4 Axis CNC Machining

Elimold offers you the latest 4-axis CNC machining services, providing accurate and efficient machining results for your parts. With state-of-the-art equipment and a team of experts in our in-house facility, we are committed to providing precision and efficiency in projects for industries around the world. Contact us now for a free instant quote.

4-Axis CNC Machining Manufacturer

Elimold has earned a solid reputation for quality and reliability, offering a range of turnkey services from prototyping to production and assembly. CNC machining services are one of our core competencies, and our 4-axis CNC machining equipment can achieve highly complex parts with tight tolerances, whether it is a large-scale production or a single part order. At Elimold, we provide our customers with a full range of services they may need, from design and production to finishing. All detailed components in our portfolio can be custom manufactured parts based on customer needs using a variety of metals, super alloys and engineered plastic materials. Our skilled technicians assist customers in selecting the most appropriate specifications, materials and surface treatments to ensure that the final product performs well and meets design requirements. And no matter the size or complexity of a customer’s order, we pride ourselves on being able to deliver the highest quality custom parts to their warehouse or production line in a timely manner without compromising quality. Looking for the best 4-axis CNC machining services? Elimold’s expertise in 4-axis machining puts us at the forefront of the field, providing our customers with cutting-edge solutions to their custom part manufacturing challenges. Whether you want to prototype a new part or go into full production, our team is ready to bring your project to reality with unparalleled precision and quality.

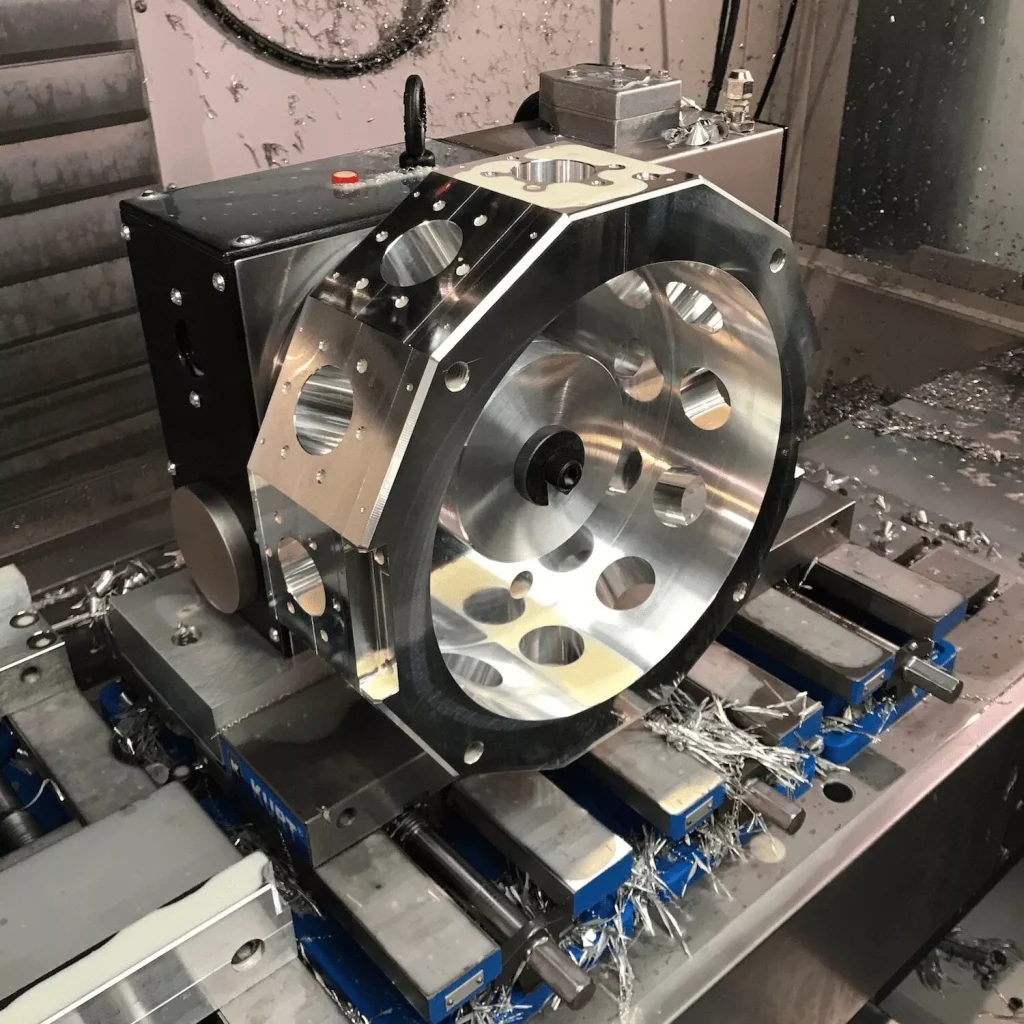

Our 4-Axis CNC Machining Factory Capabilities

Our in-house factory features state-of-the-art 4-axis CNC machining centers, including vertical and horizontal CNC machines for machining a wide range of materials. Moreover, our equipment can process parts up to 500 mm in size with tolerances of ±0.01 mm. At Elimold, our in-house factory operates 24/7 to reduce turnaround time and is equipped with in-house quality control and inspection facilities. Our team includes skilled machinists and engineers. We can handle both small and large batch production. Thus, Elimold stands out in the field of 4-axis CNC machining. We provide high-quality parts with short lead times. Our experienced team ensures precision in every project. We use cutting-edge 4-axis CNC machinery for the best results. Our prices are competitive without compromising on quality. Also, we can provide personalized services based on the needs of each customer. Our quality control measures exceed industry standards. Our team provides both prototyping and full-scale production services with a wide range of material options to meet a variety of project requirements. We have a proven track record in multiple industries. Choose Elimold for reliable, high-precision 4-axis CNC machining.

Competitive 4-axis Machining Pricing

We believe that first-class 4-axis CNC machining services should be accessible to everyone. Therefore, we offer competitive pricing packages to ensure that our services are suitable for all budgets. We are committed to value for money, which means that you can trust us to provide excellent results without spending too much. And there is no minimum order quantity for our services, ensuring high precision at an affordable price. Elimold provides 4-axis machining services for a variety of plastic and metal parts. Whether small or large, small or large quantities, we can meet different types of requirements. Our machining accuracy can reach ± 0.01 mm, giving us a significant advantage in large CNC machining, large-volume CNC machining and small-volume CNC machining. Simply upload your 2D and 3D drawings, as well as the required material, surface treatment and quantity, and you will receive a quote immediately. We look forward to working with you and providing high-quality 4-axis machining services.

4-Axis CNC Machining Contract Manufacturing Capabilities

At Elimold, our engineers have extensive experience in manufacturing complex 4-axis CNC machining projects, so they can handle complex precision parts across multiple industries without any problems. For the convenience of our customers, we use the latest 4-axis CNC machining technology to provide competitive costs without compromising on the quality and precision of the product. We will provide you with the highest quality, risk-free and cost-effective manufacturing services with experienced professionals. In addition, Elimold’s in-house facility has a large number of 4-axis CNC machining centers and a team of talented CNC operators who are capable of producing high-quality custom and standard parts in large quantities. Our team is experienced in making complex geometries; custom part designs with the help of industry-standard equipment and new technologies. Over the past years, we have worked with many companies and have had personal experience with the world’s leading OEM brands, helping them produce large quantities of advanced CNC parts and customized products. Utilizing our state-of-the-art 4-axis machining centers, we provide cost-effective 4-axis CNC machining solutions for all industries around the world. We are a precision CNC machining service provider that offers 4-axis CNC machining services to businesses large and small to help them complete complex machining contracts. Are you looking for a reliable, fast-turnaround 4-axis CNC machined plastic and metal parts manufacturer? Our in-house facility has unmatched production capabilities to ensure your precision parts are shipped on time, every time.

Tailor-made 4-axis CNC machining services

We are committed to providing you with efficient and precise 4-axis machining solutions to meet your custom part needs. 4-axis machining technology can process complex curved parts, improve production efficiency and reduce manufacturing costs. With our experienced technical team and advanced machining equipment, we are able to provide high-quality 4-axis machining services. Whether you need a single custom part or batch production, we can meet your requirements. We firmly believe in the pursuit of excellence and precision in every order. We do not apply the same approach to every order; our skilled technicians consider how we can best meet the needs of our customers and advise them accordingly. This may mean using 4-axis CNC machining to provide a high level of detail, or it may mean recommending the use of traditional machining to manufacture small batches or prototypes. We work closely with each customer to ensure that we provide a custom service that meets their needs.

Design and Manufacturing Analysis Services

No matter the size of your 4-axis machining project, we can provide you with an instant quote. Simply upload your 2D and 3D drawings, as well as material, surface treatment and quantity details, and you will receive a quick quote in minutes. In addition, we provide design and manufacturing analysis to ensure that your project progresses smoothly. We are ISO 9001:2015 certified, which proves our ability to meet a variety of customer needs. By choosing Elimold, you will not only receive high-quality machining services, but also save an average of 30% in costs. Our team of experienced and knowledgeable engineers are always ready to answer your questions and provide professional advice. Elimold is committed to providing you with efficient, precise and reliable manufacturing solutions. Choose trust and quality by choosing Elimold’s 4-axis linkage CNC machining services.

Looking for a professional 4-axis machining service provider?

We are committed to providing you with efficient and precise 4-axis machining solutions to meet your custom parts needs. 4-axis machining technology can process complex curved parts, improve production efficiency and reduce manufacturing costs. With our experienced technical team and advanced processing equipment, we are able to provide high-quality 4-axis machining services. Whether you need a single custom part or batch production, we can meet your requirements. Send us your CAD file or inquiry email, and we will quickly provide you with a free quote for 4-axis machining services. We promise to deliver high-quality machined parts on time and become your trusted manufacturing partner. Contact us now to experience professional 4-axis machining services. Let’s work together to improve your production efficiency!

Quality Management and Certification

We provide exceptional 4-axis CNC machining services utilizing state-of-the-art equipment and technology. Our team’s expertise and experience allow us to provide custom 4-axis CNC manufacturing solutions to meet our customers’ various manufacturing needs. By staying at the forefront of machining technology, Elimold ensures that our customers receive the highest quality parts, exactly to their specifications. And quality is a top priority at Elimold. Our rigorous quality control processes, adherence to industry standards, and spirit of continuous improvement ensure that every part we produce meets the highest standards of precision and quality. Our commitment to technology upgrades and innovation means we are always ready to meet the changing needs of our customers. 4-axis CNC machining provides greater precision, efficiency, and the ability to produce complex parts. In addition, at Elimold, we can provide rapid prototyping and mass manufacturing services with our ISO9001 and ISO 13485 certified CNC machining plants and equipment. We are your reliable supplier of custom 4-week cnc machined parts, custom-made to your 4 axis CNC machining project needs.

Testing equipment

- CMM (3D coordinate measuring machine)

- 2.5D projector

- Thread Gauge

- Hardness

- Caliber A closed-loop QC system

- Micro-calliper

- Automatic Inspection Optic Machine

- Tensile Strength Testers

- Third Party Inspection Available If Required

Choose Elimold for your 4-axis CNC machining needs

Whether you need prototyping, production, or custom machining, Elimold is your go-to machine shop. With our state-of-the-art 4-axis CNC machines, expert team, and commitment to excellence, we guarantee outstanding results. So contact us today to discuss your project and get a free instant quote, and let us exceed your expectations with precision 4-axis CNC machining services.

More CNC Machining Process Types

Elimold offers various types of high-precision CNC machining services, specializing in providing superior quality and tailor-made solutions for your manufacturing needs. With advanced equipment and expertise in CNC precision machining, we are able to process a wide range of materials including metals, plastics and composites. Whether you are looking for prototypes or large-scale production, Elimold can ensure accuracy, efficiency and timely delivery.

CNC Milling

CNC Turning

3 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Full range of 4-axis CNC machining services

Elimold offers a full range of 4-axis CNC machining services in a variety of materials to meet the specific needs of your project. Our advanced CNC equipment can maintain critical dimensions and extremely tight tolerances, further ensuring that precise specifications are met. From prototyping to mass production, our 4-axis custom machining services can be tailored to your requirements, with attention to detail, quality and accuracy being the fundamental components of the service. We are a reliable 4-axis CNC machining service provider, with 4-axis CNC machining facilities in both the United States and China, and a wide range of high-precision precision machining equipment. Our professional machinists and engineers utilize our state-of-the-art 4-axis CNC machines to manufacture your CNC parts within the preferred tight tolerances. And our expert team of engineers are knowledgeable in CNC machining, and we can guarantee high-quality products based on your requirements. Our services cover both small and large components, and ensure tight tolerances and smooth surface finishes. Our experts optimize the cost and efficiency of each project to provide fast turnaround times without sacrificing quality.

4-axis CNC machining material options

Elimold offers a variety of material options, including various conventional metals, super alloys, and engineering plastics, to meet the performance requirements of different industry applications.

Metals

- Stainless Steel

- Inconel

- Hardened Steel

- Brass

- Aluminum

- Hastelloy

- Armor Plate

- Chromium

- Gammalloy

- Carbon Steel

- Copper

- Tungsten

- Titanium

- Alloy Steel

- Bronze

- Nickel

- Nitralloy

- Platinum

- Incoloy

- Invar

- Manganese

- Molybdenum

- Monel

- Stellite

- Waspaloy

- Zinc

- Polymer

Plastics

- Acetal

- POM

- PA

- Nylon

- PC

- PMMA

- PVC

- PU

- Acrylic

- ABS

- PTFE

- PEEK

- Ultem

- Vespel

- LDPE

- HDPE

- Polypropylene

- Teflon

- Acrylic

- Polycarbonate

- Carbon Filled PEEK

- Delrin

- Glass filled Nylon

- Phenolic

Surface Finishing Options

Achieve the aesthetics and performance requirements of 4-axis machined parts with our range of surface finishes. No matter what type of surface finishing service you require, we can meet your requirements and specifications.

- Anodizing

- Bead blasted

- Silk Screen

- PVD Plating

- Titanium Plating

- Painting

- Powder Coated

- Passivation

- Electrophoresis

- Electro Polishing

- Etch

- Engrave

- Grinding

- Polishing

- Sandblasting

- Painting

- UV

- Electroplating

Typical Industries Using 4-Axis CNC Machining Services

4-axis CNC machining is very versatile as they can effectively process parts with a variety of complex design requirements. Here are some common industries using 4-axis CNC machining services:

- Automotive

- Medical

- Aerospace

- Oil and Gas

- Electronics

- Construction

- Defense

- Food Processing

- Heavy Equipment

- Military

- Mining

- Power Generation

- Transportation

Applications of 4-axis CNC machining

4-axis CNC machining enables custom manufacturing of a wide variety of products and parts, including those with complex geometries and curved surfaces. Products that Elimold can machine using 4-axis CNC machines include:

Engine components

Turbine blades

Complex brackets

Medical implants

Aerospace fittings

Gears and sprockets

Custom fasteners

Engraved panels

Heat sinks

Manifolds

Shafts and spindles

Custom enclosures

Electrical connectors

Optical device components

Jewelry and decorative pieces

High-precision tooling

Propeller blades

Automotive suspension components

Hydraulic pump housings

Precision bearing housings

Aircraft wing brackets

Motorcycle triple clamps

Steering knuckles

Valve bodies

Watch movement parts

Surgical instrument components

Optical lens mounts

Exhaust system components

Customized heat exchanger plates

Miniature mechanical assemblies

Turbomachinery impellers

Aerospace fuel system components

Semiconductor manufacturing parts

Pneumatic cylinder bodies

Robotics end effectors

Marine propeller hubs

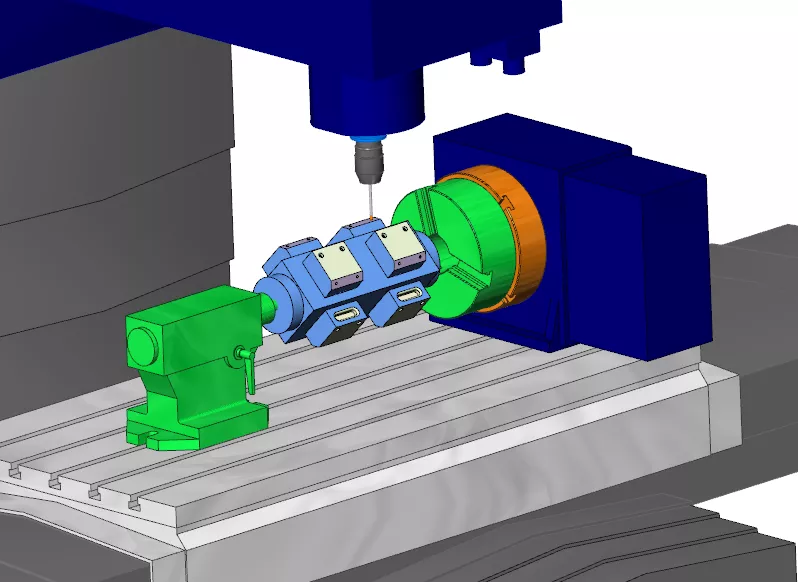

What is 4-axis machining?

4-axis CNC machining involves multi-axis machining of workpiece materials using a CNC machine with an additional rotary axis. The 4-axis machining process utilizes any CNC machine that is capable of moving at four different angles simultaneously. It typically includes three linear axes – X, Y, and Z and an additional axis (A axis). The X, Y, and Z axes represent three mutually perpendicular directions, while the A-axis rotary axis rotates the workpiece around the X axis. While there are different arrangements of 4-axis CNC machines, the standard type is vertical machining. It operates in a vertical direction and allows the spindle to move in the Z axis. More importantly, these features will make it possible to machine complex designs and mill odd angles, which is not possible with 3-axis machining.

Limitations compared to 5-axis CNC machining

5-axis CNC machining is more powerful than 4-axis CNC machining. It supports tool/workpiece movement in five directions. Three degrees of freedom are along the linear X, Y, and Z axes, and the other two are rotary axes, commonly referred to as A and B axes. 5-axis CNC machining virtually eliminates unnecessary setup changes. As a result, very complex parts can be machined in a single run. In this case, the time required is also significantly reduced. However, adding the functionality of the 5th axis increases the cost significantly. Therefore, manufacturers do not recommend using 5-axis machining unless necessary. It is mainly used for prototyping or manufacturing extremely complex parts. In addition, you will find that very few parts require 5-axis CNC machining to complete. For most parts, 4-axis machining is sufficient.

Request Your Free 4 Aixs CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom 4 Aixs CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.