber and plastic parts that are carefully manufactured for optimal performance in robotic applications.

- Robotic parts

- Prototypes

- Manipulator parts

- Sensors

- Actuators

- ABS Housings

- Polycarbonate Covers

- Nylon Gears

- Micro systems

- Nano systems

- Robotic medical devices

- End effectors

- Motors

- Polyurethane Wheels

- HDPE Structural Components

- Silicone Grippers

- Casings, housings, tubing

- Clamps

- Conveyor belt components

- Automatic control equipment

- Logic controller components

- Nitrile Seals

- EPDM Bumpers

- Neoprene Isolators

Request Your Free Robotics Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom Robotics injection molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.