Direct Metal Laser Sintering (DMLS) 3D Printing Services

Metal parts made with DMLS 3D printing technology are stronger and denser. Custom parts can be made without tooling, and design changes can be implemented quickly. This allows parts to be manufactured overnight and put into use within days, helping you get to market first with faster turnaround times. Contact us now for a free instant quote.

Professional Direct Metal Laser Sintering (DMLS) 3D Printing Manufacturer

Are you developing a new product? Are you under pressure to get it to market quickly? Do you need to verify the fit and surface finish of your metal parts, but are not ready to manufacture expensive tooling and fixtures?

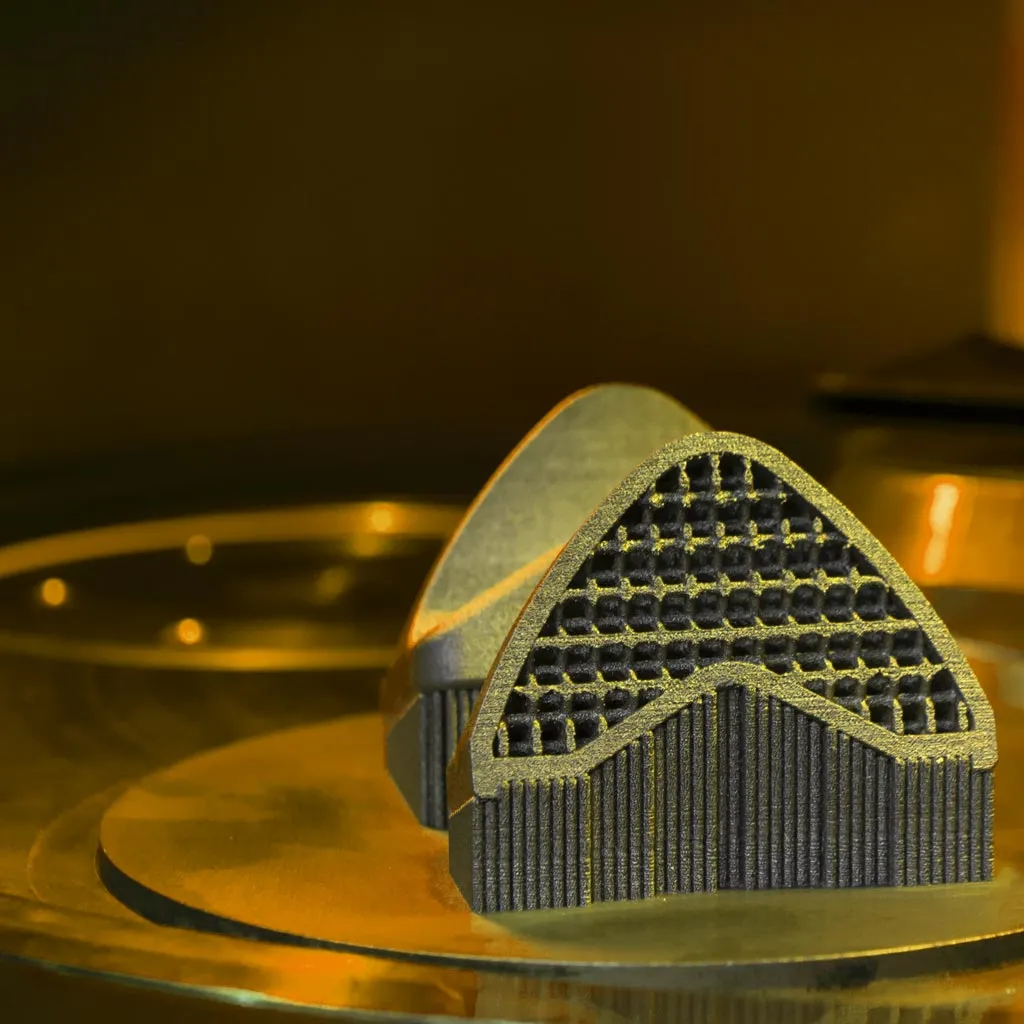

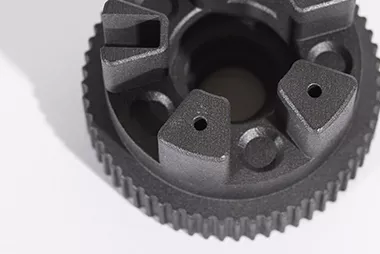

Direct Metal Laser Sintering (DMLS), also known as Direct Metal Printing, is a metal additive manufacturing technology that can help you solve this problem and accelerate your time to market. It is ideal for the production of prototype parts and bridges. Designers often choose DMLS technology because of its ability to produce one-piece metal components and high-precision metal parts with complex features such as internal supports and grids. DMLS requires no upfront setup or tooling costs, making it an affordable option for designers who need high-density metal parts with the design freedom of additive manufacturing. With the affordability, speed and superior design freedom of DMLS, companies and creators can build metal designs they never thought of and produce accurate metal parts.

Elimold's DMLS 3D Printing Factory

We offer high-quality DMLS 3D printing services with unmatched capacity, professional engineering support, and cutting-edge technology. With over 70 industrial-grade DMLS printers, we provide fast lead times and scalable production capabilities to deliver DMLS 3D printed parts in 3-5 days, whether you need a single prototype or a full production run. Our advanced Direct Metal Laser Sintering (DMLS) technology enables you to create high-quality, dense metal parts. Ideal for complex geometries and functional prototypes, this technology brings your metal concepts to life with unmatched precision and material properties. Upload your CAD file to the Elimold instant quote engine to get instant quotes covering a variety of DMLS 3D printing manufacturing options.

Our Manufacturing Capabilities

Elimold’s DMLS service is a powder-based micro-welding process that ensures the highest structural integrity of printed parts. We pride ourselves on being able to achieve precise tolerances of +/- 0.005 inches, and for well-designed parts, we can typically achieve tolerances of ±0.003 inches (0.076 mm), with tolerance values increasing by ±0.001 inches/inch (0.001 mm/mm) for every additional inch. Please note that tolerances may vary depending on part geometry. Additionally, our manufacturing capabilities cover a wide range of build sizes, from compact, complex parts of 250 × 250 × 380 mm to large, high-performance parts of 500 × 280 × 350 mm. This flexibility enables the production of both delicate small structures and rugged, functionally optimized components for demanding applications.

DMLS Resolution (Layer Thickness) Options

Layer thickness refers to the height of each layer added during the additive manufacturing or 3D printing procedure, where multiple layers are stacked upon one another to create the final product The choice of layer thickness (resolution) directly impacts the visual aesthetics, overall properties, and strength of the end parts.Elimold offers three layer thicknesses:

Economy (>60 µm)

Standard (40-60 µm)

Fine (<40 µm)

On-Demand DMLS 3D Printing Services

Elimold is a leading provider of direct metal manufacturing services that can meet all your needs with short lead times. With modern in-house 3D printers and advanced software, we can help you scale production seamlessly. Whether it’s a single functional prototype or mass production, our on-demand DMLS manufacturing services can meet your needs. With over 45 industrial-grade materials available, join us today to turn your ideas into powerful products. Not sure where to start? Contact us today to get a quote and accurate estimate for your project.

Online DMLS Printing Service

With our online DMLS service, you can take advantage of Elimold’s professional 3D printer equipment for prototyping and production without having to operate the machine yourself. In a few days, you can get a fully functional 3D printed metal part that is ready for immediate use or integration into a larger object.

Like other metal 3D printing technologies, DMLS is also suitable for small batch production. In this case, it is recommended that you contact our metal 3D printing team directly. We combine design, engineering and finishing to meet your project needs. You only need to focus on creating the best design that best meets your needs.

Brings Your Designs To Life With Advanced DMLS Manufacturing

Do you have a great idea but don’t know how to bring it to life? Our engineering and design innovation team offers 3D modeling services to help you create a mock-up of your product, and 3D printing services for testing. No need to look for a complete product design. Elimold will ensure the success of your project from start to finish. We’ll oversee its seamless transition to a 3D printable rapid prototype. Then you can thoroughly test the fit, form, and function of your model. Our engineering and design teams will tweak, simulate, analyze, 3D print, test, and repeat until you achieve perfection.

Ready To Start Your Project?

Contact a DMLS 3D printing expert today! Our team is standing by to answer your questions or provide a quote for your project.

Direct Metal Laser Sintering Solutions

Elimold produces lightweight, complex and functionally optimized metal parts using Direct Metal Laser Sintering (DMLS) and precision CNC machining. Our hybrid additive + subtractive manufacturing approach ensures parts meet the highest standards of precision and durability in demanding industries.

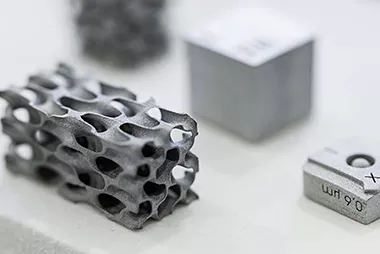

DMLS parts are typically characterized by strength, hardness and durability that is at least comparable to comparable metal cast or forged parts. In many cases, the rapid solidification rate after laser melting results in a very fine crystalline structure that is much stronger than forged or cast parts. After heat treatment, it has even higher density, durability and strength. Due to its superior quality and unique manufacturing process, part design freedom is increased, including hollow or filled structures to achieve a higher strength-to-weight ratio.

From Prototypes To High-volume Production

Our Direct Metal Laser Sintering (DMLS) printing service produces custom metal parts directly from your CAD data. This exciting process allows you to produce metal parts with challenging geometries that are impossible to create with traditional subtractive manufacturing or casting techniques. Parts can be made from a variety of dense and machinable metals. From rapid prototypes to high-volume production runs of up to 20,000 units, we can print. Not sure where to start? Contact us for an instant quote and accurate estimate for your project.

Low-cost DMLS 3D Printing

DMLS printing allows you to create highly complex and fully functional parts that are impossible to manufacture with traditional machining or casting. DMLS technology can produce ultra-light geometries optimized for performance, ultra-light “one-piece” metal components with internal features, supports and lattice structures, and fully dense metal parts. The DMLS technology used by Elimold can produce metal parts in a wide variety of shapes using a variety of metal powders. Many “super alloy” materials can be processed with DMLS, which are extremely hard and expensive to manufacture using traditional manufacturing methods. Using DMLS to produce these types of parts can significantly save time and cost, and can produce “net-shaped” parts that require little to no secondary finishing or machining.

Quality Management And Production Process

We offer a complete contract manufacturing service and qualification route that we have developed in conjunction with the standards ASTM/ISO F3301 and FF3302. Our QMS quality management system allows us to manufacture repeatable and reliable metal parts. As part of our production manufacturing process we can offer:

- Process control documents (PCD)

- Powder certification and analysis (batch control, size distribution and chemical analysis)

- Machine certification (calibration certified, in-build laser power monitoring)

- Quality reports from each build

- Mechanical testing

- Physical analysis, including porosity and density, surface and dimensional analysis

- Heat treatments certification (reports from our fully instrumented in-house inert gas box furnace)

- Advanced heat treatment certification, hot isotonic pressing (HIP) (full cycle reporting from certified heat treatment facility, customised cycles available)

Quality Controls And Functional Testing

Coordinate Measuring Machine - CMM

Involves using a Coordinate Measuring Machine to measure the geometrical characteristics of an object with high precision.

2D X-ray Inspection

Employs X-ray imaging to examine the internal structure of objects, identifying defects and ensuring structural integrity.

Computer Tomography scan - CT scan

Uses computed tomography to create detailed cross-sectional images of an object, allowing for in-depth inspection of its internal features.

Density Test

Measures the density of materials to ensure they meet specified standards and quality requirements.

Leakage Test

Checks for leaks in sealed systems or components to ensure they are airtight and function properly.

Pressure Test

Subjects parts to pressure to verify their strength and integrity, ensuring they can withstand operational conditions.

Blue Light 3D Scanning Technology

Our 3D scanners use Coherent Scanning Interferometry (CSI) to perform surface height measurements on parts using spectral broadband (“blue light”) illumination. 3D scanning is also a useful tool for FEA analysis, reverse engineering, obsolete part remanufacturing, and quality assurance measures. Elimold uses its 3D scanners to inspect each part to ensure that it meets specifications.

Industrial Engineering and Design Services

We can provide comprehensive engineering and design solutions. With our extensive experience in additive manufacturing and traditional technologies, we can provide you with a complete project preparation service from concept to mass production. We are committed to optimizing costs, quality and on-time delivery. In addition, through reverse engineering, we can transform your solid model into a digital 3D model as a basis for production or further use. This process is ideal for refurbishing existing parts, upgrading obsolete technology or creating digital archives. We use advanced technologies such as topology optimization and generative design to reduce the weight of parts or the number of components. This improves production efficiency and reduces production costs. And apply advanced technology and engineering solutions. From dedicated devices to complete automation systems, we are committed to ensuring that each project meets the specific needs of our customers.

Reverse Engineering Services

We help individuals, companies, and entrepreneurs turn their visions into reality using cutting-edge 3D scanning technology and advanced reverse engineering workflows. Whether native CAD never existed, your design files were hijacked, or you simply found a component or shape you want to incorporate into a larger assembly you are designing; we have the reverse engineering tools and workflows to achieve your goals.

Ready to Transform Your Ideas?

Discover the unmatched precision and speed of our advanced manufacturing solutions. Elevate your project today with our cutting-edge technology and expert team.

What Is DMLS?

DMLS (Direct Metal Laser Sintering) is an additive manufacturing method. It additively manufactures parts by sintering fine metal powder particles, locally fusing them together. Like the SLS process, your metal part will be created layer by layer according to your 3D model. The main difference is the sintering temperature. Polyamide needs to be sintered at a temperature of 160°C to 200°C, while the melting temperature of metal is about 1510°C to 1600°C, which means that a higher wattage laser is needed to reach this temperature.

First, the roller is coated with a layer of metal powder, then the laser sinters the powder according to the 3D file, then the build platform is lowered and a new layer of powder is applied… This process is repeated until the desired part is created. Once completed, the metal part needs to cool before it can be removed. If the metal part requires supports, these will be removed manually.

Advantages

Printed parts with DMLS technology are durable, lightweight and precisely detailed.

- Print complex geometries with strong and durable components

- Rapid prototyping with high quality and high accuracy- ideal for functional testing

- Create complex shapes, intricate details and delicate features

- Reduce cost & development time by consolidating parts, no tooling required

- Build parts in a matter of hours

Material Selection

Common materials used to produce DMLS parts include:

- Scalmalloy

- Stainless Steel 17-4PHL

- Stainless Steel CX

- Ti6Al4V

- Ti64ELI

- Stainless Steel PH1

- AMZ4

- Cobalt-Chrome MP1

- Stainless Steel 316L

- Titanium Ti64

- Aluminum AlSi10MG

- Nickel Alloy IN718

- Nickel Alloy HX

- Nickel Alloy IN625

Finishing Options for DMLS Parts

Elimold’s commercial 3D printing services offer a variety of in-house finishing options for DMLS parts. Our experts can also meet any of your outsourced finishing needs. Parts made with DMLS machines have an original rough surface comparable to precision investment castings. The surface roughness is approximately 350 Ra a-µ inches (or Ra a-µm 8.75), or a medium turned surface. This surface roughness can be improved to up to 1 Ra a-µ inch (or Ra a-µm 0.025), which is a super-mirror finish.

Elimold offers these post-processing DMLS services:

- Sanded

- Tumbled

- Media blasted

- Polished (with clearcoat)

- Electrochemically polished

- Painted (EMI shield)

- Painted (sand and paint, non-cosmetic)

- Painted (sand and paint, cosmetic)

- Painted (customer spec paint)

- Specialty coating

- Plated

- Decals

- Pad printed

- Screen printed

- Inserts

- Post-machined

- Assembly

- Abrasive flow machining

- Heat treated

- Passivated

- HIP

Improve surface roughness or finish

- Abrasive blast (grit and ceramic)

- Shot peen

- Optical polish

- Electrochemical polishing

- Abrasive flow machining (extrude hone)

- Electroplating

- Micro machine process (MMP)

- CNC finishing/machining

Post Processes

There are a large variety of secondary services that can and in some cases should be performed depending on the alloy being printed.

For Heat Treatments:

- Hot Isostatic Pressing (HIP)

- Solution Annealing

- Aging

- Stress Relieving

- NADCAP

For Powder Analysis:

- Chemistry

- Particle Size Analysis

- Traceability

For Testing:

- Tensile Bar Pull

- Rockwell Hardness

- X-Ray

- Stress Testing

Parts Assembly Service

For custom parts produced by DMLS 3D printing, many features can usually only be achieved by assembling different parts. Generally speaking, the assembly process will incur many hidden costs. Each component in the assembly has a specific geometric intent that must be communicated. Written documentation is required for each component from procurement to production. Once the parts are completed, they must be individually inspected and then shipped. Afterwards, the individual components must be brought together for assembly. For precision parts, complex assembly aids, fixtures and jigs are often required. With proper consideration of the design for additive manufacturing, metal components can often be redesigned and additively manufactured as a complete, high-density metal printed part. Therefore, utilizing the custom parts assembly service provided by Elimold can reduce the capital cost required to bring a product to market and achieve higher functionality and fewer failure modes.

When to use DMLS

For high volume production of highly complex geometry (not possible by MIM or die casting), investment casting with 3D printed pattern will be more economical.

- Functional, end-use parts

- Prototyping in production grade materials

- Low volume production (Qty < 250)

- Highly complex geometry which is impossible to generate through CNC machining

- Lattice structure metal part for weight reduction

- Specific requirement such as high temperature performance, corrosion resistant, etc.

What manufacturing processes can DMLS be paired with?

DMLS parts are dense and have mechanical properties similar to castings. If tight tolerances are required, DMLS parts can be 3D printed to near-net shape and then machined to meet tolerance requirements. Once a part is produced using direct metal printing, it can be refined using common processes for finishing metal parts, including sandblasting, metal plating, micromachining, and polishing. CNC machining can also be used to add holes or threads to a part. Titanium alloys are notoriously difficult to machine. For applications that require both lightness and high strength, the DMLS process can produce strong, lightweight parts from this specialty material.

Limitations of DMLS 3D Printing

Due to the generally high machine and material costs, this technology is not usually suitable for high-volume production. Design is also a limiting factor when using DMLS. This is because not all applications designed using traditional manufacturing techniques can be converted to an additive manufacturing solution. When using DMLS, the greater limitation is product size. Most machines, even the larger ones, have a small build volume. The average build volume offered by many suppliers is 250 mm x 250 mm x 300 mm. In addition, the machines are complex to use, come in a variety of sizes, and have strict operating, material handling, post-processing, and maintenance procedures.

High-Performance Metal 3D Printing for Complex Parts

Metal 3D printing with Direct Metal Laser Sintering (DMLS) technology combines the freedom of additive manufacturing with the performance of machined metals, making it ideal for the production of low-volume, complex components that require fast turnarounds. By building parts layer by layer, DMLS enables complex geometries and consolidates multiple components into a single part, reducing material waste, tooling costs, and production time. The resulting components are dense and strong, comparable to traditional machined parts, while offering a wide range of alloy options for specific applications. Although post-processing may be required and printing speeds may be slower, DMLS’s on-demand production, rapid iterations, and design flexibility give it significant advantages in customization, efficiency, and innovation across a wide range of industries.

DMLS 3D Printing Service Partners

Through strategic partnerships, Elimold now offers DMLS services worldwide, leveraging more than a decade of material and process development experience with companies around the world to ensure your designs perform well in the most demanding environments. This allows your company to take full advantage of the specialty materials printed on our advanced platforms. And our one-stop supplier delivery can provide complete DMLS parts and meet the most stringent specifications. If your project requires custom metal parts with high quality standards, we can meet your needs. Elimold is actively seeking DMLS sintering contracts and provides one-stop solutions for the most demanding engineering projects around the world. Contact us today to discuss your project and join the DMLS manufacturing revolution.

Other 3D Printing Services

From concept to creation, Elimold offers a variety of 3D printing services, and our state-of-the-art digital manufacturing platform enables you to get instant online quotes, manufacturing and tracking for all your additive manufacturing (3D printing), rapid prototyping, low-volume production and mass manufacturing projects. Instant quotes, delivery from 24 hours onwards.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused Deposition Modeling (FDM)

Micro 3D Printing

Metal Binder Jetting

Selective Laser Melting (SLM)

Ceramic 3D printing

Metal 3D Printing

Laser Powder Bed Fusion Metal (LPBF-M)

What is the difference between DMLS and SLM?

DMLS and Selective Laser Melting (SLM) are both metal 3D printing processes that share many similarities: both use lasers to selectively fuse metal powder particles together and build a part layer by layer. Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) are often used interchangeably, with the main difference being that SLM heats the metal powder until it completely melts into a liquid, while DMLS only sinters the hot particles enough that their surfaces weld together. While there are some differences between the two processes, the general rules outlined in this DMLS design guide apply to SLM designs.

Is DMLS More Efficient Than SLM?

Their basic technology is the same, both use lasers to selectively weld thin layers of metal powder. But the difference lies in the details and experience. Elimold’s DMLS printers have been used to manufacture more than 500,000 metal parts. This experience is incorporated into a rugged metal 3D printer for repeatability, part quality, production efficiency and low total cost of operation (TCO). The removable print module (RPM) can be replaced in 1 hour and enables 24/7 uptime. The vacuum chamber controls oxygen (O2) levels to <25ppm, ensuring consistent part performance and full utilization of powder to minimize waste. When part quality, output and efficiency are critical, DMLS is the best choice for 3D printing metal.

When Should I Choose DMLS Over Other Metal Manufacturing Methods?

If a part is difficult to stamp, laser cut, or machine on a CNC machine (e.g., requires multiple setups, multi-part assembly, has complex geometry, curved internal flow paths), then it may be a good candidate for DMLS 3D printing. The design freedom provided by this technology allows you to optimize the design and functionality to fully utilize its process capabilities. For example, a previous case study by Elimold showed that a part used by a large aircraft engine manufacturer integrated approximately 15 separately manufactured parts into a single printed part. As a result, the DMLS-printed part was 25% lighter, improved through curved internal flow paths and optimized flow properties, more reliable, and significantly reduced life cycle costs.

Request Your Free DMLS 3D Printing Quote Today

After receiving your drawings, our engineers will analyze your custom Direct Metal Laser Sintering (DMLS) 3D Printing parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.