Polyjet 3D Printing Service

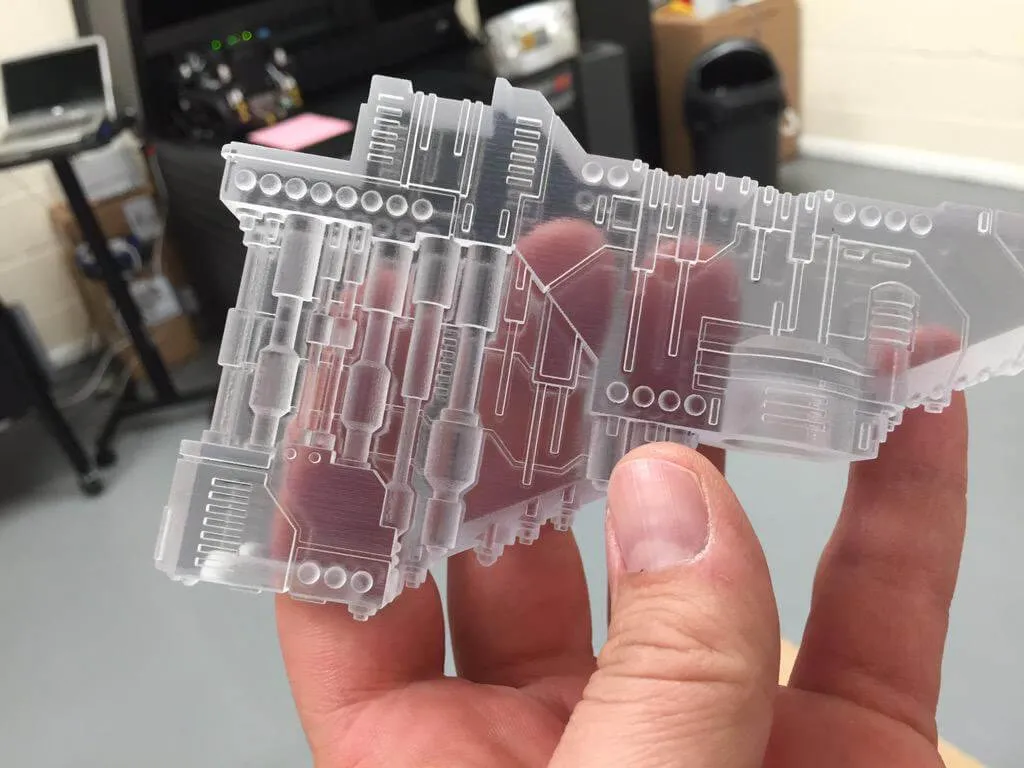

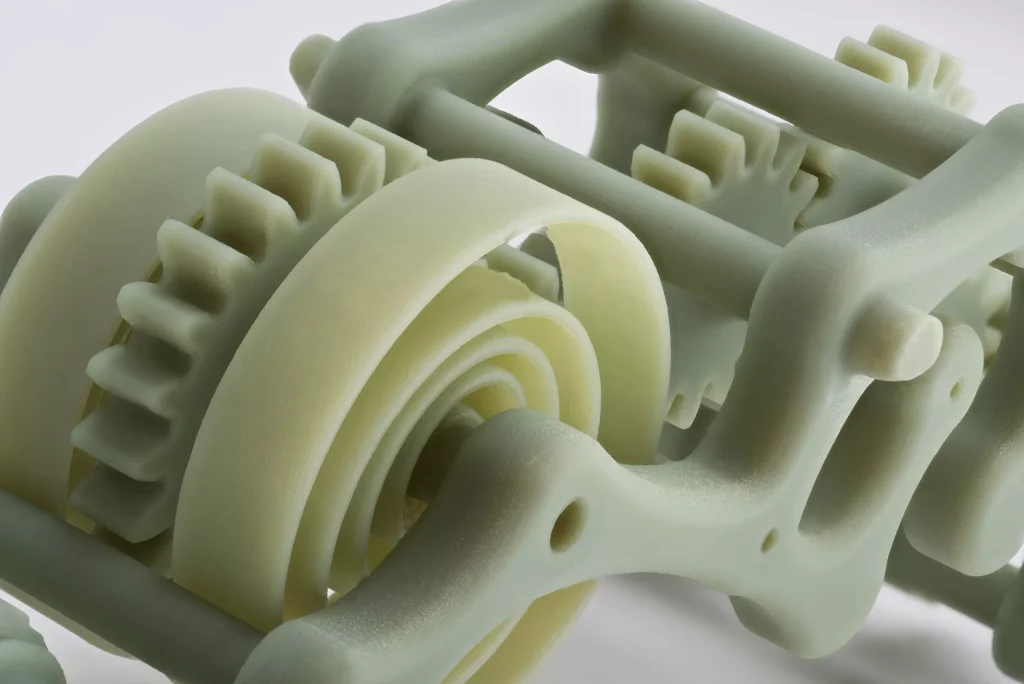

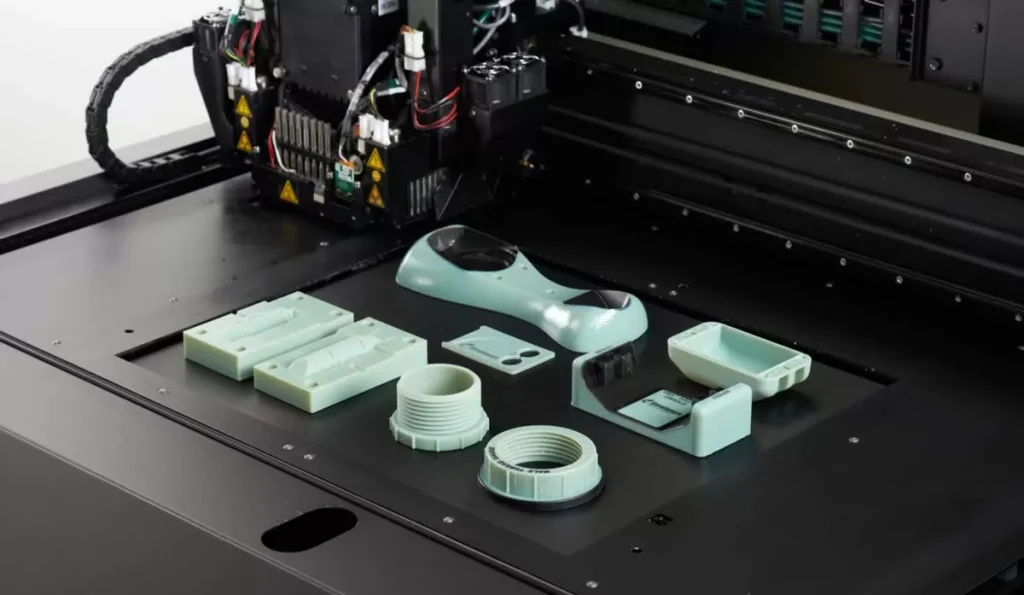

In addition to its high detail and smooth surfaces, PolyJet offers the unique ability to print precision parts and assemblies with multiple materials, all in a single build. A single part can contain different colors, levels of transparency, and diverse physical and mechanical properties, making PolyJet ideal for complex visual models and prototypes.

Get Colorful Rapid Prototype Parts Fast

Do you need to produce prototype parts to take your designs to new heights with unmatched quality? Do you need to create colorful demonstration models to help explain concepts or validate designs? Do you need to produce parts with multiple surface finishes without overmolding and other expensive processes?

PolyJet 3D printing is one of the most versatile additive manufacturing technologies in Elimold’s industrial 3D printing services. It can produce high-precision parts in different hardnesses, from hard to rubbery, multi-color, transparent and translucent materials in a single pass. It can also print multiple materials simultaneously to simulate overmolding. In addition, it can be used to manufacture workholding fixtures, molds and end-of-arm tooling with tight tolerances.

Professional PolyJet 3D Printing Manufacturer

Elimold has unparalleled expertise in PolyJet 3D printing. Our team uses advanced Stratasys color 3D printers and a rich selection of multi-color resins to transform your concepts into ultra-realistic parts and beautiful models. We can even mix resins to produce over 500,000 custom shades, ensuring your full-color prints match your brand and show your true colors. At Elimold, our experienced engineers work with our customers on their unique PolyJet projects to understand exactly what their goals are and what they expect from the final product. This means we can be involved in the entire PolyJet additive manufacturing process, from initial idea to final product, and we have the skills and expertise to guide any project from prototype to production, all the way to final completion.

PolyJet 3D Printing Service Provider

When you work with us, our project engineers will regularly assist you in selecting materials, technologies, processes, post-processing methods, and more, and our friendly customer service representatives will keep you informed of project timelines, costs, and delivery requirements. We are ISO 9001:2015 certified, so you can rest assured that your PolyJet prototypes and parts will be completed to our high quality standards and produced and delivered to you as quickly as possible. With continuous improvement as our core goal, we are constantly improving our factory processes to meet the changing needs of our customers. In addition, our Engineer Assisted Quote form allows you to further contact our engineers for a more in-depth project discussion. With every order, you can rest assured that we are always committed to achieving more sustainable and environmentally friendly standards in material handling and recycling, packaging methods, and more.

Our Capabilities

Polyjet delivery times are as quick as 1 working day, so Elimold is one of the quickest shops to offer this range of services and we can provide consultation on rapid prototypes and exterior mock-ups. Simply contact our team of engineers.

- Maximum build dimensions: Dimensions are unlimited as components may be composed of several sub-parts. The maximum build envelope is 490 x 390 x 200 mm

- Standard accuracy: 0.1 – 0.3 mm (varies depending on geometry, part orientation, and print size)

- Layer thickness: 0.032 mm

- Minimum wall thickness: 1 mm

- Surface structure: Unfinished parts have a smooth surface, which can be further smoothed through various post-production finishes

Setting the Standard in Color 3D Printing

At Elimold, our commitment to the highest quality standards begins during the design phase and continues through every stage of a project. Our team carefully removes support material and applies advanced inspection techniques to ensure dimensional accuracy, material consistency, and a flawless finish on every part. Trust us, PolyJet color printing will exceed your expectations and redefine what’s possible with printing. So take your Polyjet parts to the next level with our expert finishing and assembly services. Our dedicated team will transform your PolyJet parts into visual masterpieces. Whether it’s surface finishing, custom coatings, assembling complex components, or adding functional details, our secondary processing experts ensure your parts have stunning beauty and exceptional performance.

Engineering Design Services

Our dedicated and solution-oriented staff has extensive experience in developing, drafting and modeling project deliverables and works closely with clients to understand and apply the most appropriate level of service. We have a highly trained team with extensive expertise supporting a variety of disciplines. Our team of modelers, draftsmen and project managers, supported by world-class software, hardware and infrastructure, has the expertise required to complete complex and cost-effective deliverables on time and cost-effectively. We continuously invest in people and technology to solve complex requirements quickly and innovatively. Our approach blends traditional principles with current proven industry practices. We use forward-thinking thinking to save time, reduce costs and equip our company culture with knowledgeable and talented people.

Photorealistic 3D Printing with PolyJet

PolyJet is most well known for its ability to produce parts with extremely fine details, smooth surfaces, and a wide range of colors. One of the technology’s unique features is its ability to mix multiple colors of material together within the same print, allowing for the creation of intricate designs and patterns with a high level of color accuracy and resolution. It produces prints that look almost indistinguishable from traditionally manufactured parts, with smooth gradients and realistic textures, making it a powerful tool for creating visually striking and realistic prototypes, models, and end-use parts.

Common PolyJet 3D Printing Applications

PolyJet 3D printing has a diverse range of applications across many industries.

- Form and fit testing and product presentation

- Prototyping for complex parts

- Product development

- Prototyping designs for overmolding or silicone rubber parts

- Combining two colors or durometers into a single part

- Simulating elastomers or flexible parts

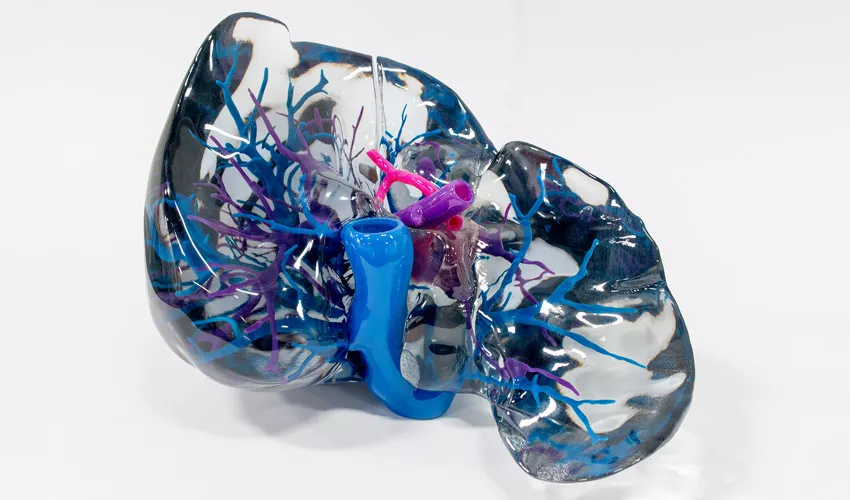

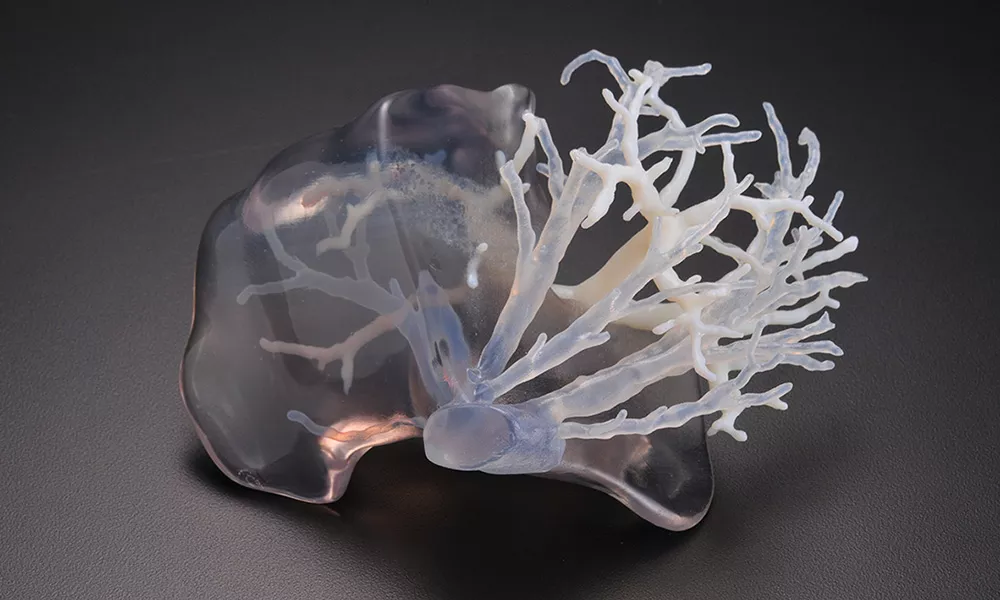

- Anatomical models

Alternatives to PolyJet

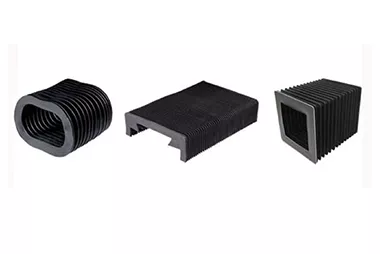

If precise tolerances are not required, FDM and SLS are viable alternatives for creating jigs and fixtures.

Want to get color demo models and high-fidelity prototype parts fast?

Do you need to produce prototype parts that help you take your designs to the next level while maintaining unmatched quality? Do you need to create color demo models to help explain a concept or validate a design? Or parts that combine multiple finishes without overmolding and other expensive processes? Contact us today for a quote.

What is PolyJet 3D Printing?

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV-curable resin onto a build tray, a process somewhat similar to inkjet printing.The main working process is:PolyJet 3D printed parts are made with photopolymer liquid resin. The printer places layers of photocurable resin on the build tray in extremely fine layers. As the layers are placed, they are simultaneously cured by exposure to ultraviolet (UV) light, which cures into a solid material that matches the programmed CAD file. The process is repeated layer by layer until the entire part is constructed. For parts with complex geometries, support structures are added to the part to ensure a successful build, and then manually removed during the finishing process.PolyJet is a revolutionary multi-material jetting photopolymer 3D printing technology that turns your ideas into reality with exceptional precision and versatility. From prototyping to production, PolyJet offers a wide range of capabilities, including the creation of complex geometries, intricate details, full color combinations, transparencies and flexible parts all in a single model.

What Polyjet Can Print?

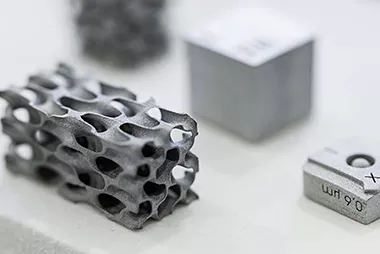

PolyJet 3D printers are renowned for their exceptional precision, delivering smooth surfaces and intricate details with incredible accuracy. These cutting-edge systems can replicate a wide range of materials, from plastics and rubber to human tissue, by combining various photopolymers in precise concentrations and microstructures. With an extensive selection of materials available, you can create prototypes, models, textures, and patterns that are incredibly detailed and diverse in their properties and aesthetics. Plus, with thousands of material options to choose from, you can achieve a full spectrum of colors in your prints. Whether you’re looking for intricate details or vibrant colors, PolyJet 3D printing offers unparalleled versatility and customization.

Material choices for PolyJet 3D printing

We stock a range of PolyJet 3D printing materials to meet customers’ needs. Base materials can be used on their own or combined with each other in specific concentrations and microstructures to create Digital materials. This enables us to produce parts that are rigid and opaque, transparent, similar to polypropylene, or rubber-like with Shore A hardnesses from 30 to 95.

- Digital materials offer a wide range of flexibility, from Shore A 27 to Shore A 95, and over 650,000 color options.

- Rigid opaque materials offer brilliant color options for unprecedented design freedom and can be combined with rubber-like materials to create a wide variety of parts.

- Simulated polypropylene replicates the appearance and functionality of polypropylene, like appearance, flexibility, strength, and toughness.

- High temperature materials offer exceptional dimensional stability for thermal functional testing.

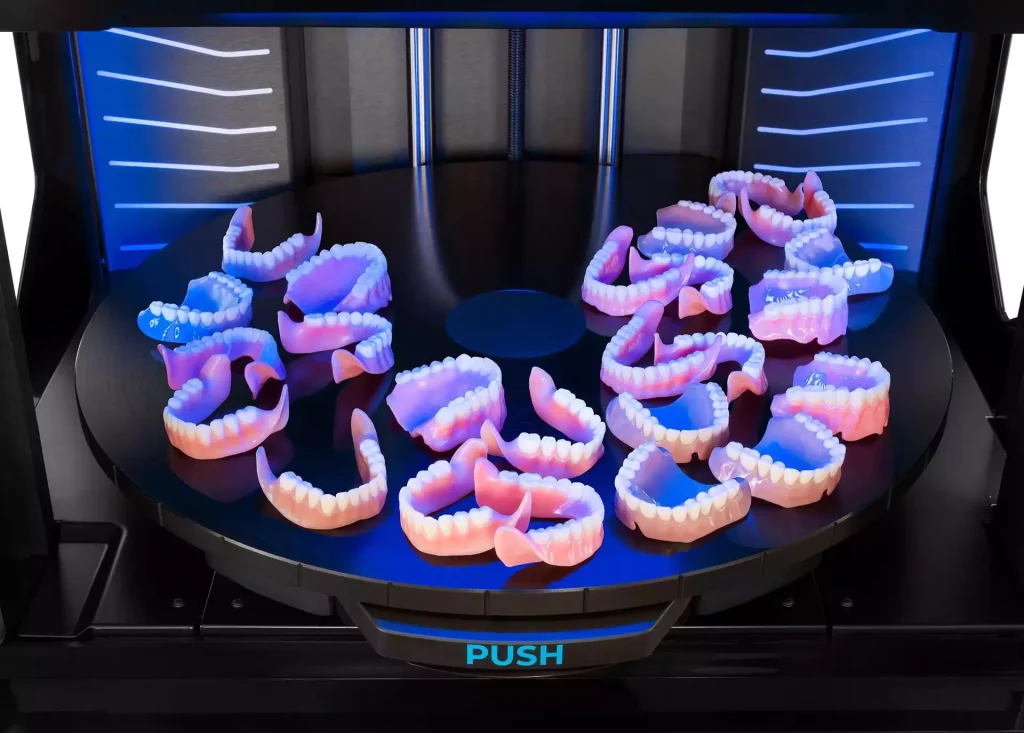

- Biomechanically accurate materials allow you to create models that mimic human cardiac and vascular anatomy.

- Transparent materials feature optical clarity and can be combined with color materials for stunning transparent shades.

- Rubber-like materials offer various levels of elastomer characteristics and can be combined with rigid materials for a variety of Shore A values, from Shore A 27 to Shore A 95.

- Digital ABS Plus simulates ABS plastics by combining strength with high temperature resistance, leading to enhanced dimensional stability for thin-walled parts.

- Biocompatible materials feature high dimensional stability and colorless transparency. The material has five medical approvals including cytotoxicity, genotoxicity, delayed type hypersensitivity, irritation and USP plastic Class VI.

Finishing Options for PolyJet 3D Printing

Here’s a complete list of the post-processing services Elimold offers for PolyJet printing service:

- Sanded

- Painted (EMI shield)

- Painted (sand and paint, non-cosmetic)

- Painted (sand and paint, cosmetic)

- Painted (customer spec paint)

- Specialty coating

- Screen printed

- Inserts

- Assembly

Benefits of Polyjet printing

The advantages of PolyJet printing technology include high precision, multi-material printing, fast printing speed, high surface quality, simulating multiple materials and realizing multiple colors, etc. These advantages make PolyJet printing technology suitable for manufacturing high-quality, complex parts and meeting different requirements. industry needs.

- High precision and high resolution: PolyJet printing technology can achieve very high precision and resolution, usually can achieve the precision below 0.1mm and the resolution below 16um, can print very delicate, smooth surface and complex geometry.

- Multi-material printing: PolyJet printing technology can use multiple materials to print complex parts at the same time. These materials can have different hardness, elasticity, transparency, heat resistance and other characteristics to meet different application requirements.

- Fast printing speed: The printing speed of PolyJet printing technology is relatively fast, and high-quality parts can usually be printed within a few hours, which can quickly meet user needs.

- High surface quality: PolyJet printing technology can print a very smooth surface, reducing the need for subsequent processing, saving manufacturing costs and time.

- Simulate multiple materials: PolyJet printing technology can simulate the appearance and properties of multiple materials within a single part, reducing manufacturing costs and time.

- A variety of colors can be achieved: PolyJet printing technology can print parts in a variety of colors, which can provide more possibilities for the appearance of the product.

PolyJet Design and Build Guidelines

Each 3D printing technology is a little different, here are standard guidelines to consider when choosing PolyJet as your 3D printing process:

- Build Layers: 0.00118” to 0.00055”

- Minimum Wall Thickness & Feature Size: 0.030”

- Standard Finish: Level 1 Support Removal Finish (see more available custom finishes)

- Standard Lead Time: 3-5 days

- Tolerances: +/- 0.005” for first inch then +/- 0.002” per inch thereafter

- Inserts: Install in post-processing with adhesives or press-fit

- Holes: Build holes and threads into model for print and chase or ream in finishing

Traditional Technologies That Can Benefit from PolyJet

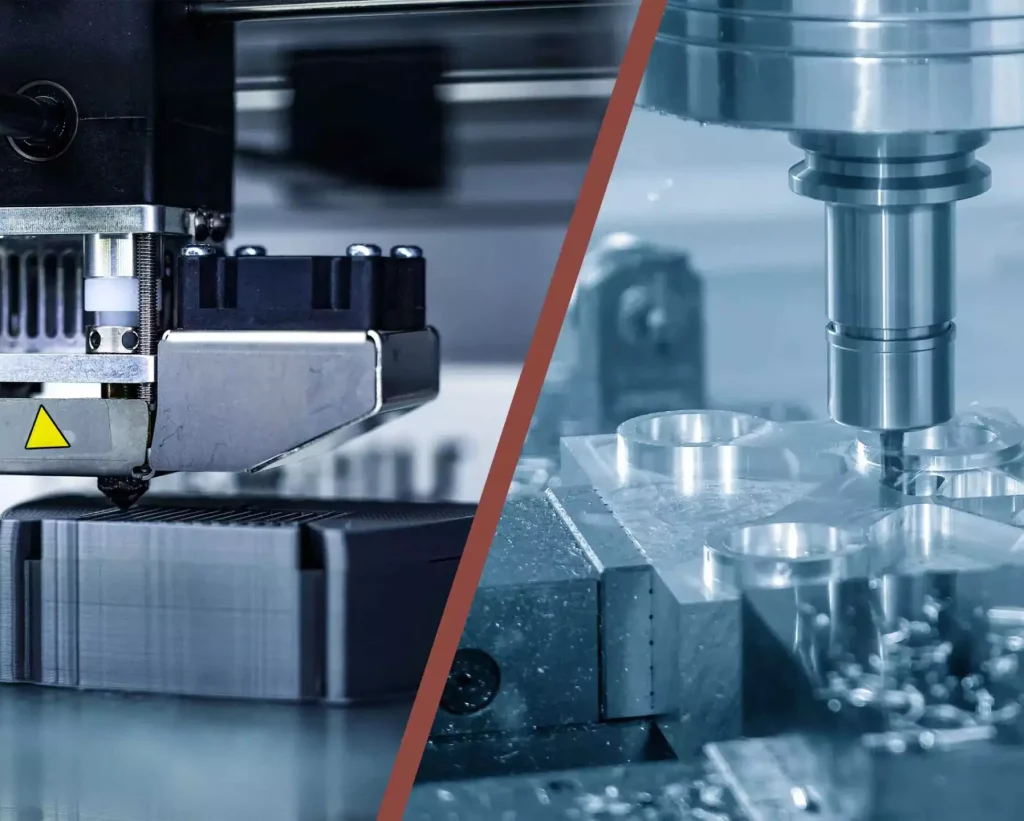

Many types of visual aids and models are now made by hand using clay, screen printing, labels and other time-consuming and often expensive manual techniques. These models can be produced much faster using PolyJet 3D printing. Inks are available in thousands of colors and can be controlled at the voxel level. It can also print a variety of surface textures. That means you can create sophisticated prototypes that exactly match the look and feel of your brand. Prototype parts are made using a variety of techniques. Having a tool built to produce a handful of prototype injection molded parts could take weeks. CNC machining prototype parts requires time-consuming machine and work holding tool setups and a skilled operator. In contrast, Elimold’s PolyJet printing service can be used to print prototype parts in a matter of hours.

Industries We Serve

PolyJet 3D printing technology is utilized by a diverse range of industries and professionals, including:

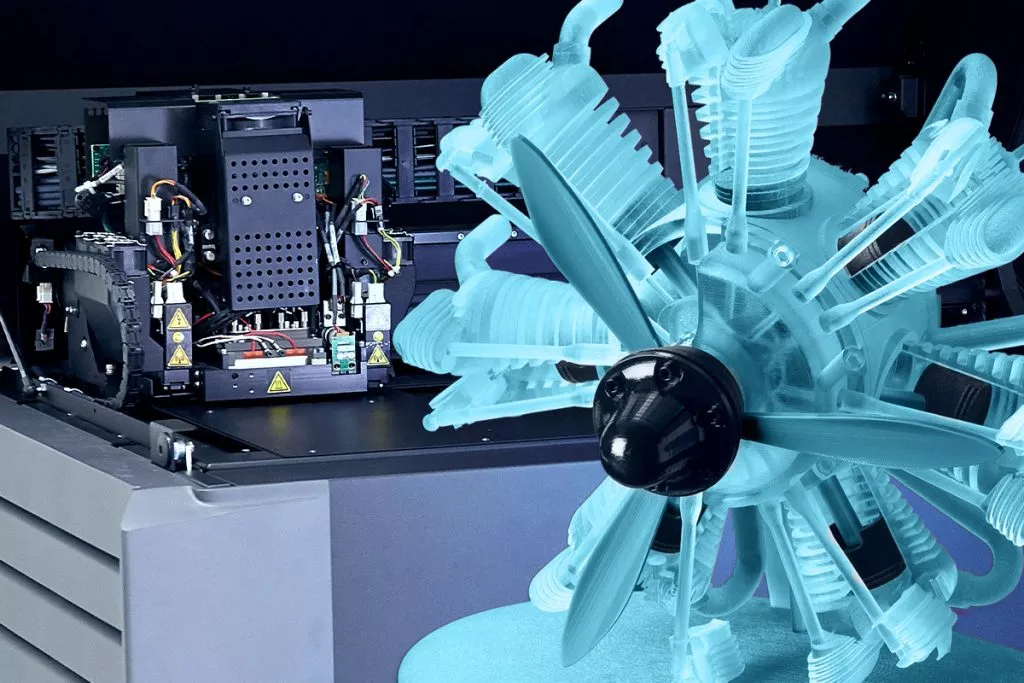

- Aerospace and Defense: PolyJet is used to create complex prototypes, tooling, and end-use parts for aircraft and spacecraft.

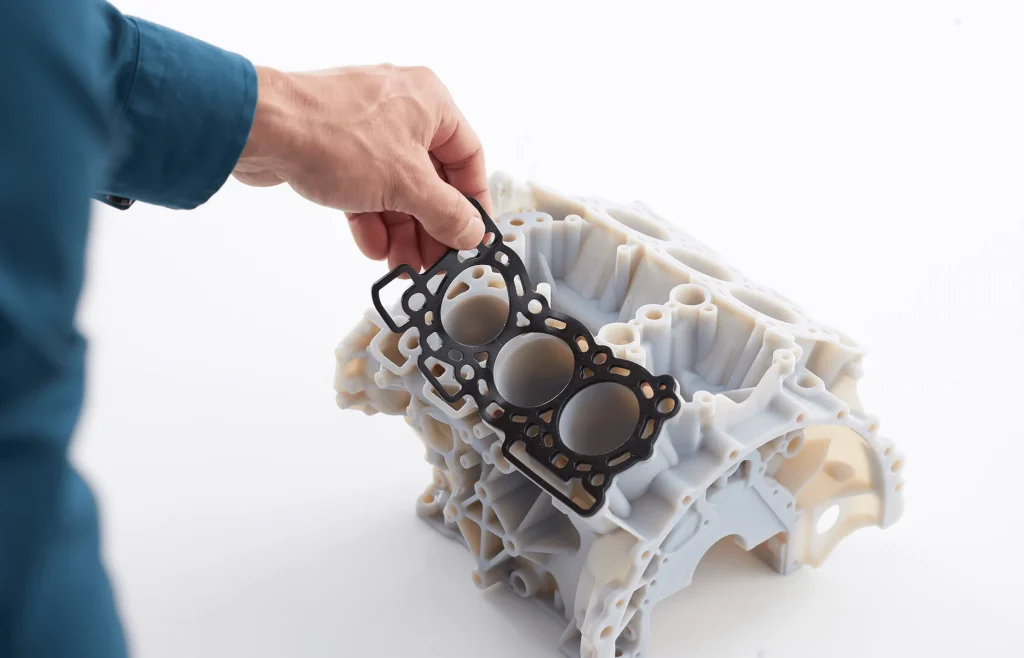

- Automotive: Automotive designers and engineers use PolyJet to create accurate, high-resolution prototypes and parts with a range of mechanical properties.

- Medical and Dental: Medical and dental professionals use PolyJet to create detailed models for surgical planning, prosthetics, and other applications that require biocompatible materials.

- Education and Research: PolyJet is used in educational institutions and research facilities for a variety of applications, including creating anatomical models, teaching aids, and prototypes.

- Manufacturing: PolyJet is used in manufacturing industries to create molds, jigs, fixtures, and other tooling, as well as end-use parts with precise geometries and mechanical properties.

Other 3D Printing Services

Elimold offers a variety of 3D printing services, giving you the flexibility to source the parts you need. Get instant quotes and order parts quickly with on-demand production. For large or complex orders, our team of experts will work with you to develop, coordinate and oversee a manufacturing quality plan from start to finish.

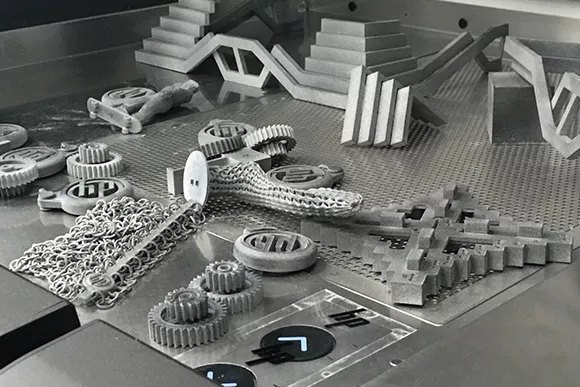

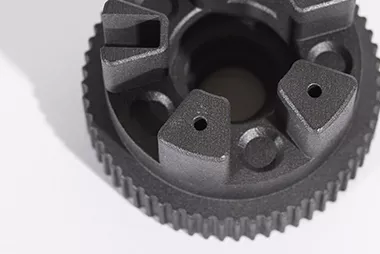

Selective Laser Sintering(SLS)

Digital Light synthesis(DLS)

Fused Deposition Modeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

Micro 3D Printing

Wire Arc Additive Manufacturing (WAAM)

Metal Binder Jetting

Selective Laser Melting (SLM)

Ceramic 3D printing

Metal 3D Printing

Comparison To Other Printing Technologies

Contrasted with FDM

PolyJet offers higher resolution, smoother surface finishes, and supports mixed multi-material printing, unlike FDM. However, PolyJet parts are generally less durable and much more expensive. While FDM excels in strength and cost-effectiveness for functional prototypes, PolyJet is better suited for detailed visual models or parts that require complex geometries and multiple material properties.

Contrasted with Reinforced FDM

Enhanced FDM has higher mechanical strength than PolyJet, but lacks the ability to print with multiple materials or colors. PolyJet is great for producing complex designs with different textures or visual features, but it can’t match the increased stiffness and durability of Enhanced FDM parts. The platforms are similar only in cost.

Contrasted with SLA or MSLA (Resin Printing)

PolyJet has the unique ability to print multi-material parts, but the mechanical strength of SLA/MSLA parts is generally better than PolyJet. SLA/MSLA-based methods also tend to be more cost-effective for single-material, high-detail applications, especially for functional parts that need to be sterilized or used in medical applications.

Contrasted with DLP (Microfluidic Printing)

While both PolyJet and DLP can produce high-resolution parts with smooth surfaces, DLP is optimized specifically for microfluidics applications, providing greater clarity and precision. PolyJet is more versatile with its multi-material capabilities, but is less specialized for these delicate, high-precision applications.

Contrasted with SLS (Selective Laser Sintering)

SLS (selective laser sintering) uses a laser to sinter or fuse powdered materials to create 3D objects. SLS can produce high-precision, high-detail parts and can use a variety of materials. However, PolyJet is capable of printing finer details.

Request Your Free Polyjet 3D Printing Quote Today

After receiving your drawings, our engineers will analyze your custom Polyjet 3D Printing parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.