3D Printing Services

Business is changing rapidly, demands are growing, and competition is fierce. To stay ahead, companies must be prepared and adaptable. Elimold provides resourceful and adaptable 3D printing solutions to global industries. Our in-house manufacturing capabilities ensure that we have the right solutions for you to grow and succeed. From prototyping to mass production, Elimold has you covered.

Professional 3D Printing Service Provider

If you need 3D printing, 3D scanning, rapid prototyping, reverse engineering or CAD design (industrial/mechanical) services, you have found the best choice. Elimold’s 3D printing services can print almost everything, from custom designed parts to prototypes for patent applications. We can also design and modify your CAD files so that you are ready for injection molding. In addition, we also provide comprehensive product design, industrial design and mechanical engineering services. Your design drawings can be transformed into actual products and brought to market. Whatever your prototyping or production needs are, we can help you achieve them. We have built products for almost all industries.

In-house 3D Printing Factory

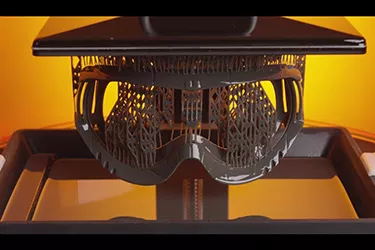

In addition to our in-house 3D printing factory, Elimold has three manufacturing centers of excellence in China. We can undertake prototype and mass production 3D printing and post-processing. We can support single or batch production according to your needs. With more than 350 devices, including large-format and biocompatible printing equipment, our in-house factory can easily turn your 3D printing projects into reality. We can provide companies with the solutions they need to help them produce better products faster and more economically. In addition, Elimold can also provide expedited services for urgent orders with a turnaround time of as fast as 24-48 hours. We have earned a good reputation among leading companies around the world for the latest 3D printing technology.

3D Printing Capabilities

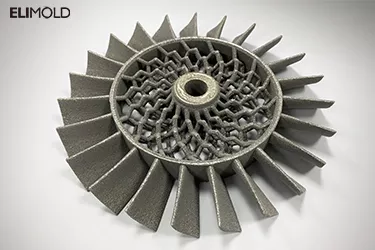

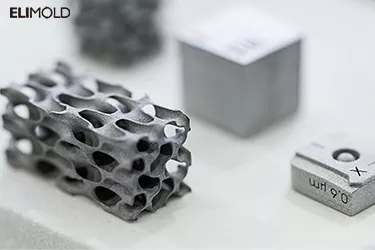

At Elimold, we use cutting-edge precision drive technology to transform complex designs into perfect reality. Our advanced 3D printing system uses AI-optimized layering and micron-level resolution to ensure dimensional accuracy up to ±0.05 mm. Unlike traditional methods, our multi-sensor feedback loop dynamically adjusts parameters during the printing process to eliminate warping and layer misalignment. In addition, our advanced industrial-grade 3D printers can achieve a resolution of 25 microns, capable of printing highly detailed and complex parts. In terms of manufacturing size, Elimold is able to produce large and complex parts up to 420 mm x 400 mm x 400 mm on an industrial scale.

3D Printing Service Process

Instant Online Quote & Order

Engineering Expert Review

Meticulous Manufacturing

Quality Control

Advanced Finishing (Optional)

Final Inspection & Shipment

Your Trusted Advanced 3D Partner

With over 20 years of experience in manufacturing innovation, Elimold is more than just a service provider. We are a committed partner to engineers, designers, and product teams. Our deep industry expertise, responsive support, and proven track record ensure you get the guidance and reliability you need at every stage of development. With global reach and local efficiency, our strategically located facilities offer the flexibility, control, and quality that comes with in-house manufacturing and a localized supply chain. From initial design review to production-ready parts, we help you confidently navigate complexity and get your products to market faster.

Elimold's Philosophy And Vision

We want to make the world a better place through 3D printing services, and we believe that democratizing 3D printing technology is one way to achieve this goal. When every business can make unique physical objects at an affordable price without the capital or technology to own and operate their own 3D printer, a new level of creativity will be unleashed around the world. Our 3D printing services are designed to bring positive power to businesses, engineers, and designers around the world.

Discover Our 3D Printing Solutions

Elimold’s expertise in 3D printing manufacturing and use of cutting-edge technologies allows us to offer solutions suitable for every stage, from prototyping to the production of complex metal or plastic parts. Meticulous attention to detail and quality assurance by a dedicated team for each project make Elimold a valued partner for demanding industries. Regardless of the origin or complexity of your project, you will find a tailor-made solution at Elimold.

Rapid Prototyping

Contract Manufacturing

On-demand Manufacturing

Full Range of 3D Printing Services

Elimold offers a full range of 3D printing manufacturing solutions for all applications, from single components for rapid prototyping to complex functional parts for mass production. Our online 3D printing services allow you to turn your designs into reality faster; by creating complex prototypes or final parts before mass production, you can speed up your product development cycle and save costs that traditional manufacturing methods cannot achieve. From sketches to final 3D printed products, we stock a wide range of materials and optimize the ordering and production processes to minimize costs at every stage. As a result, we are ultimately able to provide our customers with the most competitive 3D printing prices. Contact us for a free quote or to discuss how we can support your next project.

Types of Our 3D Printing Services

Whether you need a single prototype or large-scale production, we can help. Our commitment to quality and customer satisfaction ensures that you receive the best service and results. Customers using Elimold’s online 3D printing service can print 3D models in a variety of materials, colors, and finishes. This service is very useful in the fields of engineering, production, and product design because it allows companies to produce and test prototypes without the use of expensive equipment.

Metal 3D Printing

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Multi Jet Fusion (MJF)

PolyJet

Carbon DLS

Direct Metal Laser Sintering

Fused Deposition Modeling(FDM)

Metal Binder Jetting

Selective Laser Melting (SLM)

Digital Light Processing (DLP)

ColorJet

Ready to start making custom 3D printed parts?

Upload your 3D file to get a free instant quote! Elimold offers a range of printing processes, choose the 3D printing material and finishing options you need, and let our professional 3D printing services do the rest. Your part will be produced in our 3D printing factory and delivered to your door in a few days. Get your 3D printed parts now and be at the forefront of innovation.

Custom Parts with Elimold’s Custom 3D Printing Services

Are you validating the design complexity and manufacturability of your parts? For any stage of product development that doesn’t require consensus design decisions and mass production, 3D printing is your best option. Our 3D printing services allow you to efficiently source parts without compromising quality. We offer a wide variety of manufacturing polymers and metal materials, and our manufacturing partners are continually offering newer, stronger plastics. As a result, our 3D printing capabilities make it easier for you to produce complex end-use components or get your hands on a product for the first time without waiting for a quote. With 3D printed components, you can quickly understand how they will perform during assembly, if they will fit, and what design changes are needed before starting full-scale production with injection molding.

From Prototyping to Production

Taking your next design from early-stage testing to full production has never been so easy.Elimold’s simplified sourcing approach takes the work out of buying your prototype, models, and production parts. Let us be your one source of success!

3D Printing

Urethane Casting

Injection Molding

3D Printing in the Product Development Cycle

3D printing is a great solution when a part needs to be produced immediately in small batches and the part design is highly complex and difficult to manufacture using traditional methods. 3D printing also helps designers and engineers quickly iterate, modify designs and bring parts to market quickly without expensive inventory because parts can be printed on demand. Additive manufacturing technologies include a variety of polymers and metals for direct printing, as well as a wider range of materials printed through intermediate processes such as thermoforming and sand casting. Our 3D printing services are designed to meet tight tolerances, reduce lead times, and deliver high-performance parts for a wide range of materials and applications.

Rapid Prototyping With Our 3D Printing Services

3D printing is the perfect solution for developing prototypes. It’s faster, cheaper, and more precise. Unlike other manufacturing technologies, with 3D printing, you don’t need to develop prototype molds. Your product will be created using digital molds through 3D software. This means a huge saving of money and time. This makes prototyping more convenient, allowing you to experiment with multiple iterations efficiently. With 3D printing-driven prototyping, you can turn your ideas into reality without the high upfront costs of traditional methods. As a result, you can make all the designs you want and test them at a lower cost. Rapid 3D printing prototyping solutions from Elimold will allow you to create, test, and improve in ways you never thought possible, so you can get to market faster than ever before.

Add Another Dimension To Your Designs

You can’t get to groundbreaking if your client isn’t sold on your design, no matter how groundbreaking that design may be. There’s only so much you can do on paper when your client finds it difficult to understand your concept and vision. You could go back to the drawing board, or you could save time and skip the drawing board entirely.

High-quality 3d models put the spotlight on the final product instead of the process, letting clients experience your vision for themselves in a way that 2D renderings never could. With a physical mock-up meticulously created down to the most exacting details, your clients can engage in the review process in a meaningful way that aligns your visions and reduces rework down the line.

3D printed models enrich projects from concept to completion and offer a fast, affordable way to get an objective look at your plans every step of the way.

Comprehensive In-House Design Services

Elimold offers comprehensive in-house design services to ensure your parts are optimized for additive manufacturing. We assist you in developing 3D models from technical drawings or specifications, allowing you to move seamlessly from concept to production-ready design. Whether you have detailed technical requirements or initial ideas, our team can transform them into a viable, manufacturable model. In addition, our reverse engineering capabilities allow us to rebuild existing models or parts, helping you improve and innovate your design. This service is especially important when updating or modifying parts to better suit 3D printing technology.

Engineering Capabilities

By working with our expert mechanical engineers who are well versed in designing for 3D printing, you can create parts that perform better and better to your expectations. Our design services also include adapting existing models to make them more suitable for 3D printing. Our experienced team provides professional design advice and recommendations to ensure that your parts not only look great, but also function efficiently. Whether you need a complete redesign or minor adjustments to improve printing performance and performance, we can help. Contact us to discuss your project and see how our design expertise can accurately and efficiently turn your ideas into reality.

3D Scanning Services

3D scanning is the process of analyzing an object in the real world, collecting all the data in order to digitally reconstruct its shape and appearance. Through this process, the object can be turned into a 3D model, which can serve as the basis for the 3D project you are developing, while also helping to reconstruct, analyze or simulate ideas. With our 3D scanning services, we can provide the best selection of 3D scanning technologies in laser 3D scanning, photogrammetry and structured light scanning.

3D scanning is more popular today than ever before, with businesses around the world using it to increase productivity, save unnecessary costs, and create exciting new products and services. Whether you are an industrial engineer looking for a powerful reverse engineering solution or a doctor looking for an efficient way to create prosthetics, 3D scanning is the solution for you.

Security and Quality You Can Trust

At Elimold, quality assurance is a commitment to excellence. With ISO 9001, AS9100, and the recently acquired ISO 13485 certifications, we ensure strict compliance with regulatory standards for the aerospace and medical industries. Our certified systems provide strong process control and traceability to guarantee high part quality. Additionally, our ITAR registration, DIBNET compliance, and 110-point SPRS score ensure secure operations, while our strict adherence to NIST 800-171 guidelines keeps sensitive information secure. We prioritize the delivery of precise, high-performance parts within project parameters.

Control & Traceability

Ensuring control and traceability throughout the manufacturing process is critical. From quote request to delivery, each step is closely monitored to ensure flawless production. First, we send an engineering request to obtain a quote, followed by a contract review to ensure compliance. Once an agreement is reached, we maintain full production traceability, including manufacturing, materials, parameters, and inspection. Projects are tracked throughout the manufacturing process, including tracking of the finishing process and final inspection before packaging and shipping to ensure on-time delivery. Whether using traditional or additive manufacturing, it is critical to trace the original construction and materials of the part. From inquiry to delivery, our entire process is strictly monitored to ensure the quality of the part.

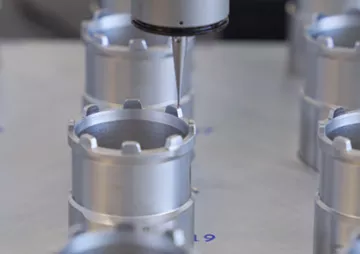

Inspection Equipment

At Elimold, our commitment to quality remains unwavering and we invest in specialized inspection equipment to ensure the excellence of the parts we manufacture. Single contact measurements are accurate to ±0.0010 inches, volume measurements are accurate to ±0.0019 inches, and laser line scan measurements are accurate to ±0.0010 inches. We maintain strict standards to ensure accurate evaluation of part dimensions and features.

Coordinate Measuring Machine - CMM

Involves using a Coordinate Measuring Machine to measure the geometrical characteristics of an object with high precision.

Geometrical optical measurement - 3D Scan

Utilizes optical measurement techniques to create a digital 3D model, used to compare and verify tolerances.

2D X-ray Inspection

Employs X-ray imaging to examine the internal structure of objects, identifying defects and ensuring structural integrity.

Computer Tomography scan - CT scan

Uses computed tomography to create detailed cross-sectional images of an object, allowing for in-depth inspection of its internal features.

Density Test

Measures the density of materials to ensure they meet specified standards and quality requirements.

Leakage Test

Checks for leaks in sealed systems or components to ensure they are airtight and function properly.

Pressure Test

Subjects parts to pressure to verify their strength and integrity, ensuring they can withstand operational conditions.

Assembly Services

We can provide a parts assembly service, and we also perform a comprehensive quality and functional inspection on the assembled product. Our rigorous testing process is designed to ensure that each component meets the highest performance and reliability standards. By providing these services from a single source, we provide a streamlined solution, saving you time and ensuring consistency and quality on every project. If you are interested in our assembly services, we recommend that you contact our sales team to discuss your specific needs. Our experienced team is ready to help you explore the best options for your project and provide a customized solution that meets your goals. Whether you already have a clear plan or need guidance, we will help you every step of the way.

Online 3D Printing Services

Elimold gives you easy access to professional 3D printing services online. Our platform provides a seamless way to upload CAD files, get instant quotes, and order parts quickly. Whether you need high-resolution 3D printing services for complex prototypes or reliable industrial 3D printing services for end-use production, our platform provides precision and speed every step of the way. As a trusted provider of additive manufacturing services, we support a wide range of custom 3D printing services to meet your application needs, ideal for commercial and industrial needs. Get the quality and performance you expect from the leading online 3D printing service.

Our online 3D printing service makes your 3D models a reality!

Speak to a 3D printing expert today! Our team is standing by, ready to help answer questions or get started on a quote for your project.

Advantages of Our 3D Printing Service

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for Low volume of complex prototypes

- We provide with our partner 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

3D Printing Complements Injection Molding

3D printing is recognized as a strong and viable alternative to traditional manufacturing due to its certified and validated processes and materials. This recognition is driving 3D printing from one-off prototyping, assembly and functional applications to end-use production components for demanding applications and industries, with annual production volumes of millions of units.

Elimold is committed to providing time-sensitive manufacturing services to meet the needs of our customers at different stages of their product launch cycle. We have historically focused on injection molded thermoplastic parts; however, as customer needs have changed and manufacturing technology has advanced, Elimold has evolved to adopt the best solutions to provide the desired results. With our expertise in both injection molding and 3D printing, we are able to provide the best solutions for every stage of our customers’ projects.

What is 3D printing?

3D printing, also known as “additive manufacturing”, is a production technology that produces high-quality products and small batches of parts by printing digital models and computer-aided design files (CAD) layer by layer into solid three-dimensional objects. The printing material can be plastic, metal or composite.

3D printing is one of the rapid prototyping technologies. It is able to print three-dimensional objects based on CAD models or digital 3D models under the control of a 3D printer. This is a process of printing objects by adding materials layer by layer, which is called additive manufacturing. 3D printing is similar to printing files with a printer, but uses different technologies. Printing a piece of paper requires a Word, PDF or Excel document, which are all two-dimensional. When printing an object, you need a 3D model design in STL file format and a printable 3D material. When the 3D model, STL file (which needs to be converted to G-code by slicing software) and 3D printing material are ready, the 3D printer can print the design layer by layer.

Unlike traditional manufacturing processes, 3D printing is a process of manufacturing products by adding materials, rather than machining on a piece of material. This additive manufacturing property makes 3D printing a unique manufacturing method that is typically fast and has relatively low setup costs. 3D printing can create more complex geometries than traditional manufacturing techniques, so it is widely used in the engineering industry, especially for prototyping and creating complex/lightweight geometries.

Advantages of 3D Printing

Building parts layer-by-layer brings about many benefits that open up design possibilities that were previously unachievable through traditional processes like injection molding, machining, or casting.

- Complex, organic geometries with limited impact on part cost

- Consolidation of multi-component assembly into a single part

- No upfront tooling costs

- Fast production for parts within 24 hours

- Internal features for advanced heat transfer and flow applications

Our 3D Printing Materials

Whether you want to create an IoT device, a medical sensor, or an industrial controller, the wide range of 3D printing materials we stock will give you the perfect choice. Rather than choosing a printing technology, we choose the material we need and then decide on the printing technology to use.

Fused Deposition Modeling (FDM) Material

- ABS-M30

- ABS-ESD7

- ABSi

- ASA

- Nylon 12

- PC-ABS

- PC

- PC-ISO

- PPSF

- PrototypingPLA

- ULTEM 9085

- ULTEM 1010

Selective Laser Sintering (SLS) Material

- Nylon 11 EX

- Nylon 12

- Nylon 12, Glass-Filled (GF)

- Nylon 12, Carbon-Filled (CF)

- Nylon 12, Aluminum-Filled(AF)

- Nylon 12, Mineral-Filled (HST)

- Nylon 12, Flame Retardant(FR)

Multi Jet Fusion (MJF) Material

- Nylon 11

- Nylon 12

- Nylon 12, Glass-Filled

- Polypropylene (PP)

- TPU 88A

Stereolithography (SLA) Material

- Accura 25

- Accura ClearVue

- Somos Watershed Black

- Somos WaterShed XC 11122

- Somos EvoLVe 128

- Accura Xtreme Grey

- Somos NeXt

- Somos ProtoGen 18420

- Somos Taurus

- Accura ABS Black (SL 7820)Accura Xtreme White 200

- Somos WaterClear Ultra 10122

- Accura 60

- Somos ProtoTherm 12120*

- Accura 48HTR*

- Somos PerFORM*

- Accura Bluestone*

Digital Light Synthesis (DLS) Material

- RPU 70

- UMA 9O

- EPX 82

- CE 221

- FPU 50

- EPU 40

- SIL 30

PolyJet Material

- Photopolymer – rigid

- Photopolymer -rubber-like(digital rubber)

- Multi-material, multi-color(digital material)

Direct Metal Laser Sintering (DMLS) Material

- Aluminum AlSi10Mg

- Stainless steel 17-4

- Stainless steel 316/L

Metal Binder Jetting (MBJ) Material

- X1 Metal 420i™

- X1 Metal 316i™

- Single alloy 316Lstainless steel

Metal 3D Printing Materials

- Aluminum

- Stainless Steel (17-4, 316L)

- Titanium

- Inconel

- Cobalt Chrome

- Copper

- Bronze

Carbon DLS Materials

- ABS

- Polypropylene

- Elastomeric Polyurethane

- EPU 40 and EPU 41

- Medical Polyurethane-MPU 100

- Silicone–SIL 30

- IND 405

- Rigid Polyurethane

- RPU 70 and RPU 130

- Epoxy – EPX 82

- Cyanate Ester – CE 221

- Urethane Methacrylate – UMA 90

3D Printing Material Testing and Validation

Our 3D printing services use powders, filaments, and resins that have been proven to last 50 times longer than standard 3D printing materials in mobile applications. We conduct comprehensive testing of our engineered composite plastic materials in our 41,000 square foot testing laboratory to ensure that every 3D printed part or component has excellent wear resistance comparable to injection molding. All 3D printed materials and parts are low-friction, maintenance-free, and self-lubricating. In addition, Elimold can also provide a variety of flame-retardant polymers that meet UL-94 V-0 and FAR 25.853 60-second burn test standards. These include FDM ULTEM 9085, FDM ULTEM 1010, and SLS Nylon 12 flame-retardant materials.

Surface Finish Options for 3D Prints

Looking to boost the strength, clarity, or appearance of your 3D-printed parts? Choose from microfluidic and micro-resolution materials, metal plating, secondary machining, and custom finishes like painting, clear coating, and decaling.

Unfinished

Dots, or standing “nibs,” remain evident on the bottom of the part from the support structure remnants.

Natural

Supported surfaces are sanded down to eliminate the support nibs.

Standard

Supported surfaces are sanded, and the entire part is finely blasted for a consistent look. Note that the layers are still present.

Clear Coat

Clear cosmetic finish that can be applied to ABS-Like Translucent/Clear (WaterShed XC 11122) and PC-Like Translucent/Clear (Accura 60) materials.

Painting

After smoothing the part with sanding and polishing, parts can be painted with automotive-grade paint. Provide a pantone color with your quote request. We also offer soft-touch painting.

Plating

Electroless nickel plating can be used to achieve parts that are similar to cast aluminum or magnesium.

Dyeing

Dyeing is another method for adding color to 3D prints. This is faster option with a limited color selection, so is a more cost-effective choice than painting.

Decaling

Decaling can be used to add a logo or other graphics to boost cosmetics or function.

Polishing

We can polish parts to a mirror-like finish. If this is a requirement, we ask that you provide either a drawing or image that indicates your finish expectations.

Heat Treatment

Harden and strengthen metal 3D prints with multiple heat treatment options: NADCAP heat treatment, hot isostatic pressing (HIP), solution annealing, and aging.

Machining

Machine metal 3D prints to achieve exceptional surface finish quality or meet tight tolerances.

Custom

Soft-touch paint, clear part finishing, painting, masking, color matching, decals/graphic, and texture finishes are available.

Get an Instant 3D Printing Quote

Upload your 3D CAD file to get an instant quote for your 3D printed design. In our quote platform, you can determine the cost impact based on your selected 3D printing material and resolution level. If you have any questions about your quote or design, you can contact our application engineering team who will guide you every step of the way.

3D Printing vs CNC Machining

3D printing can create parts with highly complex geometries, even hollow shapes that CNC machining cannot accomplish. But CNC machining can provide higher dimensional accuracy (±0.005 mm) and better surface finish (Ra 0.1 micron). Advanced five-axis CNC milling machines can perform high-precision machining of more complex parts to help you meet the toughest manufacturing challenges.

3D printing also produces less waste than CNC processes. CNC machining is cut from a whole piece of material, so material utilization is relatively low. The advantage of CNC machining is that almost all materials can be CNC machined, including production-grade engineering plastics and various metal materials. This means that CNC machining may be the most viable technology for prototypes and end-use mass production parts that require high functionality and special properties.

Features That Help You Develop Your Product

Elimold sets the standard for cutting-edge, high-quality 3D printing services designed to meet the needs of the professional and commercial sectors. Our team is ready to meet the most stringent regulatory requirements. Whether you need precision prototypes or production-grade components and materials, we provide on-demand solutions and technical support to ensure your project always stays at the forefront. With our advanced equipment, including commercial and industrial 3D printers for a variety of technologies, Elimold puts you at the forefront of additive manufacturing, ensuring your custom projects benefit from precision, reliability and innovation. As your trusted partner, Elimold is your go-to platform for high-precision custom 3D printed parts designed for professional and commercial use. Upload your CAD file to get a customized quote and lead time, simplifying the process and providing you with convenient services.

Request Your Free 3D Printing Quote Today

After receiving your drawings, our engineers will analyze your custom 3D Printing parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.