- Elimold Slogan: Make One, Made More

Quality Assurance

Our advanced manufacturing processes, rigorous quality assurance measures, and strict adherence to industry standards ensure regulatory compliance and meet or exceed quality standards for efficient product delivery. Elimold understands that a rigorous Quality Management System (QMS) and accurate, comprehensive documentation are essential to providing customers with high-quality, compliant parts. By partnering with us, you can count on our commitment to exceeding customer expectations, improving production efficiency, and meeting industry certification requirements.

Elimold Quality Policy

As a technology-driven manufacturer, Elimold maintains a comprehensive quality policy. This policy aligns with Elimold’s commitment to providing a differentiated customer experience focused on speed, urgency, and agility by uniquely integrating industrial 3D printing and additive technologies with traditional manufacturing.

Elimold’s quality policy sets a clear framework for overall quality objectives. These objectives outline our commitment to customer satisfaction through Elimold’s comprehensive capabilities, expertise, and continuous improvement initiatives.

Elimold’s experts are dedicated to understanding and anticipating customer needs to meet project requirements and exceed expectations. Elimold is committed to fostering a culture focused on technology neutrality. Elimold’s engineers and designers are able to flexibly utilize a variety of technologies, materials, and processes, providing expert advice tailored to project priorities.

Our Quality Control Procedures

Elimold is equipped with advanced in-house measuring and testing equipment. We maintain strict quality control throughout the entire production process to ensure that every item meets your requirements. Our quality assurance begins with incoming material inspection, followed by first article inspection, in-process inspection, and final inspection and testing. We provide reports and certifications before shipment.

Pre-Production

Technical assessment

Before the production stage begins, our engineering team performs a technical assessment of your parts design. This includes an assessment on important factors such as material, surface finish, structure, process, and other details of your 3D and 2D drawings.

In-Production

On-site inspection system

In precision machining, materials being worked on must be always at the right position. With an on-site inspection system, positions are examined automatically, and adjustments are made accordingly. Using an on-site inspection system further helps avoid issues at the early stage, saving cost and time.

Final-Production

Full-dimensional inspection report

For all orders, we provide full dimensional inspection reports on request. This report will include the following: quantity of parts, critical dimensions, threads and tolerances, thicknesses and depths, part appearance, etc

Material verification

On our customer’s request, we provide a certification of the material we used for making your parts. The report comes from the raw material manufacturer and usually includes material heat number, material grade, material dimensions, mechanical properties, chemical analysis, etc.

In-process quality control

At Elimold, we strictly obey the ISO9001:2015 requirements. The quality control staff conducts routine inspections for all parts that are being produced every 2 hours. This further prevents risks from happening.

Packaging

Ensuring that the parts we manufacture are of the highest quality is important. We know about the unpredictability of logistics. Therefore, we make sure we lower the risk to the parts during our packaging process. Four layers of protection: 1. wrapping paper 2. EPE 3. foam 4. paper/wooden box are applied during the packaging process, ensuring that we deliver the most high-quality and beautiful parts to you.

Production-Grade Quality Inspection Capabilities

Elimold offers a wide range of quality inspection services with state-of-the-art equipment

provided by our facilities and partner ecosystem.

XRF material verification gun

A wide range of gauges (telescoping, bore, height, surface roughness, feeler, thread, pin)

Precision scales

Coordinate measuring machines (CMM)

Testing devices for stress, impact, hardness, mold flow index

Gauge blocks and pins

3D scanners

Profile projectors

Array of micrometers and calipers

In-Depth Inspection Reports for Every Part

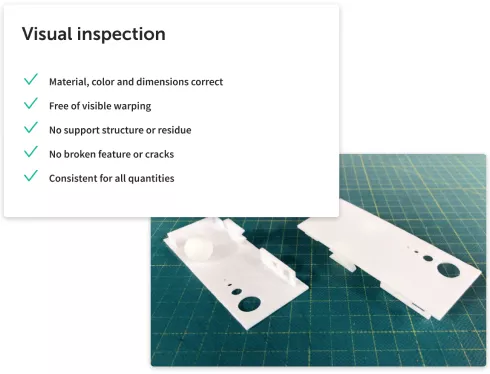

Visual Inspection

For all 3D printed parts, Elimold provides a Visual Inspection Report to verify cosmetic standards.

Free of charge

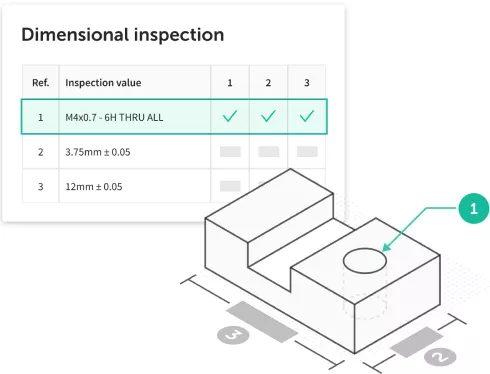

Dimensional Inspection

For all CNC parts, Elimold provides a Dimensional Inspection Report to verify dimensional accuracy for critical features.

Free of charge

Advanced Inspection

Elimold offers inspection with coordinate measuring machine (CMM) or laser scanners for an unlimited number of features.

Additional cost

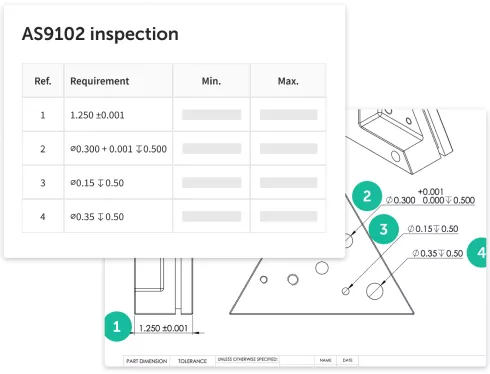

First Article Inspections

Elimold can provide a First Article Inspection Report upon request, which will be provided for 3 parts.

Additional cost

Quality Documentation

We track the performance of manufacturers in our network to ensure orders meet our quality standards and provide certifications and reports upon request.

Certificate of Conformance

Availability: CNC machining, injection molding, sheet metal fabrication

Material Test Report

Availability: CNC machining (metals)

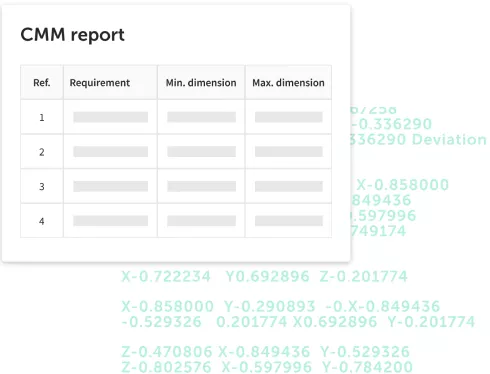

CMM Inspection Report

Availability: CNC machining

REACH

Availability: CNC machining, sheet metal fabrication

Material Certificate

Availability: CNC machining, sheet metal fabrication

First Article Inspection (FAI)

Availability: CNC machining

Dimensional Inspection Report

Availability: CNC machining, 3D printing, sheet metal fabrication

RoHS

Availability: CNC machining, injection molding, sheet metal fabrication

Elimold's Manufacturing Standards

Elimold’s web team has developed a process to ensure that every custom part you order meets the highest manufacturing standards. We perform dimensional and visual inspections on every order during and after production to ensure your custom part is delivered on time, meets your exacting specifications, and meets our high standards.

CNC Machining Standards

- Threads and tolerances

- Cosmetic standards

- Part cleaning and general finishing

- Inspection standards

- Quality documentation

- Non-standard features requirements

3D Printing Standards

- Inspection standards

- Dimensional accuracy

- Cosmetic standards

Injection Molding Standards

- Tolerances and dimensional accuracy

- Mold finish standards

- Quality control procedures

Key Quality Control Equipment

We use advanced inspection tools in our QC department, including height gauges, profile projectors, CMMs, and Olympus metal testers, to check every part carefully. This helps us deliver high-quality prototype parts and precision machining parts with reliable accuracy for industries.

X-RAY Material Tester

Purchasing material from suppliers without certificate is very risky. Even with certificate, you might receive the wrong material at the end. With X-ray material tester, we can identify all kinds of metal within 30 seconds which guarantee correct material will be used.

Imaging if wrong material were used, customers won’t be able to test the design properly. It might cause a huge loss when they go for mass production. In some industries, it is very dangerous to test the prototypes in wrong material. The best case is, you have to remake the parts, even though, lead time can’t be guaranteed. Thanks to the tester, All problem are sorted.

On-Machine Inspection System

Fundamentally, this system helps to find the material block position. It speeds up compared with doing that manually by operator, and more precise!It is a huge advantage especially when doing posted-machining on die casting parts or extrusion profiles. As we all know, they might not be consistent. And deformation is also a problem. With this system, you can either check the parts manually or pre-set the checking points. The system will adjust the cutting path automatically according to the inspection result. Find out the issues at the earliest stage, to avoid further actions which helps us to save cost and time.

Projecter

It can measure point, line, circle, arc and oval, rectangular with the multi-point positioning function, combination of measurements, center structure and the intersection of structure, the midpoint of construction, line structure, a round structure.It has various functions of data processing, display, input and output, Measurement data output Word, Excel and Auto CAD directly to conduct statistical analysis, particularly, and the work piece straightening function is very useful.

Coordinate Measuring Machine

At its most basic a coordinate is a point, a fixed singular location in three-dimensional space. A series of points can be used to define the parameters of a complex shape. Therefore a CMM is any device that is able to collect this set of points for a given object and to do so with an acceptable degree of accuracy and repeatability.

More Measuring Equipment

Elimold utilizes state-of-the-art, high-tech coordinate measuring machines (CMMs) to ensure precise part specifications. In addition to large-scale measuring equipment, Elimold also employs the following measuring tools and testing procedures to ensure part consistency and accuracy:

- Climatic Controlled Measurement Test Labs

- Tensile Testing

- Surface Finish Measurement

- Calipers

- Micrometers

- Height Gages

- Pin Gages

- Custom Attribute Gages

- Magnetic Inductance Testing

- Color Testing – Spectrophotometer

- Paint Adhesion Testing

- Humidity Logger

ISO Certifications

It is always possible to have your parts manufactured with industry-specific certifications due to our highly vetted digital network of manufacturers and ISO 9001-certified quality management system. Our network can certify to the following standards: AS9100-D & ISO 9001:2015, ISO 13485, ISO 14001, and ISO TS16949.

Contact your account representative to find out more.

Why Choose Elimold’s Quality Assurance?

Elimold has the expertise and technology to help you meet your needs faster.

When working with Elimold, expect expert engineering recommendations and project management. The experts at Elimold are well-versed in Geometric Dimensioning & Tolerancing (GD&T), the language used by engineers to communicate measurement and tolerances via engineering drawings. The Elimold team is able to accurately confirm precise dimensional requirements through technical engineering expertise. Talk to us today to start your project!

Self-Owned Factories and Manufacturing Network

At Elimold, our factories are fully equipped with cutting-edge tools and technology. Our team of skilled professionals operates CNC machines, powerful injection molding equipment (up to 2300 tons), laser cutters, benders, welders, and modern 3D printers, ect. Our production lines are automated, ensuring efficiency and accuracy in everything we make.

By managing our manufacturing in-house, we keep a close eye on quality at every step. This helps us maintain high standards, offer flexible scheduling for production, and provide affordable solutions without sacrificing quality. Direct control over these processes reduces risks and makes your supply chain more reliable.

Elimold Network Enhances Manufacturing Capabilities

The Elimold Network unlocks expanded capabilities across our services. To scale your injection molding operations from small batches (10,000+ pieces) to high-volume production (1,000,000+ pieces), explore our network. CNC machining offers anodizing and tighter tolerances. Both molding and machining offer volume pricing options to reduce part costs. You can even create prototypes quickly and cost-effectively with FDM 3D printing. Leverage our digital network to get more out of your manufacturing.

Ready To Start Your Next Project?

Trusted rapid manufacturing with full process inspection guarantee. Each project is rigorously inspected and complies with industry standards.