Semiconductors Die Casting

Elimold’s semiconductor die casting services are tailored to your semiconductor device. We also have a global network of technical experts and support engineers who can help you from planning to installation and support. From concept to completion, whether it is a prototype, tooling or a long-term production relationship, we have the knowledge and professional equipment to provide the advantages of semiconductor die casting. Contact us now for a free instant quote.

Semiconductor Die Casting Manufacturer

Elimold is an industry-leading supplier of high-quality semiconductor die castings. We have full-service capabilities to meet the needs of all semiconductor die casting projects, from initial design to casting, to precision machining, to finishing and assembly. All of our castings are custom formed, trimmed, machined and finished to our customers’ exact specifications and standards, ensuring they perform as expected in the application environment. With die casting expertise, we are able to support your semiconductor projects with a variety of metals and personalized services, while providing competitively priced processes. When it comes to castings, don’t settle for the status quo. Choose a team that can make the most of every application. And we understand that every part you order is an investment, an investment that often affects your reputation with your customers. Therefore, we work hard to perfect our processes to maximize benefits while fully leveraging internal capabilities for simplicity and efficiency.

In-House Semiconductor Die Casting Manufacturing Factory

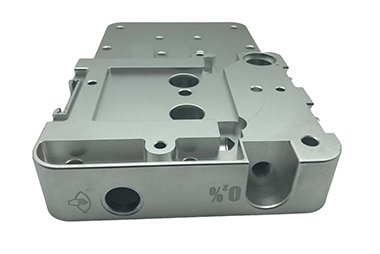

At Elimold, we are dedicated to providing high-quality semiconductor die casting services. We use the highest grade materials and techniques to ensure that our products achieve the highest accuracy and precision. Additionally, we have an in-house die casting manufacturing facility with die casting machines ranging from 120 tons to 3,500 tons and a team of experienced engineers and technicians dedicated to ensuring your project is successfully completed and providing the highest level of customer service. We are one of the industry’s leading semiconductor die casting companies, specializing in the die casting of semiconductor metal components. All areas of our process utilize the most advanced technology and methods to achieve the highest precision. Every product produced at Elimold’s in-house facility is quality inspected and checked, giving customers the peace of mind that they are receiving a reliable and durable product. We guarantee customer satisfaction on every level with fast turnaround and competitive pricing, ensuring a seamless experience with semiconductor die casting.

Turnkey Semiconductor Casting Solutions

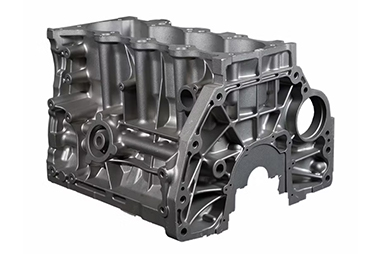

Elimold is a trusted partner to the semiconductor industry, providing precision-engineered die-cast components to support advanced manufacturing processes. Our expertise includes precision CNC machining, sheet metal production, hot and cold forged components, all tailored to meet the high-precision requirements of semiconductor machinery and equipment. With our advanced casting solutions, we are able to manufacture complex components with extreme strength and precision. These semiconductor castings are essential to the production of reliable and efficient semiconductor tools and components, and these products are essential to maintain seamless operation in cleanroom environments. The parts we manufacture withstand harsh conditions and help improve the reliability and life of semiconductor manufacturing systems. With the support of cutting-edge technology and a highly skilled team, our manufacturing facilities ensure that each component meets global standards. With certifications such as ISO9001-2015 certified company, we are committed to providing products that meet the semiconductor industry’s demand for uncompromising quality and precision. Partner with Elimold for innovative and reliable engineering solutions that meet the evolving needs of the semiconductor industry. Our commitment to excellence ensures that we play a key role in driving the future of semiconductor manufacturing.

Semiconductor Die Casting Mold Design and Manufacturing

Elimold has an in-house die casting mold manufacturing facility, and our team of engineers’ experience in semiconductor die casting mold design and use of industry-leading software and mold flow analysis tools ensures the production of high-quality semiconductor die castings. We support both large-scale production and small-volume production (soft molds). In addition, mold design is an optimization step that can increase the speed of semiconductor die casting parts manufacturing. Because our mold design engineers take into account actual manufacturing tolerances and typical wear during use. Optimizing the tool is a step that is often overlooked when dealing with die casting requirements. Adding this step to the manufacturing process saves critical time during process development and ensures that the tooling meets your project needs.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex and high-quality semiconductor die-cast parts.

Sand Casting

Investment Casting

Die Casting

Low Pressure Casting

Permanent Mold Casting

Lost Foam Casting

Centrifugal Casting

Vacuum Casting

Squeeze die casting

Elimold’s Semiconductor Die Casting Capabilities

Elimold specializes in producing complex, precision semiconductor die castings from small to large sizes. With the ability to perform secondary operations and plating on die castings, we can reduce lead times and control costs while maintaining top-notch quality. Our talented team can provide semiconductor industry die castings with the following features:

- +/- .001” tolerances

- 3 lb. shot size

- 125 ton capacity

- Accommodates molds from 3.94” to 17.71” thick and up to 16” wide or high

- Single to multi-cavity

- Surface finishes to meet customer specifications

- Complex shapes with thin-walled sections

- High yield strength

- Impact resistance

- High dimensional accuracy

- Repeatable processes for consistent quality

Semiconductor Die Casting Supplier

Elimold is dedicated to providing the semiconductor industry with a wide variety of the highest quality standard and custom die cast components. Whether you require electrostatic chuck services, or more common services such as surface treatment, rest assured that Elimold can provide it!We also offer engineering services and have been supporting the semiconductor industry for many years. We can design a custom solution and solve your problem, or provide other unique services to help reduce downtime and improve your PM cycle. Elimold is committed to meeting all customer service requirements. If you need a custom die cast product for semiconductors, please feel free to contact an Elimold product and application consultant and let our knowledgeable staff help you design the perfect part for your needs.

Semiconductor Device Casting and Prototyping

We are familiar with the semiconductor industry from our many years of experience and with many semiconductor industry customers. Our innovative engineering and design capabilities have made us a leading foundry supplier for semiconductor applications.

Despite the inherent porosity of the casting, there are ample opportunities outside the chamber regardless of the process. For decades, we have helped customers transform large die cast parts into castings with secondary operations, typically reducing costs by 40-60% while improving quality and performance. These parts can be small or one of the largest we manufacture, with high structural integrity, design freedom and reduced costs.

Semiconductor Die Casting Engineering Capabilities

Elimold provides customers with a seamless die casting manufacturing and supply process with years of expertise and a highly skilled team. When you work with us, we are deeply involved in the development and design of new products, which allows you to benefit from our extensive experience at an early stage to shorten the development cycle of components. In addition, Elimold’s team of engineers can provide design for manufacturing (DFM) advice and can also provide guidance on the correct manufacturing methods to ensure the best combination of quality and cost efficiency. From prototyping to casting, sampling, testing, finishing and inventory, we provide solutions that meet the highest quality and safety standards and provide a high level of technical support.

Request Your Free Semiconductor Die Casting Quote Today

After receiving your drawings, our engineers will analyze your custom Semiconductor Die Casting parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.

Why Choose Elimold For Cooperation?

One-Stop Service

At Elimold, we specialize in being a “one-stop shop” for your semiconductor die casting needs. With an in-house team of experts, we offer mold design engineering services, complete mold manufacturing, and mold maintenance. In addition to handling any molding needs, our die casting department also has prototype and full production capabilities. This allows us to turn your ideas into as many semiconductor die cast parts as possible.

Turnkey Capabilities

We have implemented turnkey solutions to simplify the customer experience. Elimold is responsible for nearly every step of production, from the time we receive a quote to final delivery. From that point on, we become the customer’s single point of contact, streamlining production and making everything run as smoothly as possible.

From Prototype to Production

Elimold works with customers to turn their part concepts into full production. We maintain an open line of communication during the prototyping phase to ensure that the prototype meets the customer’s design requirements before mass producing the semiconductor part.

Project Versatility

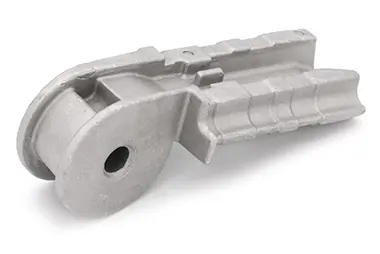

Elimold can take on semiconductor projects of all sizes. We have extensive experience, from the simplest brackets for semiconductor applications to complex, advanced parts for the industrial sector, and everything in between.

Advanced Thermal Spray Chamber Components

Do you have a particle or aluminum fluoride (ALF) problem in your semiconductor parts? Are your aluminum chamber components potentially releasing this material? The best solution is to thermally spray chamber components with state-of-the-art Al2O3 or Y2O3. Many modern semiconductor OEM tools are Y2O3 coated, but we are able to apply this new technology to existing 200mm chamber components. The powders we use are very pure to maintain the cleanliness of the process. And we can coat the entire chamber package, baffles, anodes, bellows covers, window deposits, and more.

Test capabilities

- Vacuum: vacuum leak, ultimate vacuum, gas discharge characteristics.

- Thermal: Surface temperature distribution measured by infrared thermal imager (inside vacuum chamber), heater temperature distribution measured by various temperature measuring tools, and wafer stage.

- Dimensions: Various measuring instruments, such as 2D measuring instrument, 3D measuring instrument, surface roughness meter, coating thickness gauge, etc.

- Surface analysis: SEM, EPMA, X-ray fluorescence spectrometer, sequential plasma spectrometer

Suitable Semiconductor Die Casting Materials

At Elimold, we use a wide variety of metals to produce components that meet the exact specifications of the semiconductor industry. The die casting alloy material options we offer include:

- Zinc

- Magnesium

- Aluminum

- Copper

- Tin

- Lead

- Silicon-zinc alloy

Surface Finishing Options

Elimold offers a range of surface finishes for semiconductor die castings to improve appearance, surface finish, hardness and chemical resistance. By selecting the right surface finish, you can enhance the performance, durability and aesthetics of your part, ensuring it meets both functional and cosmetic requirements.

- Painting

- Anodizing

- Powder coating

- Enameling

- Sandblasting

- Polishing

- Grinding

- Brushing

- Heat treatments

- Chromating

- Galvanizing

- Electroless nickel plating

Semiconductor Applications for Die Casting

Elimold has expertise in semiconductor die casting manufacturing, our experienced engineers can well understand the purpose of your design and always provide multiple suggestions to manufacture your parts quickly and cost-effectively. We know how to adjust semiconductor metal die casting parts so that they fit and work perfectly, saving you time and investment.

- Vacuum Chamber Housing

- CVD Chamber Side Wall

- ALD Chamber Base

- Plasma Chamber Lid

- Ion Implant Chamber Component

- Heat Treatment Chamber Housing

- Sputtering Chamber Body

- Etching Chamber Side Panel

- Deposition Chamber Support

- Cleanroom Equipment Housing

- Stage Bases

- Main Optics Plates

- Scanning Components

- Carriages

- Flange Frames

- Hinges

- Hoists Torsos

- Lids

- Stiffening Cover

- Adapter Housings

- Supports

- Chassis Components

- Joints and Wrists

- Heat Exchanger Components

- Wiring Boxes

- Power Supply Cases

- Control System Housings

- Sensor Mounting Brackets

- Motor Housings

- Gearbox Cases

- Bearing Housings

- Cooling System Components

- Gas Piping Connectors

- Vacuum Piping Connectors

- Electrical Wiring Connectors

- Safety Device Cases

- Vibration Damper Components

- Support Brackets

- Frames

- Covers

- Panels

- Cases

Ready to start your next semiconductor die casting project?

If you’re ready to start your next die casting project, Elimold is here to help. We provide fast quotes and full support to ensure the success of your project from prototyping to full production. Upload your design today and let our experts guide you through the process.