Metal 3D Printing service

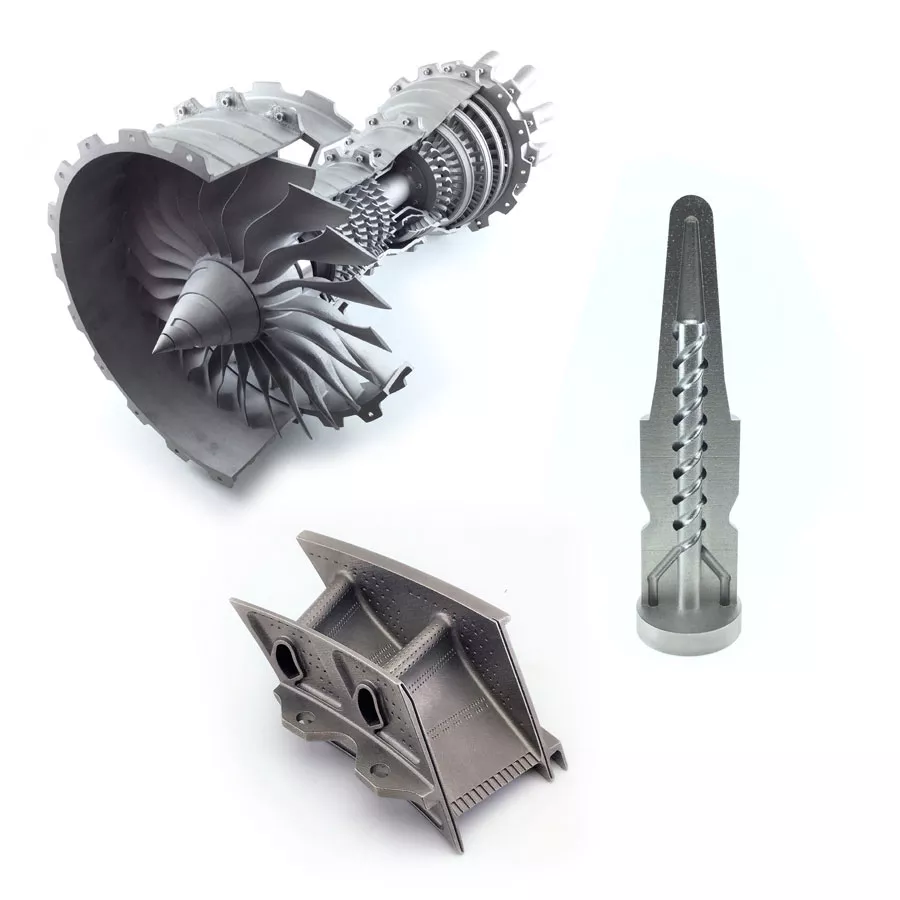

Elimold provides professional metal 3D printing services and designs, iterates and produces your complex metal parts at scale. Prototypes are the same as mass-produced parts, saying goodbye to complex product life cycles, achieving scaled production and gaining competitive advantages. You can communicate with our additive manufacturing experts for free to learn more, or upload your details to get a quote.

Professional Metal 3D Printing Manufacturer

Need to create top-quality metal 3D printed parts quickly? Want professional help to execute even the most complex manufacturing projects? Then the Elimold team can help you. We have many years of experience serving a wide range of industries that have impeccable quality requirements for metal printed parts and can easily handle even the most challenging manufacturing tasks. We have strong metal 3D printing capabilities and rich experience, and provide customized solutions. You can freely choose different metals and alloys to meet your needs. Whether your additive manufacturing needs are simple or complex, whether the quantity is small or large batches, with our various advantages of 3D printers, we can meet all your specific 3D printed metal parts needs and ensure that you get the highest quality parts in a short time.

Metal 3D Printing Factory

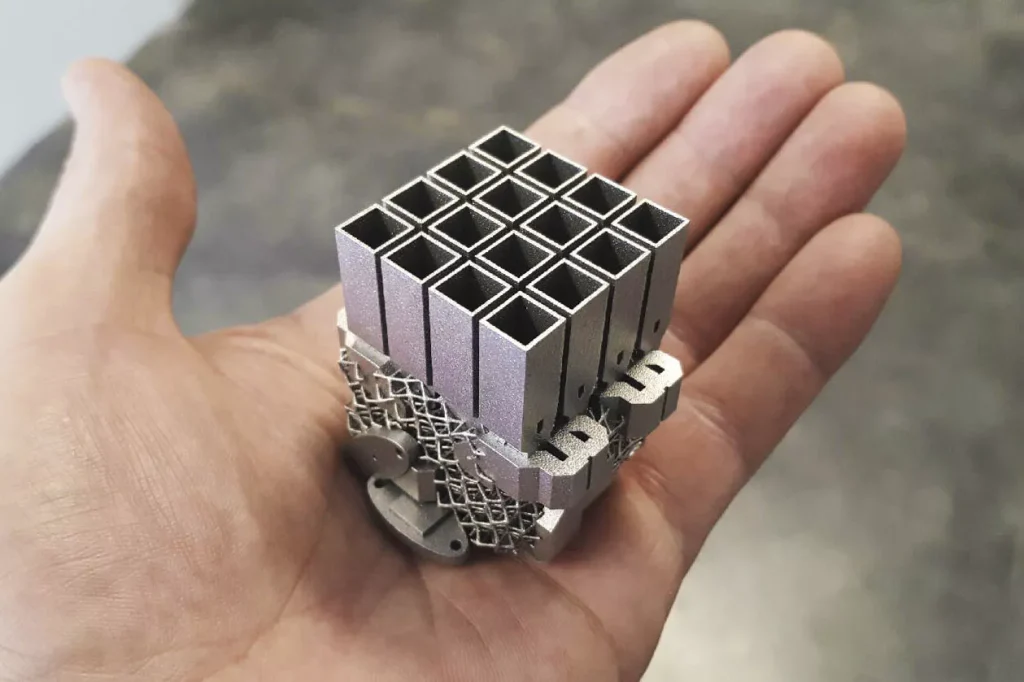

Elimold has multiple in-house factories in Shenzhen, China, staffed by an experienced team of engineers dedicated to meeting your specific requirements as efficiently and quickly as possible. You can trust us to meet all of your manufacturing needs. Each of our factories has over 100 industrial metal 3D printers of different types that can manufacture your parts in as little as 4 days. In addition, our experienced team of engineers can guide you through the DFAM process and can help you optimize your part design for production. We also offer a full range of in-house post-processing services for metal 3D printed parts. Contact us today to get a quote for your metal 3D printing project.

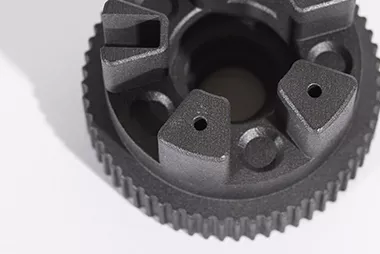

Our Manufacturing Capabilities

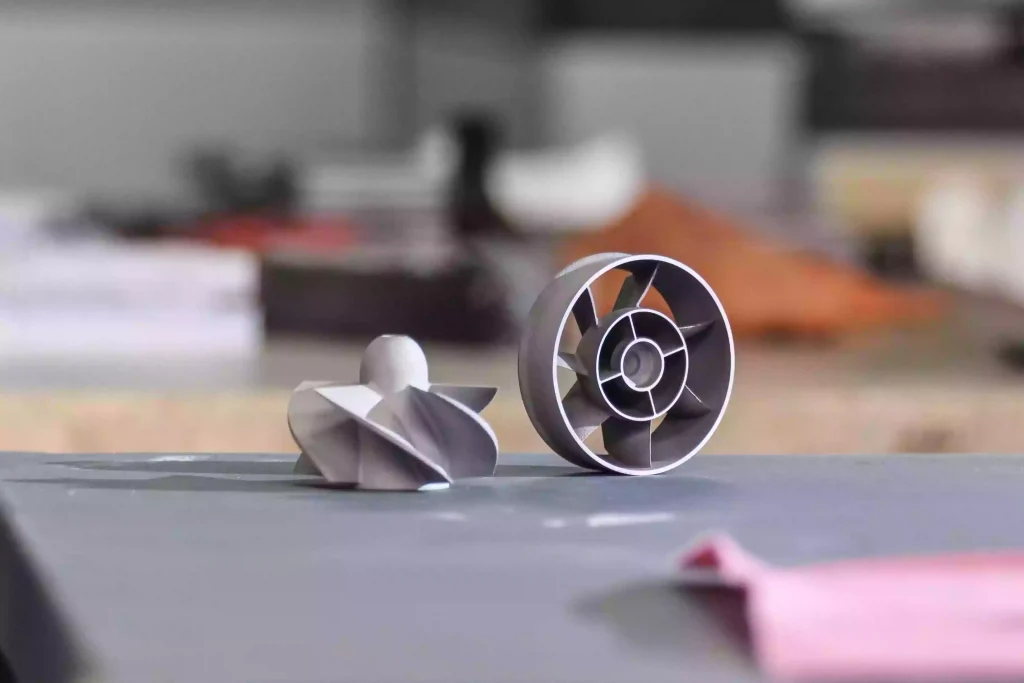

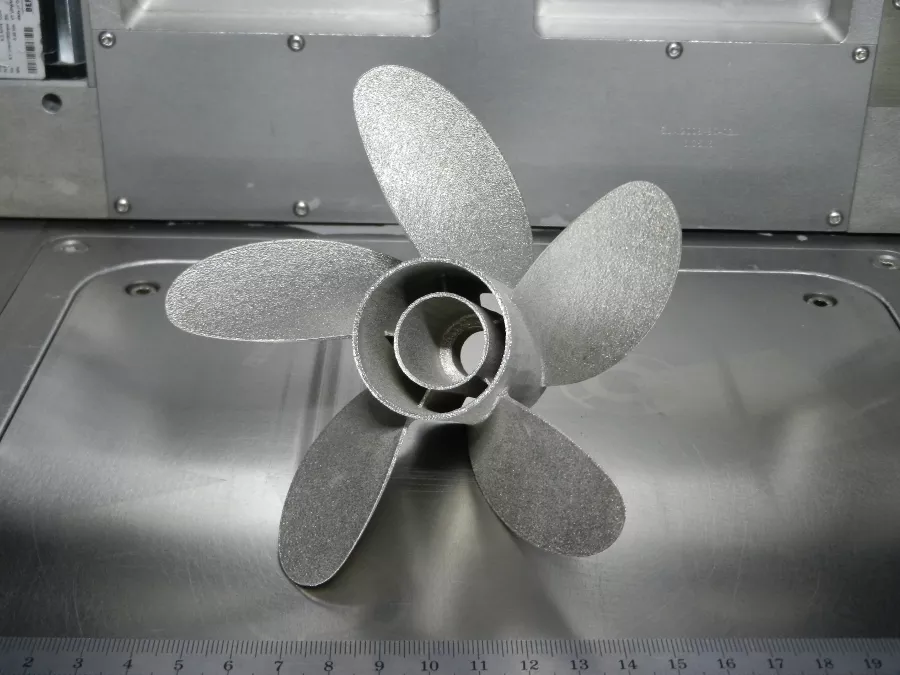

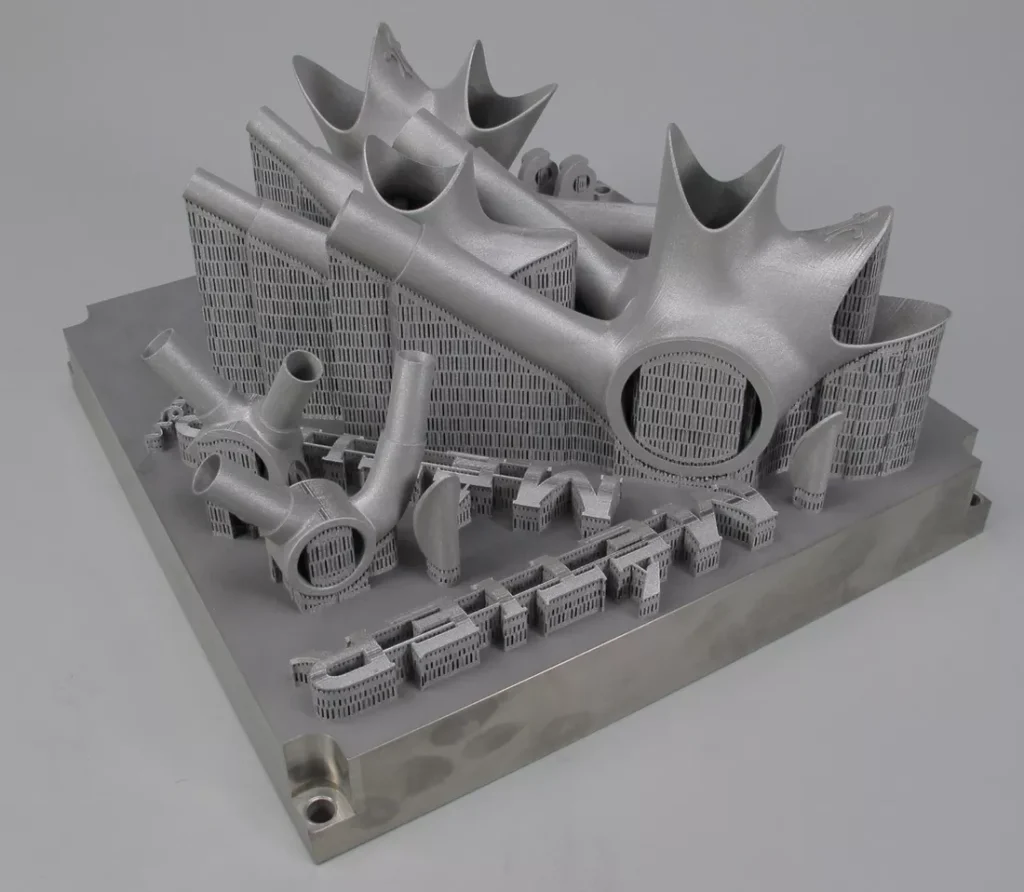

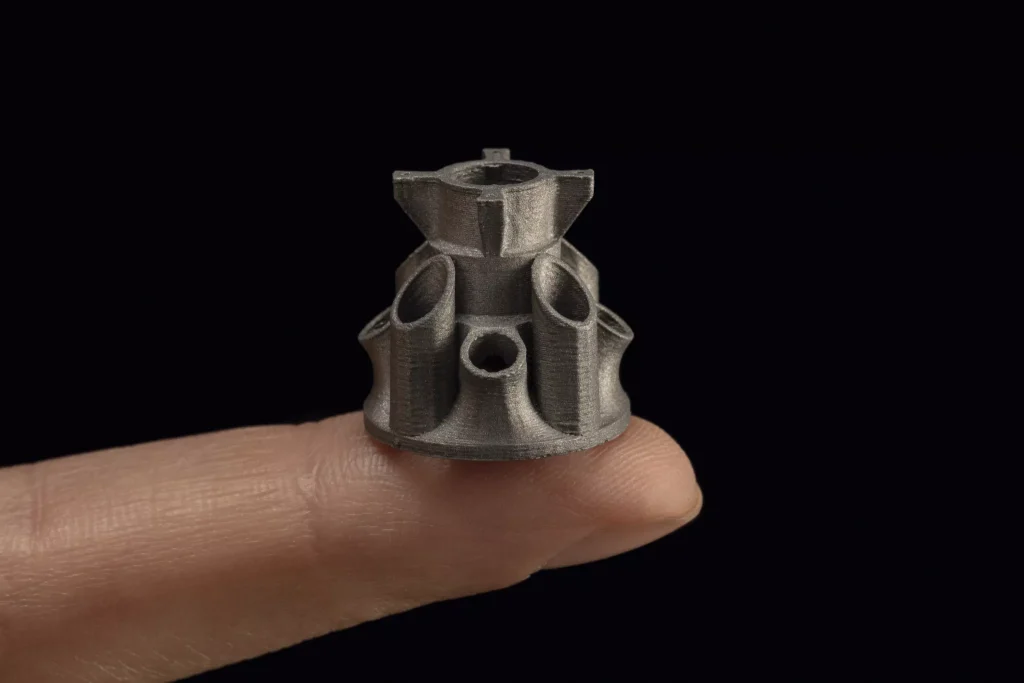

Our advanced metal 3D printers produce end-use parts with high resolution and uniform mechanical properties, comparable to traditional cast parts. We can produce large, complex parts up to 420 mm x 400 mm x 400 mm on an industrial scale. We do more than just make parts, we deliver value. Our designers and machinists assist customers through all workflows. Elimold has over 8 years of experience in metal 3D printing services. We have produced millions of metal models and have extensive experience in manufacturing complex parts. We control costs at every process to help you save money on metal printing. So whether you need a custom part or a regular production part, we can meet your needs. And we are constantly expanding our metal printing capabilities and processes, including new production sites and new printing technologies. Welcome to contact us to learn more about our 3D printed metal parts services.

Precision of Metal 3D Printing

We manufacture to an accuracy of +/- 0.05 mm. However, this depends on the design of the part, the print orientation, and the material. We recommend an actual accuracy estimate of +/- 0.2 mm per 100 mm. Also, the standard surface finish of 3D printed metal parts is slightly textured. On average, the surface roughness is about +/- 30 microns, which may be worse where supports are removed and better on some faces. Additional finishing may make the surface smoother. Also, we recommend a minimum wall thickness or feature detail of 0.5 mm. Generally speaking, circular holes and channels can be up to 10 mm thick before support structures are required, and changing the shape of internal channels can increase the thickness.

3D Printing Metal Parts Supplier

Elimold stands at the forefront of innovative manufacturing technology, providing cutting-edge metal 3D printing services. Our 3D metal printing services use advanced technologies to provide unparalleled precision and versatility for a wide range of industries. Committed to excellence, we are pioneers in additive metal printing, providing a seamless and innovative approach to manufacturing complex metal parts with extremely high precision. And our advanced metal 3D printing technology enables engineers, designers and businesses to create complex components that were once thought to be impossible through traditional manufacturing methods. So, no matter which industry you need parts for, our 3D printed metal technology can be customized to meet the various needs and expectations of our customers. From rapid prototyping to full-scale production, from small batches to large-scale metal 3D printing, our experts are ready to assist you in harnessing the strength and toughness of metal to turn your concepts into reality.

Start 3D Printing Metal Parts Directly

Contact us today to get started on your 3D printed metal parts project. Our engineers will review your design and get back to you in 4 hours or less with a quote and free project analysis.

Types of Metal 3D Printing

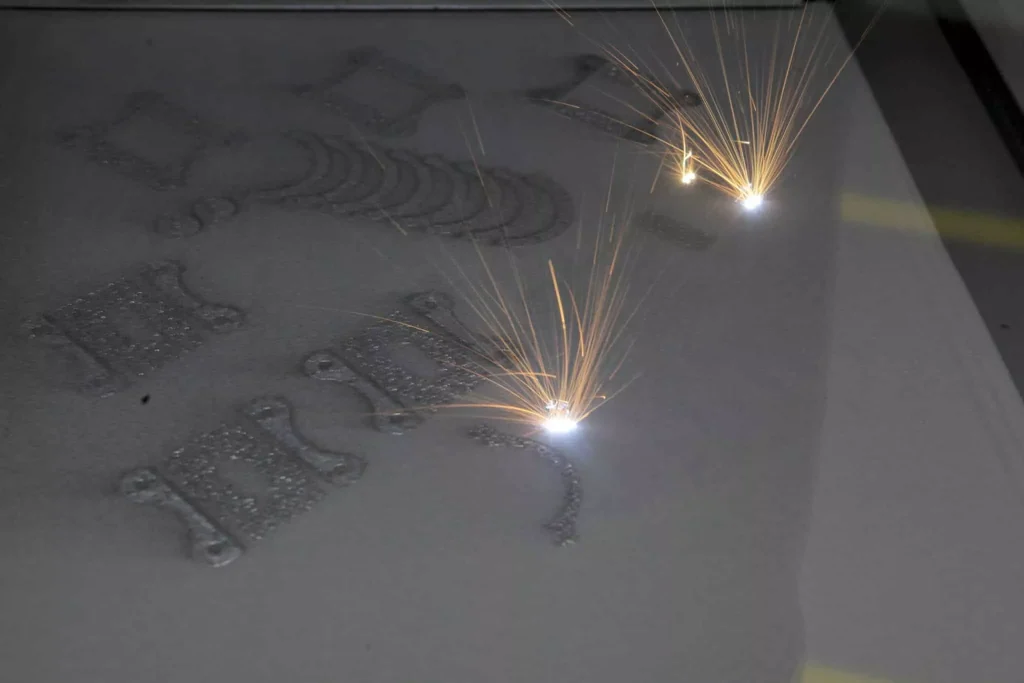

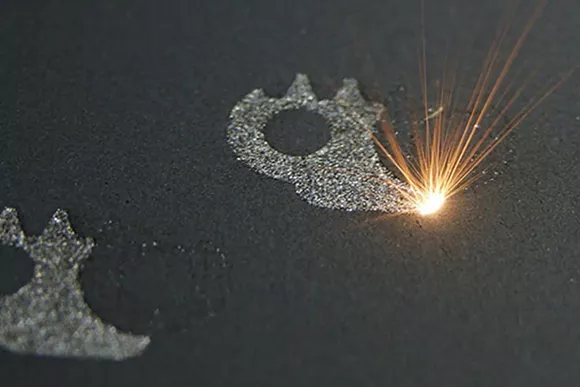

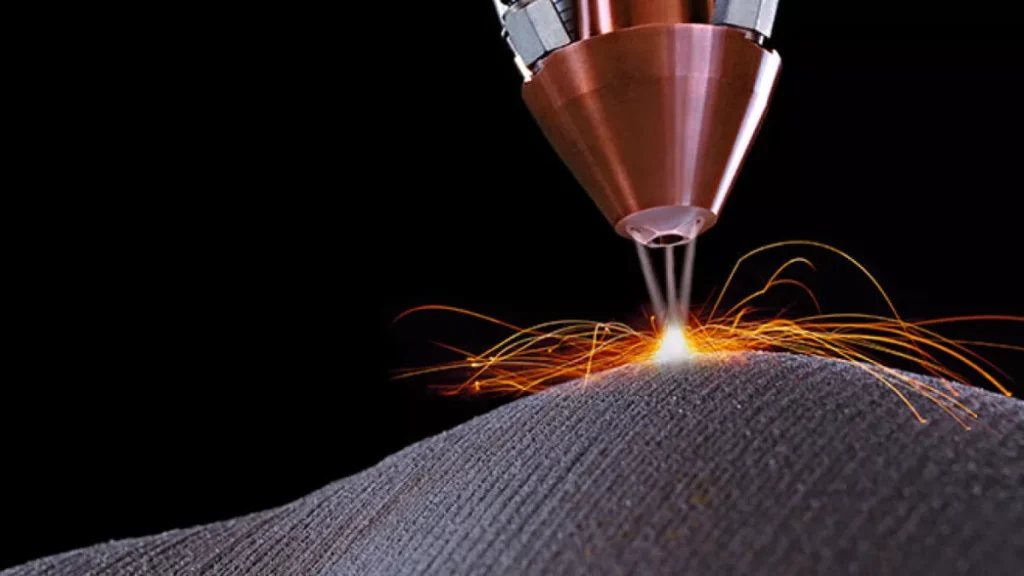

There are four main metal 3D printing technologies currently used in the industry: powder bed fusion, material jetting, binder jetting, and direct energy deposition. The most widely used metal 3D printing technology is powder bed fusion, of which direct metal laser sintering (DMLS) and selective laser melting (SLM) are the most common. The following are a variety of metal 3D printing services we commonly use.

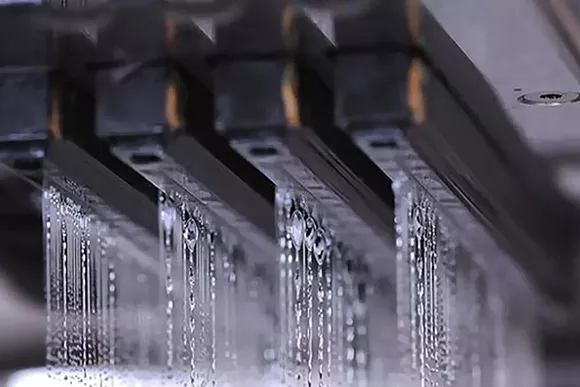

Binder Jetting Metal 3D Printing

Selective Laser Melting

Lost Wax Casting

Direct Metal Laser Sintering

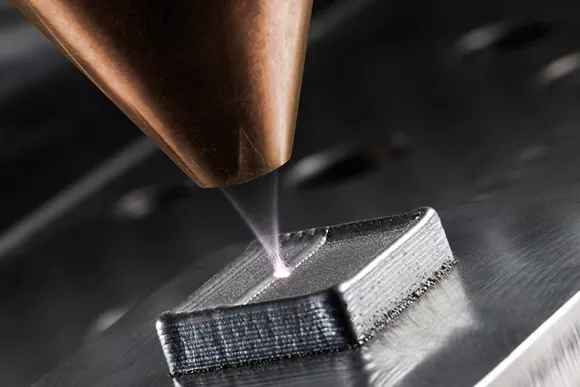

Metal 3D Printing Process

The metal 3D printing process typically involves the following steps:

1. Design Preparation

The process begins with the creation or acquisition of a digital 3D model of the desired part or component. Computer-aided design (CAD) software is commonly used to design or modify the model according to specific requirements.

2. Slicing

The 3D model is then sliced into thin, horizontal layers using specialized software. Each layer represents a cross-section of the final part and serves as a blueprint for the printing process.

3. Material Selection

A suitable metal material in powdered form is selected for the specific application. 3D printing of metal parts commonly uses stainless steel, titanium, aluminum, and cobalt-chromium.

4. Build Chamber

The 3D printer’s build chamber is prepared for the printing process. This may involve coating the build platform with a thin layer of material or applying a release agent to ensure easy removal of the printed part.

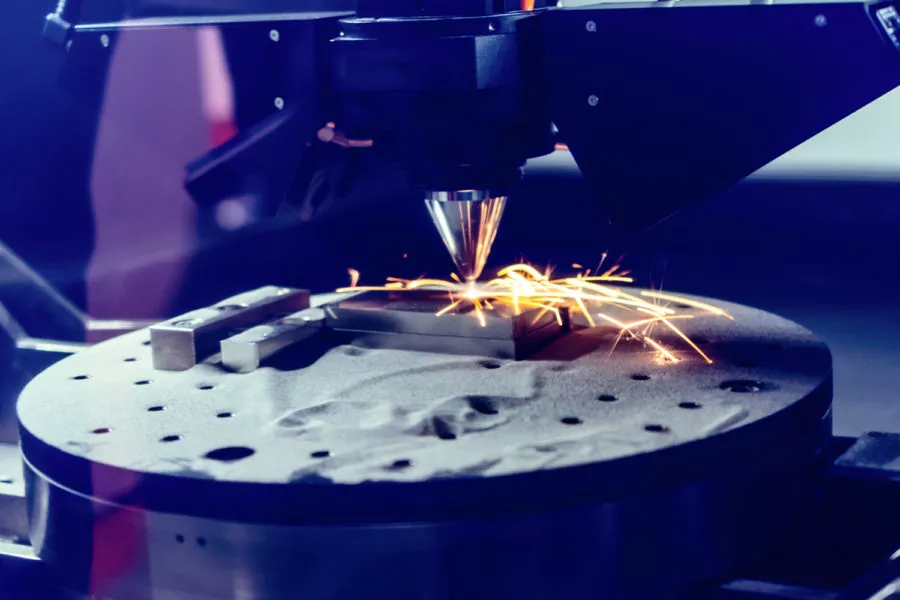

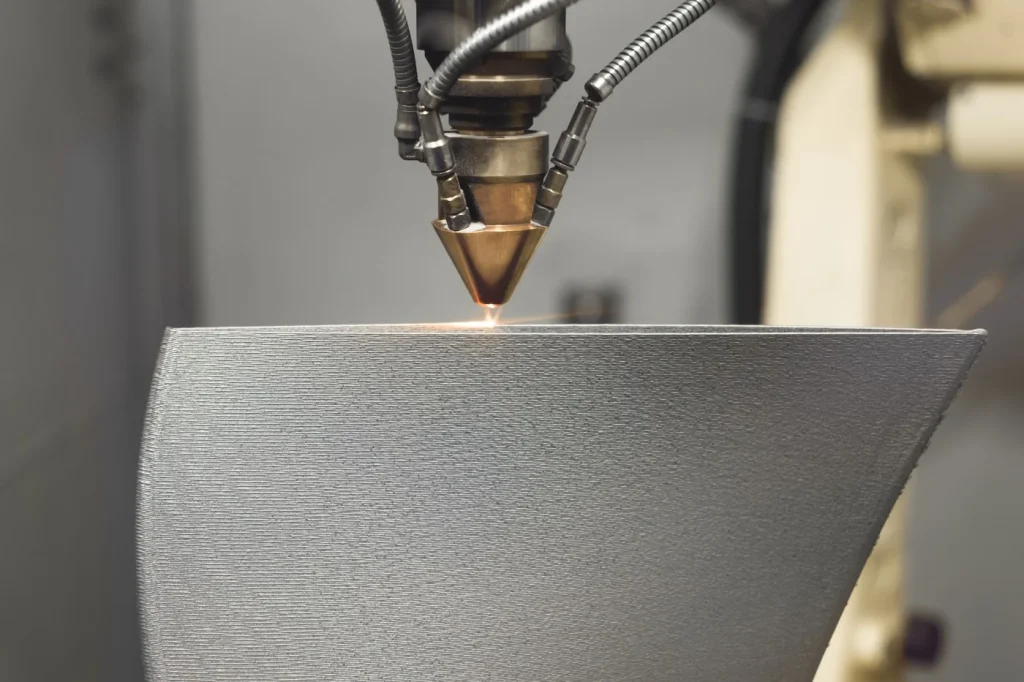

5. Printing the Part

Metal 3D printing utilizes various techniques, such as selective laser melting (SLM) or electron beam melting (EBM), to fuse the powdered metal material together layer by layer. A high-powered laser or electron beam selectively melts and fuses the metal particles according to the sliced design, creating solid layers.

6. Cooling & Support Structures

As each layer is printed, it is cooled and solidified before the next layer is added. In some cases, temporary support structures are printed alongside the part to ensure stability during the 3D metal printing process. These supports can be removed once printing is complete.

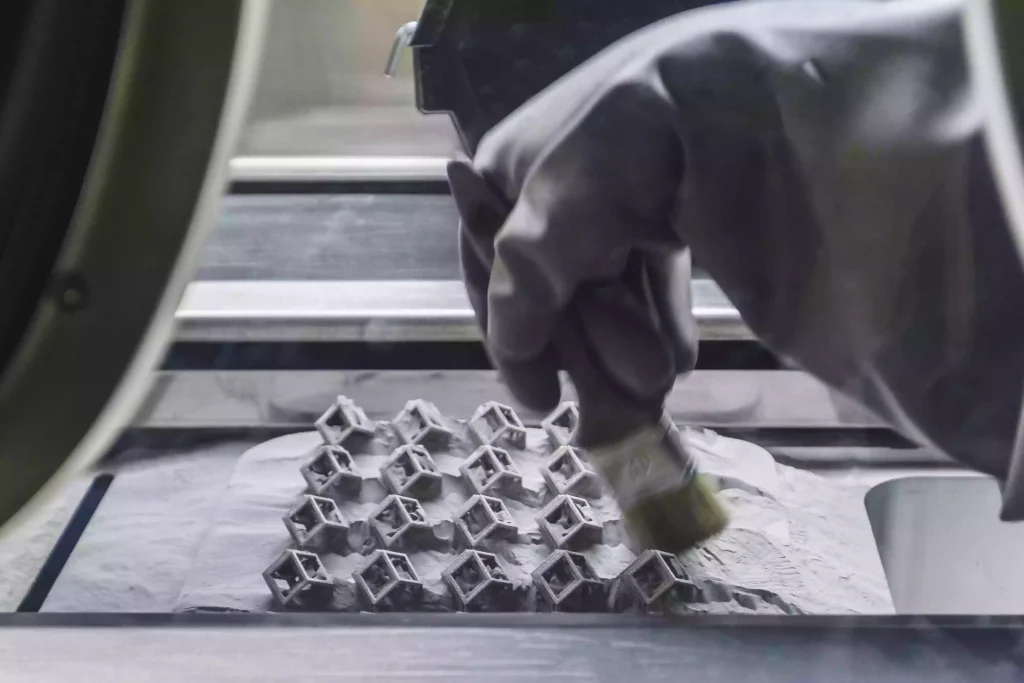

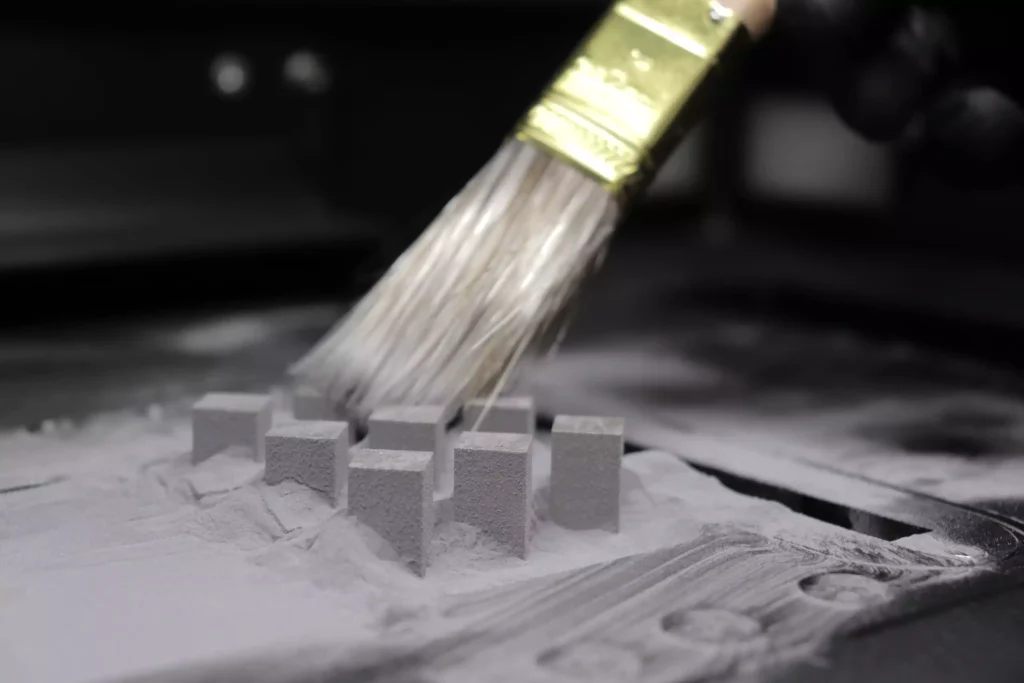

7. Post-Processing

After the printing is finished, the printed part undergoes post-processing steps. This may include removing support structures, heat treatment (annealing), machining, polishing, or surface finishing to achieve the desired final appearance and properties.

8. Inspection and Quality Control

The printed part is inspected and tested to ensure dimensional accuracy, structural integrity, and compliance with specifications. Various techniques such as dimensional measurement, non-destructive testing, and material analysis may be employed.

Your Preferred Metal 3D Printing Partner

Eilmold simplifies the process of finding the ideal manufacturing partner, ensuring smooth project execution and an excellent end result. Whether you need a prototype, custom part, or low-volume production, we make it easy for you to get a competitive quote. You can compare options and quickly select the ideal additive manufacturing service to make your metal 3D printing project a reality.

And, we pride ourselves on delivering unmatched quality, cost-effectiveness, and speed, making us the top choice for businesses looking to streamline production processes and shorten lead times. We’re more than just a service; we’re reshaping the future of manufacturing with high-quality metal 3D printing services. Choose us for your additive metal printing needs and experience the future of metal part manufacturing. Our commitment to quality, precision, and innovation ensures your project is in safe hands.

High Volume Production of 3D Printed Metal Parts

If you are looking to produce 3D printed metal parts in high volume, we have you covered. Our direct 3D metal printing service is the best choice for producing 100 to 1000 metal parts. For orders that are too small for die casting or metal injection molding, this new technology offers excellent value. Online direct custom metal 3D printing bridges the gap between existing technologies by providing a short lead time solution and direct custom manufacturing of metal parts without tooling, making it more flexible and economical than die casting or metal injection molding. Contact us today to request a quote and our engineers will review your design and send you a quote in 4 hours or less. Once your order is placed, lead time for metal 3D printed parts is typically 4-12 days.

Leading Metal 3D Printing Service Provider

Elimold provides AM consulting, part design and engineering, R&D solutions, prototyping and mass production manufacturing services. As a leading metal 3D printing service provider, we offer customized solutions based on industry needs. Value delivery and business results are always at the core of our solutions and services, supported by a strong quality framework. In addition, our metal 3D printing services ensure improved functional performance, better mechanical properties, superior topology and complex geometries to technically meet the overall requirements of the component. Do you need a bridge production? We can 3D print up to hundreds of production-grade metal parts for you. Even before your molds are manufactured, we can help you bring new products to market faster.

On-demand Metal 3D Printing Services

We work with businesses of all types and sizes to provide on-demand metal 3D printing services, helping them eliminate product backlogs and avoid supply chain issues. On-demand production improves efficiency, reduces lead times, and speeds up prototyping and metal additive manufacturing processes, creating a more agile supply chain. You can get your metal 3D printed products to market faster. And you can use our metal 3D printing services to gain rich customization opportunities while producing on demand. Another great advantage of our 3D printing technology is that all of our inventory can be managed through a single digital file, compared to traditional warehouses that store a large number of parts. Now you can get service by simply uploading a 3D model. And whether you need the parts shipped to yourself or a customer, Elimold can provide expedited shipping services.

Ready to get started on your custom metal 3D printing quote?

If you need help manufacturing your parts using metal 3D printing, we offer a free project consultation. Our additive manufacturing experts can recommend the best solution for your specific needs.

Comprehensive Metal 3D Printing Services

When you work with an outside company to manufacture custom parts, best-in-class engineering is essential. There are many factors involved in producing affordable and consistently high-quality parts, including part design, manufacturing methods, material selection, manufacturability, advanced prototyping, and efficient production process design. Therefore, hiring an inexperienced partner is risky. This can lead to part quality issues, cost overruns, and endless delays. It can also negatively impact your reputation as a supplier to your customers. Elimold’s in-house facility brings together decades of engineering experience and expertise across a wide range of metal 3D printing technologies. Whether your needs are prototypes, bridges, short-term or long-term part production, our team can help you turn your ideas into reality and streamline your supply chain with practical part design and manufacturing solutions. Expertise supports all your prototyping and production needs.

Design for Manufacturing Support

One of the many ways we apply our expertise is by offering free Design for Manufacturing support with every quote. With this service, our expert designers work closely with your team to optimize your product design for metal 3D printing. They know what challenges to expect based on the geometry of your part. They are intimately familiar with the pros and cons of each manufacturing method. They can help you achieve the perfect balance between design, material, manufacturing method, and finishing options to produce a part that meets all of your requirements and helps you avoid the headaches that can come with less structured methods.

Metal 3D Printing Solutions

We offer a full range of services including reverse engineering, process development, powder and substrate characterization, surface profile preparation, material application, post-processing, final machining and inspection. Elimold also provides services for part evaluation, verification and qualification through mechanical and physical characterization. All processes are controlled in-house to ensure product quality. We can provide you with the following services:

- Applicable part identification

- Reverse engineering/solid modeling

- Prototype and part manufacturing

- Physical/mechanical testing

- Design approval and qualification

- Equipment selection and conversion

- Modeling and simulation

- Plastic fused deposition modeling

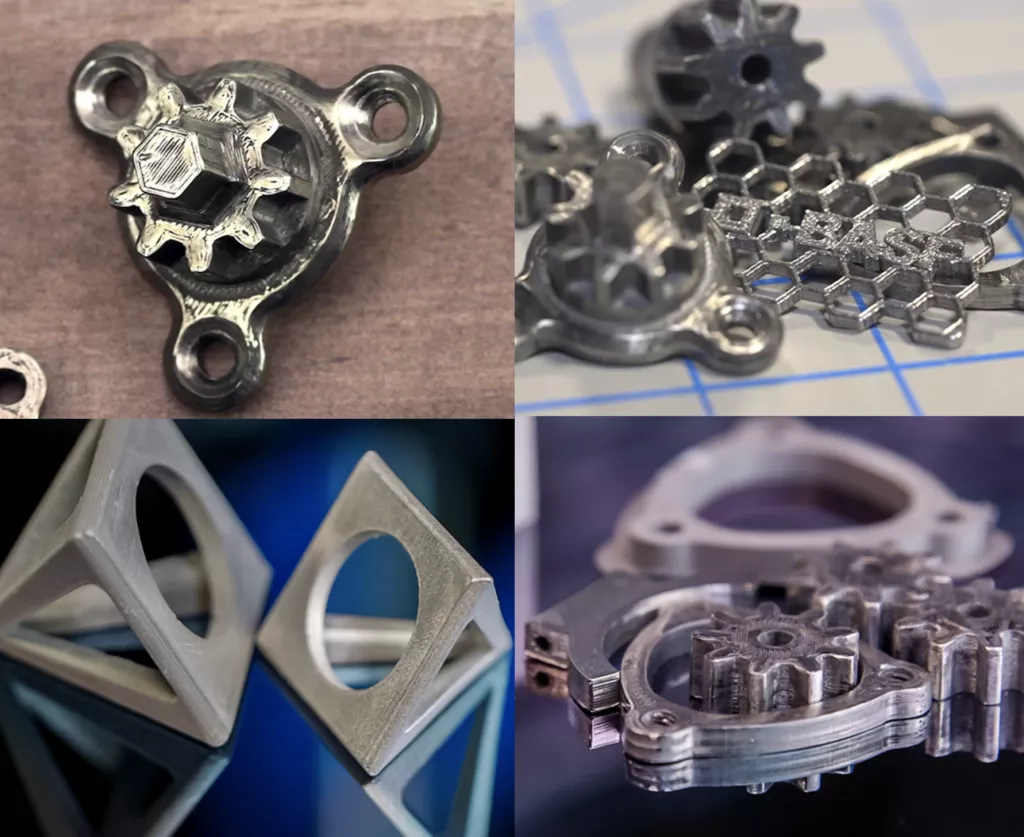

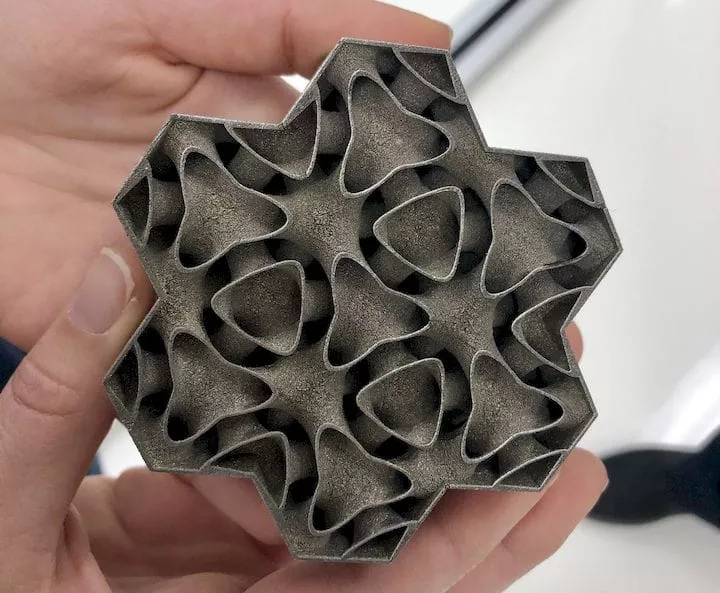

Design Freedom

There are virtually no limits to the design of metal 3D printed parts. Any design can be converted into a 3D CAD model and printed as a physical part, as long as it is within a certain size range. This opens up a wide range of possibilities, including opportunities for design optimization and rapid prototyping. Speed and design freedom bring the ability to quickly validate and develop design ideas, such as tweaking a design, quickly printing a prototype and testing its functionality. The main benefit is that you can redesign a spare part and improve it, which can have a positive impact on the performance and reliability of the part and its entire equipment.

Production Support

Anyone can make prototype parts. Designing a product that can be mass produced requires a different set of skills that require technical expertise to follow guidelines or creatively manage guidelines to streamline your unique production output. Elimold’s engineering team can help you improve the manufacturability of your parts, ensuring that they can be produced cost-effectively, maintain consistent quality, and perform well in the end application. Whether you need a bridge part, a low-volume production part, or a mass production part, we can design a cost-effective and practical production solution.

Design for Manufacturing (DFM)

Elimold has strong in-house production capabilities and a large team of experienced and skilled in-house experts. You can rely on our knowledge and resources to make critical design decisions, especially the manufacturing details of your part’s unique geometry. Our team works together to carefully identify risks early in development and effectively meet your design and manufacturing requirements. Our team’s extensive expertise can help you optimize issues from part design to material selection to improve manufacturability, save costs, and improve part quality. We can also help you identify and solve geometry and process-specific issues that DFM algorithms can easily miss.

Metal 3D Printed Part Design Features

Metal 3D printing services allow you to produce part designs that are difficult or impossible to manufacture using traditional manufacturing techniques. Here are some of the design features that metal 3D printing enables:

- Internal supports

- Weight-saving lattice wall sections

- Conformal cooling channels

- Undercuts

- No need for draft angles

- Internal cavities

- Varying wall thicknesses

Extensive Metallurgical and Design Expertise

Metal 3D printing is a rapidly evolving and ever-changing field. To achieve the best results for your products, it is essential to work with an experienced and knowledgeable manufacturer. Our team has extensive metallurgical and design expertise that you can trust to ensure your job is done right. We currently offer 3D metal printing services for metal materials such as titanium, aluminum, stainless steel, and maraging steel. Each metal is thoroughly tested for integrity and molecular composition to ensure optimal performance before printing.

Shorter Lead Times

While metal 3D printing may require more post-processing, it can still produce parts faster than traditional manufacturing. A part can be designed, uploaded, and printed in a matter of hours. This means that the overall lead time for 3D printed parts will be significantly reduced, with Elimold’s lead time being 4-30 days. Not only does this mean you get your parts faster, but it also reduces equipment downtime, saving overall costs. Another benefit of shorter production times is the ability to print on demand. Metal 3D printing can also print complex parts quickly and in small batches, making it a trusted printing method for many industries.

Reverse Engineering

We can provide reverse engineering, where we use laser scanners and CMM machines to create a 3D model when you only have a physical part and no CAD data for printing. One of the most common reasons many of our customers choose metal 3D printing is the need to manufacture a replacement for a metal part that is no longer available to order. In this case, without a digital file of the original part, reverse engineering is often the only way to create a 3D printed part. Elimold’s reverse engineering service can disassemble an object to understand how it works, then measure the physical object and rebuild it into a digital 3D model for 3D printing or other manufacturing. Our workflow 3D scans the original part and then processes the scan file in computer-aided design software to make it an exact match to the original part, or to make enhancements or improvements.

Design Considerations for 3D Printed Metal Parts

When designing a direct custom metal 3D printed part, there are several important factors to consider:

- It is best suited for 3D printing metal parts up to 5 inches in maximum dimension.

- Overhangs over 25 mm (inches) must have supports or fillets.

- Fillet radius for inside corners should be equal to wall thickness.

- Cavities require a hole to evacuate loose powder after solidification.

- Thin connections between thicker parts may buckle.

Quality Management and Inspection

After metal parts are 3D printed, they are post-processed to improve quality. Dimensional inspection is performed using a coordinate measuring machine (CMM). Our mission is to deliver high-quality parts every time. To achieve this, we use clearly documented work standards and processes. To minimize missed inspections, our team of experienced additive manufacturing technicians perform in-line quality inspections on each unique geometry. Once the part is completed, our quality control experts take over to perform visual and dimensional inspections on the physical object to ensure that it is consistent with your 3D model (or print, if available). All parts are 100% visually inspected and part measurement sampling is performed to verify that basic dimensions meet nominal tolerances. In addition, during the manufacturing process, parts are sampled according to AQL (Acceptable Quality Limit) Class II standards. If you require a report, we offer three different options, as well as a comprehensive build report. Compare the benefits of each inspection report to find the one that best suits your project needs.

Quality Inspections & Reports

Validate part geometry and evaluate material structure for quality reporting.

- Dimensional inspections with ballooned report

- First article inspection (FAI) per AS9102

- CMM, optical, and CT scanning

- X-ray

- Surface roughness

Heat Treatments

Specialized heat treatment processes improve the mechanical properties of parts by relieving internal stresses that develop during the sintering process.

- Stress relief

- Hot isostatic pressing (HIP)

- Solution annealing

- Aging

Metal 3D Printing Rapid Prototyping Services

Prototyping is another common bottleneck for getting new custom part projects up and running on time. 3D printed metal prototypes enable designers and engineers to quickly, affordably, and easily produce physical prototypes for testing and iteration. From concept models to functional prototypes, Elimold’s metal additive manufacturing solutions support complex geometries, fine details, and fast lead times. We offer a wide selection of materials and resolutions to meet your design intent. Whether you are demonstrating a visual model or testing part performance, we can provide trusted quality. We provide practical guidance throughout the project process, from design reviews and material recommendations to process selection and DFM feedback. Whether you are iterating quickly or preparing for large-scale production, we can help you make informed decisions, avoid costly delays, and ensure your prototype performs as expected.

Metal 3D Printing Production

Metal 3D printing improves efficiency by consistently printing parts to the exact specifications of your design files. And, because our process relies entirely on design files to guide production, your designers have the freedom to quickly adjust the files if you want to modify a component for your next run. Whether you are testing a prototype or designing the next generation of a product for full production, Elimold metal 3D printing services can meet your production needs. Plus, our metal 3D printing materials are designed to work with existing industry processes, so the parts you receive are ready for system integration. Plus, our finishing capabilities ensure that when you receive your part order, it is ready or nearly ready for immediate commercial applications.

24/7 Metal 3D Printing Services

Our industrial metal 3D printing factories can operate 24/7, which means we can minimize your production lead times and ensure fast delivery. Whether you choose our end-to-end subscription service or on-demand printing service, we guarantee reliable and repeatable quality across all production sites. Let you cost-effectively manufacture high-mix, low-volume metal parts. You can also manufacture complex parts that CNC machining and die casting cannot make. And our metal additive manufacturing (AM) solutions can produce lattice structures, consolidate parts for lightweighting, create complex internal channels to optimize fluid flow, and perform AM design (including topology optimization).

Request your free metal 3D printing quote now

Most of our quotes are delivered within 4 hours, often less depending on the project details. Your customer support partner will contact you directly to ensure you receive and understand all aspects of the quote and answer any questions you may have.

What are Metal 3D Printing Services?

Metal 3D Printing Services provide companies with on-demand industrial Additive Manufacturing (AM) technology that builds complex, high-strength metal parts layer by layer using advanced technologies (e.g. SLM, DMLS, EBM). These services transform digital CAD models into fully functional metal parts by selectively fusing fine metal powders layer by layer. It is often chosen as an alternative to CNC machining or metal casting because it can produce parts with the strength and durability of metal while taking full advantage of the design freedom provided by 3D printing. It can produce complex designs, including lattices and topology-generated structures, both of which are not possible with traditional CNC machining.

Material Options

If you would like to print in a material not listed above, please reach out to us. We’re qualifying new materials and would like to learn more about your application needs for using 3D metal printing. In addition to metal printing, we can also print in various plastic materials for the production of rapid prototypes and end-use parts.

Titanium (Ti6Al4V)

Titanium (Ti6Al4V) is a workhorse alloy. Versus Ti grade 23 annealed, the mechanical properties of Ti6Al4V are comparable to wrought titanium for tensile strength, elongation, and hardness. Final parts built in Ti6Al4V receive vacuum stress relief application.

Primary Benefits

- High stiffness and strength relative to weight

- High temperature and corrosion resistance

Stainless Steel (316L)

Stainless steel 316L is a workhorse material used for manufacturing acid and corrosion resistant parts. Select 316L when stainless steel flexibility is needed; 316L is a more malleable material compared to 17-4 PH. Final parts built in 316L receive stress relief application.

Primary Benefits

- Acid and corrosion resistance

- High ductility

Aluminum (AlSi10Mg)

Aluminum (AlSi10Mg) is comparable to a 3000 series alloy that is used in casting and die casting processes. It has good strength -to-weight ratio, high temperature and corrosion resistance, and good fatigue, creep and rupture strength. AlSi10Mg also exhibits thermal and electrical conductivity properties. Final parts built in AlSi10Mg receive stress relief application.

Primary Benefits

- High stiffness and strength relative to weight

- Thermal and electrical conductivity

Inconel 718

Inconel is a high strength, corrosion resistant nickel chromium superalloy ideal for parts that will experience extreme temperatures and mechanical loading. Final parts built in Inconel 718 receive stress relief application. Solution and aging per AMS 5663 is also available to increase tensile strength and hardness.

Primary Benefits

- Oxidation and corrosion resistance

- High performance tensile, fatigue, creep, and rupture strength

Cobalt Chrome (Co28Cr6Mo)

Cobalt Chrome (Co28Cr6Mo) is a superalloy is known for its high strength-to-weight ratio.

Primary Benefits

- High performance tensile and creep

- Corrosion resistance

Stainless Steel 17-4PH

Key benefits

- 17-4PH is characterized by having high yeild strength and being easily heat-treatable to obtain excellent hardness and strength.

Ideal applications

- Lifestyle/Consumer, e.g. watches, jewelry, spectacle frames, decorations

- Automotive/Industrial, e.g. non-corroding common material, food, and chemical plants

Maraging Steel (18Ni300)

Key benefits

- MS1 is characterized by having good mechanical properties and being easily heat-treatable to obtain excellent hardness and strength

Ideal applications

- Lifestyle/Consumer, e.g. watches, jewelry, spectacle frames, decorations

- Automotive/Industrial, e.g. non-corroding common material, food, and chemical plants

Nickel Alloy

Key Benefits

- High corrosion resistance, high-temperature resistance, and high electrical resistance.

Ideal Applications

- Gas turbines for both aerospace and energy industries, process industry, oil and gas, ship building.

Cobalt-chrome ( Co_Cr)

Key Benefits

- High carbon CoCrMo based superalloy, good corrosion, wear resistance, and good mechanical properties

Ideal Applications

- Orthopedic implants

- Gas turbines

- Engine components

- Jewelry

Cooper

Key Benefits

- Excellent thermal and electrical conductivity

Ideal Applications

- Inductors, electrical motors, and many other applications.

New Material Development Services

We are constantly innovating and building knowledge in the field of metal 3D printing. Over the years, we have continuously improved 3D printing processes and parameters to ensure that the materials used have excellent performance. To date, we have tried and tested a variety of metal printing material combinations. Therefore, we can work with you in new material development. In addition, we optimize the process parameters of new AM alloys to improve their mechanical properties and match them with the performance of traditional alloys. We can also match the right metal to your strength, ductility, corrosion resistance, cost and application requirements. With the guidance of Elimold’s team of experts, you can maximize design freedom, minimize material usage and ensure a successful build. It is also possible to predict residual stresses, optimize support structures and ensure geometric accuracy of demanding parts.

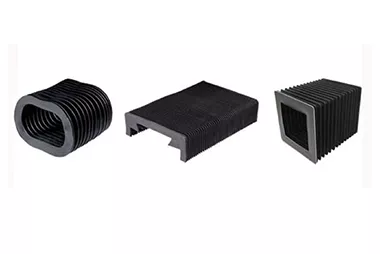

Surface Finishing Service Options

Elimold offers assembly and finishing services to further enhance the look of your designs, helping you create your own textures and colors. Whether your project is additive or traditionally manufactured, we have the tools and processes to create the best possible finish. Don’t see the finish you’re looking for here? Contact us to discuss your needs.

- Painting

- Powder Coating

- Media Blast

- Vapor Smoothing (AMT Post Pro)

- Plating (Standard)

- Chem Film (Standard)

- Decals

- Pad Printing

- Screen Printing

- Fiberglassing for Rigidity

- Drilling

- Machining

- Inserts

- Assembly

- Shot Peening

- Heat Treatments

- Mechanical Section and Bonding

- Infilteation

- Epoxy Coatings

Large Metal Part 3D Printing Manufacturing

Save time, reduce direct and indirect costs, explore more possibilities and operate at higher efficiency than traditional manufacturing operations by using our large-scale 3D metal printing technology to produce your next large part. And we are uniquely positioned to provide the right experience and technology for your project based on your material and application needs. We are able to leverage our extensive manufacturing experience, advanced equipment and knowledge to meet your needs. Each step is tailored to provide the best material, design and final product for your specific application. Every communication is the result of our team’s collaboration with you. Every result is designed to meet the needs of your operation.

Full-Service Metal Parts Manufacturer

A full-service design and printing company can guide you through the entire process. Simply provide your part concept and they can advise you on the best design, material, and post-processing options. If they offer services such as iterative design and topography optimization, they may be able to produce a more durable and economical part in a material you might not have thought of. In addition to 3D printing, Elimold offers a variety of prototyping and manufacturing processes, such as CNC machining, vacuum casting, and injection molding. In addition, you can choose to add metal inserts to your parts, stamp serial numbers on your prints, and even assemble them. To make your parts even more aesthetically pleasing, we offer a variety of surface treatment packages.

Other 3D Printing Services

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused Deposition Modeling (FDM)

P3 technology (DLP)

Solidscape (wax deposition)

Micro 3D Printing

Wire Arc Additive Manufacturing (WAAM)

Ceramic 3D printing

Laser Powder Bed Fusion Metal (LPBF-M)

Unleash your innovation potential with metal 3D printing services

Other useful features of Elimold include its extensive resources and support team. If your part is not suitable for printing or you don’t have a design plan, our experts and professional partners will be happy to help you complete the design. If you encounter problems during the ordering or delivery process, no matter which manufacturer you choose to print your parts, you can contact the Elimold team. They have experienced engineers, dedicated project managers and five well-equipped facilities to handle your small batch production, but for large-scale production, it relies on its casting and injection molding services. Our full range of metal 3D printing services covers from prototypes to mass production of metal parts. Backed by a strong quality framework, we are able to provide end-to-end technical expertise, rich consulting knowledge and multiple engagement models, so that you and your company can experience the technology before investing in the long term.

Comprehensive Service and Support

Metal part production with Elimold is designed to be simple. From working with our design and engineering teams to our industry-leading Metal Technology Center in Shenzhen, China, we help you take advantage of the flexibility and speed of metal 3D printing compared to traditional methods. Whether it’s a one-off spare part or a full series production, you can count on us from start to finish. Whether you need rapid prototyping or mass production products, we can help with your next 3D printing project. We can provide the highest quality parts at a very competitive price. We offer a wide range of materials and surface finishes, allowing you to customize parts to your desired specifications. Upload your 3D model file to our instant quote engine to get pricing and delivery time to start your process today!

Request Your Free Metal 3D Printing Quote Today

After receiving your drawings, our engineers will analyze your custom Metal 3D Printing parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.