Stereolithography(SLA) 3D Printing Service

Stereolithography (SLA) is a powerful 3D printing technology. It is capable of printing high-precision, high-resolution, and detailed parts. It can be used for direct end-use, low-volume production, or prototyping. Elimold offers more than 30 uniquely designed SLA materials to bring products to market at a lower production cost. Contact us now for a free quote.

Stereolithography (SLA) 3D Printed Parts Supplier

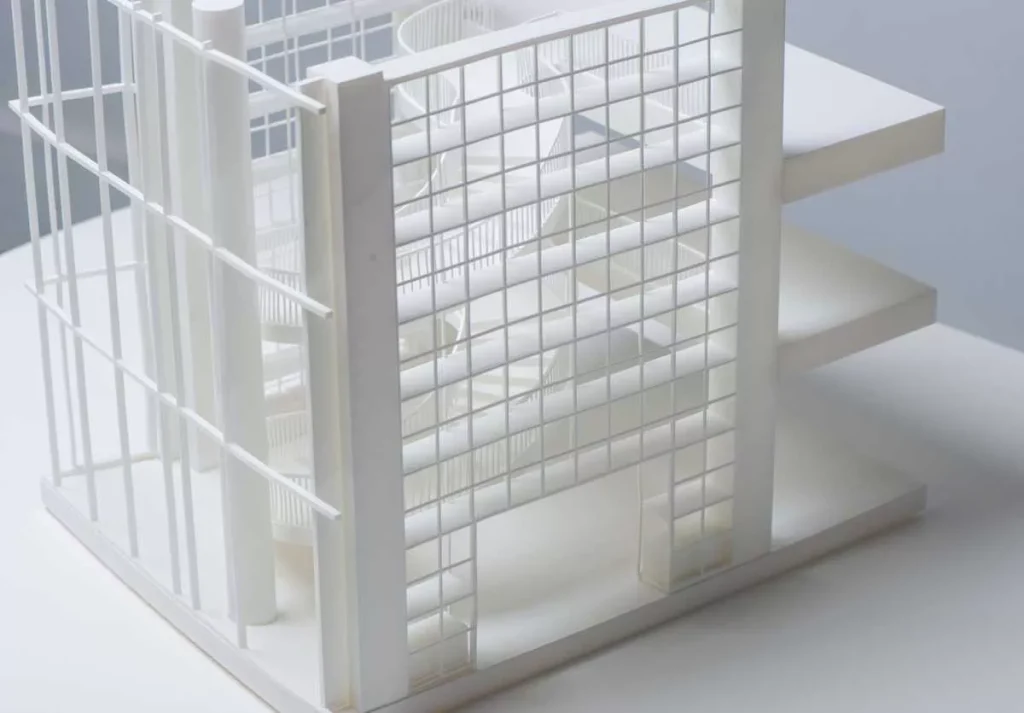

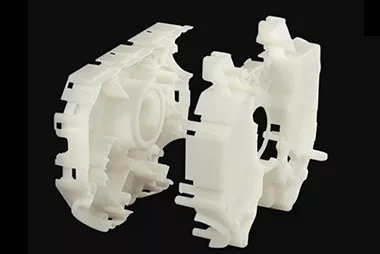

Elimold is at the forefront of Additive Manufacturing (AM), leveraging years of experience in stereolithography (SLA) to bring complex designs to life. Our custom SLA 3D printing services meet our customers’ needs for high-quality, intricate and detailed parts. Our advanced custom resin printing technology allows us to print precise models with exceptional accuracy, making it ideal for creating appearance models, product prototypes, experiential marketing materials and other complex parts. Our experienced team of designers works closely with our customers to ensure that every aspect of the project is tailored to our customers’ specific needs, from initial consultation to final product. Our custom SLA 3D printing services provide customers with the flexibility to experiment with different designs and materials to ultimately create a superior end product. With our commitment to quality and attention to detail, Elimold is the ideal partner for those who seek the ultimate in SLA 3D printing services.

Full-Service SLA 3D Printing Manufacturer

Elimold is an innovative full-service manufacturer that supports you throughout the product development process. From design consultation to final delivery, we provide end-to-end 3D printing service solutions tailored to your specific industry needs, timelines, and budget. By working with Elimold to meet your product development and production needs, you can better streamline your operations, reduce delivery time, and ensure quality control. Although we have extensive expertise in the field of additive manufacturing, Elimold’s SLA 3D printing services are only part of our business. Our team is committed to customer satisfaction and providing comprehensive solutions. To this end, we also focus on product design, engineering, CNC machining, finishing, and assembly to provide you with turnkey services, cost-effective services, and fast delivery.

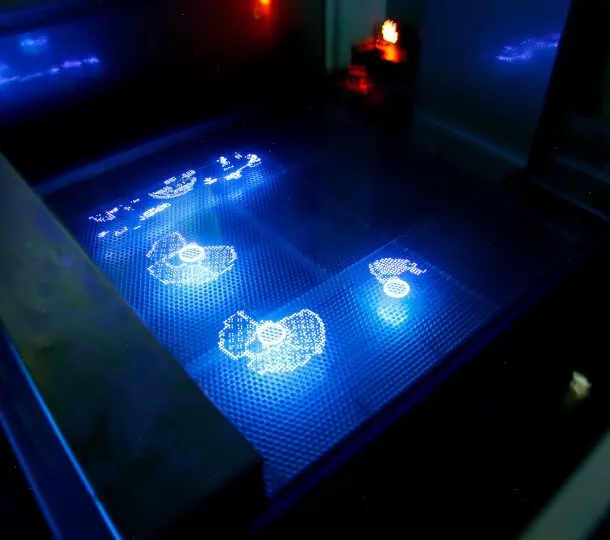

Stereolithography 3D Printing Capabilities

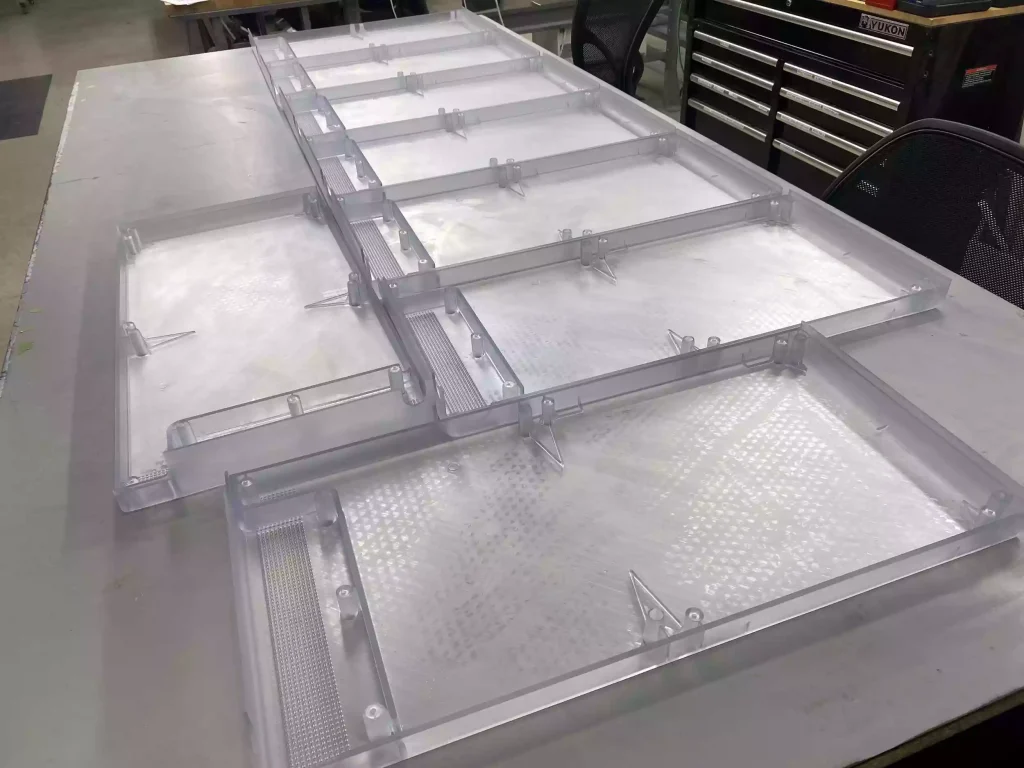

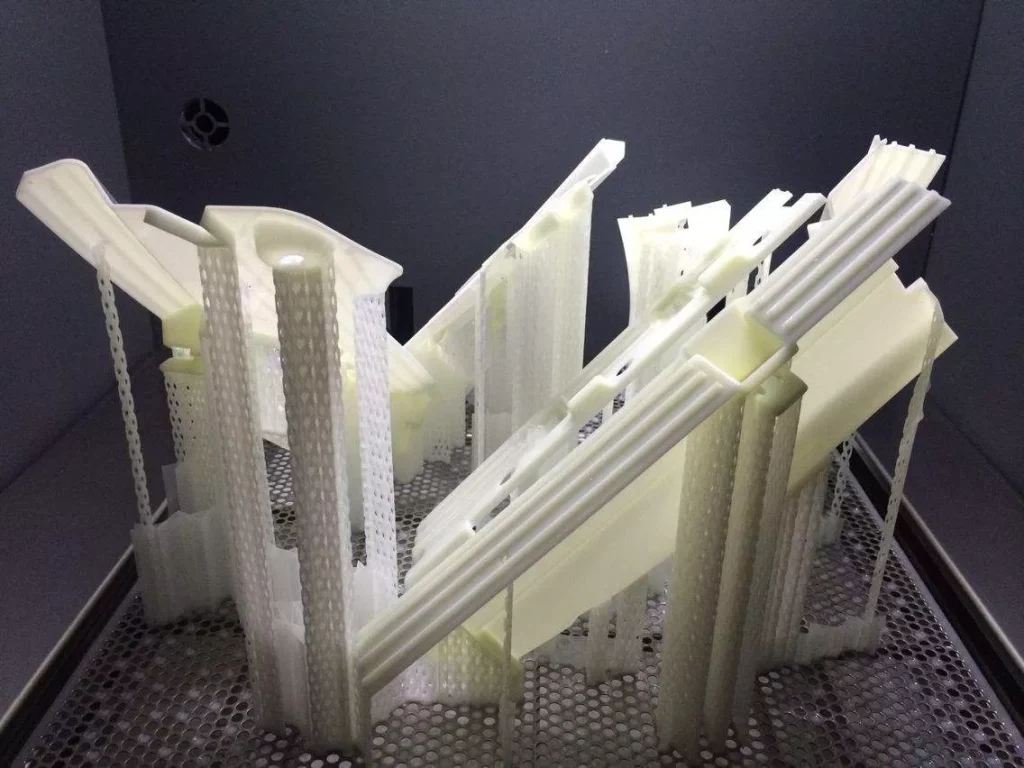

Elimold has extensive experience, professional engineers and well-equipped facilities, with over 120 of the latest 3D printers in our in-house facility to support SLA printing services, from complex prototypes to high-volume production. Our large-format printers have a build size of 1500 mm x 750 mm x 550 mm (59″ x 29.5″ x 21.5″) for regular resolution printing. The advanced equipment we use can produce parts with extremely small features and sharp details; while in normal resolution mode, they can quickly build cost-effective parts. With the expertise and attention to detail of our team of engineers and our entire team’s commitment to excellent quality assurance at every stage, we have a proven track record in manufacturing high-quality, high-precision SLA 3D printed parts.

Engineering Design Services

Elimold’s experienced engineering and designer team has the capabilities and expertise to guide the design and prototyping process to ensure product accuracy, functionality and aesthetics. We first help you determine if SLA is the right solution and guide you to optimize part design for the best results. When you work with us, our team will plan a project management plan for your project covering all aspects of CAD data design, production and post-processing, determine the best solution and professional advice for your 3D printing project, and ensure the smooth completion of the project. And our ISO9001 certified factory and standardized printing workflow ensure the quality of our products, and we have a skilled and friendly sales team that can quickly respond to internal customers 24 hours a day and provide instant quotes.

Stereolithography Rapid Prototyping

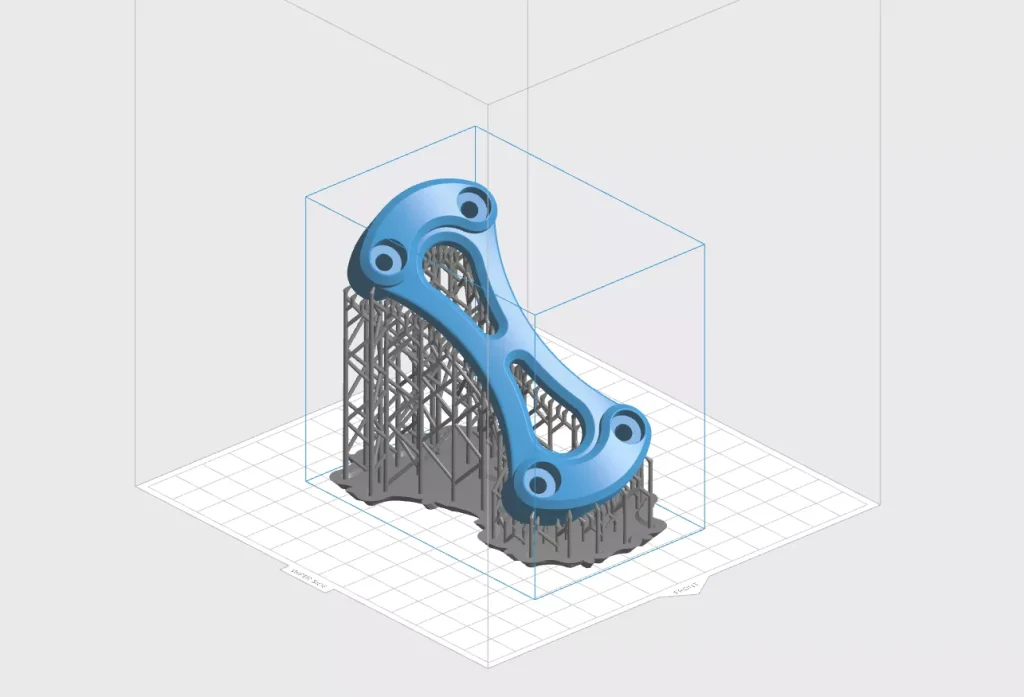

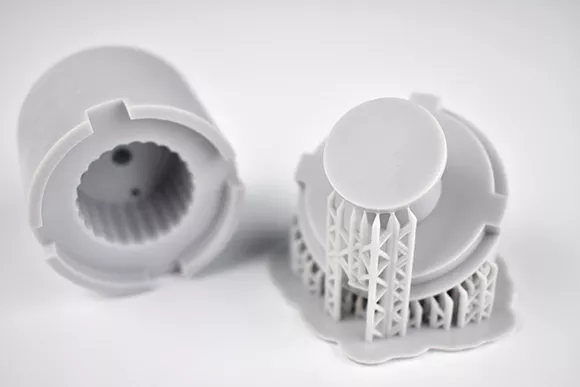

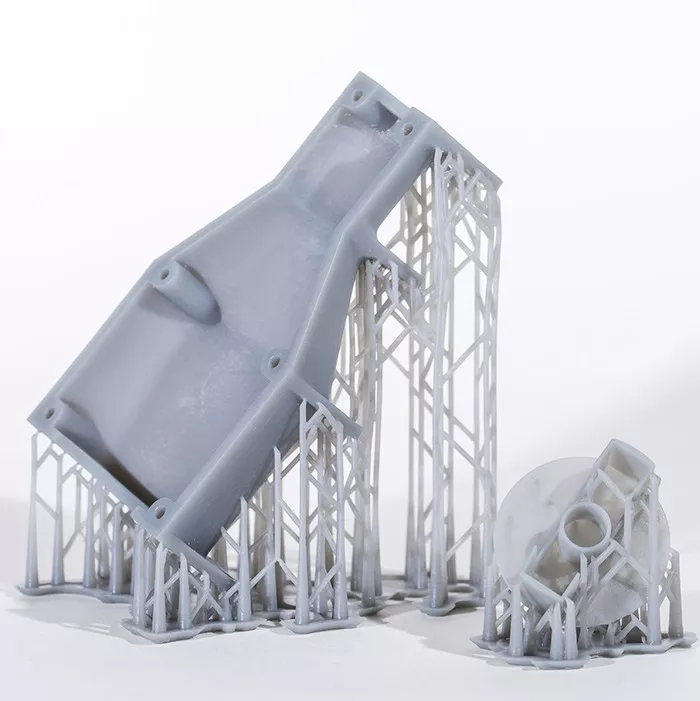

We offer high-quality resin 3D printing services for your rapid prototyping needs. Our advanced SLA printers are capable of quickly producing highly accurate, detailed parts, making them an ideal solution for prototyping and low-volume production. During the prototyping process, you typically need to iterate on a design, test new designs, and repeat the process. Almost every product we’ve seen has gone through several rounds of prototyping. Prototypes are accurate and detailed, even when unconventional shapes are required. They can be machined and used to design master patterns for production methods such as injection molding, Vacuum Casting, and thermoforming. Prototypes can then be used to evaluate the performance of the design, and they are also often used in marketing campaigns for products once they go into production.

Types Of Stereolithography 3D Printing

Stereolithography includes other technologies such as DLP (digital light processing) and MSLA (mask stereolithography). And SLA 3D printing is faster than other 3D printing methods. Many industries have adopted this efficient and economical method to speed up the production of parts and improve quality.

DLP (digital light processing)

MSLA (mask stereolithography)

Low Force Stereolithography™ (LFS)

Low Force Stereolithography™ (LFS) is an improved SLA 3D printing technology developed by Formlabs®. It helps deliver excellent surface quality, accuracy, watertight results, and versatility in creating precise prototypes and end-use parts. Like other vat photopolymerization additive manufacturing processes, LFS exposes light-reactive thermoset materials to a laser to polymerize and create a solid part.

Professional SLA 3D Printing Service Provider

Elimold provides cost-effective SLA 3D printing services to a variety of industries around the world. We outsource services to save you valuable time. Even with tight budgets and deadlines, our team can meet your needs and deliver on time. Upload your MRI and CAD files to get durable, fully functional models. We have advanced SLA printers that can print detailed parts with high accuracy and faster. Plus, with our customized SLA 3D printing services, you can get your parts ready for production faster. Let us help you take your product design and development to the next level. Whether you need rapid prototyping or low-volume production, we can provide you with on-demand printing and stereolithography materials. And, if you need special SLA materials, let us know and we will arrange it for you with no minimum order quantity. Elimold is a digital manufacturing company that provides on-demand services based on your budget, no matter what type of custom parts are needed. Contact us today to get a quote.

Ready To Get Started On Your Stereolithography(SLA) 3D Printing Quote?

Are you looking for the ideal manufacturer? Elimold offers the best online SLA 3D printing services to help you create your ideal resin parts. With our expertise in stereolithography, you can choose from a variety of options and have us produce them in our ISO 9001 certified facility. Upload your 3D files now to get started with stereolithography.

Quality Management Standards for SLA 3D Printed Parts

We produce your custom parts to strict manufacturing standards and ensure that all parts and processes meet industry standards. The inspection report we provide with each order contains a comprehensive verification of these requirements. Parts are fully cured according to the material manufacturer’s specifications before shipment, and the excess resin in the hollow part is drained and all support materials are removed, and the support pen tip must be polished smooth. Every order we process goes through multiple quality control steps to ensure that it meets professional-grade standards. By repeatedly checking each part, we are better able to ensure the success of your project. If you find a quality issue, please contact us or submit a work order if necessary.

Professional SLA 3D Printing Service Provider

Elimold provides cost-effective SLA 3D printing services to a variety of industries around the world. We outsource services to save you valuable time. Even with tight budgets and deadlines, our team can meet your needs and deliver on time. Upload your MRI and CAD files to get durable, fully functional models. We have advanced SLA printers that can print detailed parts with high accuracy and faster. Plus, with our customized SLA 3D printing services, you can get your parts ready for production faster. Let us help you take your product design and development to the next level. Whether you need rapid prototyping or low-volume production, we can provide you with on-demand printing and stereolithography materials. And, if you need special SLA materials, let us know and we will arrange it for you with no minimum order quantity. Elimold is a digital manufacturing company that provides on-demand services based on your budget, no matter what type of custom parts are needed. Contact us today to get a quote.

SLA 3D Printing Fast Turnaround Service

Elimold’s SLA 3D printing service can speed up your prototyping process by manufacturing parts in hours. This allows each stage of the project to be completed faster. Compared to machined prototypes, 3D printing is inexpensive and parts can be manufactured faster because parts can be completed in hours, allowing each design revision to be completed with greater efficiency. In addition, we understand the importance of getting products to market before the competition, so we also provide a rush service, providing quotes within hours and delivery in 4 days or less. This delivery speed is much faster than molded or machined parts. SLA 3D printing not only saves time in part manufacturing, but also reduces the cost of your project.

SLA Alternatives With Our Resin 3D Printing Service

Maybe SLA is not the perfect resin technology for you. Discover some alternatives also available at Elimold.

DLP / LCD

Polyjet

DLS

Alternative Solution to CNC Machining

If you are currently producing prototype parts using CNC machining or other traditional methods, SLA may be an affordable and flexible alternative. It is one of the lowest-cost 3D printing technologies. It can produce detailed, precise parts with excellent surface finish, which is ideal for testing fit and finish. Unlike machined parts that require fixtures and setups, parts produced by Elimold’s SLA printing service can be produced quickly and cost-effectively, making it an ideal solution for your rapid prototyping needs.

On-Demand SLA 3D Printing Services

Elimold’s SLA 3D printing services provide accurate, detailed, and durable prototypes, making them an ideal solution for rapid prototyping. In addition, our wide selection of materials can help you create prototypes that closely resemble the mechanical properties and appearance of the final product. We understand the importance of rapid prototyping and provide fast delivery cycles to help you get your products to market faster. Our streamlined process allows us to provide high-quality prints within a few days, ensuring that you can quickly test and iterate your designs. Whether you need a single prototype or multiple batches, our team can meet your needs. We work closely with our customers to ensure that their specific requirements are met and provide high-quality prints that exceed their expectations.

Stereolithography(SLA) Printing Material Types

The SLA 3D printing process uses photopolymers. These polymers ensure greater precision and stronger prints. We can offer a wide range of resin materials for custom SLA 3D printing services, including the following types.

Standard Resins

Clear Resins

Engineering Resins

Medical Grade Resins

Biomaterial Resins

Castable Resins

From Prototype to Production

If you’re looking for a fast, low-cost way to create demonstration models or test the fit and finish of prototype parts, Elimold’s Stereolithography (SLA) printing services are the ideal solution. Our advanced SLA printing services combine traditional craftsmanship with cutting-edge technology to deliver dimensional accuracy and speed, with customizable options to meet the needs of designers, engineers, hobbyists, and novices. Trust Elimold’s SLA resin printing heritage and pioneering spirit to bring your most ambitious designs to life. With our unrivaled expertise in stereolithography, you can be assured of your project’s success. We help you take full advantage of the flexibility, design freedom, and speed of 3D printing to meet your needs.

Multiple Material Options

Elimold Stereolithography Services offers a wide range of materials for you to choose from. Your project application will determine which material should be used, and we have the ability to serve customers from a wide range of industries. If you are unsure which material is best for your project, you can consult with our engineers who have extensive experience in this field.

SLA High Temp TS

SLA High Temp TS has increased strength and durability characteristics. It is great for automotive projects with isotropic mechanical properties. It has an industrial, dark blue default color, making it perfect for mechanical applications. It is also highly applicable in aerospace fields, for parts like display panels and dashboards.

SLA Imagine Black

Similar to engineering plastics, SLA Imagine Black has stable performance, dimensional stability, and is chemically resistant. It also saves on dying costs, as it comes in a pure black default color. A small drawback is that it is slightly weaker than nylon.

SLA Proto Plus

Proto Plus is an accurate and durable material. It is suitable for prototyping needs, although may not hold up as well as other materials. It comes in a default white that can appear slightly yellowish, but these parts can be dyed to other colors. This material is an excellent option for consumer medical parts.

SLA Smooth GP

This white material is water and moisture proof, and has high cost performance. It is known to turn yellowish and become brittle when left in sunlight. For products that need to be more UV resistant, we suggest nylon or another material. Smooth GP is great for digital electronic modifications.

SLA Tough Plus

SLA Tough Plus is a great option for prototyping and test parts, but is not suitable for end use pieces because of its impressionable nature. Additionally, it tends to fade to yellow with time. This material can be painted or dyed after production. Parts from SLA Tough Plus will have outstanding detail.

SLA Tough Resin Green

This material has excellent heat resistance and dimensional stability. It is also extremely stable and durable. The printing speed for Tough Resin Green is very quick and efficient. One limitation is that this material has a default color of light green/yellow. It can be modified for end use products.

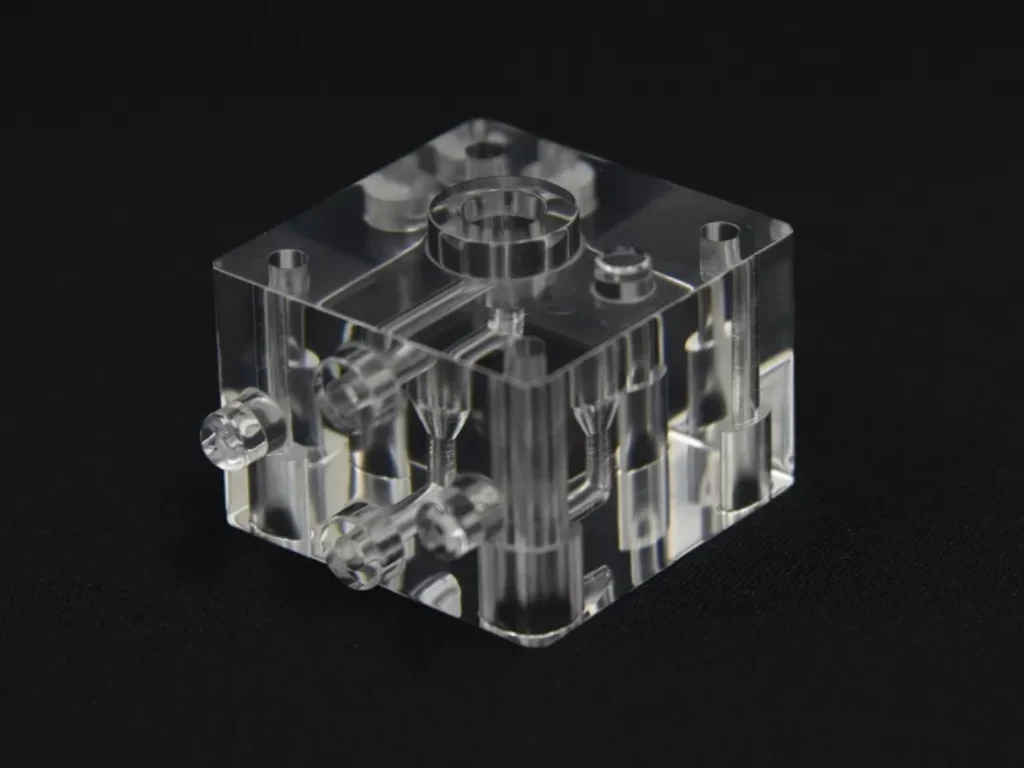

SLA Transparent Plus

This material is mostly clear when printed. It is an excellent option for projects like wind tunnels, liquid containers, and sturdy concept models. One drawback with Transparent Plus is that it may result in small air bubbles in the surface of the print. However, these can sometimes be fixed with printer adjustments.

SLA WaterTight Proto

SLA WaterTight Proto has excellent waterproof abilities. It is also very resistant and durable. It comes in a default color of whitish yellow but can be colored. It is good for use in batch runs and end use pieces, from medical models to household parts. It is also an option for interior car parts.

Accura® 25

Accura® 25 is fast and easy to process, effectively simulating the properties and aesthetics of polypropylene. Additionally, it offers high flexibility, durability, and precision.

Accura® 60

Accura® 60 is a high-quality, high-performance clear/translucent plastic for SLA. Its unique properties make it perfect for producing solid and rigid parts with the appearance of molded polycarbonate.

Accura® ClearVue

Accura® ClearVue is a high-quality material known for its exceptional clarity, making it perfect for applications requiring visual appeal.

Accura® ABS Black

Accura® ABS Black is a multi-purpose stereolithography material offering a balanced property profile, good flexibility, shock absorption, and the possibility of printing tiny structures with a high level of detail.

Accura® AMX Rigid Black

Accura® AMX Rigid Black is a high-performance SLA photopolymer resin designed for additive manufacturing applications. Its unique formulation provides superior mechanical properties.

Accura® AMX Tough FR V0 Black

Accura® AMX Tough FR V0 Black is noteworthy for being the industry’s first flame-retardant stereolithography material. This makes it ideal for applications where fire safety is paramount. Moreover, the material boasts exceptional toughness and durability, making it suitable for producing high-quality parts that withstand demanding conditions.

Accura® SL 5530

Accura® SL 5530 is perfect for creating durable, functional pieces that are solid and stable. Additionally, its translucent color makes post-processing and finishing easier.

Accura® Xtreme

Accura® Xtreme is a high-performance, rigid photopolymer material with excellent mechanical properties. Moreover, its unique blend of acrylate monomers and oligomers gives it superior toughness and impact resistance.

Accura® Xtreme White 200

Accura® Xtreme White 200 is a durable and inflexible SLA material recognized for its high precision and capability to capture intricate details. It is perfect for producing models, prototypes, and end-use parts.

Somos® BioClear

Somos® BioClear is an advanced engineered resin that produces precise, functional prototypes and parts. It is also clear and colorless, capable of producing parts with exceptional clarity, smooth surface finish, and high fidelity.

Somos® EvoLVe 128

Somos® EvoLVe 128 offers higher stiffness and strength than other existing SLA materials. Furthermore, it exhibits exceptional moisture resistance, making it an ideal material for parts exposed to humid or wet environments.

Somos® PerFORM

Somos® PerFORM is a top-performing material perfect for applications requiring high strength, durability, and precision. It is mainly used in industries such as aerospace or the medical field. It is composed of a unique blend of liquid resins and composite particles, offering a combination of stiffness and toughness. This material effectively withstands high-stress environments.

Somos® ProtoTherm

Somos® ProtoTherm offers exceptional accuracy, detail, and thermal resistance for various additive manufacturing applications. Its strong properties make it an excellent option for functional prototypes.

Somos® Taurus

Somos® Taurus is a thermoplastic resin known for its exceptional strength and durability, making it a popular choice for applications that require high performance, such as automotive, aerospace, and medical.

Somos® WaterClear Ultra 10122

Somos® WaterClear Ultra 10122

Somos® WaterClear Ultra 10122 is a durable, translucent SLA photopolymer that can produce high-quality parts with excellent accuracy and detail. The material is ideal for functional prototyping, creating models, and producing finished products with complex geometries.

Somos® WaterShed Black

Somos® WaterShed Black provides exceptional thermal stability, durability, and strength. It is ideal for producing solid and stable parts for various applications. Moreover, with its advanced properties, this resin can withstand extreme temperatures and harsh environmental conditions while maintaining its structural integrity.

Somos® WaterShed XC 11122

Somos® WaterShed XC 11122 durable and high-performance photopolymer resin combines mechanical strength, toughness, and dimensional stability, making it ideal for applications that require accurate and complex geometries. Additionally, it is suitable for a wide range of manufacturing needs.

Accura Xtreme White 200

Accura Xtreme White (XTW) is an exceptionally tough, and highly accurate industrial grade resin for demanding applications. Accura XTW resin is highly versatile, making it ideal for a number of applications from concept models to functional assemblies that require high fatigue resistance such as snap fits & enclosures. The outstanding surface finish makes it also ideal for creating master patterns for both vacuum casting & molding.

Accura Clearvue

Accura ClearVue material is a ideal for models requiring high clarity. This transparent material that simulates the properties and appearance of Polycarbonate and ABS. This material is ideal for design validation, water flow testing, and packaging.

Accura 25

Accura 25 simulates the both the material properties and aesthetics of molded Polypropylene. Accura 25 provides excellent surface finish, durability and elongation strength which allows 3D prints of highly accurate and attractive prototypes that test fit, form and function with outstanding accuracy and dimensional stability.

Accura Bluestone

Accura Bluestone is a high temperature, ultra stiff nano composite ideal for the manufacturing of stable parts. With a post-cure heat deflection of 284°C @ 0.45 MPa, Accura Bluestone is one of the most thermally stable resins available.

Accura XTW Black

Accura XTW Black is our same exceptionally tough, highly accurate industrial grade white resin dyed black. The black dye penetrates deep into the part to offer a robust, high quality black finish ideal for for demanding applications where both mechanical properties and black aesthetics are crucial.

Poly1500

Poly1500 is a durable, resilient material that offers high surface quality and dimensional accuracy. With properties similar to polypropylene, it is ideal for functional prototypes.

ProtoGen White

ProtoGen White’s resilience, surface quality, and thermal properties make it suitable for general-purpose applications such as RTV molding patterns, highly detailed parts, and durable concept models.

TuskXC2700T

Designed to simulate ABS, TuskXC2700T is a strong material that offers high resolution and a smooth surface. It is ideal for water-resistant prototypes and high-end finished models. Transparent finishes possible.

TuskXC2700W

Designed to simulate ABS, TuskXC2700W is a strong material with a rapid lead time. It is ideal for water-resistant and functional prototypes. Also available in clear.

Taurus

Taurus has the look and feel of an injection-molded part, offering strong mechanical properties and high surface detail. It’s an ideal choice for form-, fit-, and function-testing, as well as functional prototypes.

Xtreme

Xtreme is a tough, general-purpose material with high impact strength, high elongation, and excellent surface quality. With properties close to ABS, Xtreme is ideal for functional prototyping.

Tusk Somos SolidGrey3000

Tusk Somos SolidGrey3000 is an exclusive product that combines extreme stiffness and impact strength. It is ideal for functional prototypes, durable concept models, rugged scale models, and end-use parts.

PerFORM

A resin with ceramic particles, PerFORM offers high stiffness and strength, as well as excellent heat resistance and detail. It is ideal for prototyping and for rapid tooling for injection molds.

Surface Finishing Options

Elimold offers a variety of post-processing options for SLA parts, and transparent parts can be polished to an optically clear surface. We can provide the following post-processing services for SLA parts:

- Standard

- Media blasting

- Polishing

- Sanding

- Brushing

- Painting

- Silk printing

- Plating

- Specialty coating

- Plated

- Decals

- Pad printed

- Screen printed

- Inserts

- Post machined

- Assembly

Ready to Get Your Project Off the Ground?

Speak to a 3D printing expert today! Our team is standing by, ready to help answer questions or get started on a quote for your project.

What is Stereolithography(SLA) 3D Printing?

The SLA 3D printer process uses a liquid resin that cures when a laser or UV light is shined on it. This thermoset material undergoes a chemical reaction when exposed to heat or UV light, causing the liquid resin to harden (cure) into a solid. Resins are available in a variety of colors and with a variety of material properties to suit your needs. Liquid resin is loaded into bottles and then added to the resin tank of a stereolithography 3D printer. Once loaded, the printer is ready to print with a variety of resin colors.

As an SLA 3D printer applies liquid resin to an existing layer of a structure, the device emits a beam of UV light through a projector or laser to build the next thin layer. The chemical properties of the resin react to the specific wavelengths of light emitted, causing the monomers and oligomers of the resin to link into chains, forming polymers (the basis of plastics) and hardening the material of the surface layer of the build. Depending on the type of resin used, the physical properties of the final product may vary to better suit the end use of the part. These variations include color, flexibility, durability, and weight.

SLA Design & Build Guidelines

Each 3D printing technology is a little different, here are standard guidelines to consider when choosing SLA as your 3D printing process:

- Build Layers: Standard is 0.004”-0.006” (100-150 microns, High Res is 0.002” (50 micron)

- Minimum Wall Thickness & Feature Size: 0.025”

- Standard Finish: Level 2 Bead Blast Finish (see more available custom finishes)

- Standard Lead Time: 2-3 days

- Tolerances: +/- 0.005” for first inch then +/- 0.002” per inch thereafter

- Inserts: Install in post-processing with adhesives

- Holes: Build holes & threads into model for print and chase or ream in finishing

Why Stereolithography (SLA) 3D printed parts?

- Reduces per-unit costs on low- to medium-sized runs.

- Matches your exact mechanical and optical specifications with the broadest range of materials available.

- Cuts finishing time and enjoy the best surface quality available from any 3D printing.

- Identifies design flaws early with true-to-design accuracy and surface finish.

- Produces large, whole parts and cut both the time required for assembly and part weakness associated with attachment points.

- Streams the path from CAD or scan to final prototype part production.

Industries We Serve

SLA 3D printing is widely used in multiple industries, including rapid prototyping, rapid production, and low-volume manufacturing. Here are some of the areas Elimold can serve:

- Toys

- Agriculture

- Packaging

- Architecture

- Electronics

- Semiconductors

- Consumer Goods

- Construction

- Energy and Power

- Automotive

- Robotics

- Medical

- Dental

- Aerospace

- Marine

- Telecommunications

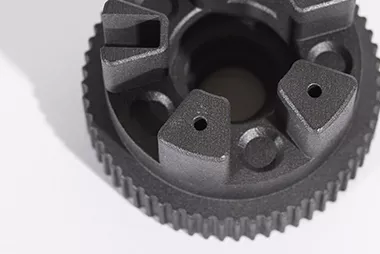

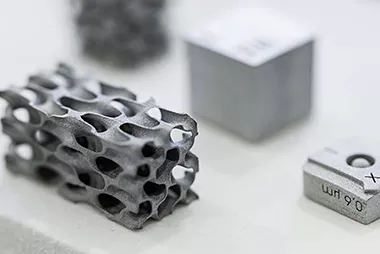

Parts and Products

Elimold’s stereolithography 3D printing services can produce parts and products with precise, fine features and high-quality surface finish for various industries around the world. The following are some of the parts and products we have produced for our customers.

- Dental aligners

- Hearing aid shells

- Microfluidic devices

- Transparent lenses

- Electronic housings

- Surgical guides

- Optical components

- Watch casings

- Smartphone cases

- Cosmetic packaging prototypes

- Scale model car parts

- Orthodontic brackets

- Snap-fit enclosures

- Wearable device prototypes

- Custom connectors

- Custom grips and handles

- Hearing device fittings

- Drone components

- Dental surgical tools

- Lab-on-a-chip systems

- Light pipe prototypes

- Small mechanical assemblies

- Waterproof enclosures

- Artistic sculptures

- Rapid tooling inserts

- Camera mount prototypes

- Complex brackets

One-Stop SLA 3D Printing Service

Our equipment lineup ensures consistent quality of SLA parts, not only in the prototype stage, but also for mass production. We support most industrial-grade materials from Somos and Accura, and support post-processing and other secondary operations such as finishing, painting or hardware installation. We can inspect SLA components as needed and are committed to providing the best quality. Our operators can solve build problems before the order and provide suggestions on direction or design as needed. We provide the best customer support in the industry before, during and after the project. Elimold is the best choice for your next SLA project.

Other 3D Printing Services

SLA can be paired with a variety of other 3D printing technologies to provide a comprehensive solution for visual or form-fitting prototypes. Therefore, Elimold can also provide the following multiple 3D printing services, providing you with everything you need for custom 3D printing projects, from rapid prototyping to small-batch production of metal 3D printing for industrial applications.

Selective Laser Sintering(SLS)

Multi Jet Fusion (MJF)

Fused Deposition Modeling (FDM)

Direct metal laser sintering (DMLS)

Solidscape (wax deposition)

Micro 3D Printing

Wire Arc Additive Manufacturing (WAAM)

Metal Binder Jetting

Selective Laser Melting (SLM)

Ceramic 3D printing

Metal 3D Printing

Custom SLA 3D Resin Printing Services

With SLA printing technology, Elimold is able to meet the needs of a wide range of rapid manufacturing applications and supports a variety of different materials and surface treatments. Compared with other 3D printing processes, our large-scale printing platform printers are capable of printing larger and more complex 3D prints, making it our most versatile 3D printing solution. Our in-house factory ensures that we have strong competitiveness and unlimited capacity. And we use data to track on-time delivery, quality and price.

If you need a part printed yesterday and delivered immediately, stereolithography is the technology for you. This technology can print models with beautiful appearance, impeccable surface quality and exquisite details for the smallest to the largest parts. When delivery time must be shortened, SLA 3D printing services are your first choice.

Comparing 3D Print Technologies

One of the great things about 3D printing is that you have the freedom to choose, whether you plan to print a prototype, logo, or other project. See our guide to FDM vs. SLA vs. SLS printing for a full comparison.

SLA vs FDM

FDM printing is fused deposition modeling, a trademarked name. It also goes by the term fused filament fabrication, or FFF. This form of additive manufacturing is similar in that designs are sliced and printed in layers. However, rather than using liquefied polymers and a laser as in SLA, the material is extruded through a multidirectional print head that contains resistance heat coils. The material is melted for printing. The fine detail of stereolithography is not possible with FDM/FFF printing. Both rely on guidance by CAD/CAM design software. Both offer rapid prototyping and single-unit production for a range of industry and business applications.

SLA vs SLS

SLS Printing or Selective laser sintering, is like SLA in that it prints with a laser. The difference is that the laser is used to fuse dry plastic particles rather than cure liquefied resins into solids. Both 3D printing methods are used for small and large parts.

SLA vs PolyJet

In PolyJet printing, Liquefied polymers are cured by UV light in PolyJet printing, just as in SLA printing. The difference is the polymers are stored in a vat in SLA 3D printing; in PolyJect printing, the polymers are stored in a print head and jetted onto the build platform where they are immediately cured. Both types offer outstanding detail.

Request Your Free Stereolithography(SLA) 3D Printing Quote Today

After receiving your drawings, our engineers will analyze your custom Stereolithography(SLA) 3D Printing parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.