3-Axis CNC Milling Services

Elimold’s team provides you with skilled 3-axis CNC milling services. To meet the needs of every customer, we have built a machining solution that can be customized to your specific needs. Equipped with advanced machinery and skilled workers, you will undoubtedly get the best quality results when working with us. Contact us now to get your free quote.

3-Axis CNC Milling Parts Manufacturer

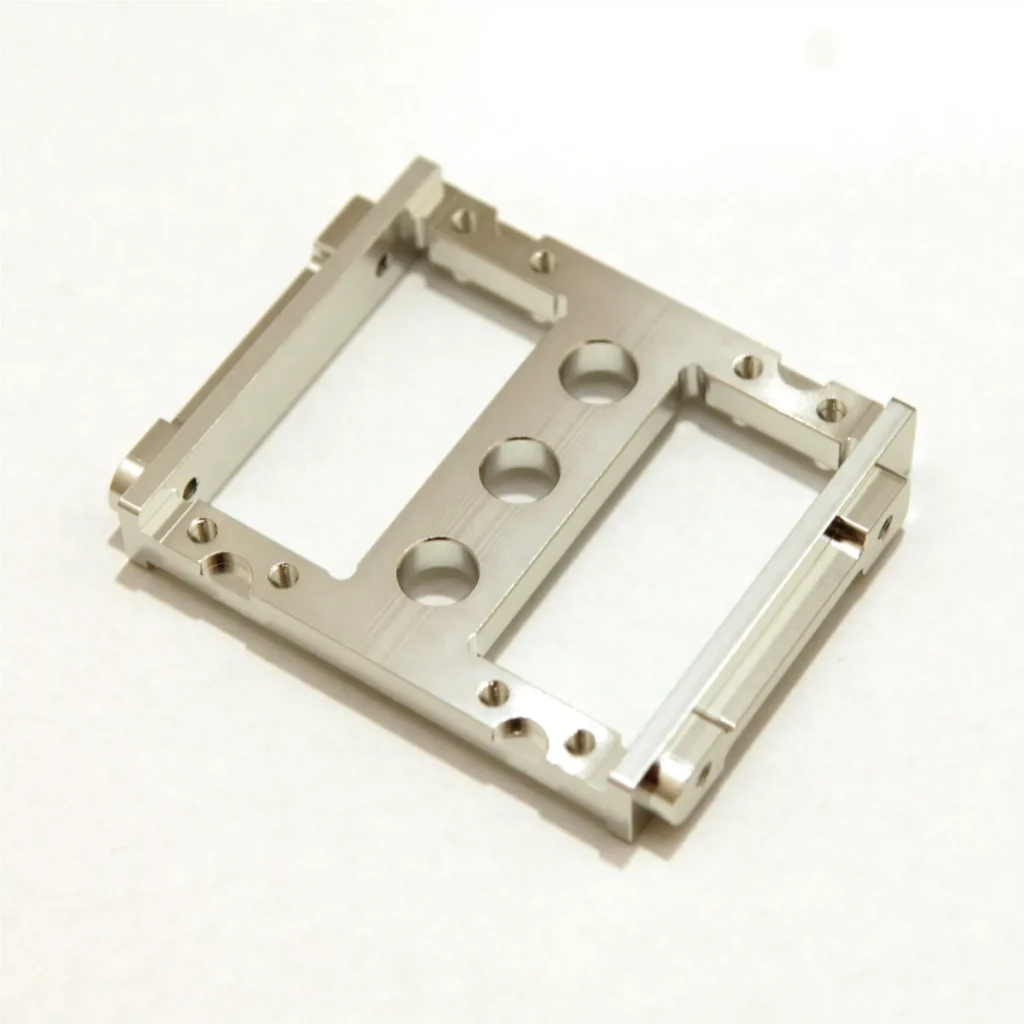

At Elimold, we specialize in manufacturing 3-axis CNC milling parts to turn your unique ideas into reality. Our team of skilled machinists carefully craft raw materials into beautiful pieces based on your exact specifications. With our state-of-the-art facilities and extensive expertise, we excel in high-volume custom flat parts. Our team is all about delivering impeccable 3-axis CNC milling. We pride ourselves on our attention to detail and commitment to customer satisfaction. From concept to completion, we work closely with you to ensure every aspect of your custom 3-axis machining manufacturing project is in line with your vision. Our team uses advanced technology and premium materials to ensure long-lasting durability and superior quality. Experience the artistry of 3-axis CNC milling manufacturing with Elimold. Let us turn your ideas into extraordinary realities. Contact us today to discuss your project and make your vision a reality.

Elimold 3-axis CNC Milling Factory Capabilities

Our company prides itself on direct, large-scale operations with comprehensive machinery, strict quality control, well-equipped facilities, and efficient and precise records. We pride ourselves on providing the best CNC milling parts at affordable prices, with fast turnaround times, and a commitment to customer satisfaction. Our 45,000 square foot facility features a wide range of state-of-the-art modern equipment. We have the ability to efficiently process and produce any volume order in a short period of time. We have a large number of machines that can handle large orders, ensuring that we can meet the needs of large volume orders without compromising quality or deadlines. And our factory has a professional 3 axis CNC milling parts team of more than 120 skilled workers who use more than 100 types of machines, ensuring precise and consistent results with great flexibility and efficiency, no matter how complex the project and how large or small the order volume is. Being a 3-axis CNC milling parts supplier allows us to achieve excellent precision, efficiency, and versatility, providing our customers with high-quality and cost-effective solutions. Elimold can provide online 3-axis CNC milling services to companies all over the world, and we look forward to any cooperation opportunities between us. Whether you need a complex part or a simple assembly, our machinery, expertise and focus on customer satisfaction make us a reliable partner for high-volume orders.

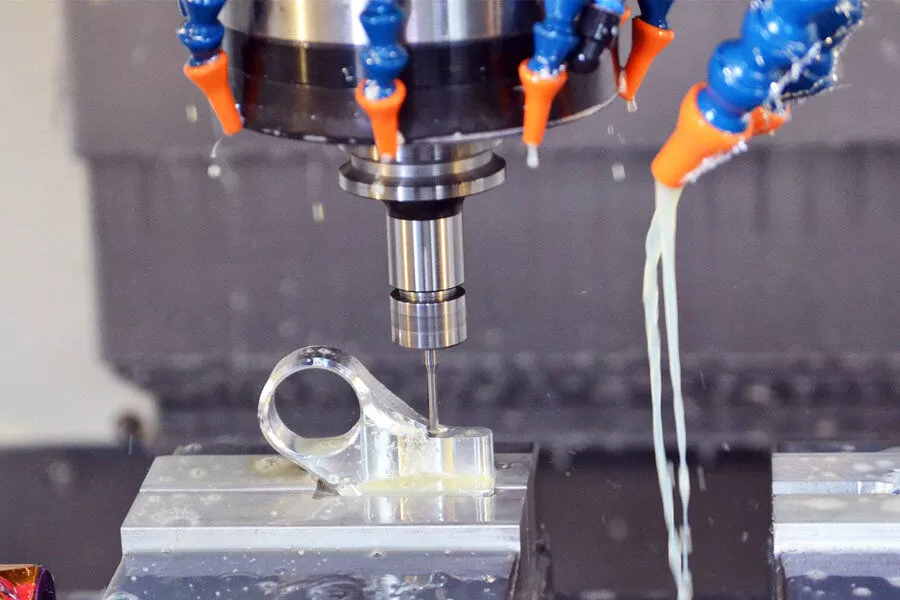

3-Axis CNC Milling Rapid Prototyping Services

Our rapid prototyping services produce samples quickly and cost-effectively, allowing our customers to validate their designs, test functionality, and make necessary modifications before entering mass production. We are excited to grow with our customers, helping them reduce development time, improve product quality, and ultimately turn innovative ideas into reality. With extensive experience in 3-axis milling, we have the knowledge, capabilities, and state-of-the-art facilities to precisely turn every vision into reality. We support prototyping, low-volume orders, and high-volume production, all of which are serviced from start to finish by Elimold’s in-house facility. We ensure the quality of your 3 axis milling parts through a strict quality management system as well as video inspection and material certification options. Contact us now to get a free analysis quote within hours and quality components within days.

3-Axis Milling Parts Supplier

With precision 3-axis CNC equipment and a wide range of tools, we can cut virtually anything to tolerances within a few thousandths of an inch or less. Engineers, innovators, maintenance managers, and others choose Elimold for custom 3-axis CNC milling because we can efficiently and accurately machine custom parts and housings with absolutely no minimum order requirements. At Elimold, you don’t have to worry about dealing with machine shop lines or having your low-volume orders delayed in production. We pride ourselves on our reliability and exceptional customer service. And our CAD/CAM integration capabilities allow us to provide comprehensive 3-axis milling solutions that not only ensure precise execution, but proactively identify and resolve any potential issues. This optimizes manufacturing processes, delivers quality components, and ultimately increases customer satisfaction.

Lead Time

Parts are graded by complexity. Lead times for less complex parts are 2-3 days. As complexity increases, lead times are 2-5 days. Lead times for more complex parts are 5 to 15 days. Likewise, quote times can range from 1 business day (or faster) to 5+ business days, depending on the complexity of the design. If you have a design that you would like our team to evaluate and quote, please use our quote request form.

Tolerances We Follow

As a high-quality 3-axis cnc milling parts producer, precision is our top priority and accuracy is the cornerstone of our CNC milling services. Whether you need a part with a tolerance of +/-0.005mm or +/-0.05mm, we will develop the appropriate production plan and the right tooling to meet your product and assembly needs. For metals, our CNC milling parts comply with ISO 2768-m standards and for plastics, we follow ISO 2768-c. For custom tolerances, please clearly mark them on your drawing and we will make them for you.

Strict Quality Control and Certification Standards

Quality is the cornerstone of Elimold. Our stringent quality control system covers all stages of production, from initial drawings to material selection, first piece inspection, and supervision of semi-finished and finished products. Our meticulous attention to detail ensures that we provide the highest quality CNC milling services and that our products meet or exceed the highest industry standards. Additionally, our commitment to quality is reflected in our ISO9001:2015 certification. This internationally recognized standard demonstrates our commitment to maintaining consistent quality management practices and consistently meeting customer expectations.

Get an accurate quote for your next 3-axis CNC millilng project

Whether your 3-axis CNC milling project is complex or simple, metal or plastic, you will get an accurate quote within 6 hours.

Elimold More CNC Machining Service Types

Start with prototypes, move to small batches, and finally manufacture large quantities of precision parts for your project. Each solution is tailored to your vision. Elimold is able to provide comprehensive CNC machining solutions.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

3-axis CNC Milling Material Options

Our 3-axis CNC milling services are available for a wide range of materials, ensuring precision and durability. This wide selection allows our customers to choose the best option for their unique project, resulting in improved part quality and performance.

Metals

- Aluminum

- Alloy Steel

- Brass

- Bronze

- Copper

- Inconel

- Invar

- Mild Steel

- Stainless Steel

- Titanium

Plastics

- ABS

- Delrin

- Nylon

- PC

- PEEK

- PEI

- PET

- PMMA

- PP

- PTFE

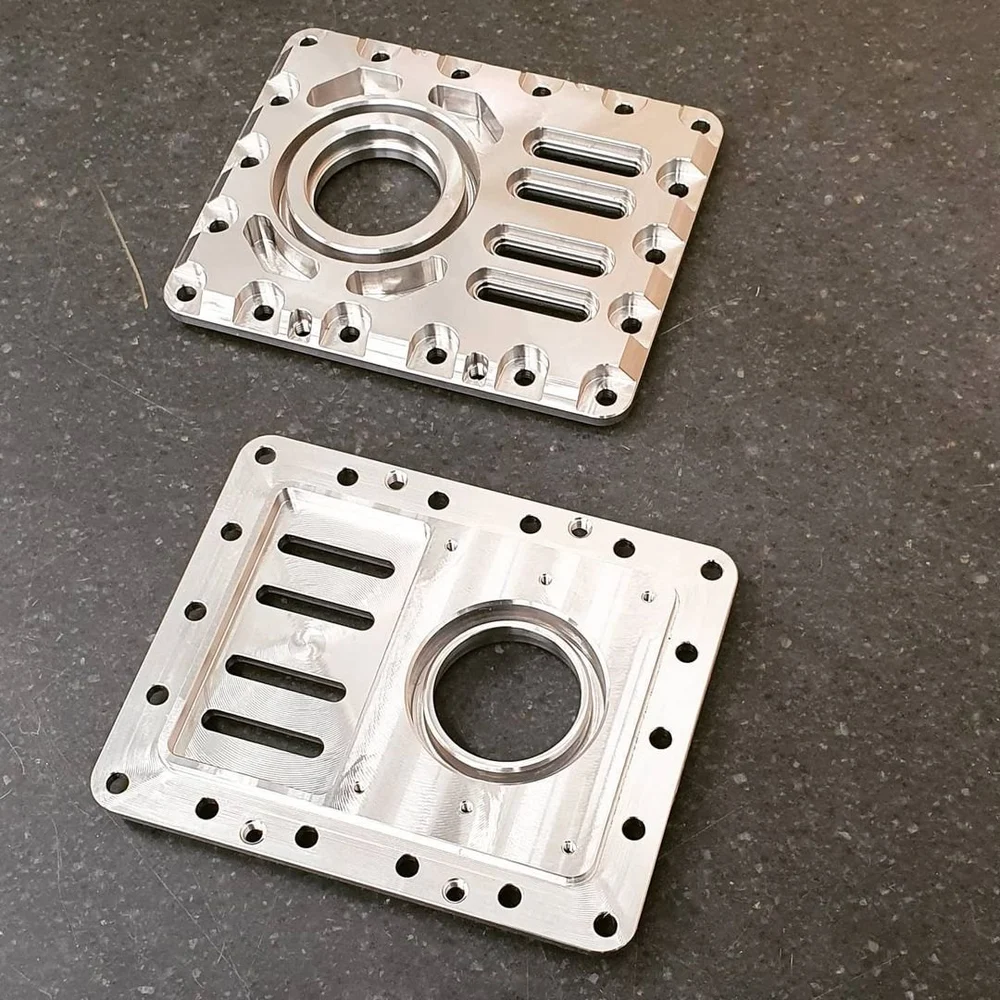

Surface Finishing Options

Elimold offers high-quality surface finishing services for all 3-axis CNC milling components and parts, regardless of the surface finishing method required for production. Our skilled experts can take care of and complete the finishing tasks, guaranteeing that the quality of your products is outstanding. We can provide the perfect surface finish for your prototypes and mass-produced flat components.

- Electroplating

- Electrophoresis

- Sandblasting

- Painting

- Powder spraying

- Oil spraying

- Plastic spraying

- Anodizing

- Thick film oxidation

- Micro arc oxidation

- Vacuum coating

- Laser marking

- Surface etching

- Painting

- Grinding

- Silk screen printing

- Wire drawing

- Blackening

- Laser carving

- Gluing

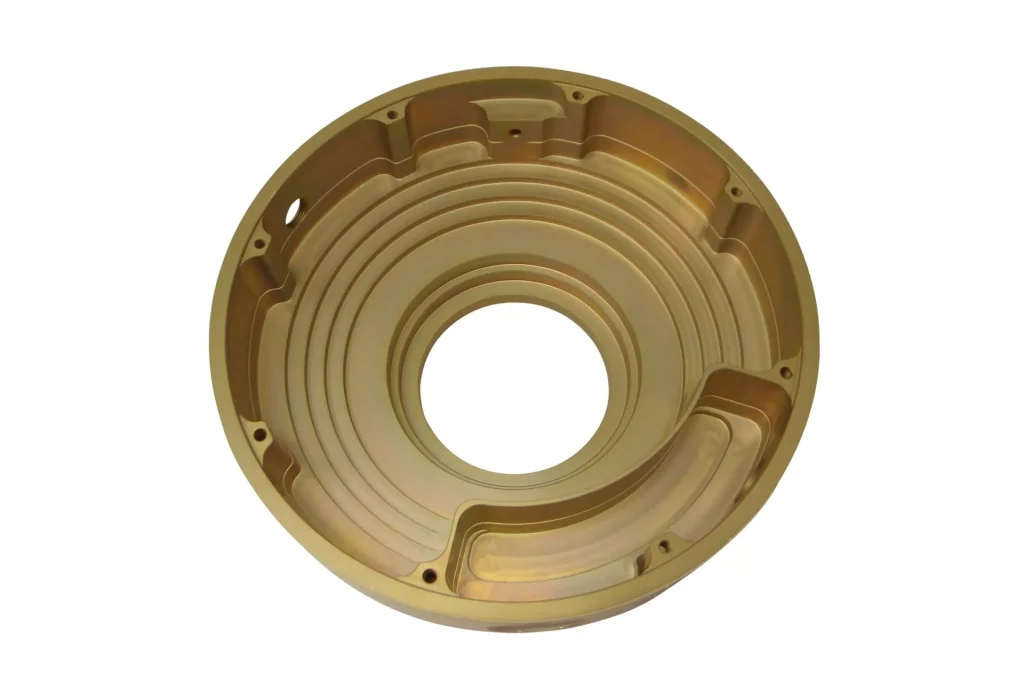

What shapes and features can be created with 3-axis CNC milling?

Basic shapes such as circles, squares, rectangles, and other polygons can be easily created using 3-axis CNC milling. Since the machine operates in three dimensions, it can create these shapes at any depth, making it ideal for creating slots, grooves, and similar features. In addition to basic 2D shapes, 3-axis CNC milling machines can also create 3D shapes such as cubes, spheres, cones, cylinders, and more. This is achieved through a process of removing material layer by layer until the desired shape is achieved. 3-axis milling can also create complex features such as undercuts, threaded holes, and complex contours. It is worth noting that the ability to create these features also depends on the tooling available, and may require specific end mills or drills.

Various Applications of 3-axis CNC Milling Manufacturing

3-axis CNC milling machine processing is mainly suitable for processing parts with relatively simple shapes and no need for complex multi-angle processing. The advantage is that it is efficient and cost-effective.

- Engine parts: turbine blades, combustion chamber housing, nozzles, etc.

- Connectors: aviation joints, fasteners, brackets, etc.

- Control parts: servo brackets, joystick parts, etc.

- Radiators: CPU heat sinks, aluminum radiators, etc.

- Housings: electronic equipment housings, control box housings, etc.

- Connectors: RF connectors, power connectors, etc.

- PCB fixtures: fixtures used for circuit board processing.

- Bracket parts: support frames and fixing frames of various shapes, etc.

- Box parts: equipment housings, control boxes, distribution boxes, etc.

- Panel parts: control panels, instrument panels, operating panels, etc.

- Fixture parts: fixture parts used to clamp workpieces.

- Engraving parts: nameplates, logo plates, artistic engravings, etc.

- Medical parts: surgical instruments, prosthetic parts, medical equipment brackets, etc.

- Optical parts: lens brackets, optical instrument housings, etc.

- Shaft parts: transmission shaft, main shaft, spline shaft, lead screw, etc.

- Gear parts: spur gear, helical gear, bevel gear, rack, etc.

- Flange parts: flat flange, flange flange, blind flange, etc.

- Bearing seat: base or bracket for mounting bearings.

- Coupling: rigid coupling, elastic coupling, etc.

- Slider: slider part for linear motion.

- Guide sleeve: sleeve part for guiding and supporting.

- Cam: cam part for mechanical transmission.

- Gasket: flat gasket, spring gasket, etc.

- Keyway parts: shaft or hub with keyway.

- Engine parts: cylinder head, piston, connecting rod, crankcase, etc.

- Chassis parts: steering knuckle, brake caliper, suspension bracket, etc.

- Transmission system parts: gearbox housing, differential housing, clutch plate, etc.

- Body parts: door hinges, seat brackets, instrument panel brackets, etc.

- Structural parts: wing ribs, wing beams, fuselage frames, etc.

How does 3-axis CNC milling compare to other milling technologies?

3-axis milling machines have three spindles (X, Y, and Z) and are used to manufacture components, drill holes, or sharpen product edges. As the name implies, 4-axis and 5-axis milling machines add additional axes to their manufacturing system, allowing for advanced rotational motion and multi-dimensional machining. These additional axes allow for highly complex parts and shapes to be manufactured at high speeds. While relatively simple compared to 4-axis and 5-axis milling, 3-axis CNC milling still provides an effective solution for precision machined parts. Elimold offers exceptional 3-axis milling services to meet or exceed your expectations.

Difference between 3-axis milling and 4-axis milling

In a 3-axis milling machine, there are three axes of motion – X, Y, and Z. The X axis is up and down, the Y axis is left and right, and the Z axis is front and back. The fourth axis of 4-axis milling allows for additional movement in all three axes simultaneously, allowing for 3D milling of parts. This is useful when drilling multiple holes along edges that don’t align perfectly; after drilling one hole, more holes can be added along that edge without repositioning the workpiece.

Difference Between 4-Axis and 5-Axis Milling

5-axis machines are similar to CNC milling machines, with a spindle and four axes, but they have an additional axis of rotation, which allows the part to rotate freely in addition to moving it left to right, up and down, or in any direction around a center point. The additional axis of rotation allows for more room for creativity, as it can be engraved, cut, or milled on all sides of a part, rather than just on one side as is done with a CNC machine’s four axes. While both types of machines can perform similar functions, 3-axis and 4-axis milling machines function differently. 3-axis milling machines use three movable arms that move in front of each other along separate X, Y, and Z planes. They provide motion, while 4-axis milling machines use all three arms. This includes the fourth arm, which moves on the A plane. This allows for easy rotation around the X/Y/Z axes. Because these two different types work differently, there are also some differences in how they handle materials.

Request Your Free 3-axis CNC Milling Quote Today

After receiving your drawings, our engineers will analyze your custom 3-axis CNC milling parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.