Carbon DLS 3D Printing Services

DLS 3D printing is a breakthrough additive technology that enables new types of part designs that product engineers previously thought were impossible. Create production-ready parts with exceptional mechanical properties, resolution, and surface finish with our Carbon DLS 3D printing technology. Contact us now for a free instant quote.

Carbon DLS 3D Printing Manufacturer

Elimold is a leading Carbon DLS 3D printed parts manufacturing company, focused on manufacturing high-quality custom parts driven by technology, high-quality data and artificial intelligence. It is a one-stop supplier for many companies around the world for their Carbon DLS 3D printing needs. In addition to its own production capabilities, Elimold is able to leverage its internal 3D printing factory in China and the extensive manufacturing capabilities of top partners in Europe and the United States to provide customers with a wide range of manufacturing services for low-volume and high-volume production and rapid prototyping.

Moreover, our data-driven AI manufacturing approach not only maximizes the overall product and service quality, but also minimizes the overall cost of parts and services. This not only provides global customers with better quality products, better inventory planning, but also improves visibility in supply chain management.

Our Capabilities

- Maximum Part Size: 7.4 x 4.6 x 12.8 inches (189 x 118 x 326 mm)

- Layer Thickness: Layerless, isotropic parts

- General Accuracy: Up to +/- 0.003 inches in + 0.001 inch per inch dimension size (Up to +/- 0.070 mm + 0.001 mm per mm dimension size)

- Production Repeatability: Up to +/- 0.002 inch (Up to +/- 0.04 mm)

- Lead Time: Can be as low as 3 days

Professional Carbon DLS 3D Printing Company

Our dedicated and solution-oriented staff has extensive experience in developing, drafting and modeling project deliverables, and works closely with clients to understand and apply the most appropriate level of service. We have an excellent team of well-trained people with extensive expertise supporting a variety of disciplines. Our team consists of modelers, draftsmen and project managers, supported by world-class software, hardware and infrastructure, who have the expertise required to complete complex and cost-effective delivery parts on time and cost-effectively. In addition, we continue to invest in people and technology to solve complex needs quickly and innovatively. Our approach combines traditional principles with current proven industry practices. We adopt forward-looking thinking, save time, reduce costs, and equip knowledgeable and talented people to further enhance the culture of our company.

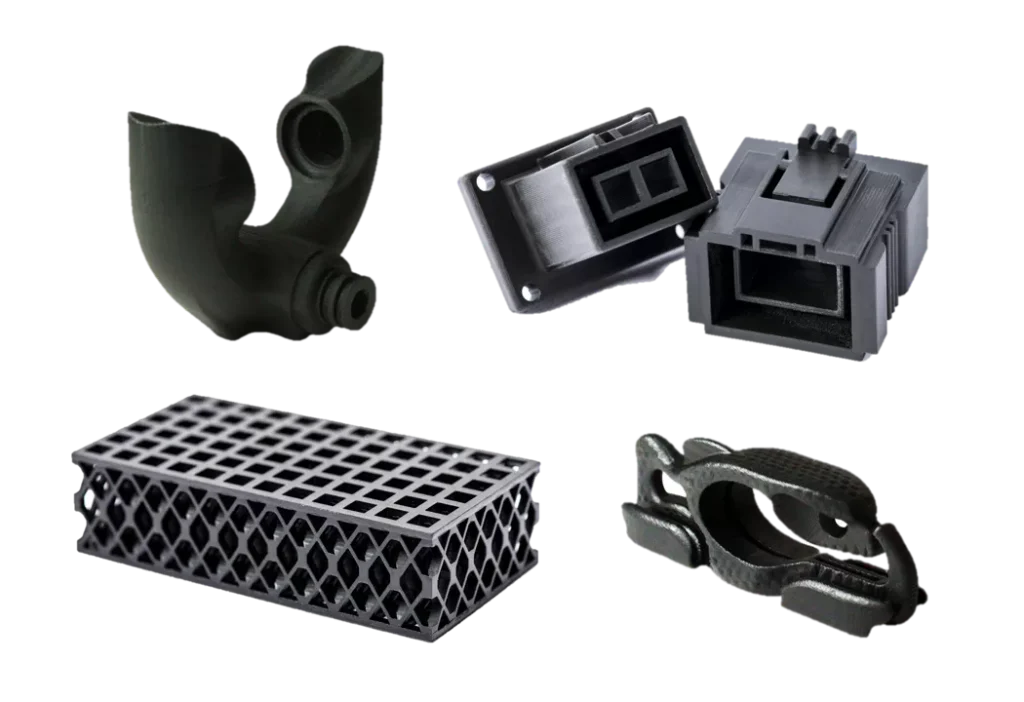

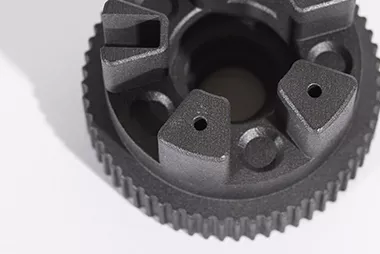

Complex Designs Are Easily Achievable

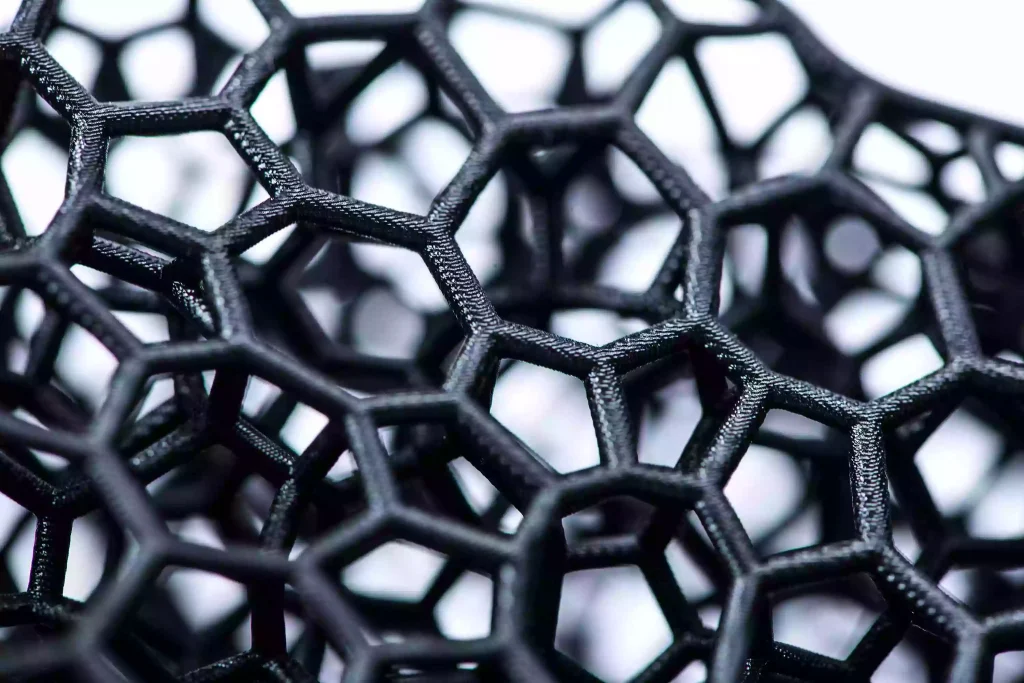

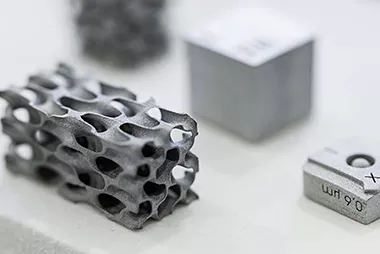

Although Carbon DLS technology can create support structures, it is more suitable for complex designs because it uses resin, unlike powder bed fusion technologies such as SLS and MJF. The use of resin gives the design fluidity, which helps to achieve complex designs and intricate internal features. Most complex designs that cannot be achieved even using traditional processing methods such as CNC machining can be achieved with Carbon DLS. This 3D printing technology is able to create undercuts and perfectly straight walls without sacrificing manufacturability. In addition, Carbon DLS’s unique lattice structure production technology allows engineers to redesign products (for example, lattice designs can replace foam in shoes).

Our Service Process

Send Details

Contact an Engineer

Sign the contract and start production

Receiving Your Product

Engineering Design Services

As a full-service Carbon DLS 3D printing company, we can provide services from concept development to prototyping, first article production and low-volume production. Our team of engineers are skilled in determining applications, materials and processes to quickly deliver high-quality prototypes and end-use parts. And we can optimize your Carbon Printer design by minimizing support materials, reducing hand-finishing time, developing custom surface textures and applying lattice structures. Leverage our team’s expertise to use digital printing technology to produce end-use quality prototypes and bridge runs of 100 to 10,000 parts.

Our Equipment Capabilities

We use Carbon’s Smart Parts Washers and MMD (meter/mix/dispense) equipment to automate labor-intensive material cleaning and dispensing, reducing production operating costs. Smart Parts Washers use next-generation software to provide automated, part-specific cleaning programs, process control data for part traceability, and regular software updates to continuously clean parts. MMD machines reduce material costs through bulk material packaging, reduce resin handling, and improve production reliability and quality through automated, precise material dispensing. We rely on the M3 to produce consistent, precise, reliable parts.

From Prototype to Production

One of the hidden costs of new product development is the need to revalidate materials and processes from prototyping to pre-production to production. With Carbon DLS printing, you can move from prototype to production with one material and one technology, reducing validation costs. Because “design iterations are free,” many of our customers produce three or more designs per production cycle. Traditional injection molding processes are slow and costly, especially when complex geometries are involved. We know that time and budget constraints can make this difficult, so we invested in Carbon DLS 3D printing technology, which allows you to quickly prototype and produce complex parts like lattice structures without long lead times or high tooling costs.

Beyond Prototyping

If your project requires advanced mechanical performance beyond Stereolithography (SLA) and PolyJet, explore our advanced photopolymer materials unlocked by Axtra3D Hybrid Light Synthesis (HPS) technology. HPS leverages the best features of Carbon Digital Light Synthesis (DLS) printers, such as speed, near-isotropic parts, and smooth surface finish, while adding the faster speed and higher resolution of Stereolithography (SLA). We have been at the forefront of leveraging digital tools for Design for Additive Manufacturing (DFAM). We can assist you in identifying applications, selecting materials, developing processes, and more. Combining our design experience with on-site manufacturing helps us accelerate the product development process. At Elimold, we focus on timely delivery of high-quality parts.

Manufacturing Complex Geometries with Additive Manufacturing

Companies are increasingly turning to Carbon DLS 3D printing to achieve high-performance end-use applications with specialized geometries. In particular, being able to integrate channels within a part based on a few simple design rules can significantly improve part performance. Customized lattices with different mechanical responses in different areas enable a single part to replace two or more other components. Over the life of the part, this can reduce assembly costs, logistics costs, and reduce supply chain risk.

Ready to get started on your Carbon DLS 3D printing quote?

Are you ready to embark on a transformative engineering journey? Our team of experts is eager to help you explore the possibilities of Carbon DLS 3D printing and engineering design. Contact us today to discuss your unique needs and let us help you turn your ideas into reality.

Carbon DLS Material Options

The resolution and gentleness of the Carbon process provides the ability to work with a wide range of materials, meeting the surface finish and detail requirements necessary for end-use parts. Furthermore, Carbon offers a range of materials that are comparable to traditional thermoplastics commonly used in manufacturing.While Carbon is continuously adding to their materials offered, these are some of the materials we currently print:

- Rigid: RPU 70 and RPU 130

- Flexible: FPU 50

- Elastomeric: EPU 40, EPU 41, EPU 43 and EPU 45

- Cyanate Ester: CE 221

- Epoxy: EPX 82 & EPX 86FR

- Silicone: SIL 30

- Multi-Purpose: MPU 100

- Prototype: UMA 90

- Clear: HENKEL LOCTITE 3D IND405 Clear

- Dental: WHIPMIX, DPR 10 and Keysplint

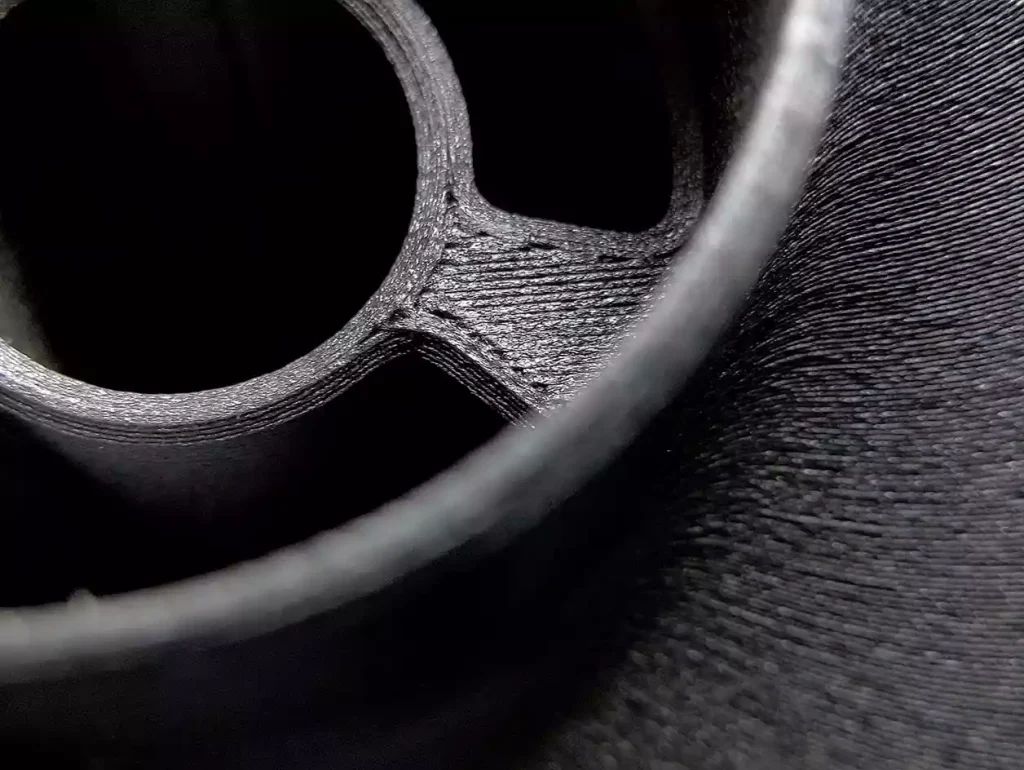

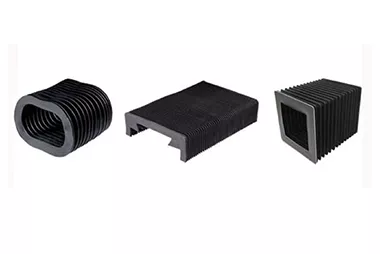

Available Finishes for Carbon DLS™ Parts

Parts built with Carbon DLS technology will typically have a matte to semi-gloss surface finish depending on feature direction. Extended protrusions will show vertical lines in the part that are parallel to the direction of growth. Supports are removed and mitigated as required.

UMA 90 materials come in different colors available for custom mixing. Although the standard is black or white, other solid colors can be available for part productions.

With natural finishing, you get varying aesthetics based on build orientation. Standing nibs are sanded flat.

With unfinished, you get varying aesthetics based on build orientation. Dots or standing nibs remain evident on the bottom of the part from the support structure remnants.

Don’t see the finish you need? Send us an email at [email protected] and we’ll research the finish for you.

Industries We Serve

We provide custom DLS 3D printed parts services to mechanical engineers across a wide range of industries. Choosing Elimold’s expert 3D printing services and taking advantage of our network of professional 3D printing capabilities means our customers receive both highly competitive pricing and fast lead times.

Common Carbon DLS™ applications

Carbon DLS™ is often used for end-use parts because it produces high tolerances and smooth surface finishes. The speed of the Carbon DLS™ 3D printing process makes it an attractive option for rapid prototyping.

- Custom medical devices

- Medical grade surgical guides

- Automotive under-the-hood components

- Rapid tooling

- Tear resistant wearables

- Industrial components

- Complex end-use parts

- Higher volume production of small parts

Are you ready to experience the future of precision digital manufacturing?

Put our team to work for you and transform your production processes with smart Carbon DLS strategies and unmatched part quality.

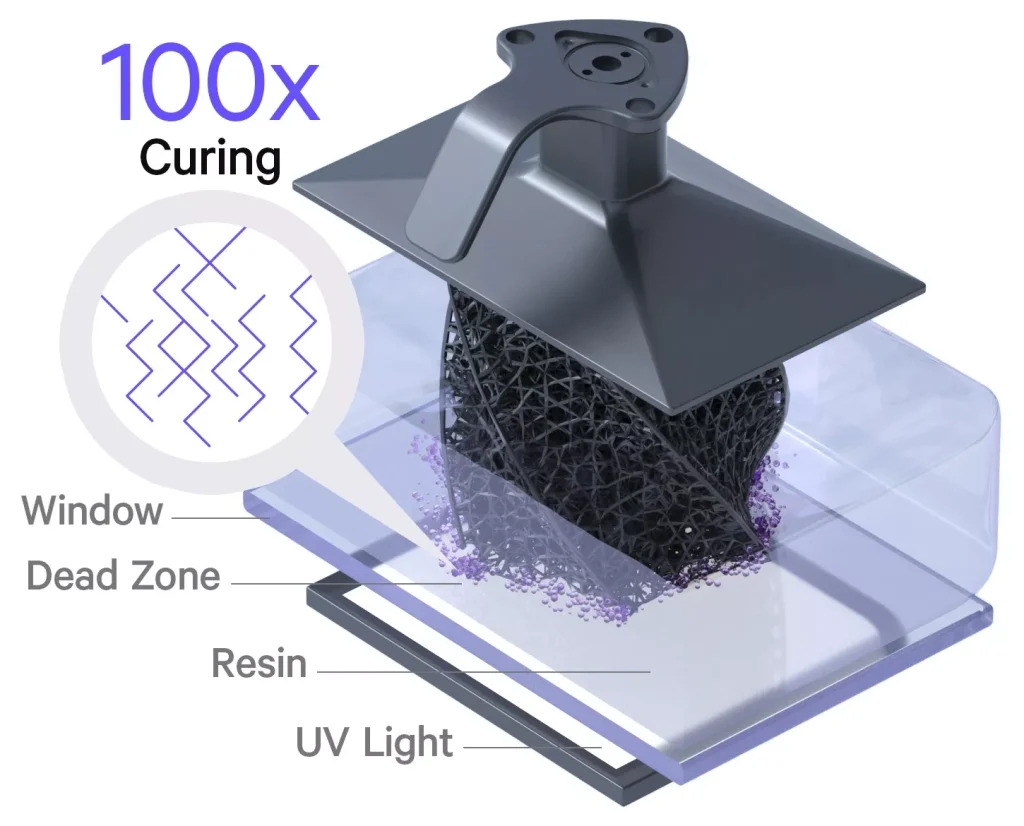

What is Carbon DLS™ Technology?

Carbon DLS™ is a resin-based polymer process that uses light and heat to create parts with isotropic properties, complex geometries, and excellent surface finishes. Carbon uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution, and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). DLS offers a wide range of production-grade materials, allowing engineers to build end-use parts right off the printer. Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

The Carbon DLS™ Process

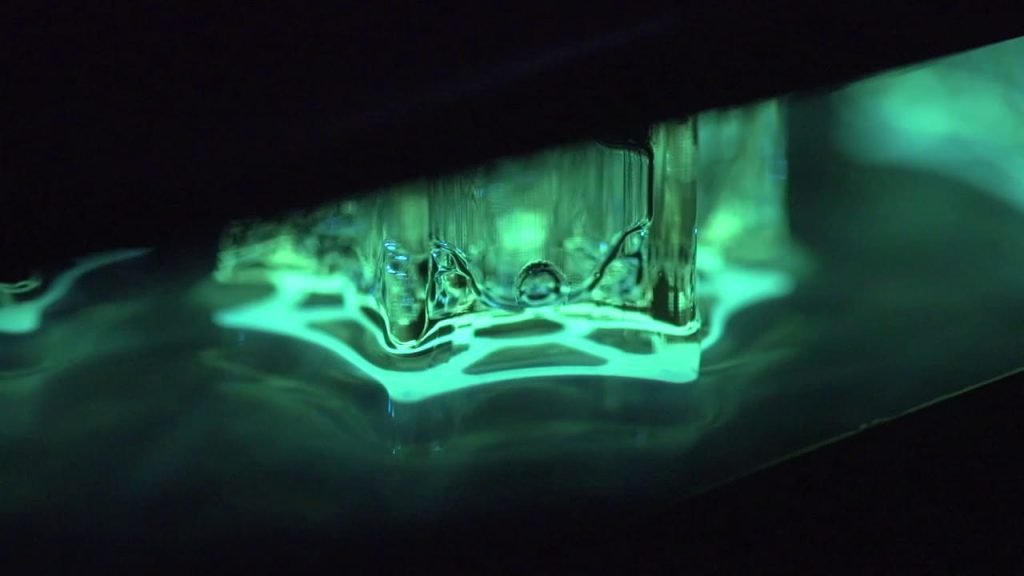

Digital light projection: UV light shapes the part

The Digital Light Synthesis process is driven by Carbon’s groundbreaking Continuous Liquid Interface Production™, or CLIP™. CLIP is a photochemical process that cures liquid plastic resin into solid parts using ultraviolet light. It works by projecting light through an oxygen-permeable window into a reservoir of UV-curable resin. As a sequence of UV images is projected, the part solidifies, and the build platform rises.

Oxygen-permeable optics: fast printing via the "dead zone"

The heart of the CLIP process is the “dead zone”—a thin, liquid interface of uncured resin between the window and the printing part. Light passes through the dead zone, curing the resin above it to form a solid part without curing the part onto the window. Resin flows beneath the curing part as the print progresses, maintaining the “continuous liquid interface” that powers CLIP and avoiding the slow and forceful peeling process inherent to many other resin-based printers.

Dual-cure materials: mechanical properties set by heat

Traditional resin-based 3D printing processes produce weak, brittle parts. Carbon overcomes this by embedding a second heat-activated programmable chemistry in our materials. Once a part is printed on a Carbon printer, it’s baked in an oven. Heat sets off a secondary chemical reaction that causes the materials to adapt and strengthen, taking on exceptionally strong characteristics. This produces high-resolution parts with engineering-grade mechanical properties.

Advantages of Carbon DLS 3D Printing

- Wide range of elastomeric and rigid engineering-grade materials

- Biocompatible and sterilizable materials

- Reduce time to market

- Isotropic parts, air-tight and leak-proof

- Outstanding surface finish

- Smart equipment for industry 4.0

Carbon DLS Build & Design Guidelines

Carbon DLS offers amazing part details and quality, but each 3D printing technology ranges on what size features it can build. See below for best standard practices.

- Build Layers = Standard is 0.004” (100 micron) but can reduce to 0.001”-0.002” (25-50 micron)

- Minimum Walls Thickness & Feature = 0.040” (1mm)

- Standard Finish = Level 1 Support Removal Finish (available custom finishes)

- Standard Lead Time = 3-5 days

- Tolerances = +/- 0.005” for first inch then +/- 0.002” per inch thereafter

- Inserts = Preferred for threads; install in post-processing with heat stake or adhesives

- Holes = Drill, Ream, and Tap (Print threads then chase or ream in finishing)

This table depicts the general tolerances for Digital Light Synthesis™. Stresses during the build, support strategy, and other geometry considerations may cause deviation in tolerances and flatness. Improved tolerances may be possible with a manual quote review, after successful completion of a prototype build, and must be approved on a case-by-case basis. General tolerances apply before secondary finishing or post-processing unless otherwise specified. Please check out Elimold’s Manufacturing Standards for more information on tolerances per process.

Why the Carbon DLS™ Process?

Accelerate every step of product development

Rapid Design Iterations

Test dozens of designs in the time it used to take to try one.

Functional and Rapid Prototyping

Don’t settle for fragile prototypes. Bring your designs to life with the industry’s best materials, then start testing and iterating immediately.

Scale to Production

Seamlessly transition into production while still being able to revise your designs immediately and without retooling. Scaling has already been done by leading brands like Adidas, Specialized, and fizik.

Find the perfect design for your application, not a mold

Undercuts and Undrafted Walls

Moldability constraints don’t apply here. Enjoy the freedom of designing with undercuts and perfectly straight walls without sacrificing manufacturability.

Performance-oriented Lattices

Lattices allow you to specify your required characteristics at every millimeter. Determine your product’s ideal mechanical response and leverage Carbon Design Engine™ software to generate the right lattice for it.

Consolidated Parts

A single printed part frequently offers better mechanical performance than an assembled one. Streamline production with reduced SKUs and less labor by consolidating assemblies.

Discover new aesthetics

Customization

With no tooling costs, you’re free to make every unit unique. Offer personalized designs, or build entire products around individuals.

Surface Design and Textures

Enhance your parts by applying textures to complex curved surfaces like grips and enclosures with Carbon design software.

Other 3D Printing Services

If you are new to our 3D printing services and are unsure which additive technology is best for your 3D design, explore the capabilities of each of the different 3D printing services below to determine the option that best suits your application needs.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Fused Deposition Modeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Micro 3D Printing

Metal Binder Jetting

Selective Laser Melting (SLM)

Ceramic 3D printing

Metal 3D Printing

On-demand CLIP (DLS) 3D Printing Service

Elimold provides you the best online 3D Printing Services for your resin parts. Thanks to our expertise in CLIP (DLS) technology, you can choose between several options, instantly receive a quote, and let us handle the manufacturing in our ISO 9001 certified factory.Start using CLIP (DLS) today by uploading a 3D file.